Denmark’s Port Infrastructure: A Strategic Advantage for Solar Component Supply Chains

When entrepreneurs enter the solar manufacturing sector, their initial focus naturally lands on production machinery and technology. But even the most efficient production line can be crippled by an often-overlooked factor: logistics. A volatile supply chain, with its unpredictable delays and costs, can erode profitability before the first solar module is sold.

Choosing a manufacturing base with world-class port infrastructure isn’t a minor detail; it’s a foundational business decision. This article examines the logistical advantages of building a solar component supply chain around Denmark’s key maritime hubs. We’ll explore how ports like Esbjerg and Aarhus offer far more than just a place to dock ships—they provide a competitive edge in stability, efficiency, and market access for the burgeoning solar industry.

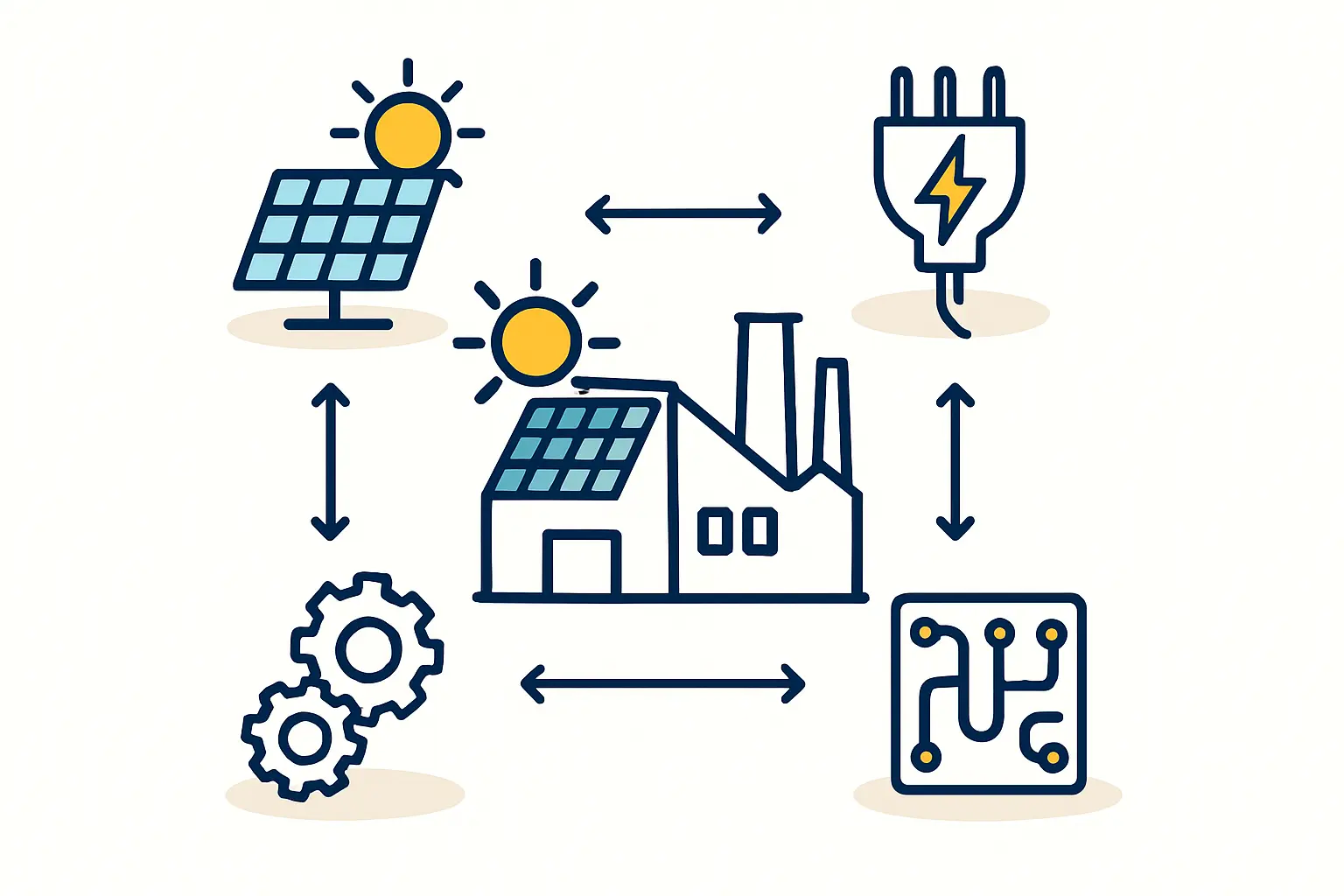

The Critical Role of Logistics in Solar Manufacturing

A solar module factory depends on a constant, two-way flow of materials. Raw materials flow in—solar glass from one continent, aluminum frames from another, and specialized films or cells from various global suppliers. Finished, fragile solar modules flow out, destined for projects across a region or the globe.

Managing this dual flow effectively is paramount. Inefficient logistics can lead to:

-

Production Halts: Delays in receiving a single critical component, such as EVA film, can bring an entire production line to a standstill.

-

Increased Costs: High port fees, demurrage charges for delayed containers, and expensive last-mile transportation inflate the final cost per module.

-

Product Damage: Poor handling infrastructure increases the risk of damage, a significant concern when dealing with large, fragile items like solar glass and finished panels.

A location with an efficient, reliable, and well-connected port system is a powerful strategic asset. It is a crucial consideration when planning a turnkey solar manufacturing line, as logistics can account for a significant portion of a module’s final price.

