An entrepreneur planning to establish a solar panel factory in Egypt might look at the country’s vast deserts and ask a logical question: “With so much sun and sand, can we not produce all the necessary components right here?”

The answer is nuanced, resting on a complex trade-off between national resources, global supply chains, and economic realities. The choice between sourcing materials locally and importing them is one of the most critical strategic decisions a new manufacturer will face.

This article provides a strategic framework for evaluating this decision. It examines the key raw materials needed for solar module production and analyzes the costs, benefits, and risks of sourcing them from within Egypt versus international suppliers. Understanding this balance is essential for building a competitive and resilient manufacturing operation.

The Egyptian Solar Opportunity: A Favourable Landscape

Egypt’s strategic commitment to renewable energy creates fertile ground for new manufacturing ventures. Two key factors drive this opportunity:

- Exceptional Solar Resources: Egypt is situated in the global Sun Belt, receiving some of the highest levels of solar irradiation in the world, ranging from 2,000 to 3,000 kWh per square meter annually. This natural advantage ensures strong and consistent demand for solar installations.

- Government Vision: The Egyptian government has set an ambitious target to generate 42% of its electricity from renewable sources by 2035. This policy creates a stable, long-term domestic market for locally produced solar modules, often supported by incentives designed to encourage local industry.

However, capitalizing on this opportunity means navigating the high initial investment required for a solar panel factory and competing with established global manufacturers. A well-defined material sourcing strategy is essential for achieving profitability.

