An entrepreneur secures an ideal plot of land for a new solar panel factory. The location has excellent transport links, a willing workforce, and supportive local authorities. The business plan is robust and financing is in place.

A few months into the project, however, an unexpected and costly obstacle emerges: the local power grid cannot support the factory’s energy demands. The project is now facing significant delays and a potential budget overrun of over one million euros.

This scenario, or one like it, is more common than many investors realize. While machinery and building permits are often the focus of planning, the single most critical—and frequently underestimated—requirement is securing a high-capacity, stable connection to the national power grid. For a solar manufacturing facility in Croatia, this process involves detailed engagement with the national grid operator and can fundamentally determine a project’s final location, timeline, and budget.

Why Standard Power Is Not Enough for Solar Manufacturing

Unlike a typical commercial building or warehouse, a solar panel manufacturing facility is a sophisticated industrial operation with substantial and specific energy requirements.

A small-scale 50 MW production line requires a continuous power supply of approximately 500 kilowatts (kW). For a larger 250 MW facility, this demand climbs to between 1.5 and 2 megawatts (MW)—a level of consumption far beyond what a standard commercial power line can provide.

Equally important is the stability of that power. Sensitive solar panel manufacturing machines, such as stringers and laminators, are vulnerable to voltage fluctuations and power outages. An unstable supply can lead to equipment damage, production halts, and significant material waste, directly impacting profitability. A reliable, high-quality power connection is not a luxury but a core operational necessity.

The “Water Pipe” Analogy: Understanding Grid Capacity

A simple way to understand the challenge is to think of the electrical grid as a municipal water system. A residential home needs a small-diameter pipe to meet its water needs. An office building may require a slightly larger one. A large industrial factory, however, needs the equivalent of a primary water main connected directly to its site to function.

You can’t simply connect a large-diameter pipe to a small residential line; the underlying infrastructure must be able to support the demand. Similarly, a factory requiring 2 MW of power cannot simply “plug in” to a grid designed for residential or light commercial use. The local substation, transformers, and power lines must have the capacity to deliver that energy safely and reliably. Verifying this capacity is the first—and most crucial—step.

Navigating the Process with Croatia’s Grid Operator (HEP ODS)

In Croatia, the authority responsible for the national electricity distribution network is Hrvatska elektroprivreda – Operator distribucijskog sustava d.o.o., commonly known as HEP ODS. Any new high-consumption industrial project must go through their formal application and approval process.

The process typically follows these key stages:

-

Initial Inquiry: The project developer submits a formal request to HEP ODS, detailing the planned factory location and its estimated power requirements.

-

Grid Capacity Study: Upon receiving the inquiry, HEP ODS initiates a technical study to determine if the grid in the proposed area can handle the additional load. This is not a quick check but a comprehensive engineering analysis that can take several months.

-

Connection Offer: Based on the study’s findings, HEP ODS issues a connection offer if capacity is sufficient. If the grid requires upgrades, the offer will instead include a detailed breakdown of the necessary work and associated costs.

-

Obtaining the “Energetska Suglasnost”: Once the terms of the offer are accepted and fulfilled, HEP ODS issues the Energetska suglasnost, or “Energy Approval.” This official document is the final permission required to connect the facility to the grid and is a prerequisite for obtaining a building permit.

The Two Hidden Risks: Time and Cost

This process often reveals two significant business risks that must be incorporated into any serious solar panel manufacturing business plan: unforeseen costs and project delays.

Unexpected Costs for Grid Upgrades

If the grid study reveals that the local infrastructure is insufficient, the developer—not the grid operator—is typically responsible for funding the necessary upgrades. These costs can be substantial. Depending on the distance to the nearest high-capacity line and the complexity of the work, investments can range from 500,000 euros to over 2 million euros. These expenses may include:

- Installation of a new, dedicated transformer station.

- Laying new high-voltage cables from a more distant, robust part of the grid.

- Upgrading existing substations to handle the increased load.

This potential capital expenditure must be factored into financial planning from the very beginning to avoid jeopardizing the project’s viability.

Significant Time Delays

The timeline for the grid capacity study and approval process can also be lengthy. The initial study by HEP ODS often takes three to six months, sometimes longer. If major upgrades are required, the engineering, procurement, and construction work can add another 12 to 18 months to the project timeline. Failing to initiate this process at the very beginning is a common and costly mistake that can delay the start of production by over a year.

