Imagine the core of your new solar module factory: a multi-million-dollar lamination machine is halfway through its 15-minute cycle, precisely bonding layers of glass, EVA, and solar cells under heat and vacuum. Suddenly, the power cuts out.

The cycle is ruined, an entire batch of expensive materials is wasted, and your production schedule is thrown into disarray. This is not a hypothetical risk—for manufacturers in regions with developing grid infrastructure, it is a daily operational reality.

In Guinea, where the national electricity access rate is approximately 43% and power outages are frequent, establishing a solar module factory requires more than just production machinery. It demands a robust, independent power strategy. This article outlines the critical challenge of securing a 24/7 power supply and explores viable solutions that can transform this liability into a competitive advantage.

The High Cost of Unreliable Power in Manufacturing

For any industrial operation, an unstable power supply is a significant financial drain. Research indicates that power outages cost businesses in Africa an estimated 1-2% of their annual GDP through lost productivity and damaged equipment. In the high-precision world of solar manufacturing, the consequences are even more severe.

The intricate solar module manufacturing process relies on a sequence of sensitive, automated machines that must run without interruption. A sudden power loss can lead to:

- Material Waste: Half-processed materials in laminators or cell stringers must often be discarded, incurring direct financial losses.

- Machine Damage: Abrupt shutdowns can damage sensitive electronic components and mechanical systems, leading to costly repairs and extended downtime.

- Production Delays: Each hour of downtime is an hour of lost output, delaying order fulfillment and impacting revenue.

- Quality Control Issues: Voltage fluctuations can affect the precision of machines like testers and sorters, potentially compromising the quality and certification of the final product.

Simply put, a reliable power source is not a utility expense; it is a core component of the production line itself.

Defining the Power Requirement for a Solar Factory

A common question from entrepreneurs entering this sector is, “How much power does a solar factory actually need?” Based on J.v.G. Technology GmbH’s experience with turnkey projects, a typical semi-automated factory with a 50 MW annual capacity requires a stable, continuous power supply of approximately 300 to 500 kilowatts (kW).

However, the requirement extends beyond sheer quantity to include quality and continuity. The power must be “clean”—free from the voltage sags and frequency fluctuations common in unstable grids—and it must be available 24/7 to support continuous or multi-shift operations.

This level of reliability is rarely available from the public grid in many emerging markets, making an independent power solution an essential component of any serious industrial plan.

Evaluating Power Solutions for Industrial Independence

An entrepreneur planning a factory in Guinea has several options for powering the facility. This choice directly impacts operational uptime, production cost, and long-term profitability.

Option 1: Relying on the National Grid

Relying solely on the public grid is often the first option considered, but it is the highest-risk strategy. Grid performance is measured by metrics like the System Average Interruption Duration Index (SAIDI), which measures the total time an average customer is without power, and the System Average Interruption Frequency Index (SAIFI), which measures how often they experience an outage.

In regions with high SAIDI and SAIFI figures, like Guinea, where outages can average 15 times per month, the grid cannot be the primary power source for a mission-critical manufacturing operation. It can serve as a potential backup, but it cannot be the foundation.

Option 2: The Traditional Approach – Diesel Generators

The most common solution for grid instability has historically been diesel generators (gensets). They provide on-demand power and are a mature technology. However, they come with significant and often unpredictable drawbacks:

- High Operational Cost: In many parts of Africa, the electricity cost from diesel can range from $0.25 to $0.40 per kWh. These costs fluctuate with global oil prices.

- Fuel Logistics: Securing a consistent, high-quality supply of diesel fuel in remote or developing areas can be a major logistical challenge.

- Maintenance Burden: Generators require regular, skilled maintenance, adding to the operational overhead.

- Environmental Impact: Emissions and noise pollution are increasingly important considerations for modern industrial companies.

While a diesel genset is a necessary component of a comprehensive backup plan, relying on it as a primary power source is an expensive and logistically demanding model.

