When planning a new manufacturing facility, an entrepreneur’s focus typically falls on land acquisition, equipment procurement, and supply chains. The electrical connection is often an afterthought, treated as a standard utility request, much like setting up an office.

But for a large industrial operation in a highly regulated country like Denmark, securing a high-capacity grid connection is a major infrastructure project in its own right—a process that can take up to two years and require significant investment long before a single machine is powered on.

This guide outlines the technical and regulatory journey of connecting a new production facility to Denmark’s high-voltage grid, explaining the role of the national operator, Energinet, and providing a roadmap of the steps, costs, and potential challenges involved. Understanding this process from the start is critical for accurate project planning, budgeting, and avoiding costly delays.

Understanding the Danish Electrical Grid and Energinet’s Role

While homes and small businesses draw electricity from the local distribution grid managed by a Distribution System Operator (DSO), a manufacturing plant with significant power requirements—like a solar module factory—must connect directly to the high-voltage transmission grid. This is akin to needing access to a national motorway instead of a local street.

In Denmark, this “motorway” is managed by Energinet, the national Transmission System Operator (TSO). Energinet operates the high-voltage electricity grid at 100, 132, 150, and 400 kilovolts (kV). A direct connection at this level ensures the stability and capacity required for large-scale industrial processes.

Connecting to the backbone of the national power supply is a structured, multi-stage process that requires detailed technical planning and close coordination with Energinet from the very beginning.

The Four-Stage Process for Grid Connection

Energinet divides the journey from initial inquiry to a fully commissioned connection into four distinct stages.

Stage 1: Initial Inquiry and Scoping

The process begins as soon as a potential site for the facility is identified—long before any land is purchased. At this stage, you’ll need to contact Energinet and provide preliminary information about your planned facility, including:

- The expected maximum power consumption (in megawatts).

- The nature of your industrial load (e.g., machinery types, operating hours).

- The precise geographical location of the proposed site.

This initial contact allows Energinet to perform a preliminary assessment of grid availability in the region.

Stage 2: The Feasibility Study

If the initial assessment is positive, Energinet will propose a formal Feasibility Study. This detailed technical analysis determines the most viable way to connect your facility to the grid. The study typically:

- Identifies the optimal connection point on the high-voltage grid.

- Analyzes the impact of your facility’s load on grid stability.

- Outlines the required construction work, such as new substations or transmission lines.

- Provides a preliminary cost estimate for the connection.

This study is a paid service, with costs typically ranging from DKK 200,000 to DKK 500,000. It can take between three and six months to complete, and its findings are essential for refining your overall project budget and site plans.

Stage 3: The Connection Agreement

Once the feasibility study is complete, the next step is to enter into a formal Connection Agreement with Energinet. This legally binding document details all technical and commercial terms, including:

- Final technical specifications for the connection point.

- A definitive timeline for construction and commissioning.

- A detailed breakdown of costs and payment schedules.

- Responsibilities of both your company and Energinet during the project.

This agreement forms the contractual basis for the entire grid connection project.

Stage 4: Project Execution and Commissioning

With the agreement in place, physical construction can begin. This phase involves building the necessary infrastructure—such as a dedicated substation on your property and high-voltage cables to the connection point—while Energinet oversees corresponding work on the public grid. Once construction is complete, a rigorous testing and commissioning process ensures the connection is safe, stable, and compliant with all technical standards before it is energized.

Key Technical and Regulatory Hurdles

Securing a grid connection involves more than just physical construction; it requires navigating a complex web of technical standards and government regulations.

