An entrepreneur considering a solar module factory in Equatorial Guinea faces a unique landscape. The government’s mandate for national economic participation is both a significant compliance challenge and a strategic opportunity.

While the national ambition is to foster local industry, the reality is that specialized raw materials for solar panel manufacturing are not readily available within the country or the broader CEMAC region. This raises a critical question for any investor: How can one build a resilient, cost-effective supply chain while adhering to increasingly strict local content regulations?

Success hinges on a strategy that balances the necessity of international sourcing with a credible, long-term plan for localization.

Understanding Equatorial Guinea’s National Content Framework

Though originally designed for the petroleum industry, Equatorial Guinea’s national content regulations provide the legal blueprint for other strategic sectors, including renewable energy. The cornerstone of this framework is Law No. 2/2021, which mandates prioritizing local companies, workforce development, and technology transfer.

For a foreign investor or a joint venture planning a solar manufacturing facility, the implications are direct:

-

The National Content Plan: Before operations begin, companies must submit a detailed plan to the Ministry of Mines and Hydrocarbons (MMH). This document must outline how the project will use local goods and services, employ and train Equatoguinean nationals, and transfer knowledge.

-

Preference for Local Entities: The law requires that preference be given to local companies in the procurement of goods and services, a factor that directly impacts supply chain decisions.

-

Significant Penalties: Non-compliance is not taken lightly. Regulations stipulate fines that can range from $100,000 to over $1,000,000, making adherence a critical part of risk management.

These rules are not merely administrative hurdles but a central part of the country’s economic development strategy. A successful entry strategy must integrate these requirements into the core of the business plan for a solar manufacturing plant from the very beginning.