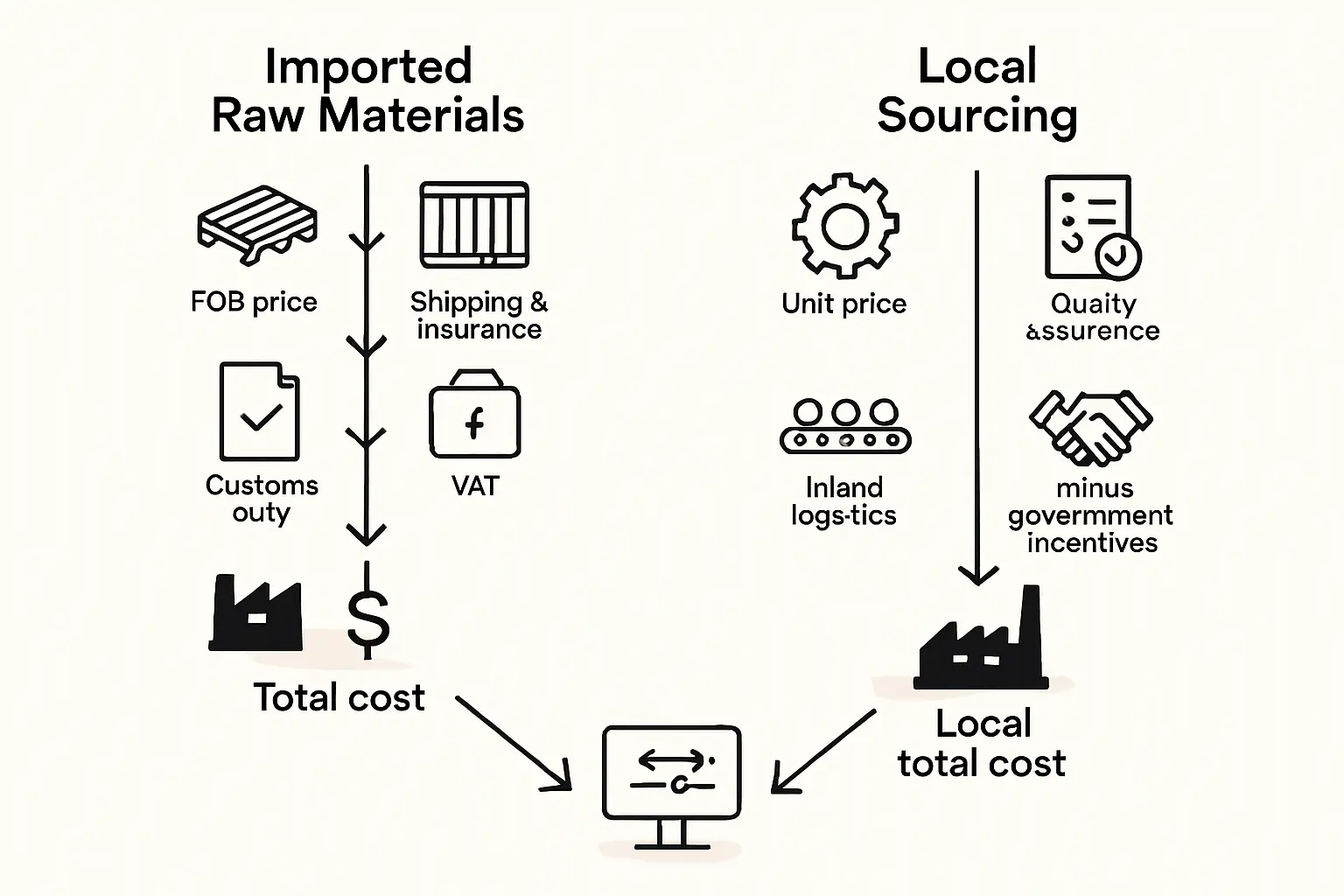

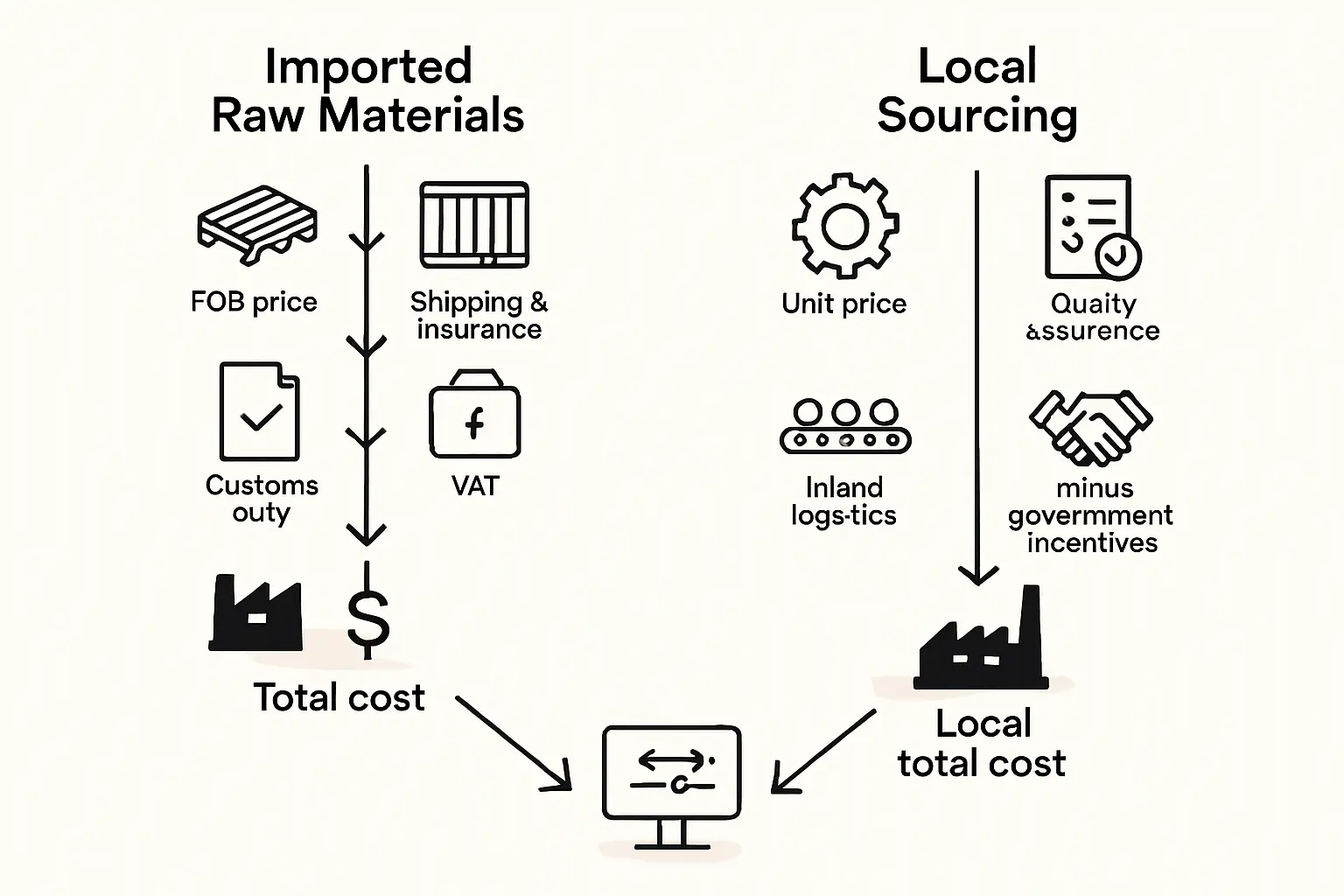

The Core Sourcing Dilemma: Local Procurement vs. Global Imports

Every solar panel manufacturer must decide on a primary sourcing route for each component. The choice is rarely absolute; most factories employ a hybrid model. The fundamental decision comes down to balancing the logistical simplicity and economic support of local sourcing against the scale and established quality of the global market.

A typical analysis weighs factors such as landed cost, quality assurance, and supply chain reliability. For an Egyptian enterprise, this requires a close look at the nation’s industrial capabilities.

Evaluating Locally Sourced Materials in Egypt

Egypt possesses a strong industrial base and rich natural resources for manufacturing certain solar panel components. The most prominent candidates for localization are solar glass and aluminum frames.

Solar Glass: Tapping into Egypt’s Silica Sand Reserves

One of Egypt’s most significant natural advantages is its abundant supply of high-purity silica sand—the primary raw material for glass. Local production of solar-grade glass offers compelling benefits:

- Reduced Logistics Costs: Solar glass is heavy and fragile, making international shipping expensive and risky. Sourcing locally drastically reduces these costs.

- Shorter Lead Times: Local supply chains can respond more quickly to production demands, reducing the need for large, capital-intensive inventories.

- Economic Contribution: Procuring glass locally supports the national economy and ancillary industries.

The primary challenge lies in quality. Solar glass requires specific properties, such as high light transmittance and low iron content, that differ from standard glass. Meeting these stringent international standards consistently depends on local suppliers having the right technology and quality control processes.

Aluminum Frames: Leveraging Existing Industrial Strength

Egypt has a well-established aluminum extrusion industry capable of producing the frames that give solar modules their structural integrity.

- Cost-Effectiveness for Bulky Components: Like glass, aluminum frames are bulky. Sourcing them locally avoids significant international freight charges.

- Customization Potential: Working with a local supplier facilitates collaboration on custom frame designs tailored to specific module requirements.

The key considerations are the quality of the aluminum alloy and the precision of the anodization process, which protects the frame from corrosion for 25 years or more. A new manufacturer must rigorously vet local suppliers to ensure their output meets the durability requirements of the solar industry.

The Case for Importing Key Components

Despite the benefits of localization, certain high-technology components are almost exclusively sourced from established international suppliers, primarily in Asia. For a new factory, attempting to produce these materials locally is often impractical and not cost-effective.

