Disclaimer: This case study represents a composite example derived from real-world

consulting work by J.v.G. Technology GmbH in solar module production and factory optimization. All data points are realistic but simplified for clarity and educational purposes.

Imagine securing a promising government tender for a large-scale solar project in Egypt. The financing is in place and the market opportunity is clear. However, a critical clause in the contract stipulates a ‘40% local content requirement,’ a mandate that can quickly become a significant hurdle for new investors.

This is a common scenario for many entrepreneurs entering Egypt’s booming solar sector. What appears to be a simple administrative detail is, in fact, a central pillar of the nation’s industrial strategy.

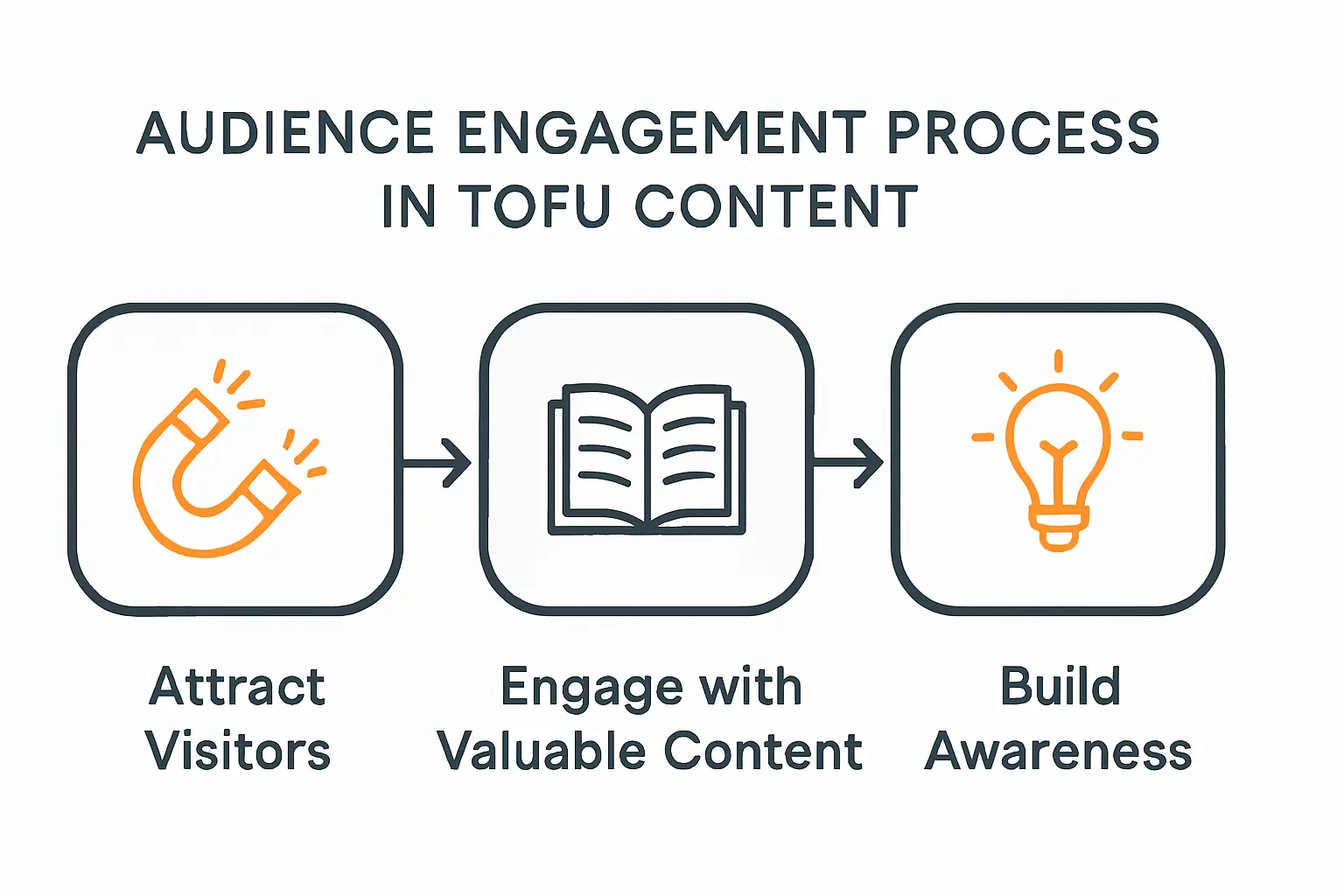

This guide unpacks Egypt’s local content policies for solar manufacturing, exploring the strategic benefits of compliance, providing a practical framework for meeting these requirements, and addressing the common challenges faced by foreign investors. Understanding these regulations isn’t merely about compliance—it’s about unlocking preferential market access and positioning your business for long-term success.

