A solar module factory might seem immune to energy supply challenges by its very nature. The reality is that securing a stable, high-capacity industrial electricity connection is one of the most critical and often underestimated steps in establishing a successful manufacturing operation.

Before the first solar panel can be produced, the factory’s sophisticated machinery needs a significant and reliable power source from the local grid. For entrepreneurs and investors considering El Salvador, understanding the local energy landscape isn’t just a technical detail—it’s a fundamental component of strategic business planning. This guide breaks down the process, costs, and reliability of industrial electricity in El Salvador, providing a clear framework for navigating this essential requirement.

Understanding the Energy Landscape in El Salvador

El Salvador’s energy sector presents a distinct mix of challenges and opportunities for industrial users. While the government is actively promoting the integration of renewables, the country has historically relied on imported thermal fuels, which contributes to some of the higher electricity costs in Latin America.

Key market characteristics include:

-

Regulatory Oversight: The energy sector is regulated by the General Superintendence of Electricity and Telecommunications (SIGET), which oversees market operations and tariff structures.

-

Grid Infrastructure: The national transmission grid is managed by ETESAL (Empresa Transmisora de El Salvador), which handles high-voltage power lines. Distribution to end-users is managed by several companies, with AES and Delsur being the most prominent.

-

Energy Sourcing: While traditionally dependent on oil imports, El Salvador is increasingly leveraging its geothermal, hydroelectric, and solar resources. It is also part of the Central American Electrical Interconnection System (SIEPAC), which offers additional stability and supply options.

Crucially for large-scale investors, regulations in El Salvador may permit large industrial consumers to contract directly with power generation companies. This offers a strategic path to securing more predictable pricing and supply terms, bypassing standard utility tariffs.

