An entrepreneur with a successful banana exportation business in Ecuador’s El Oro province faces a growing challenge. While global demand for his product remains strong, his operational costs are rising uncontrollably, driven primarily by the increasing price of diesel for essential irrigation pumps.

As government subsidies are phased out, what was once a predictable expense now threatens his profitability. This scenario is unfolding across Ecuador’s vital agricultural sector, creating a substantial, underserved market for a specific solution: locally produced, application-focused solar modules.

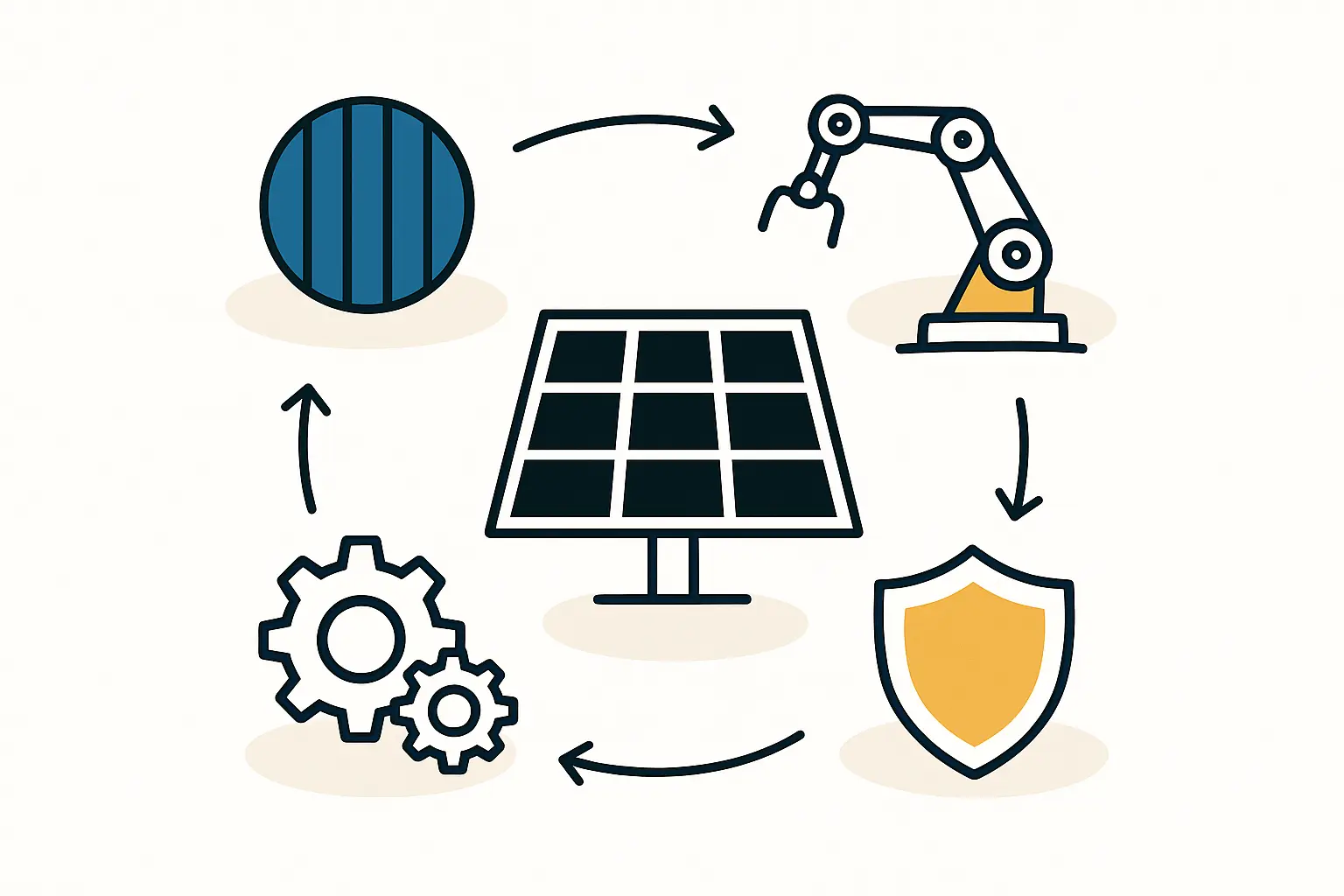

This analysis explores the opportunity to manufacture these modules, examining the market drivers, technical requirements, and the business case for establishing local production.

The Convergence of Need and Opportunity in Ecuadorian Agriculture

Ecuador’s economy is deeply rooted in its agricultural output, which accounts for nearly 10% of the nation’s GDP. Key exports like bananas, flowers, shrimp, and cocoa are not just commodities; they are the lifeblood of rural economies. However, this sector’s productivity depends heavily on consistent energy for irrigation, processing, and refrigeration—a dependence that has become a critical vulnerability.

Two major factors are driving the urgent need for an alternative energy source:

-

Rising Fuel Costs: The gradual removal of long-standing diesel subsidies is causing a sharp increase in energy expenses, making reliance on diesel generators for irrigation economically unsustainable.

