Imagine a pristine, high-stakes environment like the Galápagos Islands, where the goal is to power conservation and research facilities with clean solar energy. An investment in a standard solar installation here could fail within just a few years.

The constant, corrosive salt mist carried by sea breezes can aggressively degrade solar modules not engineered for such a challenge. This scenario isn’t unique to remote islands; it’s a critical consideration for any solar project along coastlines, from Ecuador to the Middle East and beyond.

For the entrepreneur planning to enter the solar industry, understanding these environmental challenges is not just a technical detail—it’s fundamental to building a reputable brand and ensuring the long-term bankability of a product. This article breaks down the key technical modifications required to manufacture solar modules that can withstand and perform reliably in highly corrosive marine environments.

Why Standard Solar Modules Fail in Coastal Regions

The air in coastal areas contains fine droplets of saline water, known as salt mist. When this mist settles on a solar module, it creates a highly corrosive film, especially when combined with ambient humidity and UV radiation. This film accelerates the degradation of a module’s components.

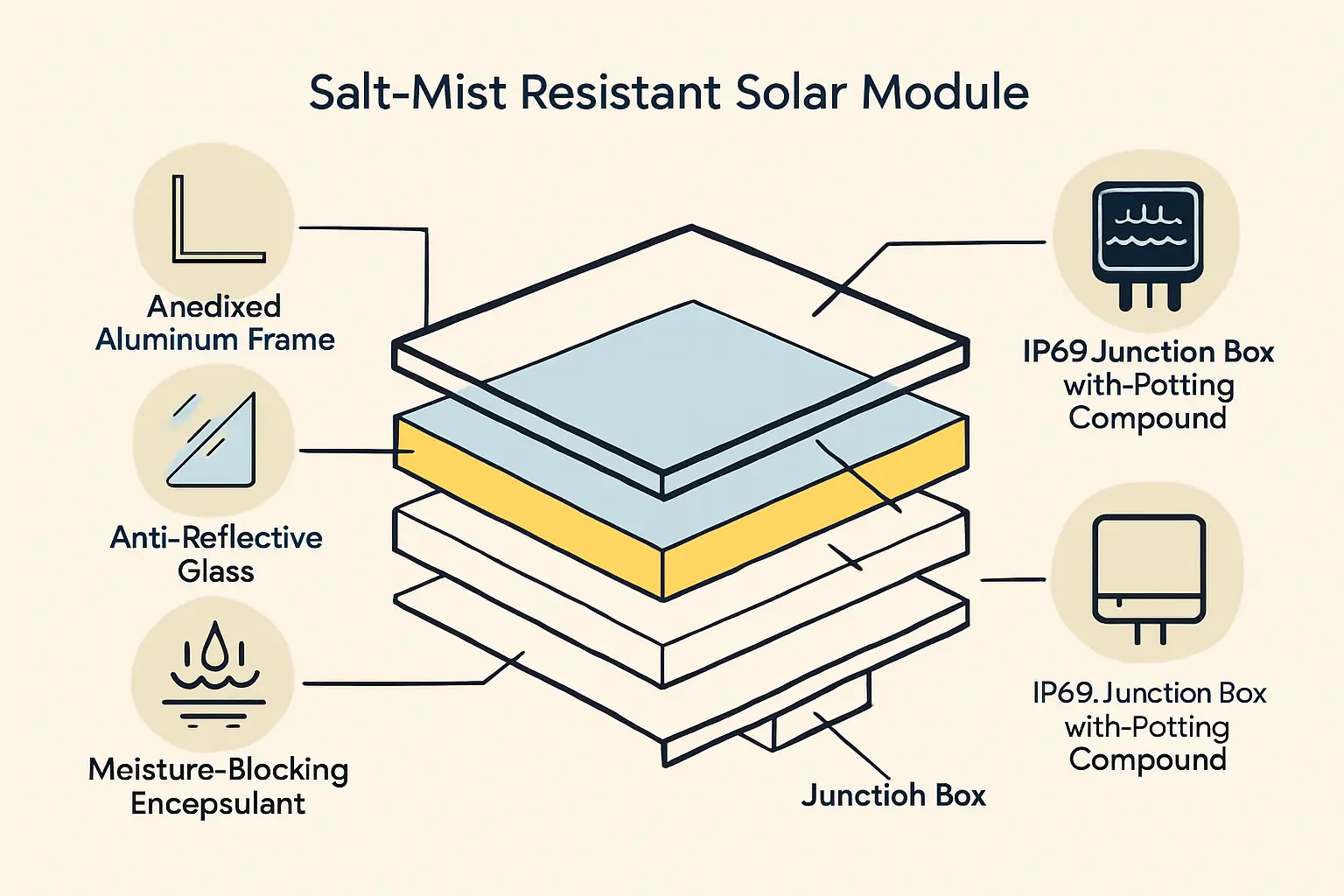

Standard aluminum frames can experience frame corrosion, oxidizing rapidly and compromising structural integrity. Moisture and sodium ions can also penetrate the module’s layers, causing component delamination where the encapsulant bonding the glass, cells, and backsheet separates. Finally, corrosion can affect electrical connections within the junction box and increase the risk of Potential-Induced Degradation (PID), a phenomenon that significantly reduces the module’s power output and leads to power degradation.

These factors can lead to premature failure, turning a promising renewable energy asset into a significant financial liability.

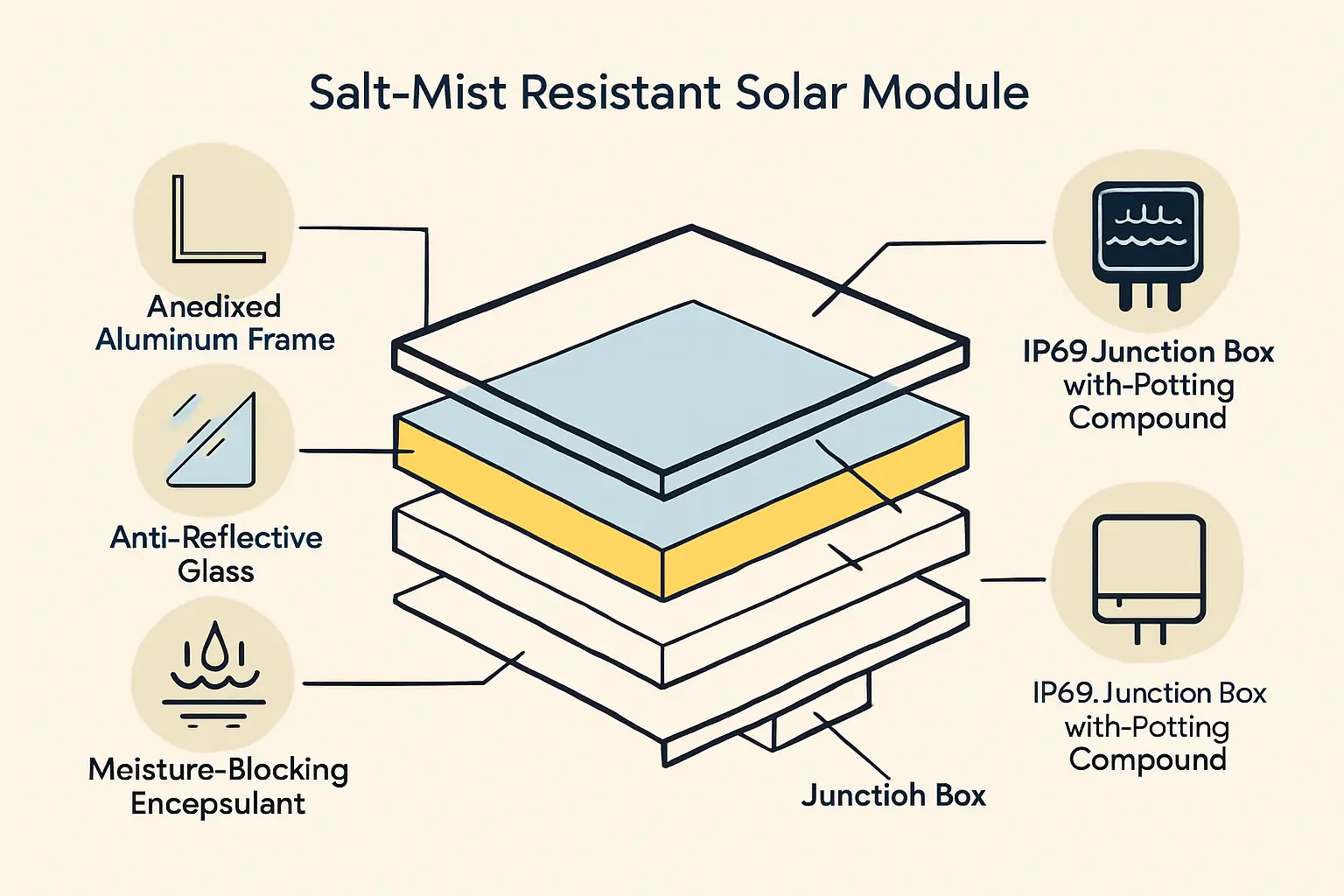

Key Modifications for Marine-Grade PV Modules

Manufacturing a salt-mist resistant module requires specific choices in materials and processes. These choices go beyond a standard solar panel manufacturing process and demand a focus on long-term durability.

