An entrepreneur’s vision for a solar module factory often focuses on state-of-the-art machinery and skilled labor. Yet the success of such a venture hinges on something far more fundamental: the timely arrival of a single 40-foot shipping container.

Imagine a production line standing idle, not due to a technical fault, but because a crucial shipment of solar cells is held up in port. For any manufacturer operating in an island nation, logistics are not merely a support function—they are a central pillar of the entire business model.

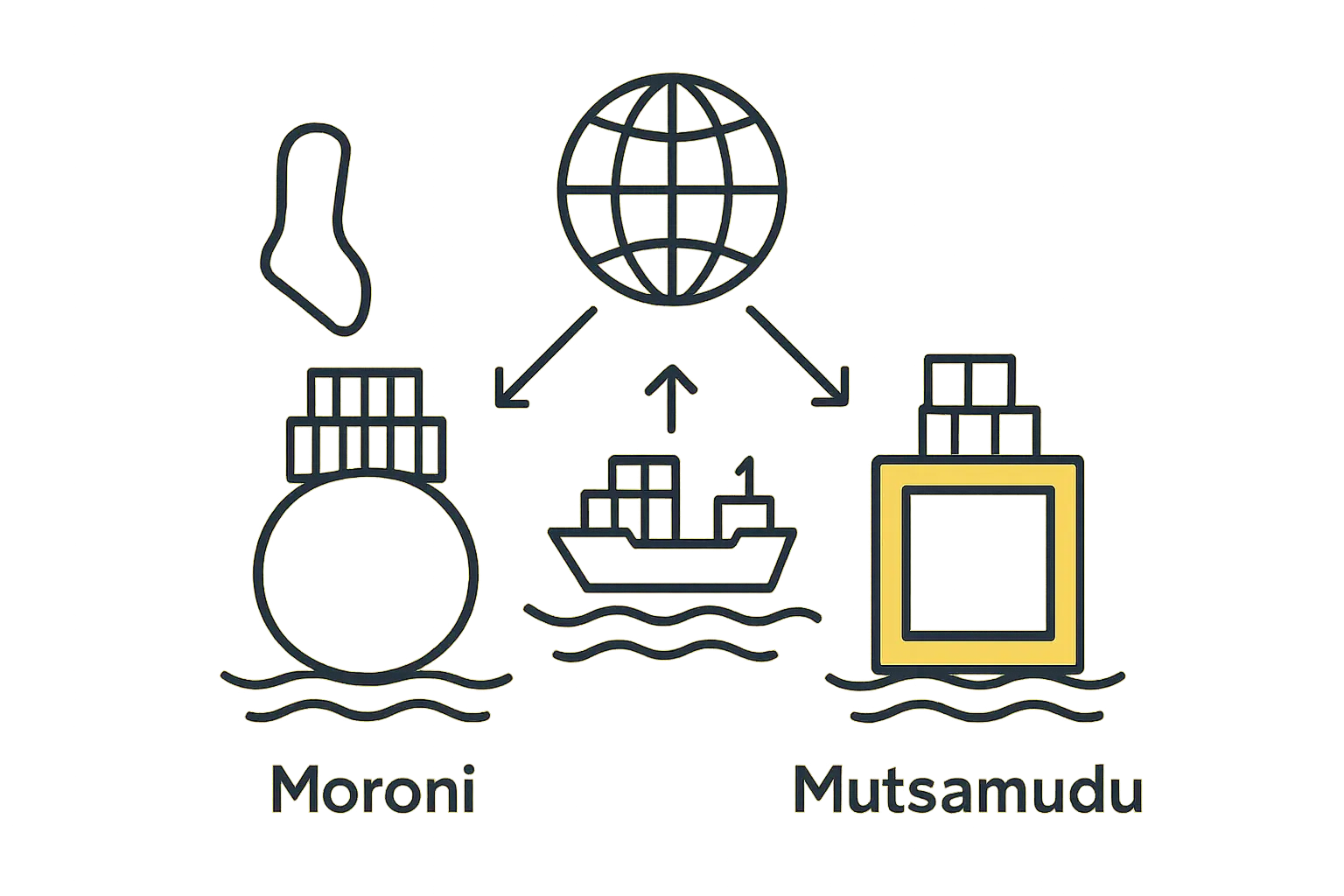

This reality is particularly stark in Comoros, where navigating the complexities of maritime import is a critical skill. For anyone planning to establish a solar manufacturing presence, understanding the distinct roles and challenges of the country’s primary ports—Moroni and Mutsamudu—is essential. This guide provides a practical overview of the port logistics and customs procedures that directly impact a factory’s efficiency and profitability.

Table of Contents

The Maritime Lifeline: Why Port Operations Define Comorian Manufacturing Success

For an archipelagic nation like Comoros, maritime transport is not just one option among many—it is the only option for industrial-scale imports. Research from the World Food Programme’s Logistics Cluster underscores that the country is 100% reliant on maritime transport for its international trade. This absolute dependence means that the efficiency, capacity, and reliability of its ports have a direct, magnified effect on every stage of a manufacturing business.

Every component, from solar glass and EVA film to delicate photovoltaic cells, must arrive by sea. A comprehensive understanding of the logistical landscape is therefore essential to creating a resilient and predictable production schedule. The journey these components take from a global supplier to the factory floor begins at, and is largely defined by, the port of entry.

Choosing the Right Gateway: Moroni vs. Mutsamudu

Comoros has two main commercial ports, each with a distinct profile. The choice of port for importing raw materials is a strategic decision with significant implications for cost, time, and reliability.

Port of Moroni (Grande Comore): The Local Hub

Located on the main island, the Port of Moroni is often the first point of consideration. However, it has several key limitations for large-scale industrial importers.

