A solar module factory in the Comoros Islands presents a compelling opportunity. With annual solar irradiation levels exceeding 2,000 kWh/m² and electricity costs among the region’s highest ($0.45-$0.55/kWh), the demand for affordable, local solar energy is undeniable.

This opportunity, however, is coupled with a significant logistical challenge: managing a complex supply chain for an island nation heavily reliant on imports. For a new manufacturing venture, every component—from solar cells to cardboard packaging—must be shipped internationally. This process introduces risks of delays, high freight costs, and dependency on volatile global markets.

This article examines a strategic approach to mitigate these risks by sourcing ancillary, or non-core, components from local or regional suppliers. We break down the associated costs, benefits, and practical steps for a successful implementation.

Table of Contents

The Core Challenge: Supply Chain Logistics for an Island Nation

The first step in planning is to grasp the scale of the logistical operation. A modest 20 MW solar module factory, for example, requires over 2,000 tons of raw materials annually. For a country like Comoros, where 90% of energy already comes from imported fossil fuels, adding thousands more tons of manufacturing inputs would place further strain on its port infrastructure and shipping lanes.

This heavy reliance on global supply chains creates several critical business risks:

- High Freight Costs: Shipping bulky materials like aluminum frames and glass to a remote location significantly increases the final cost per module.

- Long Lead Times: Transit times can be unpredictable, making it difficult to manage inventory and production schedules effectively.

- Vulnerability to Disruptions: Global events, from port congestion to trade policy shifts, can halt production and jeopardize project timelines.

Addressing these vulnerabilities is crucial for success. A hybrid supply chain model that blends global and local sourcing offers the most resilient path forward.

Differentiating Between Core and Ancillary Components

A solar module is an assembly of specialized parts that fall into two broad categories: core and ancillary. Understanding this distinction is key to developing a viable local sourcing strategy.

Core Components are the technologically advanced materials that determine a module’s performance and efficiency. These include:

- Solar Cells: The heart of the module, requiring a highly sophisticated and capital-intensive manufacturing industry.

- Solar Glass: Specially tempered, low-iron glass designed for maximum light transmission and durability.

- Encapsulants (EVA/POE) and Backsheets: Polymers that protect the cells from moisture, UV radiation, and mechanical stress.

For a new enterprise in an emerging market, these components must be sourced from established international suppliers, as the scale and technical expertise required for their production are currently prohibitive.

Ancillary Components are the “passive” or structural parts of the module. While essential for the final product, their manufacturing is less complex. These include:

- Aluminum Frames: Provide structural rigidity and a means for mounting.

- Junction Boxes: House the bypass diodes and provide a connection point for cables.

- Packaging Materials: Cardboard boxes, corner protectors, and strapping used for shipping.

- Cables and Connectors: Used for interconnecting modules.

These ancillary components represent the most promising opportunity for local or regional sourcing, reducing reliance on distant suppliers.

Each component plays a specific role, and substituting any part requires careful quality validation to maintain product integrity.

The Business Case for Local Sourcing in Comoros

Evaluating the shift to local sourcing requires a clear-eyed cost-benefit analysis. This decision involves balancing upfront investment against long-term operational savings and supply chain resilience.

The Opportunity: Cost Reduction and Supply Chain Control

The primary driver for local sourcing is economic. Producing bulky or simple components locally offers a manufacturer significant advantages:

- Cost Savings: Sourcing aluminum frames locally, for instance, could reduce component costs by 15-25% by eliminating international shipping and import duties.

- Reduced Lead Times: Shifting from a 60-day international lead time to a 5-day local production schedule drastically improves inventory management and responsiveness.

- Local Job Creation: An in-house aluminum frame processing line could create 10-15 skilled jobs, contributing to the local economy and building goodwill.

The Investment: Initial Capital and Quality Assurance

These benefits, however, require upfront capital expenditure for machinery and training. For aluminum frames, this would mean investing in an aluminum extrusion press, an anodizing line, and precision cutting and drilling equipment.

Crucially, any locally sourced component must meet stringent international quality standards. Failure to do so would make the final product ineligible for certification (e.g., IEC 61215) and unsellable in professional markets. A significant portion of the investment must therefore go toward establishing a robust quality control laboratory and training personnel—costs that must be factored into the factory’s overall investment requirements.