The Crucial Role of Encapsulants: EVA vs. POE

The encapsulant is the adhesive material that laminates the solar cells between the front glass and the backsheet.

Ethylene Vinyl Acetate (EVA) is the industry standard due to its lower cost and established manufacturing process. However, EVA has a higher water vapor transmission rate (WVTR). In humid, saline environments, moisture can seep in, carrying corrosive ions that accelerate cell degradation and delamination.

Polyolefin Elastomer (POE) offers superior resistance to moisture ingress and is more chemically stable. It acts as a more robust barrier against salt mist and humidity, making it the preferred choice for marine applications. While historically more expensive, the falling costs of POE make it an increasingly viable option for producing high-reliability modules. The choice between EVA and POE is a critical decision point when specifying solar panel manufacturing equipment.

Fortifying the Frame: Anodization and Material Choice

The module’s frame provides its structural strength, but in a marine environment, it’s also the component most visibly susceptible to corrosion.

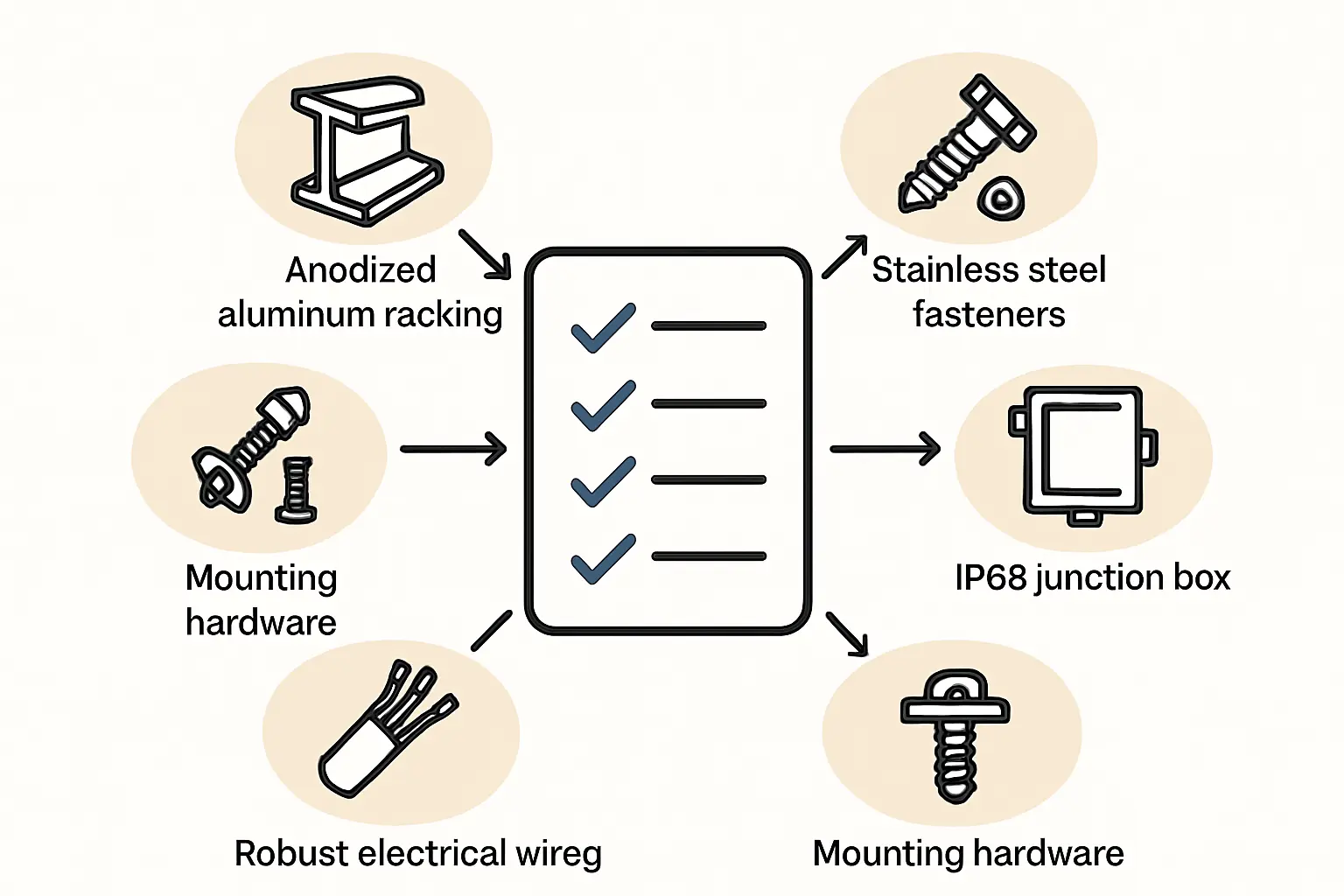

A standard aluminum frame will quickly show pitting and chalky white oxidation, so the alloy must be protected. The most effective method is anodization, an electrochemical process that creates a thick, durable, and non-reactive layer of aluminum oxide on the frame’s surface. A typical specification for marine-grade modules calls for an anodization layer of at least 15 micrometers (μm). In addition, fasteners like screws and clamps should be made from stainless steel (grade 304 or, for extreme conditions, 316) to prevent galvanic corrosion where different metals meet.

Selecting the Right Backsheet for Maximum Protection

The backsheet is the module’s rearmost layer, acting as an environmental shield. Standard backsheets may not provide sufficient protection against the high humidity and corrosive agents found in coastal areas. For these applications, multi-layer backsheets with a core of PET (polyethylene terephthalate) and an outer layer of PVF (polyvinyl fluoride) or similar highly resistant fluoropolymers are recommended. These materials offer low water vapor permeability and high resistance to UV degradation and salt spray.

Sealing the Junction Box: The First Line of Defense

The junction box, which houses the module’s electrical connections and bypass diodes, is another critical point of failure. Effective sealing is paramount. High-quality junction boxes for marine environments should have an IP67 or IP68 rating, indicating they are fully protected against dust and water ingress. This is achieved with durable silicone sealants and properly designed cable glands that prevent moisture from wicking along the cables into the enclosure. Neglecting this detail can lead to short circuits and complete module failure.

The Business Case: Balancing Cost and Long-Term Performance

From a business perspective, manufacturing salt-mist resistant modules involves a trade-off between cost and long-term performance. Using premium materials like POE encapsulants, thicker anodized frames, and high-performance backsheets increases the per-module production cost.

