An entrepreneur invests millions of dollars in state-of-the-art machinery for a new solar module factory. The equipment is manufactured, tested, and shipped, but upon arrival at the destination port, the entire project stalls. The high-value cargo is held up by unforeseen customs complexities, documentation errors, and logistical bottlenecks, costing the project valuable time and money. This scenario is an all-too-common reality for investors entering new industrial sectors.

For entrepreneurs aiming to establish a solar manufacturing presence in Guinea, the Port of Conakry is the primary gateway. While it offers strategic access to West African markets, navigating its unique logistical landscape is critical for success. This guide outlines the procedures, common challenges, and effective solutions for importing sensitive solar manufacturing equipment through this vital hub. A well-structured logistical plan is as crucial as the machinery itself.

The Strategic Role of the Port of Conakry

The Port of Conakry is more than just a national entry point; it is a critical artery for regional trade, serving landlocked countries like Mali. Recent developments, including the management of the container terminal by a Turkish operator and significant investments in modernization, aim to enhance its capacity and efficiency. The implementation of a single window system for customs (GUCEG) represents a step toward streamlining a historically complex bureaucratic process.

However, despite these improvements, importers must remain aware of persistent challenges. Port congestion can lead to significant vessel waiting times, and container dwell times—the period a container spends at the port after being offloaded—can still be lengthy. Understanding this operational context is the first step toward developing a realistic timeline and budget for your project—a core component of any robust solar business plan.

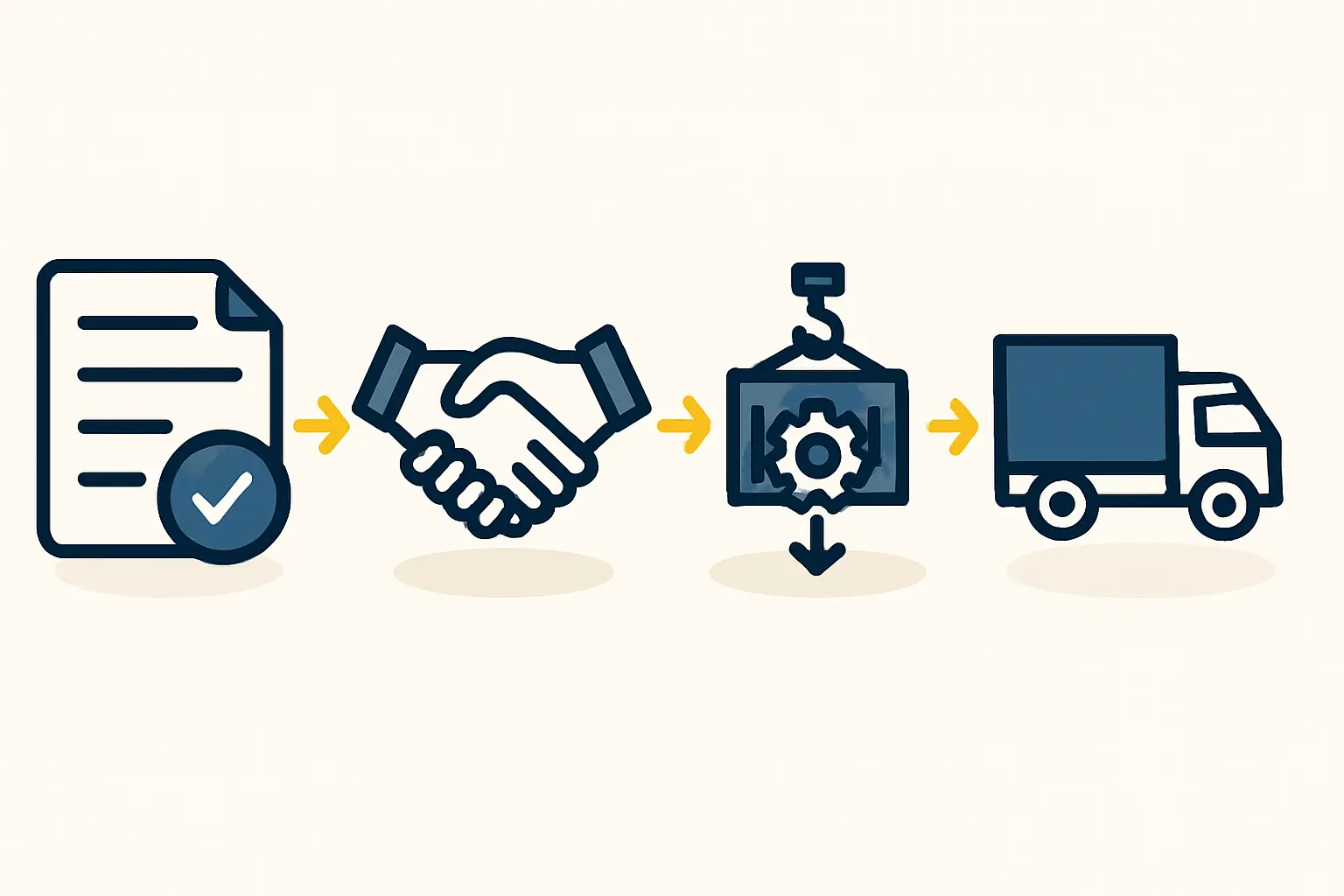

Key Logistical Phases for Importing High-Value Machinery

The journey of your equipment from the manufacturer to your factory floor involves four distinct phases, each demanding meticulous attention to detail.