-

Grid Instability: Many of Ecuador’s most productive agricultural zones are in rural areas with unreliable grid infrastructure, where frequent power outages can disrupt irrigation schedules and threaten crop yields.

This convergence of need creates a powerful opportunity. Ecuador is blessed with excellent solar potential, receiving an average of 4.5 to 5.5 kWh/m² of solar irradiation daily. Harnessing this abundant resource offers a direct solution to the energy challenges facing its most important industry—a solution that gives a local entrepreneur the chance to build a business serving a clear and pressing market need.

Technical Requirements for Agricultural Solar Modules

Serving the agricultural market is not as simple as importing standard residential solar panels. The operational environment and specific applications demand modules with distinct technical characteristics. A successful local manufacturer would focus on producing panels designed for performance and longevity in these conditions.

Designing for Off-Grid Resilience

The primary application in rural agriculture is powering water pumps. These systems are often off-grid or hybrid, requiring modules that integrate seamlessly with controllers, batteries, and the pumps themselves.

Reliability is key. A solar array for irrigation cannot fail, as even a short interruption in water supply can have severe consequences for high-value crops like flowers or cacao. The entire system, starting with the module, must be engineered for autonomous and consistent operation.

Durability in Demanding Climates

Ecuador’s diverse geography presents unique environmental challenges. A solar module on a coastal shrimp farm will be exposed to high humidity and salt mist, while one on a flower plantation in the Andean highlands will face significant daily temperature fluctuations and intense UV radiation.

Manufacturing must therefore prioritize durability, using materials like:

- Robust Framing: To withstand high winds and mechanical stress.

- High-Quality Encapsulants (EVA): To prevent moisture ingress, which can lead to delamination and corrosion.

- Resilient Backsheets: To protect cells from humidity and environmental degradation over a 25-year lifespan.

Experience from J.v.G. turnkey projects in similar climates confirms that module durability is non-negotiable for earning the trust of the agricultural community.

Performance Optimization

Consistent energy output is crucial. Modules must be optimized for the specific needs of water pumping, which often requires a high starting current. Performance in low-light conditions is also important for regions with frequent cloud cover, ensuring the system can operate reliably throughout the day.

Analyzing the Business Case for Local Manufacturing

The opportunity extends beyond simply meeting a need; it presents a compelling business case. The potential market for distributed solar in Ecuador’s agricultural sector is estimated to be over 500 MW within the next seven years.

The economic argument for the end-user is powerful. The Levelized Cost of Energy (LCOE) from a solar installation is between $0.05 and $0.07 per kWh. This is a dramatic saving compared to the post-subsidy cost of diesel-generated power, which can range from $0.20 to $0.30 per kWh.

Establishing a local solar module manufacturing plant offers distinct advantages over relying on imports:

- Customization: Products can be designed specifically for the local climate and applications.

- Supply Chain Control: Reduces dependence on international shipping and avoids potential import tariffs.

- Economic Development: Creates skilled jobs and supports the national goal of energy independence.

- Service and Trust: A local presence allows for better customer support and builds trust with farmers who value long-term reliability.

An entrepreneur considering this venture would need to evaluate the required investment for a 20-50 MW factory and understand the components of a turnkey production line. With the right planning, a local facility can be highly competitive.

Frequently Asked Questions (FAQ)

What is the typical initial investment for a small-scale solar factory?

The initial capital required depends on the level of automation and production capacity. A semi-automated line with a capacity of 20-50 MW, suitable for serving a niche market like this, requires a different level of investment than a gigawatt-scale factory.

How can a local manufacturer compete with mass-produced Asian imports?

Competition is not solely on price per watt. A local manufacturer competes by offering a specialized, higher-quality product designed for local conditions, superior customer service, and faster availability, while also eliminating international shipping costs and import duties. The value proposition is focused on long-term reliability for a critical business application.

What core skills are needed to operate a module production facility?

A factory requires a mix of technically skilled line operators, quality control engineers, and a management team with experience in manufacturing processes. pvknowhow.com provides structured e-courses to help new entrants understand the operational requirements.

Are government incentives a reliable factor in the business model?

While government support, such as net-metering policies, can be beneficial, the core business case in Ecuador’s agricultural sector is driven by the fundamental economic advantage of solar over unsubsidized diesel. This makes the business model resilient and less dependent on shifting political policies.

The Path Forward: From Analysis to Action

The conditions in Ecuador’s agricultural sector present a clear and compelling opportunity for entrepreneurs to enter the solar manufacturing space. A pressing economic need, driven by rising fuel costs, has converged with a viable, cost-effective technological solution.

For business professionals investigating this market, the next step involves detailed strategic planning. Developing a comprehensive business plan for solar manufacturing is essential to understanding project costs, operational logistics, and the route to market. By focusing on a specific, underserved niche and producing a high-quality, application-specific product, a local solar module factory can become a profitable enterprise and a key partner in the sustainable growth of Ecuador’s most important industry.