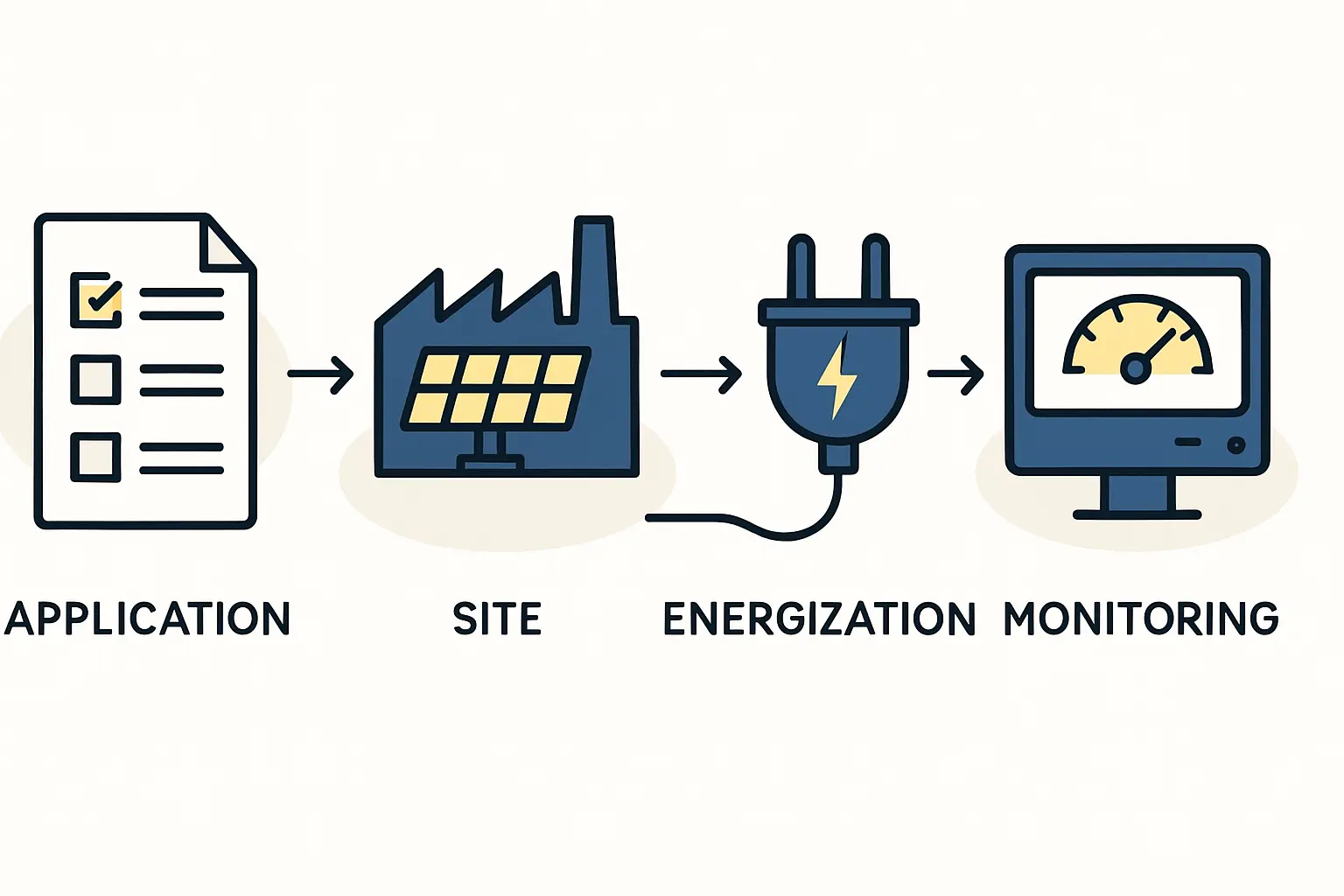

The Process of Obtaining an Industrial Electricity Connection

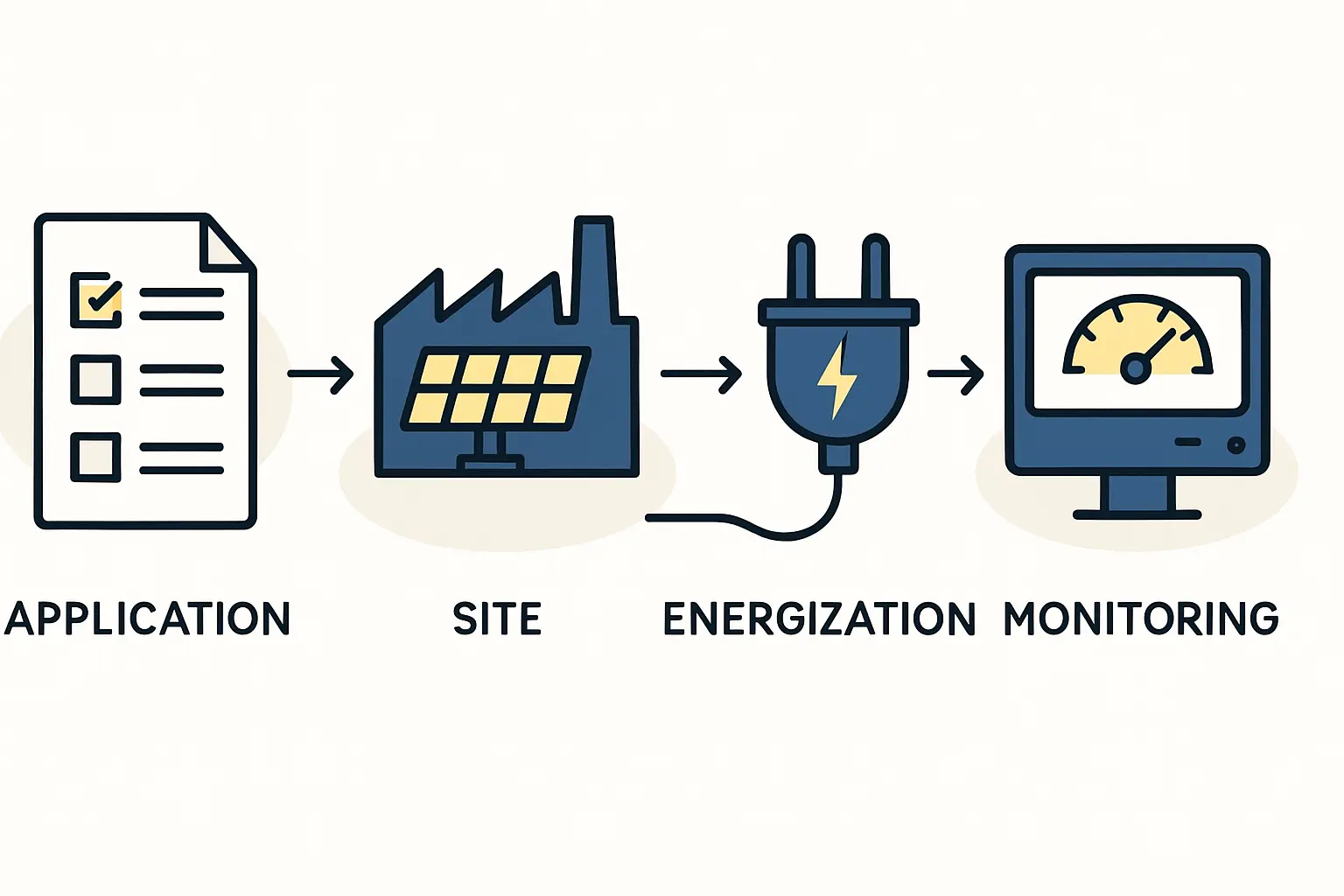

Establishing a connection for a new factory is a structured process requiring careful coordination with local authorities and utility companies. According to World Bank data, the process in El Salvador typically involves four main procedures and takes an average of 59 days to complete.

