An investor is considering a solar module factory in Central Europe. Their primary concern isn’t labor availability or energy costs, but a simple geographical reality: the proposed site is over 500 kilometers from the nearest major seaport.

How can a factory in a landlocked country like the Czech Republic efficiently manage a global supply chain that relies on maritime shipping for critical components?

This scenario highlights a common challenge for entrepreneurs entering the solar industry. While a coastal location may seem ideal, a landlocked position within a major economic bloc can offer distinct strategic advantages. With proper planning, a central location can become a powerful logistical asset rather than a liability.

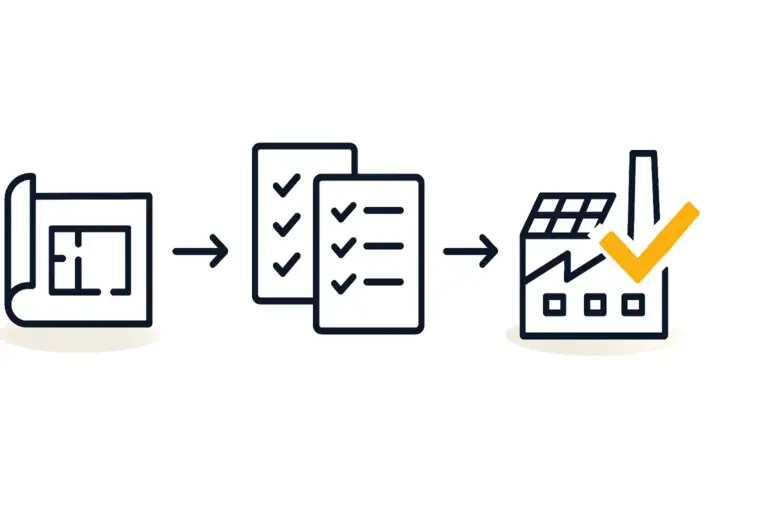

This article explores practical strategies for managing supply chains in such a setting, with insights applicable to any region where geography presents a similar challenge. For those just starting out, understanding these fundamentals is a critical first step in learning how to start a solar panel factory.

The Geographic Advantage: Why Central Europe is a Logistical Hub

The initial perception of a landlocked country as “isolated” is often misleading, particularly within the European Union. In fact, the Czech Republic’s central position is one of its greatest strengths. Unlocking this potential lies in understanding and using the surrounding infrastructure.

The most significant factor is membership in the EU Single Market. This economic union allows for the free movement of goods between member states without internal customs checks, tariffs, or extensive paperwork. Once a container of solar cells from Asia is cleared at a port in Germany or the Netherlands, it can travel to a Czech factory as easily as it would to one in the same city.

