For entrepreneurs planning to enter the solar module manufacturing industry, the global supply chain presents both great opportunities and significant risks. A production line can be perfectly designed, but if a critical shipment of aluminum frames is delayed at a port for six weeks, the entire operation grinds to a halt. This scenario, once a distant possibility, has become a common challenge for manufacturers worldwide, underscoring the strategic vulnerability of long-distance supply chains.

This article explores a practical solution for European, Middle Eastern, and North African solar enterprises: sourcing key components like aluminum frames and solar glass from Croatia. By examining the capabilities of Croatia’s industrial sector, business leaders can reduce import dependency, lower logistical costs, and build a more resilient and competitive manufacturing operation.

The Critical Role of Frames and Glass in Solar Module Production

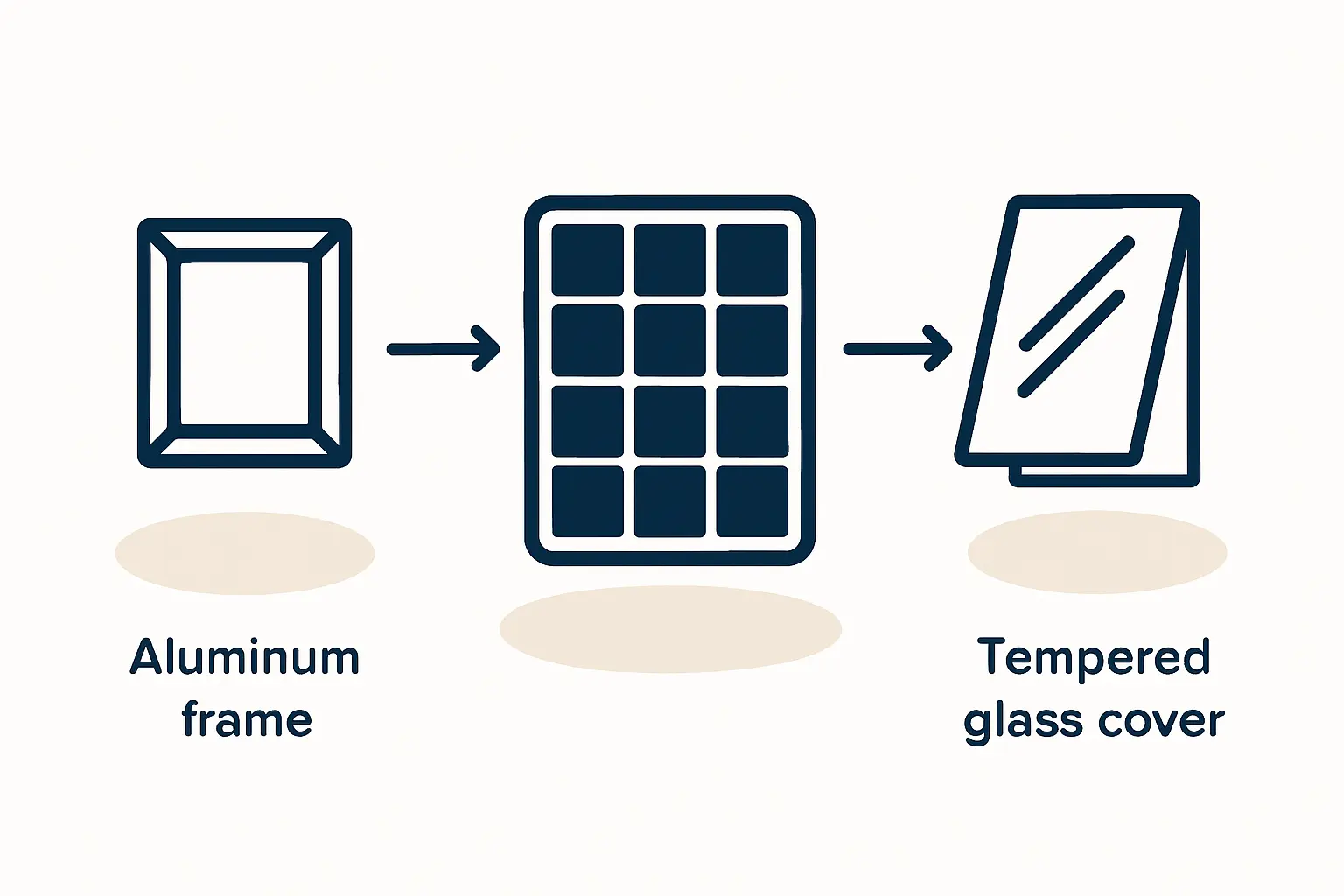

While photovoltaic cells are the technological heart of a solar module, the aluminum frame and front glass are its essential protectors. They provide the structural integrity and durability required to withstand decades of exposure to harsh weather conditions.

Aluminum Frames:

These provide rigidity to the module, protect the edges of the glass laminate, and offer a standardized method for mounting the panel onto racking systems.

