The Republic of Cyprus, a jewel of the Mediterranean, has a tourism industry that is both a pillar of its economy and a major energy consumer. With over 50,000 hotel beds catering to millions of visitors annually, the sector’s operational costs are deeply tied to energy prices.

This creates a unique challenge, particularly during the sun-drenched summer months when peak tourism coincides with peak energy demand for air conditioning. For an entrepreneur or investor exploring the solar industry, this scenario presents a focused and compelling business opportunity: establishing a local solar module manufacturing facility tailored to the specific needs of the Cypriot hospitality sector.

The Energy Challenge of Cyprus’s Hospitality Industry

The energy profile of a hotel is demanding and seasonal. A typical 150-room hotel in Cyprus can consume approximately 450,000 kWh of electricity per year. Scaled across the entire sector, this consumption is estimated to be around 250 GWh annually.

This substantial demand is concentrated in the peak summer season, placing immense strain on the grid and exposing hotel operators to volatile electricity prices tied to imported fossil fuels—a significant operational risk.

Yet the very element that drives this demand—intense, reliable sunshine—is also the key to a solution. With solar irradiation levels exceeding 1,900 kWh/m² per year, Cyprus is one of the most favorable locations in Europe for solar power generation. The abundant and underutilized rooftop space on hotels and resorts offers a clear path toward energy independence and cost control.

A Tailored Solution: The Local Solar Manufacturing Opportunity

While importing solar modules is a common approach, a local manufacturing strategy offers distinct advantages for the high-end tourism market. For those considering how to start a solar manufacturing plant, this niche presents a viable entry point that avoids direct competition with global, large-scale commodity producers.

The opportunity is built on three pillars:

Concentrated B2B Demand

Unlike a fragmented residential market, the hotel sector consists of a smaller number of large-volume consumers. Hotel chains and large resort operators are ideal B2B clients who prefer to negotiate long-term, single-source contracts. A local manufacturer can build direct relationships, offer customized solutions, and secure predictable revenue streams.

Specific Aesthetic Requirements

For a luxury hotel or resort, appearance is paramount. Standard industrial solar panels with visible silver lines and blue cells can detract from a building’s architecture. This is where a local factory can excel, producing premium, aesthetically pleasing modules such as:

- Black-on-black modules: These offer a sleek, uniform appearance that integrates seamlessly into modern roof designs.

- Custom-colored modules: For projects where brand identity or specific architectural aesthetics are critical, modules with colored glass or backsheets can be produced.

This ability to customize is a powerful differentiator that large-scale importers focused on volume cannot easily match.

The “Made in Cyprus” Advantage

In an era of conscious travel, sustainability is a powerful marketing tool. Hotels powered by locally manufactured solar modules can build a compelling “green tourism” narrative. This branding strengthens their appeal to environmentally aware European tourists and can command premium pricing, creating a win-win situation for both the hotel and the module supplier.

Technical and Product Specifications for the Cypriot Market

Operating in a coastal Mediterranean environment requires more than standard photovoltaic technology. A local factory can engineer products specifically designed to withstand the region’s climate challenges, building a reputation for quality and durability.

-

Salt Mist Resistance: Proximity to the sea means a high concentration of airborne salt, which can corrode module components over time. Manufacturing modules with certified salt mist resistance is essential for long-term performance and bankability.

-

High-Temperature Performance: Modules must be optimized to perform efficiently in the high ambient temperatures common during Cypriot summers. Understanding the solar panel manufacturing process allows for the selection of materials, like specialized encapsulants and backsheets, that ensure reliability under thermal stress.

-

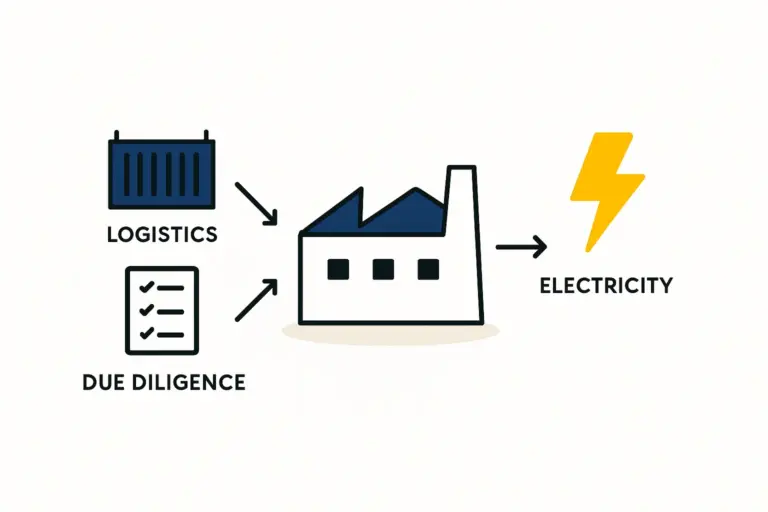

Logistical Superiority: A domestic factory eliminates long international shipping times, reduces the risk of transport damage, and simplifies logistics. In addition, offering local technical support and warranty fulfillment provides a level of service and responsiveness that foreign suppliers cannot replicate.

Experience from J.v.G. Technology GmbH turnkey projects shows that establishing a production line focused on such a high-value niche can be more strategic than competing in the broad commodity market.

The Business Case for a Cypriot Solar Module Factory

Establishing a solar manufacturing facility in Cyprus to serve the tourism sector is a sound business proposition. The market is well-defined, the demand is significant, and the value proposition is clear.

An investor can create a detailed financial model by analyzing the potential rooftop capacity of hotels and resorts. Capturing even a fraction of the 250 GWh annual demand translates into a substantial and sustainable business. Such a venture also contributes directly to the national economy by creating skilled jobs, reducing dependency on energy imports, and enhancing the competitiveness of the vital tourism industry. Government and EU incentives for renewable energy and local industry can further strengthen the project’s financial viability—a key component of any thorough solar factory business plan.

Frequently Asked Questions (FAQ)

Why can’t hotels simply import standard solar panels?

They can, but they miss out on the key advantages a local manufacturer offers. These include aesthetic customization to match hotel architecture, modules engineered for local climate conditions (salt mist, high heat), faster delivery, and accessible, in-person technical support and warranty service.

What is the typical factory size required for this market?

A small-to-medium-scale facility, potentially in the 20 MW to 50 MW annual capacity range, could effectively serve the niche B2B demand from the tourism sector. This allows for a focus on quality and customization rather than mass production.

Does producing custom or aesthetic modules require special skills?

The fundamental manufacturing process is similar to that of standard modules. However, it requires rigorous quality control, specialized bills of materials (e.g., black backsheets, specific cell technologies), and precise handling to ensure a flawless aesthetic finish.

How does local production impact the warranty and service for a hotel?

Local production offers a significant advantage. If a hotel experiences an issue, having the manufacturer located in the same country means faster response times, easier logistics for replacements, and direct access to the technical experts who built the product. This minimizes potential downtime and operational disruption.

Conclusion: Seizing a Focused Market Opportunity

The energy demand of Cyprus’s tourism industry presents a distinct challenge that also holds the seed of a strategic business opportunity. An entrepreneur does not need to compete with global giants to enter the solar manufacturing space. By identifying and serving a niche market with specific, high-value requirements, a local factory can build a defensible and profitable business.

For hotels in Cyprus, solar energy is an investment in sustainability and cost control. For a forward-thinking investor, manufacturing those panels is an investment in the future of both energy and tourism in the region. Understanding the distinct demands of this target market is the key to building a successful and impactful manufacturing venture.