When considering an investment in solar module manufacturing, entrepreneurs often focus first on machinery and capital. Yet a factory’s long-term success ultimately depends on its people.

This raises a critical question for investors eyeing El Salvador: does the country have the technical labor pool to run a sophisticated solar panel factory? The answer is both nuanced and promising, pointing to a workforce with strong foundational skills ready for specialized training.

This analysis offers a realistic overview of El Salvador’s labor market, examining its transferable skills, targeted training needs, and the wage structures an investor can expect.

The Foundation: El Salvador’s Existing Technical Skills

It’s a common misconception that a country needs a pre-existing solar industry to have a suitable workforce. The key is the presence of transferable skills. El Salvador’s established maquiladora sector, particularly in electronics assembly, has cultivated a workforce adept at tasks directly applicable to solar module production.

Workers from this sector are typically experienced in:

- Precision Assembly: Handling delicate components with care and accuracy.

- Production Line Discipline: Working efficiently within a structured, multi-stage process.

- Quality Control: Adhering to strict standards to minimize defects.

These competencies are crucial for the core stages of the solar panel manufacturing process, such as cell stringing, bussing, lamination, and framing. Moreover, the country’s vocational institutions, like ITCA-FEPADE, produce graduates with solid qualifications in mechatronics, industrial mechanics, and electrical engineering—the exact disciplines required to manage and maintain automated production equipment.

Bridging the Gap: From General Assembly to Solar-Specific Expertise

While El Salvador offers a strong foundation, direct experience in photovoltaic (PV) manufacturing is not yet widespread. This skills gap is a typical challenge in emerging solar markets, but it’s a gap that can be bridged through a structured knowledge transfer program—not an insurmountable obstacle, but a planned phase of the project.

An effective strategy combines two key elements:

-

Partnerships with Local Institutions: Organizations like INSAFORP (Salvadoran Institute for Professional Formation) can collaborate with new businesses to develop customized training modules, ensuring a steady pipeline of qualified personnel.

Ready to make big Profits?

The solar Industry is Booming

WE HELP NEWCOMERS to the solar industry start their own solar module production line. Customers can make BIG PROFITS by selling modules and finding investors, without wasting money and time on things they don't need!

-

On-Site Expert Training: The initial operational phase is critical. For example, experience with J.v.G. turnkey projects shows that having German engineers on-site for the first several months is essential. They oversee the final installation, commission the equipment, and provide intensive, hands-on training for the new local team. This direct mentorship ensures that standard operating procedures, quality benchmarks, and maintenance routines are established correctly from day one.

This early investment in expert-led training significantly de-risks the project, accelerating the local team’s path to operational independence and ensuring the facility meets international quality standards.

A Realistic Look at Wage Structures and Labor Costs

A clear understanding of labor costs is fundamental to any viable financial model. El Salvador offers a competitive wage structure compared to North American or European markets, contributing to a favorable operational expenditure profile.