Solar Glass:

This specially formulated, low-iron, tempered glass protects the solar cells from impact, moisture, and UV degradation while maximizing light transmission.

Together, these two components typically account for 10% to 15% of the total solar module bill of materials. While this may seem modest, their bulk and weight make them disproportionately influential on overall logistics costs and supply chain complexity.

The Hidden Risks of a Concentrated Global Supply Chain

The modern solar industry has relied heavily on established supply chains, predominantly centered in East Asia. This concentration has enabled remarkable cost reductions and scalability. However, it has also created systemic risks that business planners must now address:

-

Logistical Volatility: Shipping routes are susceptible to disruptions, from port congestion to geopolitical events. A six-to-eight-week transit time from Asia to Europe can easily extend to ten or twelve weeks, severely impacting production schedules.

-

Rising Freight Costs: Container shipping rates have shown extreme volatility in recent years, making it difficult to forecast landed costs accurately.

-

Working Capital Inefficiency: When components spend weeks in transit, a significant amount of capital is tied up in unproductive inventory.

-

Quality Control Challenges: Auditing a supplier or resolving a quality issue becomes significantly more complex and expensive when the facility is thousands of kilometers away.

For a new venture, these uncertainties can erode profitability before the first module is even sold.

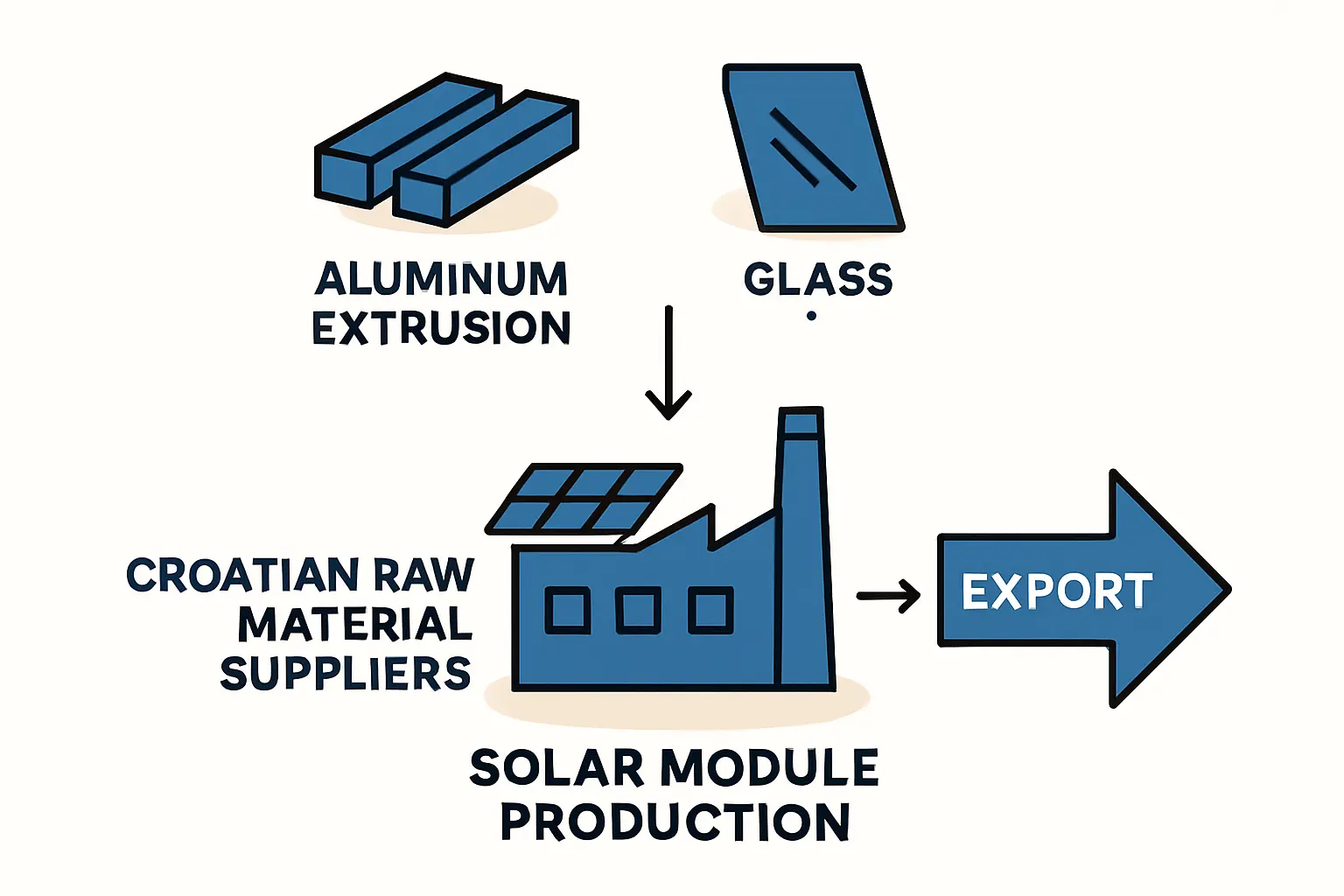

Croatia’s Industrial Landscape: An Untapped Resource for Solar Manufacturing

Croatia, an EU member state with a strategic location on the Adriatic Sea, has a well-established industrial base that is often overlooked in the context of solar energy. Its capabilities in aluminum extrusion and glass manufacturing present a compelling nearshoring opportunity.

