Imagine your new, multi-million-dollar solar module production line has just been installed. The machinery, imported with great care, is ready for commissioning.

Within the first month, however, intermittent production halts and error codes plague the sensitive lamination and stringing equipment. The cause is not a machine defect but something often overlooked in the initial business plan: minor, frequent fluctuations in the local power grid. These are too small to cause a blackout but significant enough to disrupt high-precision manufacturing processes.

This scenario highlights a common challenge for entrepreneurs entering the capital-intensive world of solar manufacturing. While Egypt presents a compelling opportunity with its strategic location and growing commitment to renewable energy, a successful venture depends on a thorough assessment of its foundational infrastructure.

This guide lays out a framework for evaluating two critical pillars: the stability of the electrical supply and the efficiency of the logistics network. Far from being a secondary task, understanding these elements is fundamental to de-risking an investment and ensuring a smooth path from factory setup to market delivery.

The Critical Importance of Power Stability

A solar panel factory is not like a conventional assembly plant. The machinery involved, particularly stringers, laminators, and testers, relies on precise, uninterrupted electrical power to function correctly and safely.

Why Standard Grid Power May Not Be Sufficient

While Egypt has made substantial investments in its national electricity grid, boasting a surplus capacity that reached 25% in recent years, the challenge for industrial manufacturing lies in power quality, not just availability.

-

Voltage Fluctuations: Dips or surges in voltage can damage sensitive electronic components within the machinery, leading to costly repairs and extended downtime.

-

Frequency Variations: Deviations from the standard grid frequency (50 Hz in Egypt) can affect motor speeds and the timing of automated processes, resulting in production defects.

-

Micro-interruptions: Brief power cuts, even for a fraction of a second, can force a complete reset of a production cycle. For a process like lamination, which can take over 15 minutes, such an interruption can destroy the materials currently in the machine.

Experience from J.v.G. turnkey projects shows that an unstable power supply is a leading cause of reduced factory output (yield) and lower module quality in the first few years of operation.