Phase 1: Pre-Shipment and Documentation

The foundation for smooth customs clearance is laid long before the vessel arrives in Conakry. Inaccurate or incomplete documentation is the most frequent cause of costly delays. Essential documents typically include:

- Bill of Lading (B/L): The contract between the owner of the goods and the carrier.

- Commercial Invoice: Must clearly state the value, description, and Harmonized System (HS) codes for all equipment.

- Packing List: A detailed inventory of each crate or container.

- Certificate of Origin: Verifies the country where the equipment was manufactured.

- Bordereau de Suivi des Cargaisons (BSC) / Cargo Tracking Note (CTN): This is a mandatory document for all shipments to Guinea. Failure to obtain a BSC/CTN number before shipment will result in significant penalties and delays.

Working closely with the equipment supplier and a proficient freight forwarder is essential to ensure every document is prepared correctly. The specific, high-tech nature of solar panel manufacturing machines requires precise classification to avoid disputes with customs authorities.

Phase 2: Customs Clearance Procedures

Once the shipment arrives, the customs clearance process begins. The process involves submitting documentation through the GUCEG platform, assessing duties and taxes, and potentially a physical inspection of the goods.

While the single window system is designed to simplify procedures, the process remains intricate. An experienced, licensed customs broker with a strong track record in Conakry is not a luxury but a necessity. This partner can navigate the administrative formalities, correctly interpret tariff codes, and anticipate potential issues. Based on J.v.G. Technology’s experience with turnkey projects, engaging a reliable local partner at this stage can prevent delays that might otherwise last for weeks.

Phase 3: Inland Transportation from Port to Factory Site

After customs release, the equipment must be transported to the factory. This phase presents its own set of challenges, particularly if the site is located outside Conakry.

- Infrastructure: Road conditions can be unpredictable. A thorough route survey is essential to identify potential obstacles like weak bridges, low overhead clearances, or difficult terrain.

- Specialized Equipment: Solar manufacturing machinery is often heavy, oversized, and sensitive to vibration. Standard trucks are unsuitable. This stage demands specialized low-bed trucks, cranes for loading and unloading, and experienced drivers.

- Security: High-value assets require robust security protocols during transit. This may involve engaging private security escorts to ensure the cargo reaches its destination safely.

Planning for inland transport should begin months in advance to book the right equipment and personnel, ensuring a seamless transition from the port.

Phase 4: Secure Warehousing and Installation

Upon arrival at the factory site, the equipment may need to be stored before installation can begin. This storage must be secure, dry, and climate-controlled to protect sensitive electronic components from dust and humidity, which are prevalent in Guinea’s climate. Coordinating the arrival of the machinery with the readiness of the factory building is a key project management task.

Case Insight: Navigating Logistics for a 50 MW Line

An investor group from North America partnered with J.v.G. Technology to establish a 50 MW solar module factory in a provincial capital of Guinea. The logistical plan was a core component of the project from day one.

By pre-vetting and engaging a top-tier local logistics partner six months before shipment, the project team conducted a complete route survey from the Port of Conakry to the project site. All import documentation, including the critical BSC, was prepared and triple-checked with the customs broker weeks before the vessel’s departure. A three-week buffer was built into the project timeline to account for potential port delays.

As a result, when the machinery arrived, the clearance process was predictable. The pre-booked specialized transport fleet was on standby, and the convoy moved the equipment to the secured factory building without incident. This proactive approach transformed a high-risk phase of the project into a managed, successful operation, demonstrating that with expert guidance, it is entirely possible to learn how to set up a solar panel factory successfully in a complex environment.

Frequently Asked Questions (FAQ)

What is a BSC/CTN and why is it mandatory for Guinea?

The BSC (Bordereau de Suivi des Cargaisons), or Cargo Tracking Note, is a document required by Guinean authorities to track all cargo imported into the country. It must be obtained from an authorized agent at the port of loading before the vessel departs. Non-compliance results in significant fines and prevents customs clearance.

How long does customs clearance typically take in Conakry?

While the official goal is a few days, a realistic timeline should account for one to three weeks, assuming all documentation is correct. Delays can occur due to port congestion, customs inspections, or administrative backlogs. It is prudent to build this buffer into your project schedule.

What are the risks of using a non-specialized transport company?

Using a general haulage company is a major risk. Standard trucks lack the proper suspension and load-bearing capacity for sensitive machinery, potentially causing irreparable damage from shocks and vibrations. Non-specialized operators may also lack the experience to navigate challenging routes or the necessary permits for oversized loads.

Is cargo insurance necessary for shipping to Guinea?

Absolutely. Comprehensive cargo insurance, often called ‘All-Risk’ insurance, is non-negotiable. It should cover the entire journey from the manufacturer’s warehouse to the final installation site, including transit through the port and inland transport. Given the value of the equipment, this is a critical measure for mitigating financial risk.

The Importance of Strategic Logistical Planning

Importing high-value solar manufacturing equipment into Guinea via the Port of Conakry is a complex but manageable undertaking. Success hinges not on luck, but on meticulous planning, an understanding of the local context, and the engagement of experienced local partners. By treating logistics as a strategic project pillar—equal in importance to finance and technology—entrepreneurs can effectively de-risk their investment and lay a solid foundation for a successful manufacturing operation in one of Africa’s most promising markets.