High-Efficiency Solar Cells

The solar cell is the heart of the module, converting sunlight into electricity. Its production is a highly sophisticated, capital-intensive process rooted in semiconductor technology. Global leaders have invested billions in research and development to achieve incremental efficiency gains, creating massive economies of scale that are difficult for a new entrant to challenge. Importing high-quality solar cells is therefore the standard—and most pragmatic—approach for a new assembly plant.

Specialized Polymers: EVA and Backsheets

Encapsulant (EVA) and backsheets are specialty polymer films that protect the solar cells from moisture, UV radiation, and mechanical stress, ensuring the module’s 25- to 30-year lifespan. Their production requires a specialized chemical industry and extensive R&D. Sourcing these materials from reputable global suppliers with a proven track record of durability is critical for product bankability.

Junction Boxes and Connectors

The junction box is a small but vital electronic component. It houses the bypass diodes and serves as the connection point for the module’s output cables. Like solar cells, these are specialized products where global economies of scale make importing the most logical financial choice.

A Framework for Your Sourcing Decision

A successful sourcing strategy isn’t about choosing a single path but creating the optimal blend for your specific business case. This requires a systematic evaluation based on the following criteria:

| Factor | Local Sourcing Considerations | Imported Sourcing Considerations |

|---|---|---|

| Cost | Lower transport fees; insulation from international shipping volatility; potential exposure to local inflation and currency fluctuations. | Benefit from global economies of scale; subject to shipping costs, import tariffs, and customs fees; high exposure to foreign currency risk (USD/EUR). |

| Quality | Requires rigorous supplier vetting and incoming quality control; potential need for co-development to meet solar standards. | Suppliers often have established certifications (e.g., TÜV, UL); quality is generally consistent but requires verification upon receipt. |

| Logistics | Shorter lead times and more flexible delivery schedules; vulnerable to local transport or production disruptions. | Longer lead times (4-8 weeks); risk of port congestion and customs delays; requires more sophisticated inventory management. |

| Certification | Local supplier may need assistance and time to achieve the necessary IEC certifications for solar panels, such as IEC 61215 and IEC 61730. | Established suppliers typically provide pre-certified components, simplifying the final module certification process. |

Based on experience from J.v.G. turnkey projects, a common and effective approach is to begin with a higher percentage of imported, pre-certified materials to ensure a smooth start and product bankability. In parallel, the factory can work to develop and qualify local suppliers for components like glass and frames, gradually increasing its local content over time.

Frequently Asked Questions (FAQ)

- Can a new solar factory begin operations using 100% imported materials?

Yes, this is a common strategy. It simplifies the initial setup and supplier qualification process, allowing the business to focus on mastering the solar panel manufacturing process. However, it may result in higher landed costs and longer lead times compared to a model with local components. - What is the typical cost breakdown for materials in a standard solar panel?

While prices fluctuate, solar cells typically represent the largest portion of the material cost (often 40-50%). This is followed by the aluminum frame, solar glass, backsheet, and EVA encapsulant. - Is it better to focus on local sourcing from day one?

A phased approach is often the most prudent. Starting with reliable, certified imported components ensures that your first products meet international quality standards. At the same time, you can initiate a program to audit, test, and qualify local suppliers for components like frames and glass, integrating them into your supply chain once they meet your requirements. - How much working capital is needed to source raw materials?

The capital required for inventory is a significant component of the overall business plan. Imported materials, with their long lead times, often require placing orders and making payments months in advance of production. This must be factored into financial planning from the outset.

Building a Resilient Supply Chain for Your Egyptian Solar Factory

The decision to source raw materials locally or from abroad is not a single choice but an ongoing strategic process. For an Egyptian solar module manufacturer, the optimal path is to leverage the country’s strengths in glass and aluminum while relying on the global market for high-tech components like solar cells.

By carefully analyzing the costs, quality requirements, and logistical risks associated with each component, an entrepreneur can build a resilient and cost-effective supply chain. This balanced approach positions the new venture to successfully compete in Egypt’s growing solar market and contribute to its renewable energy future.