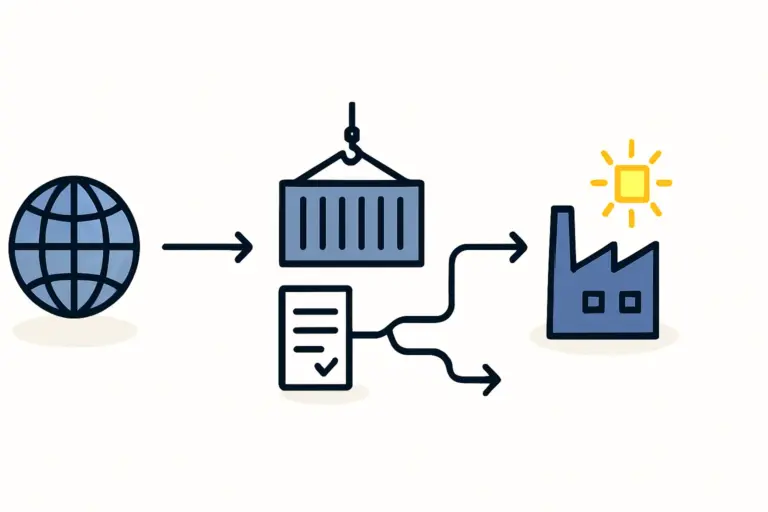

Expanding the Horizon: A Regional Sourcing Strategy

Given Comoros’ limited industrial base, a purely local sourcing strategy may be challenging to implement immediately. A pragmatic intermediate step is to explore regional sourcing from more industrialized nearby countries.

Rather than shipping frames from Asia, a manufacturer in Comoros could source them from industrial hubs in Tanzania, Kenya, or South Africa. While still an import, this approach offers several advantages:

- Shorter Shipping Routes: Reduces transit times and freight costs compared to transcontinental shipping.

- Regional Trade Agreements: May offer preferential tariff rates and simplified customs procedures.

- Greater Supplier Oversight: Proximity makes it easier to conduct site audits and manage quality control.

This regional “hub and spoke” model provides a stepping stone toward greater localization, allowing a new business to build resilience without bearing the full burden of vertical integration from day one.

Navigating Institutional and Infrastructural Hurdles

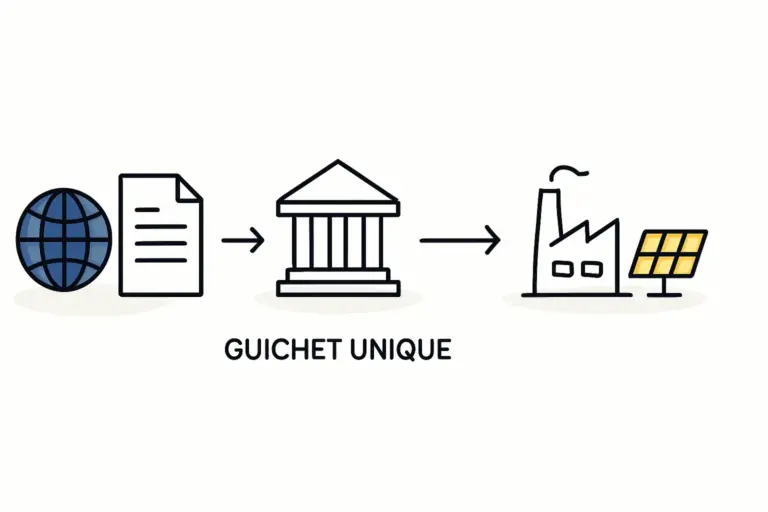

The success of any manufacturing enterprise, particularly one with a novel sourcing strategy, depends heavily on the local business environment. Drawing on experience from J.v.G. turnkey projects, entrepreneurs should assess the “4i-framework”: Institutions, Infrastructure, Investment, and Industry.

For a project in Comoros, this means entrepreneurs planning a solar module factory must engage with government bodies. Key discussion points include incentives for local manufacturing, streamlined customs for raw materials, and potential infrastructure upgrades to support industrial growth. These institutional factors are just as important as the technical and financial calculations.

Frequently Asked Questions (FAQ)

Q: Why can’t solar cells be produced locally in Comoros?

A: Solar cell manufacturing is an extremely capital-intensive process that requires immense scale (typically multiple gigawatts), a highly stable power grid, access to specialized chemicals, and a deeply established high-tech ecosystem. Establishing this capability is not feasible for an emerging market without massive state-level investment over many years.

Q: What is the first ancillary component to consider for local sourcing?

A: Packaging materials and aluminum frames are often the most practical starting points. Cardboard production is a relatively standard industrial process. Aluminum frames require investment in extrusion and finishing machinery but are less technologically complex than electronic components like junction boxes.

Q: Does local sourcing affect the final solar module certification?

A: Yes, absolutely. Every component in a certified solar module, regardless of its origin, must meet the standards required by bodies like the IEC. If a manufacturer substitutes a certified, imported frame with a locally produced one, the new component must undergo rigorous testing to ensure it meets durability, corrosion resistance, and mechanical load requirements. A strong in-house quality assurance program is non-negotiable.

Q: Is this local sourcing model applicable to other island nations?

A: Yes, the principles are highly relevant for any market facing high logistical costs and supply chain vulnerabilities. Island nations in the Caribbean, the Pacific, and other parts of Africa can benefit from a similar hybrid sourcing strategy to improve the economic viability and resilience of local solar manufacturing.

By carefully segmenting the bill of materials and pursuing a phased approach—starting with regional sourcing before moving to local production—entrepreneurs can build a more robust and cost-effective solar manufacturing business, turning a logistical challenge into a strategic advantage.