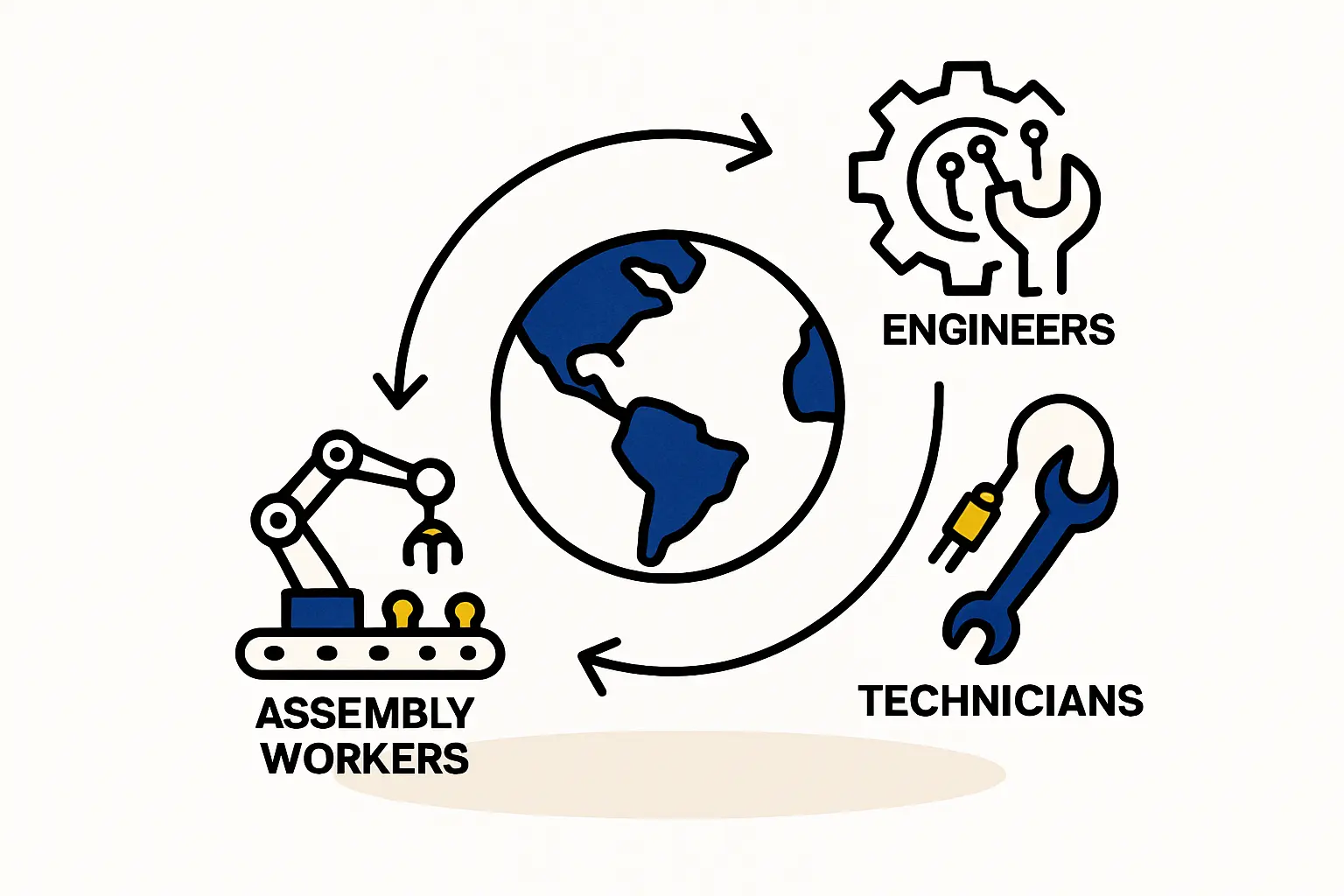

Typical monthly wage ranges for a solar manufacturing facility are as follows:

-

Assembly Line Operators: While the national minimum wage is approximately $365 USD per month, skilled operators in a technical environment can expect a premium, often in the range of $400 – $550.

-

Technicians (Maintenance & Quality Control): These more specialized roles, vital for minimizing downtime and ensuring product quality, typically command salaries between $600 and $900.

-

Engineers (Process & Electrical): University-educated engineers responsible for process optimization and high-level troubleshooting generally earn between $1,200 and $2,000.

These figures help investors accurately forecast operational costs and confirm the economic feasibility of manufacturing in the region.

Strategic Considerations for Building a High-Performing Team

Hiring individuals is only the first step; building a cohesive, high-performing team requires a strategic approach.

Establishing a Quality-First Culture

The Salvadoran workforce is known for its strong work ethic. This inherent diligence should be channeled through a robust quality management system, such as ISO 9001. Implementing such a framework from day one is crucial for producing modules that meet the performance and reliability standards required for essential factory certifications.

Leveraging Government Support

El Salvador’s government has shown a clear commitment to renewable energy through legislation like the Ley de Incentivos Fiscales para el Fomento de las Energías Renovables. This supportive policy environment not only provides financial incentives but also signals the kind of stability that helps attract and retain skilled local talent looking for a long-term future in the industry.

The Role of a Turnkey Solution

For entrepreneurs without a deep background in manufacturing, a turnkey solar production line offers a significant advantage. These solutions typically include a comprehensive training package for the local workforce, addressing the skills gap and ensuring the team is competent and confident from the first day of operation.

Frequently Asked Questions (FAQ)

How many employees are needed for a small-scale (e.g., 50 MW) solar factory?

A 50 MW line operating on a single shift typically requires a team of 25 to 35 personnel. This includes assembly operators, maintenance technicians, quality control inspectors, engineers, and a small administrative and management team.

What are the most critical roles to hire first?

The foundational team should consist of a Plant Manager with a background in industrial manufacturing, a lead Electrical or Mechanical Engineer to oversee the equipment, and a Quality Control Supervisor to establish inspection protocols. Operators and junior technicians can be recruited and trained closer to the facility’s commissioning date.

Is English proficiency common among engineers and technicians in El Salvador?

While Spanish is the official language, many technical professionals and engineers from the country’s leading universities have a working proficiency in English. This is a major advantage for interpreting technical manuals from international suppliers and communicating with expatriate trainers.

How long does it take to train a local team to operate the production line independently?

With intensive, on-site training from experienced engineers, a local team can generally manage day-to-day production processes independently within three to six months. Achieving full autonomy, including advanced troubleshooting and process optimization, may take closer to one year.

Conclusion and Next Steps

From a labor perspective, El Salvador presents a compelling case for solar module manufacturing. The country has a cost-effective workforce with highly relevant, transferable skills from its electronics assembly sector. The primary challenge isn’t a lack of talent, but the need for specialized knowledge in PV manufacturing.

This gap can be effectively bridged through a structured training program, ideally led by experienced engineers during the critical start-up phase. For any strategic investor, the Salvadoran labor pool represents a significant operational asset, not a liability.

With a clear picture of the human resources landscape, the logical next step is to explore other operational pillars: factory building requirements, raw material supply chains, and regional logistics.