However, this higher initial investment creates significant long-term value. In coastal regions, developers and financiers prioritize reliability and a predictable return on investment. A module certified for salt-mist resistance can command a premium price and is more likely to be specified for large-scale projects. Building a reputation for producing durable, marine-grade modules can become a powerful market differentiator, particularly for a new entrant looking to establish credibility. Understanding these market dynamics is a crucial element of learning how to start a solar panel business.

A Note on Certification: The IEC 61701 Standard

To formally validate a module’s resistance to salt mist, manufacturers can seek certification under the IEC 61701 standard. This involves subjecting the modules to a rigorous test where they are sprayed with a salt solution in a controlled chamber for an extended period. Test severity levels vary, with Severity Level 6 being one of the most stringent and suitable for extreme marine environments.

Achieving this certification provides independent, third-party proof of product quality. It’s often a prerequisite for bidding on government tenders or securing financing for projects in coastal zones. The layout of testing and quality assurance stations within the solar panel factory layout must accommodate such rigorous quality checks.

Frequently Asked Questions (FAQ)

Can a standard module be treated or coated for salt resistance?

Post-manufacturing coatings are generally not a reliable long-term solution. True salt-mist resistance is engineered into the module from the ground up through the careful selection of core materials like the encapsulant, backsheet, and frame.

How much more does a salt-mist resistant module typically cost to produce?

The cost premium can vary, but it generally ranges from 5% to 15% depending on the specific materials chosen and the scale of production. This additional cost is almost always justified by the extended lifespan and reduced warranty claims for modules deployed in coastal areas.

Is salt-mist resistance only relevant for locations directly on the ocean?

The impact of salt mist can extend several kilometers inland, depending on prevailing winds and weather patterns. Projects located even 5-10 km from the coast can benefit from modules with enhanced salt-mist resistance.

Next Steps in Your Manufacturing Journey

Understanding the technical requirements for specialized modules, such as those resistant to salt mist, demonstrates a deep commitment to quality and market awareness. It signals to potential customers that you are not simply assembling components, but are engineering a reliable, long-term energy solution.

For entrepreneurs and business leaders exploring this industry, mastering these nuances is what separates a commodity producer from a high-value, specialized manufacturer. The ability to produce modules for challenging environments like the Galápagos opens up premium markets and builds a foundation of technical trust that is invaluable in the renewable energy sector.