Understanding Egypt’s ‘Local Content’ Mandate

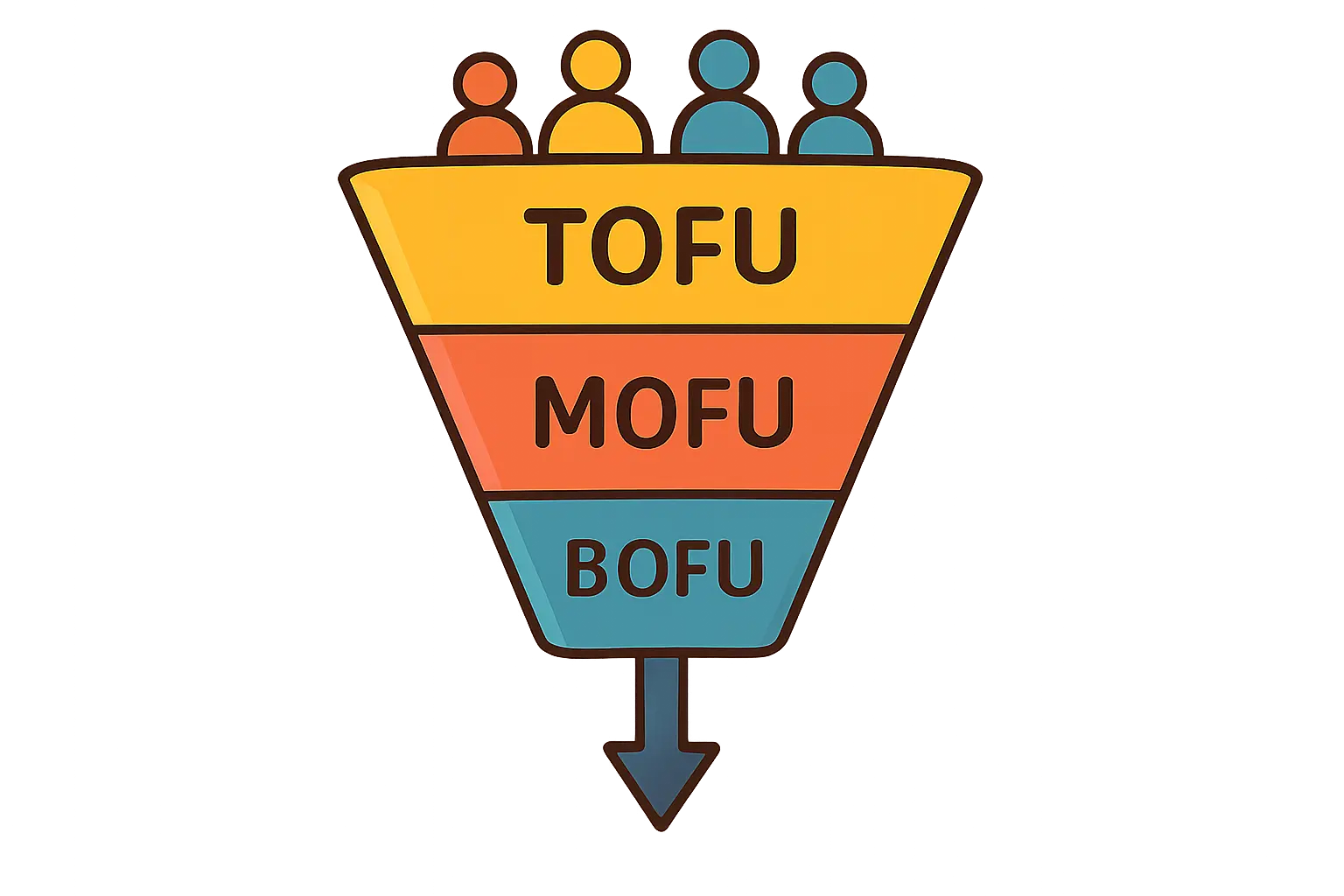

In simple terms, local content requirements are policies implemented by governments to encourage domestic industry. They mandate that a certain percentage of the value of goods or services in a given project must be sourced from within the country.

For Egypt’s solar industry, the government has set this requirement at approximately 40-42% for projects seeking specific incentives or participating in government-led initiatives. The primary objective is to move beyond simply installing imported solar panels and cultivate a robust domestic manufacturing ecosystem. This strategy is driven by several national goals:

- Economic Diversification: Reducing reliance on imported energy technology and building a self-sufficient industrial base.

- Job Creation: Fostering skilled employment in manufacturing, engineering, and logistics.

- Technology Transfer: Encouraging international companies to share expertise and build local technical capacity.

These policies are integral to Egypt’s long-term vision, including its Integrated Sustainable Energy Strategy (ISES) to 2035 and the National Climate Change Strategy 2050, which aim to significantly increase the share of renewable energy in the nation’s power mix.