Why Denmark? A Gateway to European and Global Markets

Situated at the crossroads of Scandinavia and continental Europe, Denmark offers a unique geographical advantage. Its political stability and strong focus on green energy create a favorable business environment. But its primary logistical strength lies in its world-class port infrastructure.

Feasibility studies by J.v.G. Technology GmbH for European projects consistently highlight Danish ports for their efficiency and specialization. These ports are not just points of entry and exit; they are highly integrated logistical hubs that connect sea routes with extensive road and rail networks, ensuring the seamless transit of goods across the continent and beyond.

Case Study: The Port of Esbjerg – From Wind to Solar

The Port of Esbjerg is globally recognized as a leading hub for the offshore wind industry. This specialization has fostered an infrastructure and expertise directly transferable to the solar manufacturing sector.

Established Expertise in Renewable Energy Logistics

Day-to-day operations at Esbjerg involve handling enormous wind turbine components, which has cultivated a unique ecosystem of logistics providers skilled in managing large, heavy, and high-value goods. The port features:

-

Heavy-Lift Capacity: Cranes and handling equipment designed for massive loads are perfectly suited for pallets of solar glass or crates of finished modules.

-

Expansive Storage Areas: Over 2,000,000 square meters of storage and production area are available, allowing for flexible warehousing of both raw materials and finished products—a critical step in the solar panel manufacturing process.

-

Specialized Service Providers: A network of companies specializing in transport, assembly, and maintenance for the renewables sector is already in place.

This existing infrastructure means a new solar manufacturer can bypass building these capabilities from scratch, leveraging a mature, proven system to significantly reduce initial investment and operational risks.

Case Study: The Port of Aarhus – A Global Container Hub

While Esbjerg excels in specialized handling, the Port of Aarhus serves as Denmark’s largest container port and a primary gateway for global trade. For a solar manufacturer, this provides a vital connection to international suppliers and customers.

High-Volume Handling and Global Reach

The Port of Aarhus is a model of efficiency, handling over 600,000 TEUs (twenty-foot equivalent units) annually. Its key advantages include:

-

Direct Global Shipping Routes: Aarhus offers direct connections to major ports in Asia, the Americas, and Africa. This is crucial for cost-effectively sourcing the raw materials needed for solar module production from global suppliers.

-

Rapid Turnaround Times: Highly efficient, often automated, container handling systems minimize the time ships spend in port, translating directly to shorter lead times and a more predictable supply chain. Average container processing times are among the best in Northern Europe, reducing the risk of costly delays.

-

Intermodal Connectivity: The port is seamlessly integrated with Denmark’s highway and rail systems, enabling swift distribution of imported materials to a nearby factory and efficient dispatch of finished modules to European markets.

Access to a global hub like Aarhus directly impacts both supply chain reliability and market access, making it a fundamental factor when choosing the right location for your solar factory.

Integrating Port Logistics into Your Business Plan

Understanding the capabilities of Danish ports is the first step. The next is integrating this knowledge into a comprehensive business plan.

-

Supply Chain Modeling: A business plan should map the entire journey of components from supplier to factory and finished goods from factory to customer, factoring in the efficiencies offered by ports like Esbjerg or Aarhus.

-

Cost-Benefit Analysis: This analysis should weigh the potential savings from reduced shipping times, lower inventory levels, and minimized delays against other location-based factors.

-

Risk Mitigation: A stable logistical base in Denmark can serve as a powerful risk mitigation tool, especially for businesses operating or selling in regions with less predictable infrastructure. This stability is a key component when calculating the overall investment requirements for a solar factory.

Experience from J.v.G. turnkey projects shows that entrepreneurs who prioritize logistics from day one are better positioned for long-term, sustainable growth. The reliability of their operations becomes a competitive advantage in itself.

Frequently Asked Questions (FAQ)

Is Denmark only suitable for serving the European market?

No. While it offers outstanding access to the EU market via road and rail, major ports like Aarhus are global container hubs with direct shipping lines to Asia, North America, and other key international markets. This makes it a viable location for exporting finished solar modules worldwide.

What are the primary raw materials that would be imported through these ports?

A typical solar module factory would need to import materials such as solar glass, aluminum for frames, EVA (ethylene vinyl acetate) and backsheets, junction boxes, and potentially solar cells, depending on its level of vertical integration.

How does this logistical setup compare to manufacturing closer to raw material sources in Asia?

This is a classic business trade-off. While manufacturing in Asia may reduce inbound logistics costs for raw materials, a European base like Denmark offers proximity to the high-demand European market, reducing outbound logistics costs and delivery times. It also provides greater operational stability, lower political risk, and the potential advantages of “Made in Europe” branding.

Are specialized logistics providers available in these Danish ports?

Yes. The Port of Esbjerg, in particular, has a mature ecosystem of logistics companies with deep expertise in handling large and sensitive components for the renewable energy industry. This existing expertise is a significant advantage for a new solar enterprise.

Conclusion: Building a Foundation for Success

The decision of where to establish a solar manufacturing facility extends far beyond the factory walls. Choosing a logistical hub is a strategic decision that impacts cost, efficiency, and market access. Denmark’s port infrastructure, with specialized hubs like Esbjerg and global gateways like Aarhus, offers a compelling foundation for building a resilient and competitive solar component supply chain.

By placing logistics at the core of the planning process, solar manufacturers can create a stable operational base, ready to meet the growing global demand for clean energy. For those exploring this path, understanding these foundational elements is the first step toward building a successful enterprise.