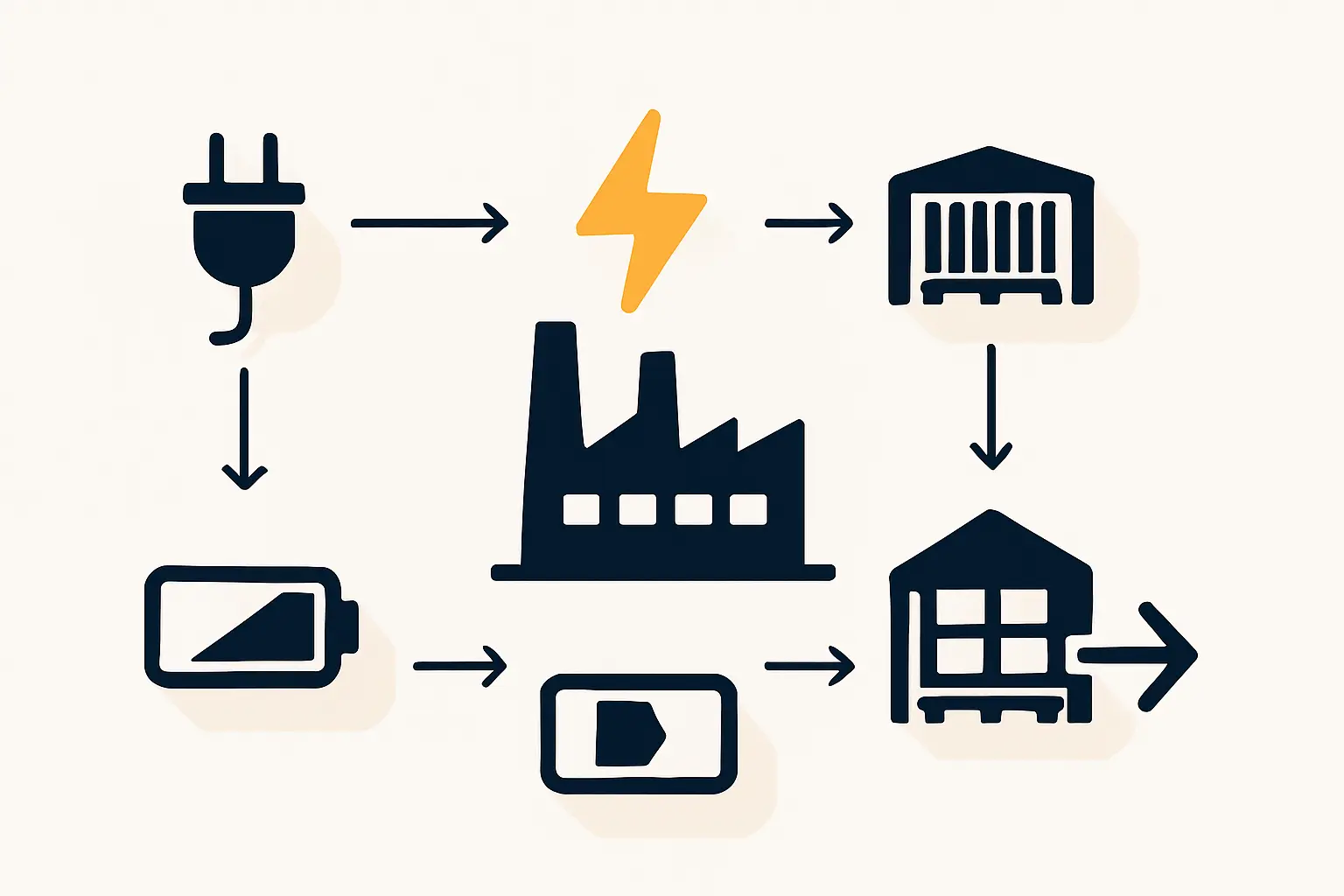

Safeguarding Your Production Line: Essential Power Solutions

To mitigate these risks, a factory’s electrical design must include protective measures. Simply connecting machines to the grid is insufficient.

-

Uninterruptible Power Supply (UPS): A UPS system provides instantaneous battery backup during micro-interruptions and filters the power to smooth out voltage and frequency variations. It is essential for protecting process-critical machinery and control systems.

-

Backup Generators: For longer outages, diesel generators are necessary to power the entire production line or, at a minimum, to enable a safe and orderly shutdown of equipment like the laminator, which must complete its cycle.

-

Voltage Stabilizers: These devices are installed at the main intake to regulate incoming voltage, providing a first line of defense against grid instability.

Planning for these systems from the outset prevents unexpected costs and operational delays after the factory is built.

Navigating the Logistics Network: From Port to Customer

The physical movement of goods, both inbound equipment and outbound finished products, is the second cornerstone of a successful operation. Egypt’s strategic location, with the Suez Canal as a global trade artery, offers significant advantages. However, success depends on understanding the entire supply chain.

Inbound Logistics: Importing Your Machinery

The journey of your production equipment from its manufacturer in Europe or Asia to your factory floor is a complex logistical operation.

-

Port Selection: Egypt’s primary ports, such as Alexandria and Port Said, are well-equipped to handle heavy and oversized cargo. The Suez Canal Economic Zone (SCZONE) offers streamlined customs procedures and incentives, making it an attractive entry point. Thoroughly analyzing port capacities, customs clearance times, and associated costs is critical.

-

Inland Transport: The ‘last mile’ from the port to the factory site often presents the greatest challenge. The assessment should include:

-

Road Quality: Are the roads suitable for heavy trucks carrying sensitive equipment?

-

Bridge Clearances: Are there any low bridges or obstacles on the route?

-

Local Expertise: Engaging an experienced local logistics partner is non-negotiable. They can navigate local regulations, manage transport permits, and ensure the safe delivery of multi-million-dollar assets.

-

The factory’s location is therefore closely tied to logistical efficiency and must account for transport infrastructure.

Outbound Logistics: Distributing Your Solar Modules

Once in production, an efficient distribution network is key to reaching customers.

-

Domestic Market: Egypt’s Vision 2030 aims for 42% of its electricity to come from renewables, creating a substantial domestic market. A factory’s location should offer efficient access to major population centers and development zones via the national road and rail network.

-

Export Markets: Egypt’s trade agreements with the EU and other African nations create significant export potential. Proximity to major ports is vital for cost-effective exporting. To access these markets, obtaining the necessary certifications for export, such as those from the IEC, is a mandatory step that influences production processes and material selection.

A logistics strategy that considers both inbound and outbound requirements builds a more resilient and profitable business model.

Frequently Asked Questions (FAQ)

How much power does a typical 50 MW solar production line require?

A semi-automated 50 MW line typically requires a continuous power supply of around 300-400 kW. However, the peak load when machines start up simultaneously can be significantly higher. A detailed power audit with your equipment supplier is essential.

Can a factory run entirely on generators to avoid grid issues?

While technically possible, it is not economically viable or reliable for continuous operation. The cost of diesel and generator maintenance is substantially higher than grid electricity. The recommended approach is to use the grid as the primary source and have generators for emergency backup only.

What are the most common customs clearance challenges in Egypt?

Common challenges include complex documentation requirements, potential delays in inspection, and ensuring all imported goods comply with local standards. Working with an experienced local customs broker who understands the specific requirements for industrial machinery is crucial to avoid costly delays at the port.

How long does it typically take to import and install production machinery?

From the time equipment leaves the manufacturer, shipping can take 4-6 weeks. Port clearance and inland transport can add another 2-4 weeks, depending on preparedness. The installation and commissioning phase, managed by specialists, typically takes an additional 4-8 weeks.

Conclusion: Building on a Solid Foundation

Establishing a solar panel factory in Egypt is an enterprise with immense potential. Realizing that potential, however, depends on building the project on a solid infrastructural foundation.

A proactive and detailed assessment of power stability and logistics is more than a formality—it is a critical investment in risk management. Addressing these factors during the planning phase helps an entrepreneur avoid the common pitfalls that lead to budget overruns, production delays, and quality compromises. Such diligent preparation is a crucial step toward building a successful solar manufacturing venture.