The Strategic Advantage: Why Compliance Unlocks Growth

Meeting local content requirements is less a burden and more a strategic advantage that unlocks significant commercial benefits. Companies that successfully integrate local sourcing into their operations gain access to a range of powerful incentives.

- Preferential Treatment in Government Tenders: Certified companies often receive a price preference of up to 15% in government procurement bids. This means their bid can be considered competitive even if it is up to 15% higher than that of a non-compliant competitor.

- Access to Financial Incentives: Compliance is often a prerequisite for investment credits, tax breaks, and other financial support mechanisms offered by the Egyptian government to promote industrial development.

- Eligibility for Key Energy Programs: Participation in national renewable energy schemes, such as the feed-in tariff (FiT) or net metering programs, is often tied to meeting local content thresholds.

- Enhanced Market Credibility: A certificate of compliance from the Industrial Development Authority (IDA) signals a company’s commitment to the local economy, building trust with government partners, financial institutions, and customers.

A Practical Framework for Achieving Compliance

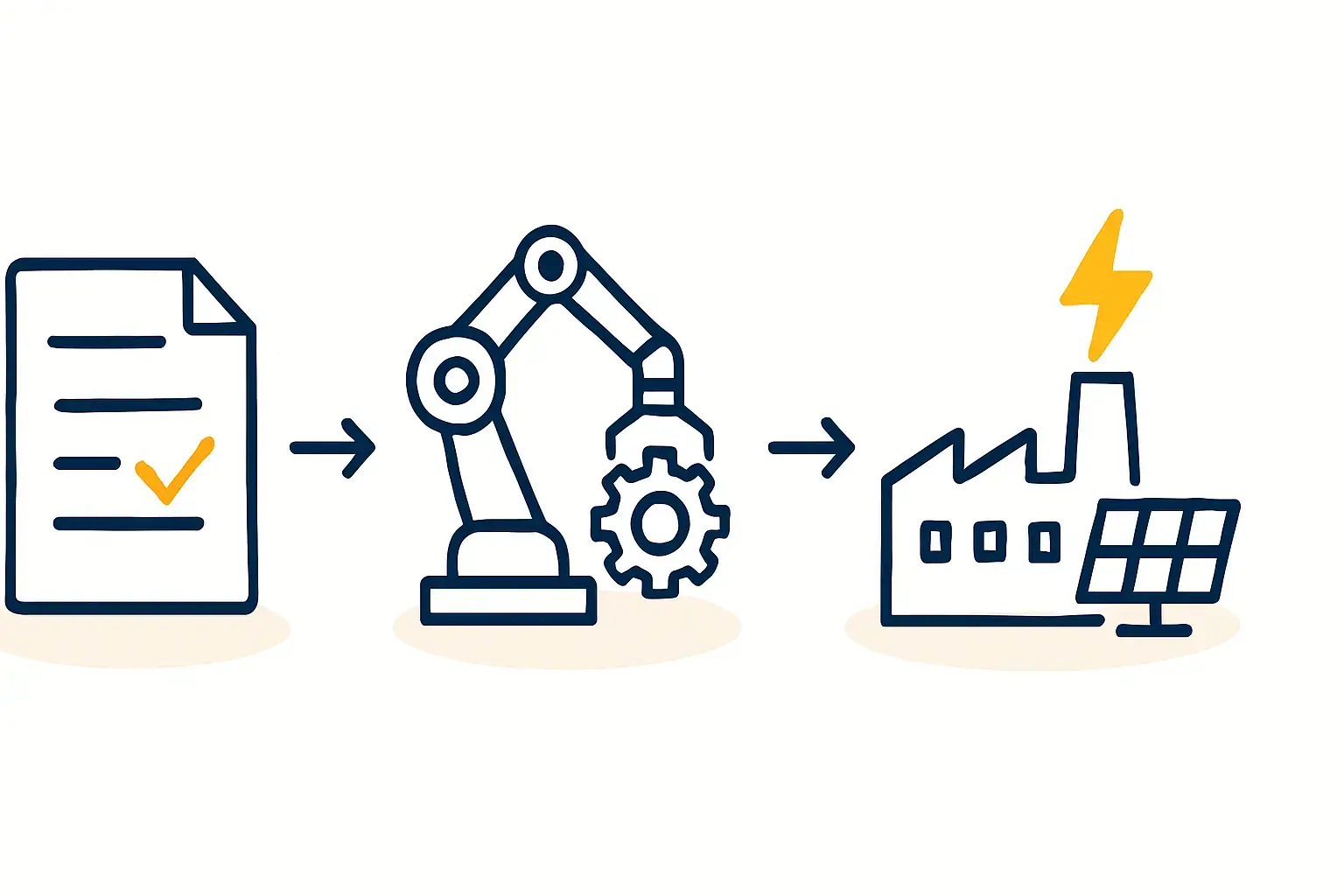

Achieving the 40% local content threshold requires careful strategic planning. It’s not simply about finding a few local suppliers; it requires a methodical approach to sourcing and production. A comprehensive solar panel manufacturing business plan should incorporate these steps from the outset.