The Practical Realities of Sourcing Solar Components

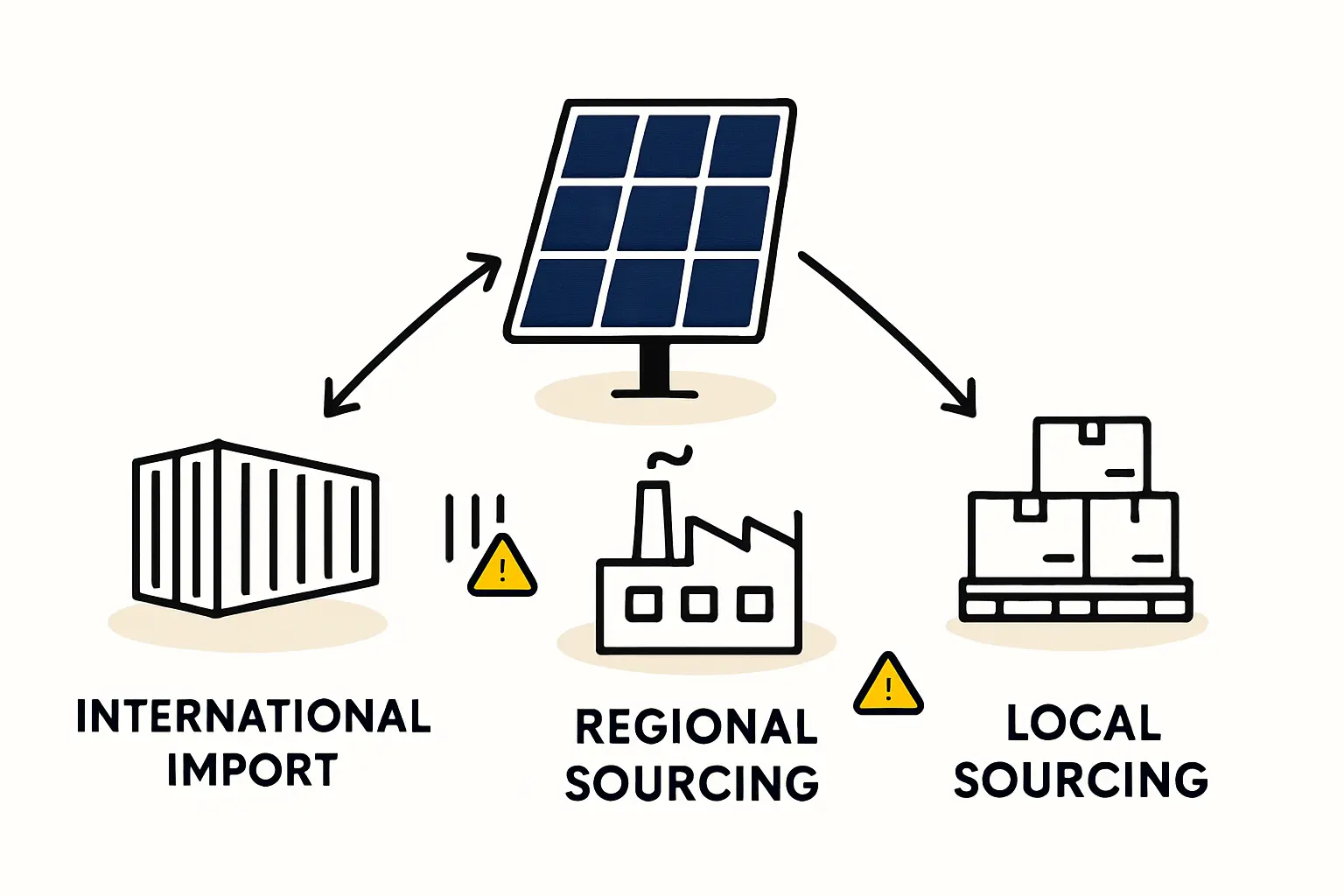

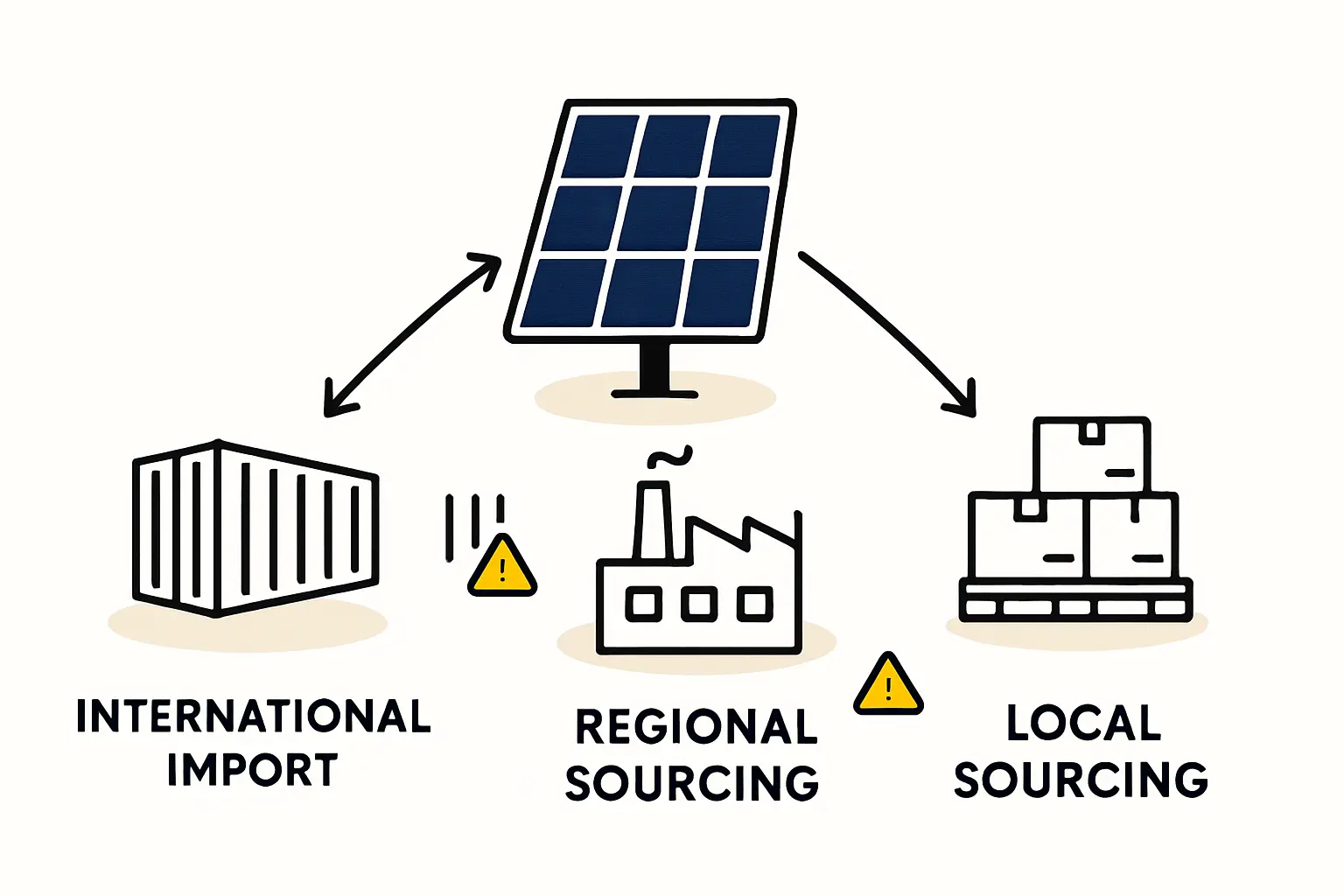

A standard solar module is an assembly of highly specialized materials. A feasibility analysis for a factory in Equatorial Guinea must realistically assess where these components can be sourced.

Local Sourcing (Equatorial Guinea)

The current industrial base in Equatorial Guinea cannot support the manufacturing of key solar components.

-

Solar Glass: Producing the high-transparency, low-iron tempered glass required for solar panels is a capital-intensive process that requires specialized facilities not yet present in the country.

