For an entrepreneur considering a solar module factory in Cyprus, the island presents a compelling opportunity. With solar irradiation levels among the highest in Europe, averaging between 1,750 and 2,000 kWh/m² annually, the island has an abundance of the fundamental resource for solar power.

However, this advantageous climate also poses significant technical challenges that can undermine a project’s long-term financial success. The high ultraviolet (UV) radiation, elevated ambient temperatures, and saline coastal air create a highly corrosive environment for any outdoor infrastructure.

This reality brings a critical decision to the forefront for any new manufacturing venture: which solar module technology to produce? The choice between the industry-standard Glass-Foil module and the more robust Glass-Glass module is not merely a technical detail. It is a strategic decision that will define the product’s durability, bankability, and the manufacturer’s market position for years to come. This analysis offers a clear comparison to guide this foundational choice.

Understanding the Core Technologies: A Structural Overview

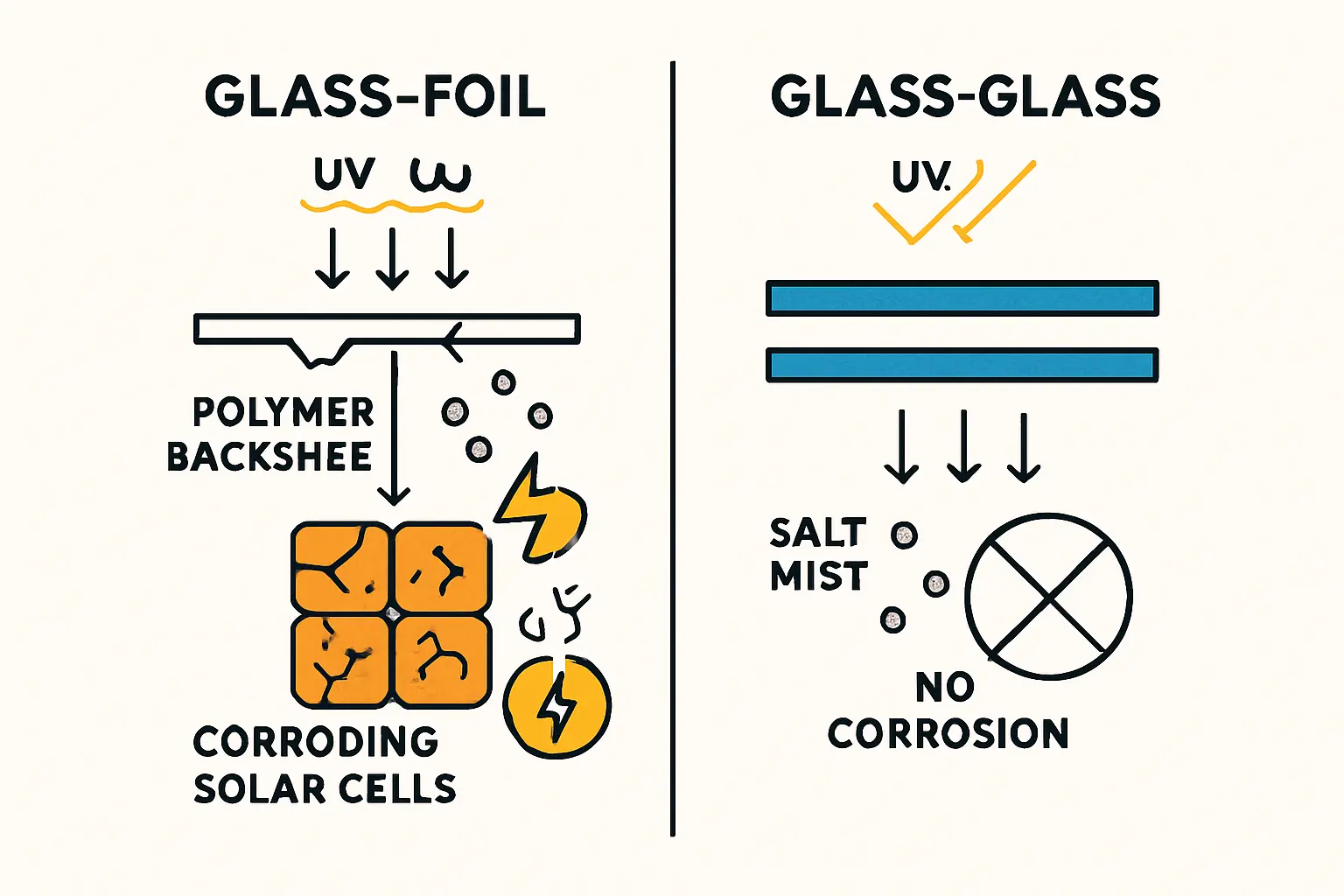

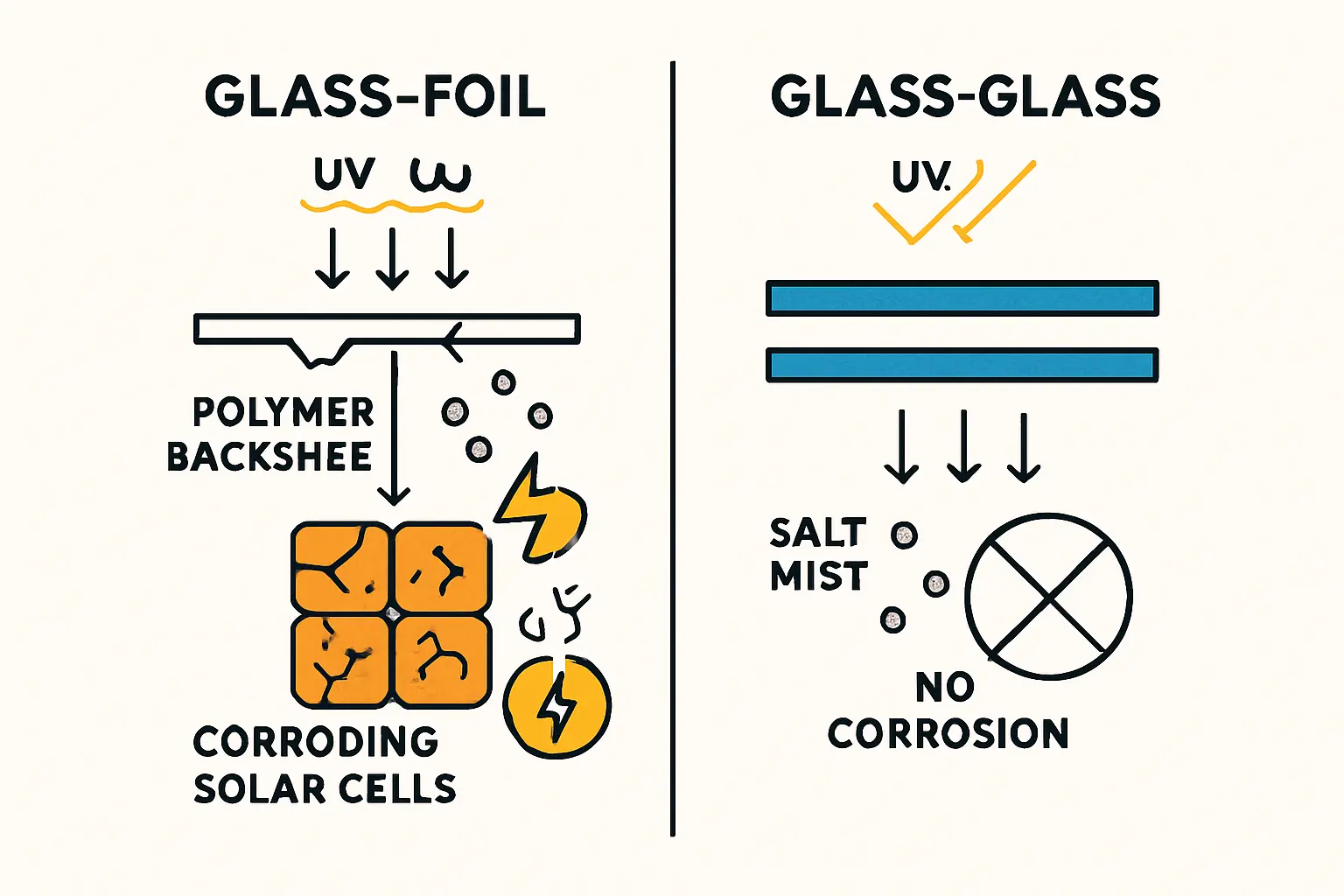

At first glance, most solar panels appear similar. The crucial difference between Glass-Foil and Glass-Glass modules lies in their rear-side construction, which dictates their resilience and lifespan.

The Conventional Approach: Glass-Foil Modules

A Glass-Foil module, often called a glass-backsheet module, consists of a pane of tempered solar glass on the front, an encapsulant layer surrounding the solar cells, and a polymer-based backsheet on the rear. This backsheet, typically made from materials like PVF (Tedlar), PVDF, or PET, acts as a protective barrier. For decades, this has been the standard, cost-effective design for solar panels worldwide.

The Advanced Solution: Glass-Glass Modules

A Glass-Glass module replaces the polymer backsheet with a second pane of heat-strengthened or tempered glass. This creates a symmetrical ‘sandwich’ structure: glass, encapsulant, solar cells, encapsulant, and another layer of glass. This design naturally forms a hermetic seal around the solar cells, offering superior protection from environmental stressors.