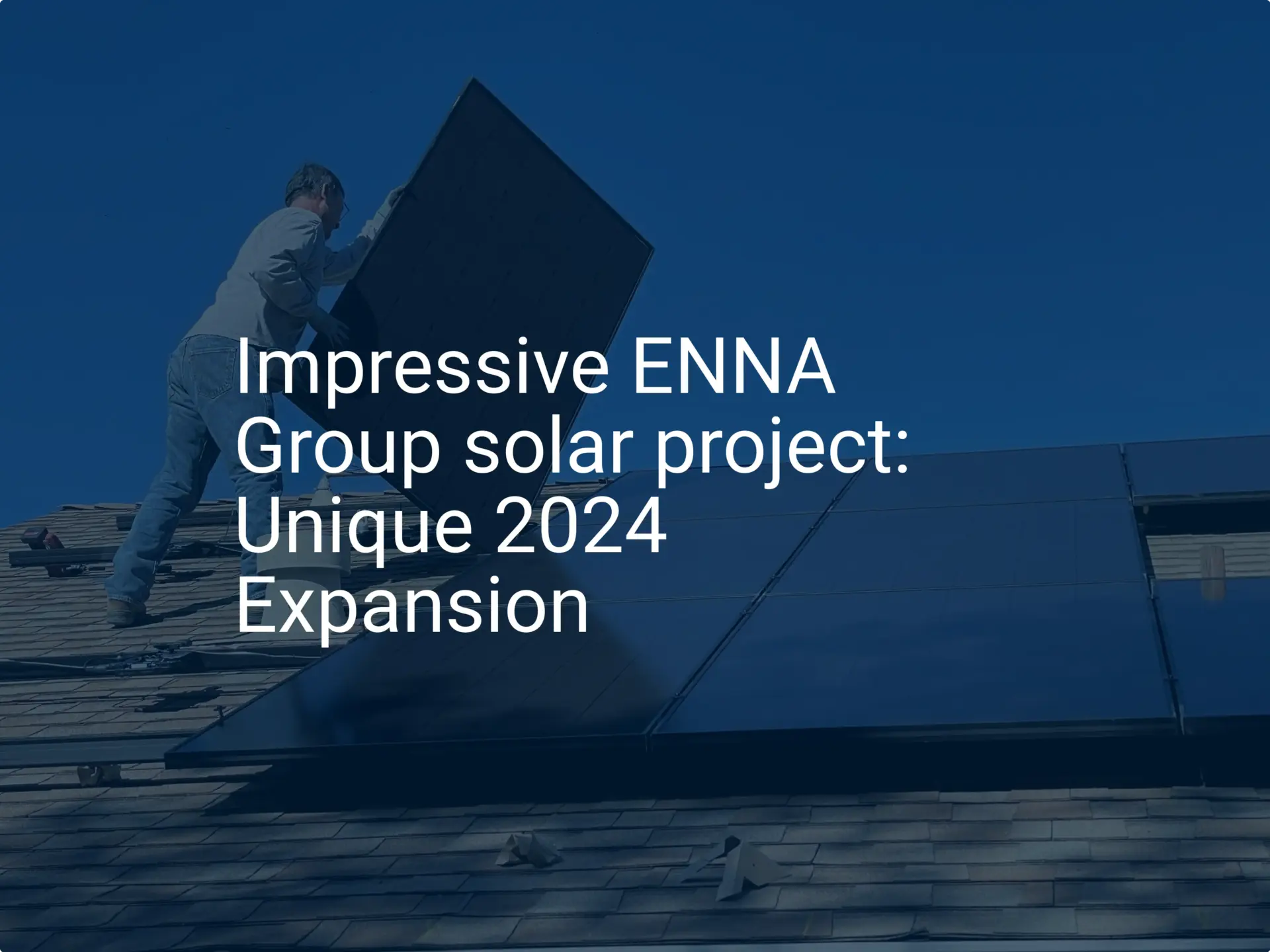

A Practical Example: Lessons from a 250 MW Croatian Project

A case from a J.v.G. Technology GmbH project in the region illustrates this point perfectly. During the planning phase for a 250 MW turnkey solar manufacturing line in Croatia, the power requirement was calculated to be approximately 1.5 MW.

The project team initiated contact with HEP ODS before the final land purchase was concluded. The subsequent grid study confirmed that while the location was generally suitable, a significant grid reinforcement project was necessary.

By having this information early, the investor was able to:

- Negotiate the costs and timeline for the grid upgrade with HEP ODS.

- Incorporate the multi-million-euro investment into the final project budget.

- Align the factory construction timeline with the grid connection schedule, avoiding idle periods.

This proactive approach transformed a potential project-ending obstacle into a manageable, planned-for milestone.

Frequently Asked Questions (FAQ)

Can I use generators instead of a grid connection?

For primary, 24/7 power, diesel generators are not a viable long-term solution. The fuel costs would be prohibitively high, maintenance is intensive, and the power quality may not meet the stability requirements of sensitive manufacturing equipment. They are suitable only for short-term emergency backup.

How much does the location of the land matter?

The location is absolutely critical. A plot of land situated near existing high-voltage power lines or a major electrical substation is vastly preferable, as it significantly reduces the potential cost and complexity of establishing a connection.

Who pays for the grid upgrade?

In nearly all cases, the project developer or investor is responsible for financing the infrastructure upgrades required to service their facility. These costs are paid to the utility operator (HEP ODS), who then manages the construction work.

How early should I start the grid connection process?

The grid connection inquiry should be one of the very first steps in your project, initiated even before land acquisition is finalized. The results of the grid study should inform your final decision on the site, your budget, and your overall project timeline.

Securing Power as a Strategic Foundation

Establishing a solar panel factory is a complex undertaking. While machinery, logistics, and staffing are visible components of the plan, the invisible infrastructure of the power grid is the true foundation of the operation.

In Croatia, successfully navigating the approval process with HEP ODS is not merely an administrative task; it is a strategic imperative that directly influences project feasibility. By addressing the grid connection early and treating it with the seriousness it deserves, entrepreneurs can avoid costly surprises and build their manufacturing venture on solid ground.