-

Aluminum Frames: Although aluminum is widely used, the country lacks bauxite mining and primary aluminum smelting capabilities. Establishing an extrusion and anodizing plant to produce frames would be a major industrial project in its own right.

-

Cells, EVA, and Backsheets: These highly specialized polymer and electronic components are produced by a concentrated group of global manufacturers, making local production unfeasible in the short to medium term.

Regional Sourcing (CEMAC & Africa)

Expanding the search to neighboring countries and the wider continent opens up some possibilities but also introduces logistical challenges.

-

CEMAC Region: The Central African Economic and Monetary Community (including Cameroon, Gabon, and Chad) has a developing industrial base but lacks the specialized manufacturing needed for solar components. Furthermore, logistics and customs between member states can be complex.

-

Nigeria and South Africa: These countries have more developed industrial capabilities. Nigeria has aluminum extrusion companies that could potentially supply frames, while South Africa and Egypt have more advanced manufacturing. However, sourcing from these locations involves significant shipping costs and lead times to Malabo or Bata, potentially disrupting production schedules.

International Sourcing

For the most critical and technologically advanced components, the global market remains the only viable option.

-

Necessity: High-efficiency solar cells, specialized encapsulants (EVA), and durable backsheets must be imported from established manufacturers in Asia, Europe, or North America.

-

Challenge: This creates a dependency on international logistics, exposing the operation to currency fluctuations, shipping delays, and global supply chain disruptions. It also directly conflicts with the spirit of local content laws if not managed properly.

Developing a Hybrid Supply Chain for Resilience and Compliance

The most pragmatic approach is not to choose a single sourcing strategy but to blend them into a phased, hybrid model. This model acknowledges current realities while creating a clear path toward future localization, satisfying both operational needs and regulatory expectations.

A hybrid strategy could be structured as follows:

-

Phase 1: Foundation (Years 1-2): Rely on a stable international supply chain for all critical components like cells, glass, EVA, backsheets, and junction boxes. For bulkier items like aluminum frames, source from a reliable regional or global supplier to ensure quality while setting up a solar module production line. This phase prioritizes getting the plant operational and producing certified modules.

-

Phase 2: Localization (Years 3-5): With the factory established, focus on localizing the supply of components with lower technological barriers. Aluminum frames are the most logical candidate. This could involve partnering with a local company to establish an assembly or finishing facility for imported aluminum profiles, creating local jobs and demonstrating a tangible commitment to the National Content Plan.

-

Phase 3: Regional Integration (Years 5+): Explore deeper partnerships within the CEMAC region. As regional industrial capacity grows, it may become feasible to source other components, such as junction boxes or even locally fabricated glass, reducing reliance on transcontinental shipping.

This phased approach allows a business to present a compelling and realistic National Content Plan to the MMH that shows foresight and a genuine commitment to local development—moving beyond mere compliance to strategic partnership.

Based on experience from J.v.G. turnkey projects, regulatory bodies are often more receptive to a credible, multi-year plan for gradual localization than to an unrealistic promise of 100% local sourcing from day one.

Frequently Asked Questions (FAQ)

What is a ‘National Content Plan’ in the context of Equatorial Guinea?

A National Content Plan is a formal document submitted to the government detailing how a new project will contribute to the local economy. It must outline specific commitments regarding local employment and training, subcontracting to Equatoguinean companies, and transferring technology and skills.

Is it permissible to import all raw materials when starting a solar factory?

Initially, yes. The government understands that a local supply chain for specialized materials does not yet exist. However, a business must present a clear and actionable plan for how it will gradually increase local or regional sourcing over time. A plan that relies indefinitely on 100% imports is unlikely to meet regulatory approval.

Are there any existing suppliers for solar components in Equatorial Guinea?

As of today, there are no established local manufacturers for the primary components of a solar module, such as cells, specialized glass, encapsulants, backsheets, or aluminum frames. The opportunity lies in being one of the first to help develop this ecosystem.

What is the most critical first step to ensure compliance?

The most critical first step is to conduct a thorough feasibility study that includes a detailed supply chain analysis and a draft of your National Content Plan. Engaging with local advisors or consultants with experience in the region can provide invaluable insight into the expectations of the Ministry of Mines and Hydrocarbons.

The Path Forward: From Strategy to Operation

Entering the solar manufacturing market in Equatorial Guinea requires more than technical expertise; it demands a nuanced understanding of the local regulatory environment and a forward-thinking supply chain strategy.

The optimal path is not a choice between global efficiency and local compliance, but a fusion of the two. By designing a hybrid, phased supply chain, an investor can de-risk operations, build a resilient business, and position their enterprise as a valuable partner in Equatorial Guinea’s economic development.

For those considering this venture, a turnkey solar factory solution often incorporates this level of strategic planning, ensuring the facility is viable not only technically but also within its unique regulatory context.