Step 1: Deconstructing the 40% Requirement

The first step is understanding how the percentage is calculated. The Industrial Development Authority (IDA) is the body responsible for assessing and certifying local content. The calculation is typically based on the cost of production, comparing the value of locally sourced components and labor against the total ex-factory cost of the finished solar module.

This involves breaking down the bill of materials (BOM) and production costs to identify which elements can be localized.

Step 2: Building a Local Sourcing Strategy

While core components like high-efficiency solar cells are often imported, many other materials can be sourced from within Egypt. A successful strategy balances quality, cost, and availability.

- Feasible Local Components: Items such as aluminum frames, junction boxes, cables, and packaging materials are often available from Egyptian suppliers. Some projects have also found success sourcing solar glass and steel for mounting structures domestically.

- Imported Core Technology: Specialized solar manufacturing equipment and critical raw materials like photovoltaic cells and encapsulants (EVA/POE) are typically imported to ensure final product quality and performance.

- Supplier Vetting: Thorough due diligence on local suppliers is essential to ensure their products meet international quality standards and that they have the capacity for reliable delivery. Based on experience gained from European PV manufacturers’ turnkey projects, establishing strong supplier relationships is a critical success factor.

Step 3: Navigating Certification with the IDA

Once a local sourcing and production plan is in place, the next step is applying for certification with the IDA. This requires submitting detailed documentation, including:

- The complete bill of materials for the solar module.

- Invoices and certificates of origin for all imported components.

- Contracts and invoices from local suppliers.

- A breakdown of local labor costs and other manufacturing overheads.

The IDA will review the documentation and may conduct a factory audit to verify the claims before issuing a certificate of compliance.

Common Challenges and How to Mitigate Them

Investors new to the Egyptian market may encounter several common challenges. Proactive planning can help mitigate these risks.

-

Challenge: Inconsistent Supplier Quality. The quality of locally sourced materials can vary.

-

Mitigation: Implement a rigorous quality control process for all incoming materials. Work closely with local suppliers to establish clear technical specifications and quality standards from the beginning.

-

Challenge: Bureaucratic Delays. The certification process can sometimes be slower than anticipated.

-

Mitigation: Prepare all documentation meticulously and engage with the IDA early in the planning process. Working with a local consultant or partner who understands the administrative landscape can be highly beneficial.

-

Challenge: Integrating Local and Imported Components. Ensuring seamless integration in the production process requires technical expertise.

-

Mitigation: A well-designed production process, often established as part of a turnkey PV manufacturing line, helps ensure that all components, regardless of origin, work together to produce a high-quality final product.

Frequently Asked Questions (FAQ)

-

What exactly qualifies as ‘local content’?

Local content includes the value of raw materials and components produced in Egypt, as well as the cost of local labor, utilities, and other overheads associated with manufacturing within the country. -

Is the 40% requirement mandatory for all solar projects in Egypt?

No, it is not mandatory for all projects. It is, however, typically a requirement for participating in government tenders, receiving specific investment incentives, or qualifying for programs like the feed-in tariff. Private projects for self-consumption may not be subject to the same rules. -

Can I import all my machinery and still meet the requirement?

Yes. The local content calculation is focused on the components and labor that go into the final product—the solar module—not the capital equipment used to produce it. Since the cost of imported machinery is a capital expenditure, it is generally not part of the product’s local content calculation. -

How long does the local content certification process typically take?

The timeline can vary depending on the completeness of the application and the IDA’s current workload. It is advisable to plan for a period of several months and to begin the process well in advance of any tender deadlines. -

What is the first step I should take to ensure compliance?

The first step is to conduct a detailed feasibility study and create a business plan that incorporates a local sourcing strategy from the very beginning. This process involves identifying potential local suppliers and deconstructing your product’s cost structure to map a clear path to the 40% threshold.

Conclusion: From Compliance to Competitive Edge

For the international investor, Egypt’s local content requirements are more than a regulatory checklist; they are a clear roadmap to deeper market integration. By strategically developing local supply chains and embedding operations within the Egyptian industrial fabric, a company transitions from being a foreign entity to a valued local partner. This approach not only fulfills government mandates but also builds a resilient, competitive, and sustainable business poised for long-term growth in one of the world’s most promising solar markets.

Download: Egypt Solar Local Content Requirements Case Study [PDF]

Author: This case study was prepared by the

turnkey solar module production specialists at J.V.G. Technology GmbH

It is based on real data and consulting experience from J.v.G. projects

worldwide, including installations ranging from 20 MW to 500 MW capacity.