The Vulnerability of Glass-Foil Modules in Harsh Climates

While cost-effective to produce, the polymer backsheet of a Glass-Foil module is its primary point of failure, especially in an environment like Cyprus. The combination of intense UV radiation, heat, and humidity accelerates the degradation of these plastic materials.

Over time, this exposure leads to several critical issues:

- UV Degradation: Polymers become brittle and can develop micro-cracks, compromising the module’s protective barrier.

- Moisture Ingress: Through these micro-cracks or around the module’s edges, humidity and salt mist can penetrate the interior. This is a significant risk in coastal regions.

- Delamination: The bond between the backsheet and the encapsulant can weaken, allowing for further moisture ingress.

- Potential Induced Degradation (PID): When moisture enters the module, it can create pathways for electrical current leakage, leading to a rapid and significant loss of power output. This is a common failure mode in hot, humid climates.

- Corrosion: Saline moisture can corrode the metallic contacts and interconnectors of the solar cells, causing irreversible damage and reducing the module’s efficiency and lifespan.

These degradation mechanisms mean a standard Glass-Foil module may struggle to perform optimally or reach its expected 25-year lifetime in a demanding coastal climate. For a manufacturer, this translates into a higher risk of warranty claims and potential damage to brand reputation.

The Resilience of Glass-Glass Modules: A Long-Term Solution

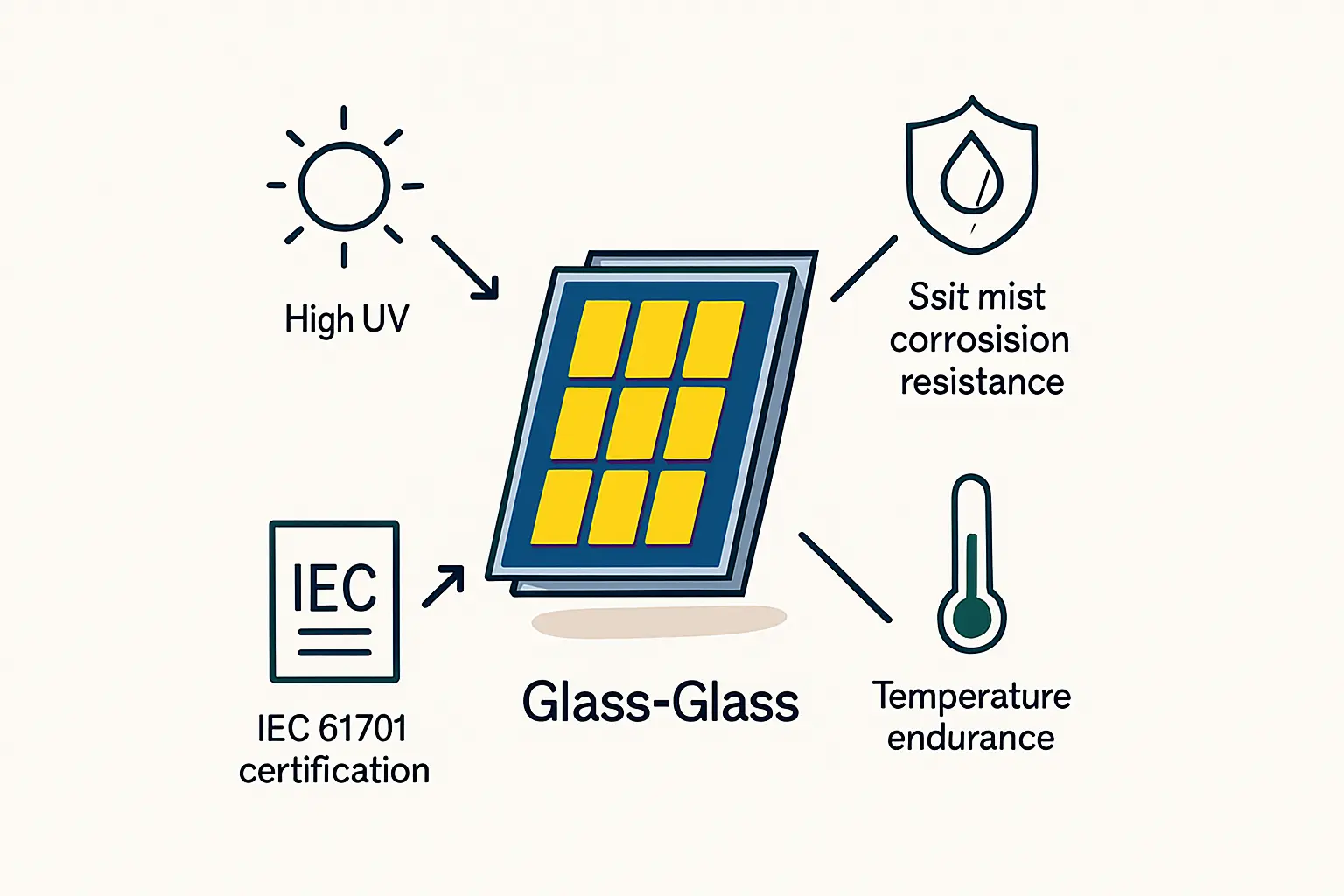

The Glass-Glass construction directly addresses the weaknesses of the polymer backsheet. Glass is an exceptionally stable material; it is impermeable to moisture and unaffected by UV radiation. The result is a superior long-term shield for the sensitive solar cells.