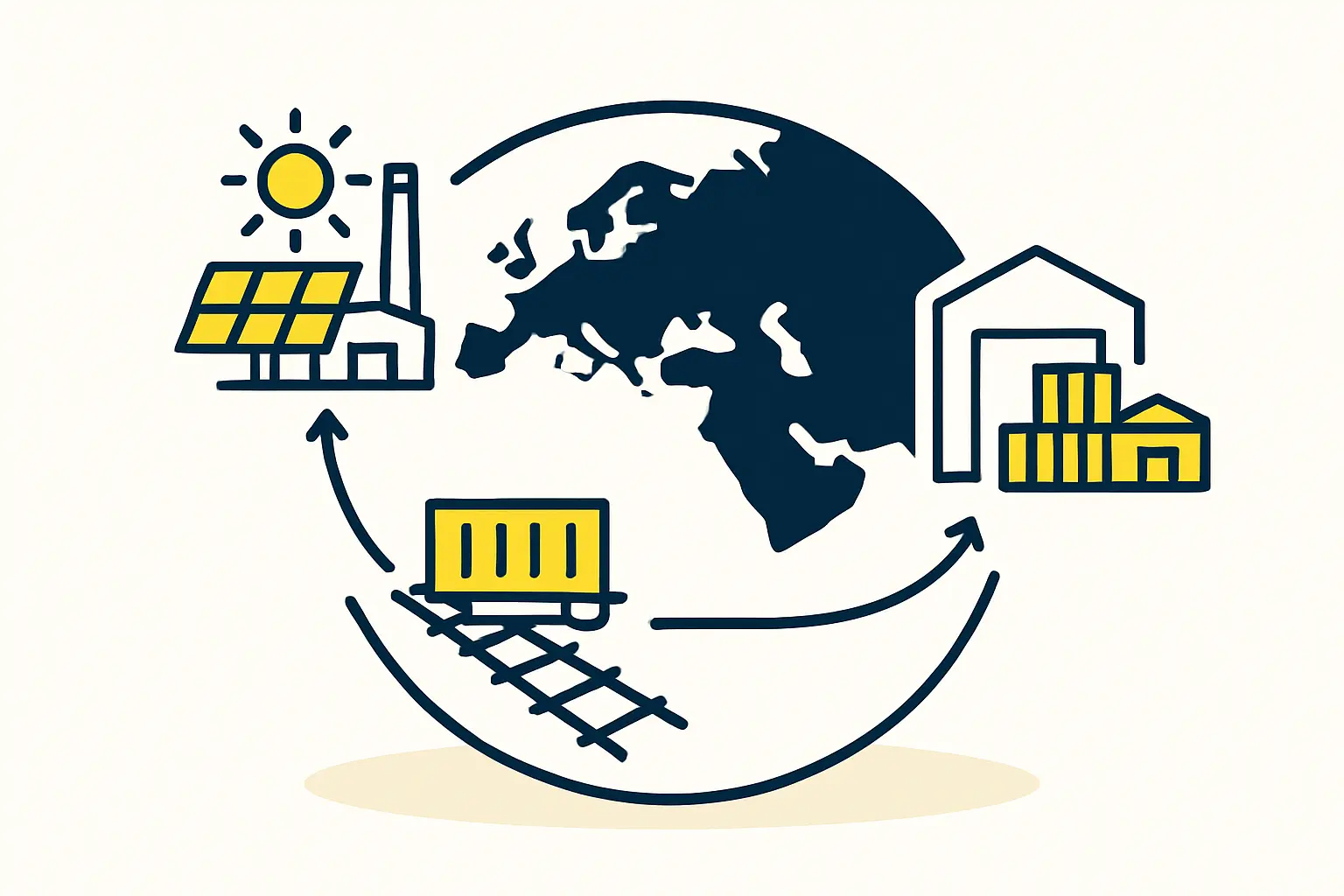

This creates a seamless “extended hinterland,” connecting the factory to multiple world-class ports via highly developed transport networks.

This integrated system transforms the challenge of distance into a choice of efficiency, allowing a manufacturer to select the best port based on shipping routes, cost, and transit times, rather than being limited to a single local option.

Mapping the Inbound Supply Chain: From Global Ports to the Factory Floor

A solar module factory relies on a diverse bill of materials with components sourced globally. Solar cells may come from Southeast Asia, specialized glass from Germany, and aluminum frames from Turkey—a logistical challenge the supply chain strategy must address. For a Czech facility, several key European ports serve as the main gateways.

-

Port of Hamburg, Germany: Often called “Prague’s Port,” Hamburg has direct and efficient rail and road links. The Elbe River also provides a less common but cost-effective inland waterway option for certain bulk materials.

-

Port of Rotterdam, Netherlands: As Europe’s largest port, Rotterdam offers unparalleled global connections. Its excellent rail and road infrastructure ensures reliable transit into Central Europe.

-

Port of Koper, Slovenia: For shipments arriving from Asia via the Suez Canal, Koper offers a southern entry point that can reduce maritime travel time.

-

Port of Gdansk, Poland: A strategic option on the Baltic Sea, Gdansk provides another competitive route, particularly for supply chains originating in Northern Asia.

Choosing the Right Transport Mode

Once goods arrive at these ports, the journey to the factory begins. The choice of transport mode is a critical decision, balancing cost, speed, and volume.