J.v.G. Technology GmbH’s experience scouting and qualifying suppliers for turnkey projects shows that Croatian manufacturers have a strong capacity for producing high-quality industrial goods that meet stringent European standards.

Aluminum Extrusion Capabilities

Croatia is home to several sophisticated aluminum processing companies that serve demanding sectors like construction, automotive, and shipbuilding. These facilities have the technical capacity for precision extrusion, anodization, and machining required for solar module frames. Their key advantage is the ability to produce high-quality frames compliant with EN and ISO standards, often with greater flexibility for custom designs and smaller order volumes compared to massive overseas producers.

Solar and Float Glass Production

The region has a long history of high-quality glass manufacturing. While dedicated solar glass production may require investment or adaptation, the fundamental float glass technology is mature. Local producers can be qualified to supply the low-iron, tempered glass needed for photovoltaic modules. Proximity allows for easier collaboration on specifications, quality assurance, and just-in-time delivery, reducing the risk of breakage during long-distance transport.

Analyzing the Business Case: Cost, Logistics, and Quality

Shifting sourcing from Asia to Croatia is not merely about geographic proximity; it is a strategic business decision with tangible financial and operational benefits. The total cost of ownership often proves more favorable than a simple per-unit price comparison suggests.

Cost Competitiveness

While the ex-works price for a component from a Croatian supplier might be marginally higher than that of a mass producer in Asia, the final landed cost at the factory gate can be significantly lower. This is because:

-

Transportation costs are drastically reduced: Trucking from Croatia to a factory in Central Europe or a port serving North Africa is a fraction of the cost of ocean freight.

-

Tariffs and Carbon Taxes: Sourcing within the EU avoids import tariffs and will prove advantageous as mechanisms like the Carbon Border Adjustment Mechanism (CBAM), which taxes the carbon footprint of imported goods, come into effect.

Logistical Advantages

The most significant benefits lie in logistics. Delivery lead times can be reduced from over a month to less than a week. This agility allows a factory to:

-

Reduce inventory levels: Lower the need for large buffer stocks and free up working capital.

-

Respond faster to market changes: Quickly adapt production to different module sizes or frame specifications.

-

Improve production planning: With reliable delivery schedules, the entire factory layout planning and workflow can be optimized for efficiency.

One J.v.G. client in the Balkan region was able to reduce their frame and glass inventory holding by 75% after transitioning to a regional supplier, directly improving their cash flow.

Quality and Standards

Sourcing from within the European Union offers greater assurance on quality standards, labor practices, and material certifications. Conducting on-site supplier audits and collaborating on process improvements becomes a matter of a short flight rather than an intercontinental trip. This proximity is invaluable when setting up turnkey solar production lines, where close cooperation with suppliers is essential.

Frequently Asked Questions (FAQ)

Why focus specifically on Croatia?

Croatia’s combination of EU membership, strategic port access at Rijeka, established industrial expertise in metals and glass, and competitive labor costs makes it a logistical and economic sweet spot for supplying future solar factories in Europe, the Middle East, and North Africa.

Can Croatian suppliers handle the volume for a 100 MW or larger factory?

Scalability is a key consideration. While some suppliers may already have sufficient capacity, others may need to invest to meet the demands of a large solar manufacturer. This is why thorough supplier due diligence and qualification, including capacity audits, are a critical first step.

What about other components like cells, EVA, and backsheets?

Currently, the supply chain for solar cells and specialized polymers like EVA remains heavily concentrated in Asia. However, the business principle of diversifying where possible remains sound. Securing the bulkiest components locally is an impactful first step in de-risking the overall supply chain.

How does an entrepreneur find and qualify these suppliers?

Identifying and validating suitable industrial partners requires specialized knowledge. It involves technical audits of production capabilities, quality management system reviews (e.g., ISO 9001), and financial stability checks. This is a core part of the planning that determines the long-term success and cost of setting up a solar factory.

Building a Resilient and Competitive Solar Manufacturing Operation

For business leaders entering the solar manufacturing space, success depends on more than just technology; it relies on smart, resilient operational planning. Relying solely on long-distance supply chains for essential, bulky components like aluminum frames and glass is a strategic liability.

By exploring regional industrial hubs like Croatia, entrepreneurs can build a significant competitive advantage. This approach leads to a more predictable, cost-effective, and agile operation, transforming a potential supply chain vulnerability into a source of strength. Building a robust regional supply network is a foundational element for long-term success in the competitive solar industry.