Key advantages include:

- Zero Moisture Ingress: The glass-on-glass structure creates a perfect seal, virtually eliminating the risk of moisture-related issues like PID and internal corrosion.

- Enhanced Mechanical Stability: The symmetrical structure reduces mechanical stress on the solar cells during transport, installation, and under environmental loads like wind. This significantly lowers the probability of micro-cracks forming in the cells themselves, which are a primary source of power loss.

- Lower Degradation Rates: Industry studies consistently show that Glass-Glass modules have much lower annual power degradation rates. While a Glass-Foil module might lose 0.5% to 0.7% of its power annually, a Glass-Glass module typically degrades at just 0.25% to 0.3%. Over the module’s extended 30+ year lifespan, this difference adds up to substantially more energy production.

- Bifacial Energy Gain: Glass-Glass modules can be designed as bifacial, meaning they can capture sunlight from both the front and rear sides. In installations over reflective surfaces like light-colored ground or rooftops, this can increase annual energy yield by 10% to 25%—a significant financial advantage.

Financial Implications: Initial Investment vs. Levelized Cost of Energy (LCOE)

From a business perspective, technical specifications are only relevant when they translate into financial performance. The key metric for this is the Levelized Cost of Energy (LCOE), which represents the average net present cost of electricity generation for a generating plant over its lifetime.

Manufacturing Glass-Glass modules does require a slightly higher initial investment. The second pane of glass is more expensive than a polymer backsheet, and certain solar panel manufacturing machines like the laminator must be specified for this purpose.

However, the higher upfront cost is often offset by superior long-term performance. The lower degradation rate, longer lifespan (30-year warranties are common), and potential for bifacial gain mean a Glass-Glass module produces significantly more energy over its lifetime. This increased energy output drastically lowers the project’s LCOE, making it a more profitable and bankable investment for the end customer.

A lower LCOE is the ultimate goal for any power project developer, and a module that delivers this gives its manufacturer a powerful competitive advantage.

Manufacturing and Market Positioning Considerations

For a new entrant into the solar industry in Cyprus, the choice of technology defines the business strategy.

Opting to produce standard Glass-Foil modules means competing primarily on price in a crowded market. Conversely, choosing to manufacture Glass-Glass modules positions the company as a provider of premium, high-durability solutions tailored for the specific challenges of the region. Based on experience from J.v.G. turnkey projects in similar climates, manufacturers who opt for durable technologies can command a higher price point, build a stronger brand reputation, and access project financing more easily due to lower perceived risk.

This strategic direction must inform the initial solar module manufacturing business plan. The factory layout, bill of materials, and marketing strategy will all revolve around this core product decision. A partner specializing in a turnkey solar module production line can ensure the facility is optimally configured for high-efficiency Glass-Glass manufacturing from day one.

Frequently Asked Questions (FAQ)

Are Glass-Glass modules much heavier than Glass-Foil modules?

Yes, they are heavier due to the second pane of glass. However, modern mounting systems are designed to handle this additional weight, and the structural and performance benefits typically outweigh this consideration for most large-scale and commercial installations.

Is the manufacturing process for Glass-Glass modules significantly more complex?

The core manufacturing steps are largely the same. The primary difference lies in the lamination stage, which requires a laminator capable of handling the Glass-Glass structure. With a properly designed production line, the process is just as streamlined and automated as it is for Glass-Foil production.

Can a single factory produce both types of modules?

While technically possible with a highly flexible production line, it is often more efficient for a new factory to specialize. Specialization allows for an optimized supply chain, production processes, and marketing efforts, leading to a clearer market identity and better operational efficiency.

Conclusion and Next Steps

For a solar module manufacturing plant in Cyprus, the environmental conditions are too demanding to ignore. While Glass-Foil modules may offer a lower entry cost, their susceptibility to degradation from UV, heat, and salt mist poses a significant long-term risk to both performance and profitability.

Glass-Glass technology, with its inherent resilience, lower degradation rates, and potential for bifacial gain, represents a strategically superior choice. It allows a new manufacturer to produce a high-value product perfectly suited to its target market, delivering a lower Levelized Cost of Energy for its customers and building a reputation for quality and durability. This decision, made at the planning stage, can set the foundation for a sustainable and successful enterprise.