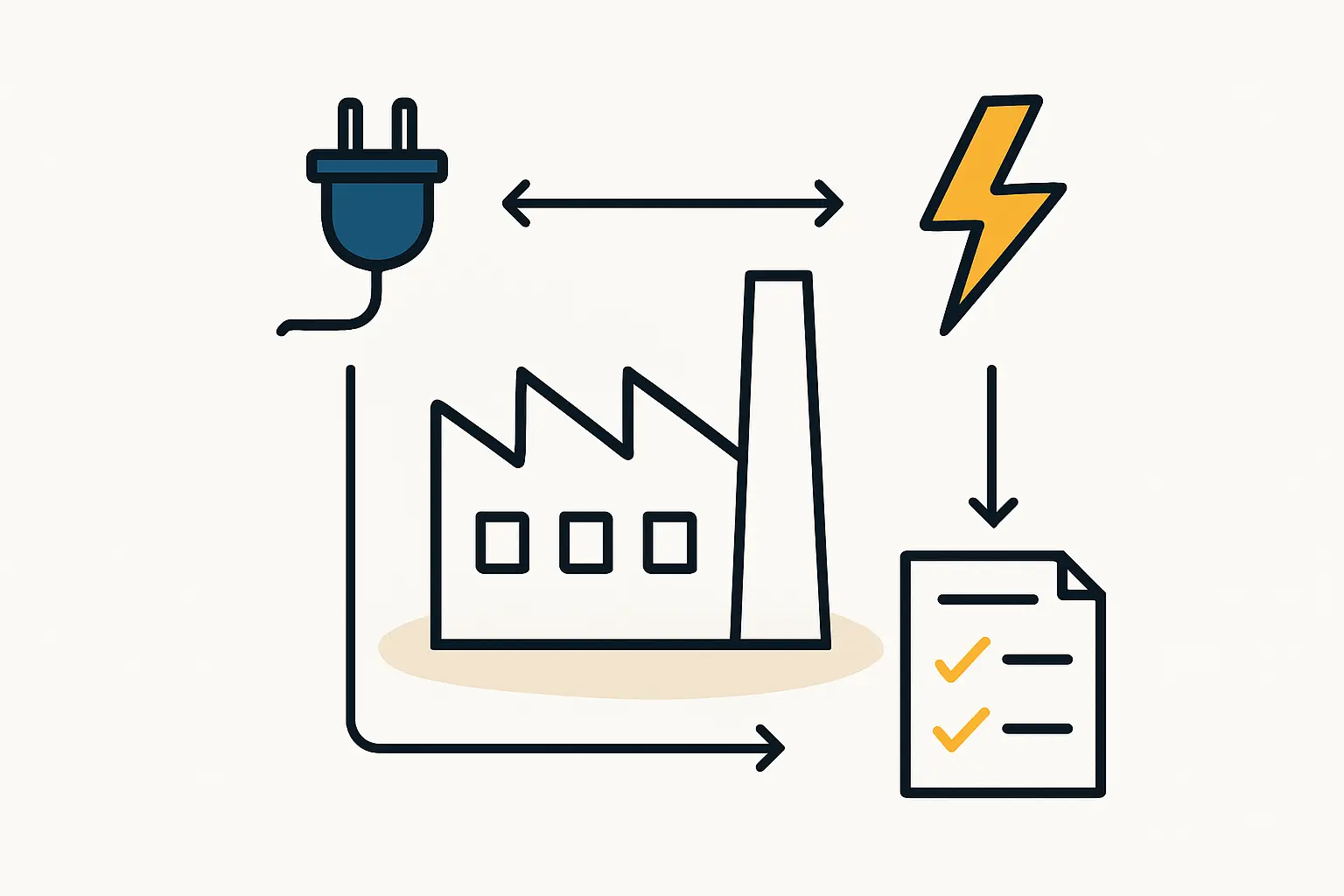

Technical Compliance: More Than Just Plugging In

A large factory introduces a powerful and potentially disruptive load to the grid, which is why Energinet enforces strict technical requirements to maintain stability for all users. Your facility’s electrical systems must be designed to control factors such as:

- Harmonic Distortion: Electrical noise created by modern industrial equipment that can interfere with the grid.

- Voltage Fluctuations: Sudden changes in power demand that can cause dips or swells in the grid voltage.

- Reactive Power: Ensuring an efficient balance of power to prevent energy losses in the transmission system.

A SCADA (Supervisory Control and Data Acquisition) system is also required. This system gives Energinet real-time visibility and control over your connection point, allowing it to manage the grid effectively.

Navigating the Regulatory Landscape

All grid connections in Denmark are governed by rules set by the Danish Energy Agency (Energistyrelsen). Because Denmark is part of the integrated European electricity market, regulations from the European Union—such as the “Requirements for Generators” (RfG) Network Code—also apply.

Compliance requires extensive documentation, technical reports, and formal applications. This process is meticulous and demands a high level of expertise in both Danish and EU energy law. Missteps can lead to significant delays.

Practical Business Considerations: Timelines and Costs

For business planners, two of the most critical considerations are the project’s timeline and cost.

The entire grid connection process, from initial inquiry to final commissioning, can take between 12 and 24 months. This timeline must be factored into your overall project plan, as the factory cannot operate without power. Delays often stem from long lead times for high-voltage equipment like transformers or from complex approval processes.

The costs are also substantial, often running into millions of Danish Kroner. The final amount depends heavily on the distance to the nearest viable connection point and the extent of new infrastructure required.

This is why choosing a location for your factory is not just a logistical decision but a critical financial one. An otherwise perfect site may be prohibitively expensive to connect. Therefore, evaluating the Denmark electrical grid access should be treated as a core infrastructure requirement right from the start.

Frequently Asked Questions (FAQ)

What is Energinet?

Energinet is Denmark’s independent public enterprise that owns, operates, and develops the national transmission systems for both electricity and gas. It is responsible for the high-voltage grid (100 kV and above).

Why can’t I just connect to the local low-voltage grid?

The local grid is not designed to handle the massive, continuous power demands of an industrial facility. Connecting a large factory to it would cause instability and outages for other users. A direct high-voltage connection is required to ensure the necessary capacity and stability without disrupting the public supply.

How early should I start the grid connection process?

You should contact Energinet for an initial inquiry as soon as you have identified one or more potential sites. This should be done before any financial commitment is made to purchasing or leasing land.

What happens if the grid has no capacity in my chosen area?

This is a real possibility in some regions, which the feasibility study will determine. If capacity is insufficient, Energinet may propose grid reinforcement work, but this would significantly increase the cost and timeline of your connection. In some cases, it may make the chosen location economically unviable.

Is this process the same for all types of factories?

While the four-stage process is standard, the technical requirements and costs will vary depending on the factory’s size, power consumption profile, and the sensitivity of its equipment. A data center, for example, has different load characteristics than a solar panel assembly plant.

Conclusion: Integrating Grid Strategy into Your Business Plan

Connecting a new production facility to the Danish national grid is a complex, time-consuming, and capital-intensive undertaking. It is a strategic project that must be integrated into your business plan from the outset, rather than treated as a final administrative step.

Success hinges on early and transparent communication with Energinet, a realistic grasp of timelines and costs, and access to specialized technical and regulatory expertise. By treating the grid connection as a primary project milestone, entrepreneurs can avoid unforeseen delays and budget overruns, paving the way for a smooth start to operations.