While this timeline might seem straightforward, experience from J.v.G. turnkey projects shows it is prudent to budget additional time for unforeseen delays, particularly those related to land rights, permits, and site-specific technical assessments.

The typical steps include:

-

Application and Technical Review: The investor submits an application to the local distribution company with detailed plans of the factory’s expected load and technical requirements. The utility then conducts a study to determine the feasibility and design of the connection.

-

External Inspection and Permitting: An external electrical engineer is often required to inspect and approve the facility’s internal wiring plans to ensure compliance with national safety and technical standards.

-

Connection Works: The utility company carries out the external connection, which may involve installing new transformers, laying cables, or extending power lines to the factory site. The scope of this work heavily influences the final cost and timeline.

-

Meter Installation and Final Activation: Once all work is complete and inspections are passed, the meter is installed and the power supply is formally activated.

Analyzing the True Cost of Electricity for Your Factory

Electricity is a significant recurring cost for a solar module factory, so a clear understanding of these operational expenditures is vital. The baseline price for industrial electricity in El Salvador is approximately USD 0.177 per kWh.

This figure, however, is only part of the total cost. A comprehensive financial model must also account for:

-

Connection Costs: The one-time cost to establish the connection can be substantial. World Bank analysis suggests this figure can exceed 700% of the country’s income per capita. This fee covers the infrastructure work carried out by the utility.

-

Demand Charges: Many industrial tariffs include charges based on peak power demand (measured in kVA or kW), regardless of total consumption. These charges are designed to cover the utility’s investment in capacity.

-

Other Fees: Additional taxes, administrative fees, and public lighting charges may also appear on monthly invoices.

For context, a medium-sized solar factory with a 50 MW annual capacity could have a power demand of 700 kVA or more. Calculating the projected monthly energy bill is a critical part of developing a business plan for a solar factory.

Grid Reliability: The Hidden Risk to Production

Beyond cost and connectivity, grid reliability is arguably the most important energy factor for a high-tech manufacturing facility. Production machinery like cell stringers and laminators operates on precise cycles and is highly sensitive to power fluctuations.

Data on El Salvador’s grid performance reveals a notable risk. The average electricity customer experiences approximately 13.7 interruptions per year, with a cumulative downtime of 18.2 hours.

What does this mean in a manufacturing context?

-

Production Stoppages: Every outage, even a brief one, can halt the entire production line.

-

Material Waste: An interruption during a lamination or curing cycle can render a batch of modules unusable, leading to significant financial losses.

-

Equipment Damage: Sudden power surges or drops can damage sensitive electronic components in machinery, resulting in costly repairs and extended downtime.

An investment plan must therefore include mitigation strategies. This often involves integrating voltage stabilizers and uninterruptible power supplies (UPS) for critical control systems, as well as considering a backup generator large enough to power the entire production line during extended outages. These considerations are a key part of the overall factory building requirements.

Frequently Asked Questions (FAQ)

Can the solar factory power itself with its own panels?

While a factory can install a large rooftop solar system to offset energy consumption, it cannot be fully self-sufficient. Heavy machinery requires more power to start up and operate than a PV system alone can provide, especially at night or on overcast days. A stable grid connection remains essential.

How much power does a typical solar factory need?

This varies with the line’s capacity and automation level. As a general estimate, a 20–50 MW semi-automated assembly line would require an industrial connection with a capacity of 500 kVA to 1 MVA.

Are there government incentives related to energy for manufacturers?

El Salvador’s government is keen to attract foreign investment, particularly in sectors like renewable energy. Specific incentives, tax benefits, or streamlined processes may be available. Investigating these possibilities with a local legal and business consultant is highly recommended.

How does a turnkey partner assist with this process?

An experienced partner in setting up global manufacturing plants can provide invaluable support. During the planning phase of a turnkey solar manufacturing line, an experienced partner conducts a thorough site assessment. This includes evaluating the local grid’s capacity and reliability, liaising with utility providers, and integrating necessary power conditioning and backup systems into the factory design from the outset. This foresight helps prevent costly surprises and delays.