Road Freight: Trucks offer the greatest flexibility and are essential for “last-mile” delivery directly to the factory doors. For time-sensitive or smaller shipments, road transport is often the fastest option.

Rail Freight: For standard containerized goods like solar cells, glass, and aluminum frames, rail transport is highly efficient and cost-effective. Regular block train services connect major ports directly with inland terminals throughout the Czech Republic and neighboring countries. This mode is ideal for predictable, high-volume inbound logistics.

Inland Waterways: While more specialized, river transport on the Elbe can be an economical choice for non-urgent, heavy raw materials, reducing road congestion and fuel costs.

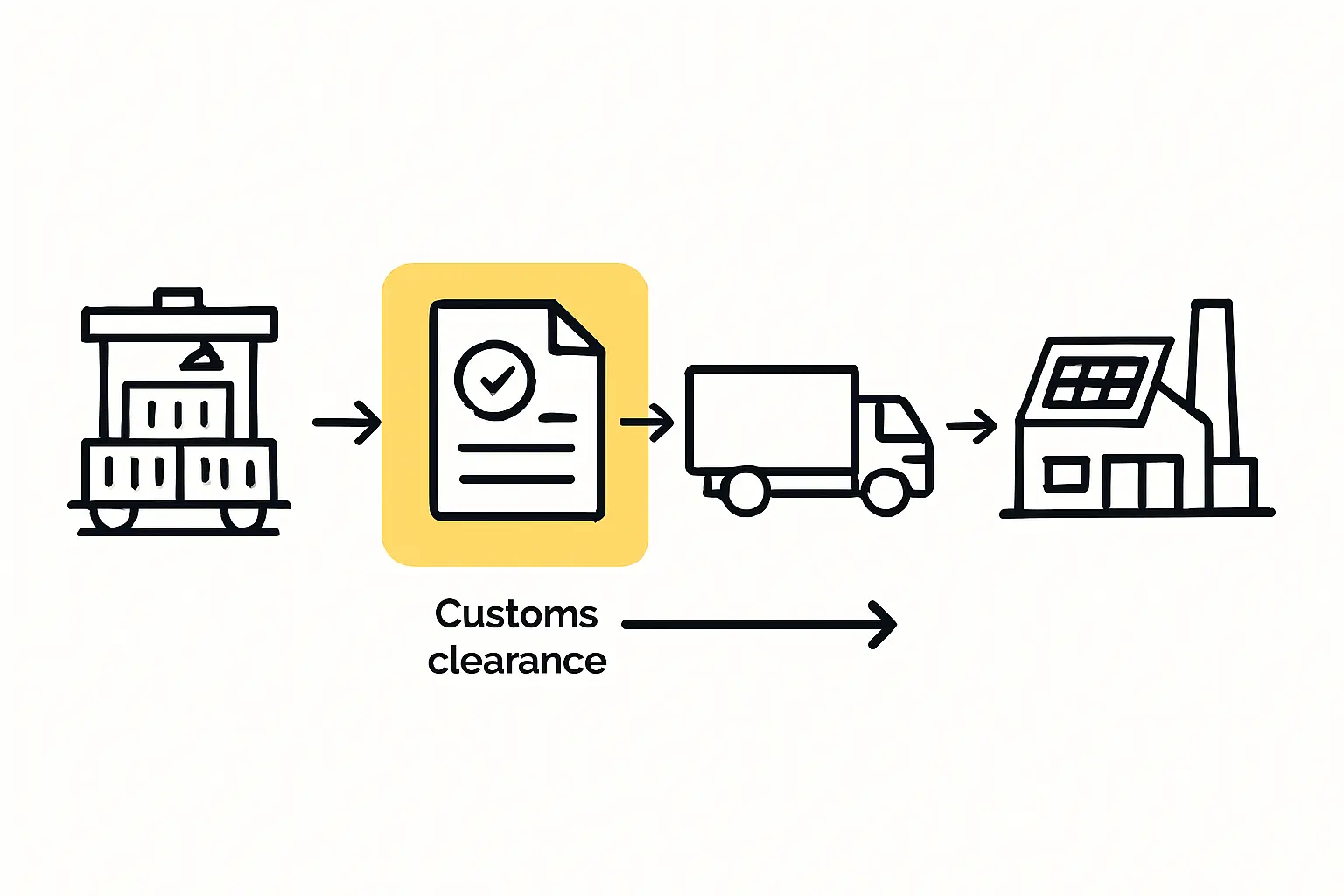

Navigating Customs for Non-EU Components

The efficiency of the EU Single Market applies after goods have officially entered the union. For components sourced from outside the EU, such as solar cells from China or junction boxes from Taiwan, a formal customs clearance process is required.