- Infrastructure: Moroni is a relatively small and shallow port. This limits the size of vessels that can dock, meaning international cargo often needs to be transshipped from larger vessels at other regional ports.

- Congestion: The port suffers from a significant lack of space for container storage. This congestion is a primary cause of delays, as containers must be moved frequently, increasing the risk of handling errors and extending clearance times.

- Primary Function: It primarily serves inter-island traffic and smaller cargo shipments, making it less equipped for the consistent, high-volume needs of a manufacturing plant.

Port of Mutsamudu (Anjouan): The International Gateway

The Port of Mutsamudu is the country’s main commercial and only deep-water port. For industrial importers, it offers several distinct advantages.

- Capacity: As the primary deep-water port, Mutsamudu can accommodate larger international container ships directly. It handles approximately 80% of the nation’s total import and export volume.

- Storage: While it can still face congestion, its container storage area is significantly larger than Moroni’s, providing more operational flexibility.

- Strategic Importance: As the main commercial hub, it generally has more established procedures for handling international freight, though challenges remain.

For a solar module factory requiring regular shipments of 40-foot containers—each holding materials for approximately 1 MW of production—Mutsamudu is almost always the more logical and reliable choice for international imports.

The Customs Challenge: Navigating Bureaucracy and Delays

But successfully docking a container is only the first step. The next, and often most unpredictable, phase is customs clearance. Data from the U.S. International Trade Administration shows that customs procedures in Comoros can be complex, non-transparent, and a significant source of delays.

Business planners must account for this reality. The World Bank’s research quantifies the challenge: the average time for border compliance to import goods into Comoros is 150 hours. That figure isn’t a worst-case scenario; it is the standard expectation.

Key challenges include:

- Strict Documentation: All paperwork, including the bill of lading, commercial invoice, and packing list, must be meticulously accurate. Minor discrepancies can lead to significant delays.

- Procedural Opacity: The clearance process can be difficult to navigate without local expertise. Steps and requirements are often not clearly communicated.

- Potential for Unofficial Costs: As in many developing markets, there can be pressure for unofficial payments to expedite processes.

Experience from J.v.G. Technology GmbH’s turnkey projects in similar markets shows that engaging a reputable local customs broker is not an optional expense but a critical investment in operational stability. A good broker can navigate the system, ensure compliance, and act as a crucial intermediary.

Financial and Operational Impact of Port Inefficiencies

The tangible costs of port logistics extend far beyond official fees. The World Bank reports that the average cost for border compliance per container is over $1,200—a figure significantly higher than the average for Sub-Saharan Africa.

The indirect costs, however, are often even more damaging. For a turnkey solar module manufacturing line designed for 20–50 MW annual output, a delay of just one week can halt the production of nearly 1 MW of solar modules. This translates directly into lost revenue, strained cash flow, and potential penalties for failing to meet customer delivery deadlines.

These logistical friction costs must be factored into financial modeling from day one to avoid an unrealistic business plan.

Strategies for Mitigating Supply Chain Risks in Comoros

While these challenges are significant, they are manageable with proactive planning. A robust supply chain strategy should include:

- Select an Experienced Local Partner: Engage a high-quality, vetted customs broker and freight forwarder with a proven track record in Comoros. This is arguably the single most important step.

- Prioritize Documentation Accuracy: Invest in processes to ensure all shipping documents are 100% correct and submitted well in advance of the vessel’s arrival.

- Build in Buffer Time and Stock: Do not base production schedules on best-case-scenario shipping times. Incorporate a buffer of several weeks into your lead times and consider holding a larger inventory of critical raw materials on-site.

- Factor in Realistic Costs: Budget for both the official port and customs fees and the potential for unforeseen expenses related to delays or procedural hurdles.

Frequently Asked Questions (FAQ)

Q: What are the main materials I will be importing for a solar factory?

A: A solar module assembly line requires several key imported components: photovoltaic (PV) cells, tempered solar glass, encapsulant films (like EVA or POE), backsheets or a second pane of glass, aluminum frames, and junction boxes.

Q: How much does it cost to clear a container in Comoros?

A: While costs can vary, a business should budget over $1,200 per container for standard border and port compliance fees, as reported by the World Bank. This does not include shipping costs, inland transport, or the fees for a customs broker.

Q: How does port congestion directly affect my production schedule?

A: Congestion means your container may not be unloaded promptly upon arrival. Even after unloading, it may be difficult to access for inspection and release. This creates an unpredictable delay between the ship docking and the materials arriving at your factory, making consistent production planning a significant challenge. A delay of a few days at the port can easily cause a week of production downtime.

Q: Should my factory be located closer to Moroni or Mutsamudu?

A: Given that Mutsamudu is the primary international port, locating a factory on the island of Anjouan can significantly reduce the complexity and cost of inland logistics. If the factory must be on Grande Comore, an additional inter-island shipping leg from Mutsamudu to Moroni must be factored into every single shipment’s timeline and cost.

From Port to Production: Integrating Logistics into Your Business Plan

The journey of raw materials through the ports of Comoros is a critical, and often underestimated, component of running a successful solar manufacturing operation. The choice between Moroni and Mutsamudu, the strategy for navigating customs, and the financial buffers built to absorb delays are not minor operational details; they are strategic decisions that can determine the viability of the entire enterprise.

By treating logistics with the same seriousness as production technology and market strategy, an entrepreneur can build a resilient operation capable of thriving in the unique Comorian environment. A thorough and realistic logistics plan is a cornerstone of a credible business plan for a solar factory, demonstrating a true understanding of the local operating conditions.