This process takes place at the first point of entry—for example, the Port of Hamburg. Here, import declarations are filed, and any applicable duties or taxes are paid. Once cleared, the goods are in “free circulation” and can move throughout the EU without further customs hurdles.

Managing this step successfully requires meticulous documentation and coordination. Working with an experienced freight forwarder or customs broker is not just advisable—it is essential. These partners handle the complex paperwork, ensure compliance with import regulations, and coordinate with port authorities to minimize delays. Their expertise ensures that the list of solar panel manufacturing machines and raw materials arrive on schedule.

New entrepreneurs often underestimate this process, but customs delays can halt an entire production line, making the choice of a competent logistics partner a critical business decision.

Strategic Inventory Management: Balancing Costs and Resilience

A landlocked location, with its longer and more complex transit routes, directly impacts inventory strategy. While a “Just-in-Time” (JIT) approach, which minimizes warehousing costs, is attractive, it carries higher risk. A single delay at a port or a disruption in the rail network could stop production.

A factory in Central Europe usually adopts a hybrid approach:

-

Buffer Stock: Maintaining a larger inventory of critical, long-lead-time components (e.g., a two- to four-week supply of solar cells) provides a cushion against unforeseen supply chain disruptions.

-

Strategic Warehousing: The factory design must accommodate this larger inventory, meaning building plans must include adequate, climate-controlled warehouse space to safely store sensitive materials like EVA film and solar cells.

This balanced approach trades slightly higher inventory holding costs for significantly increased production resilience and reliability—a worthwhile investment for ensuring consistent output.

Frequently Asked Questions (FAQ)

What is the main advantage of the EU Single Market for logistics?

The primary advantage is the elimination of customs duties, tariffs, and administrative procedures for goods moving between EU member states. Once a container is cleared at any EU port, it can be transported to a factory in another member country without further customs inspections, drastically simplifying logistics.

How long does a typical shipment from Asia to the Czech Republic take?

A standard sea freight shipment from a major port in Asia to a port like Hamburg or Rotterdam typically takes 4 to 6 weeks. Factoring in inland transport by rail or road, the total door-to-door transit time is usually between 35 and 50 days.

Is rail or road transport better for a solar factory?

Neither is universally “better”; they serve different purposes. Rail transport is generally more cost-effective and environmentally friendly for large, regular shipments of containerized goods from the port to an inland hub. Road transport offers greater flexibility and is essential for the final delivery from the hub to the factory, as well as for urgent or less-than-container-load (LCL) shipments.

Who handles customs clearance for imported goods?

Customs clearance is a specialized legal and administrative process typically handled by a licensed customs broker or a full-service freight forwarder. These partners act on behalf of the importer to ensure all documentation is correct and that all duties and taxes are paid in compliance with EU regulations.

Conclusion: Turning Geography into a Competitive Advantage

A landlocked location is not a barrier to building a successful solar module factory. On the contrary, a central position within a large, integrated economic zone like the European Union can offer superior market access and logistical efficiency.

The key is a shift in perspective: from focusing on the distance to the sea to leveraging the dense network of road, rail, and waterway infrastructure that connects the site to multiple global gateways. By selecting the right ports, working with expert logistics partners to manage customs, and implementing a resilient inventory strategy, a manufacturer can create a supply chain that is both highly reliable and cost-effective.

Ultimately, what appears to be a geographical challenge can be transformed into a distinct competitive advantage through strategic planning and execution—a positive story for anyone following Czech solar news and industrial development.