Option 3: The Modern Solution – A Captive Hybrid Power Plant

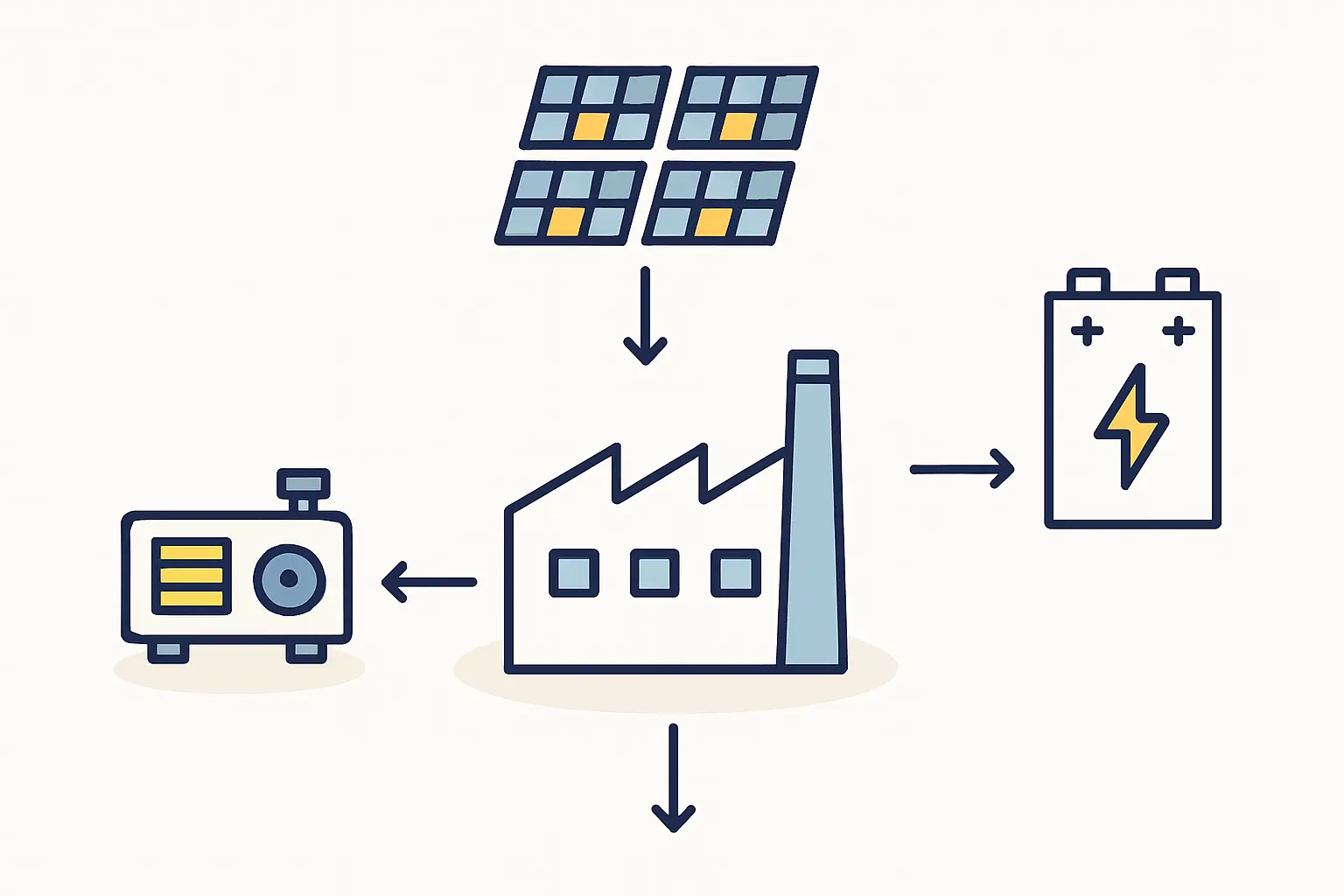

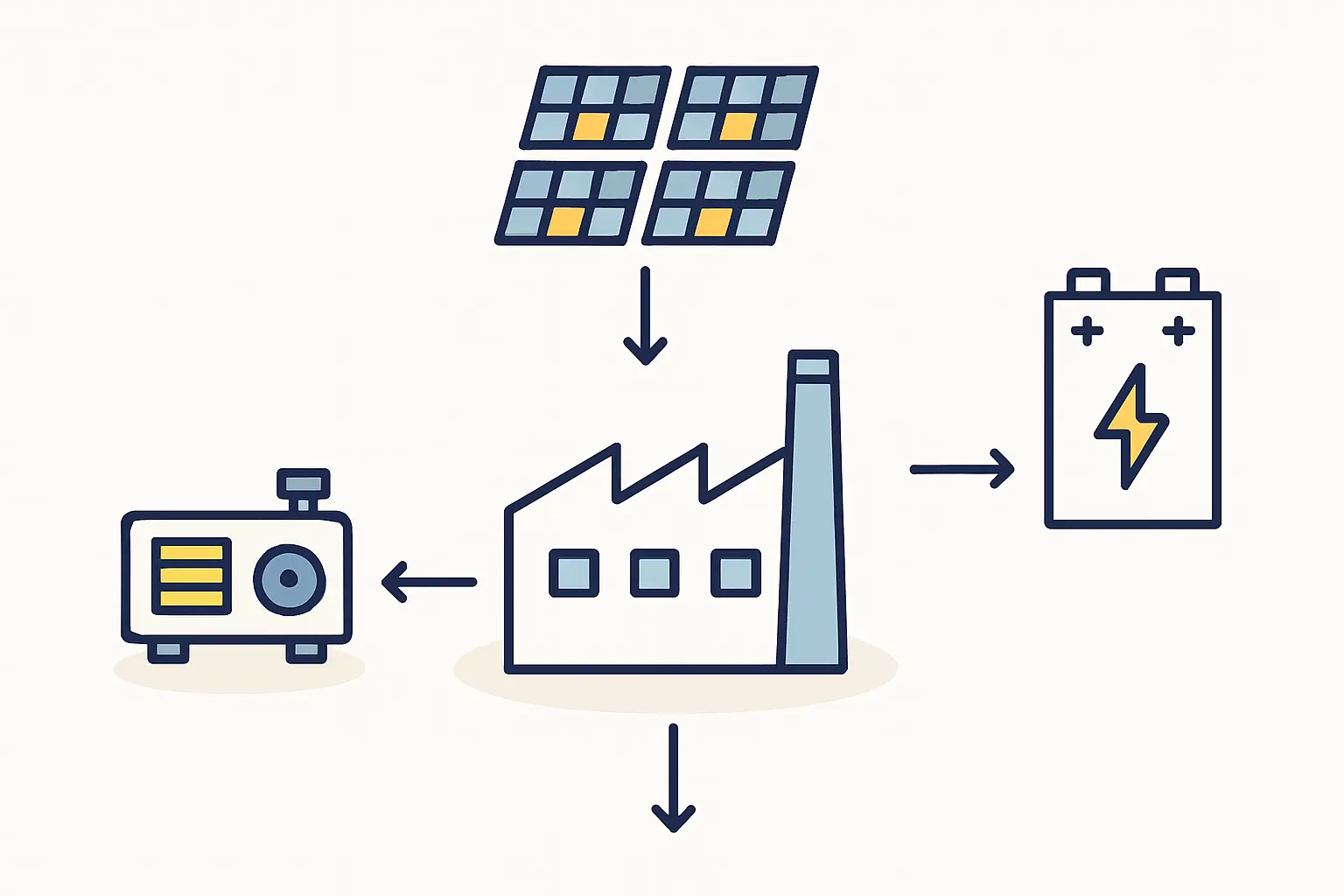

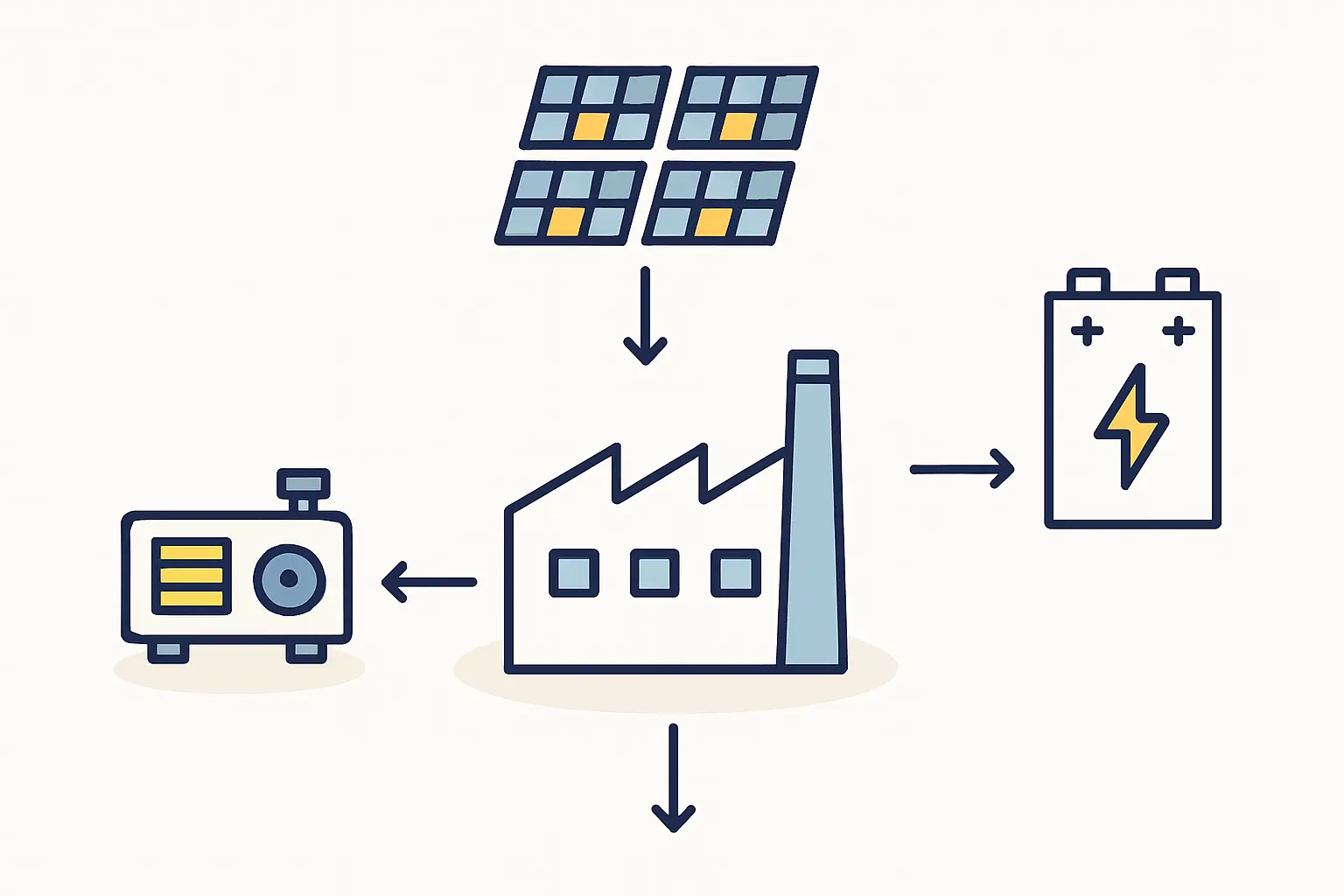

The most effective and increasingly economical solution is a “captive power plant”—a system designed to generate electricity primarily for the factory’s own use. For a solar factory, the ideal configuration is a hybrid system combining solar PV, a Battery Energy Storage System (BESS), and a backup diesel generator.

This integrated system operates as follows:

- Solar PV Array: A rooftop or ground-mounted solar array acts as the primary power source during daylight hours, running the factory and charging the batteries.

- Battery Energy Storage System (BESS): The batteries store excess solar energy. They provide seamless power during the night, on cloudy days, or in the event of a brief grid outage, ensuring a smooth transition with no interruption to machinery.

- Backup Diesel Generator: The genset serves as the final layer of security. It is programmed to automatically start only if the batteries are depleted after an extended period of low solar irradiation, ensuring 100% uptime.

The Business Case for a Solar-Plus-Storage System

While the initial investment for a hybrid system is higher than for a diesel generator alone, the long-term business case is compelling. The Levelized Cost of Energy (LCOE)—the average cost per kWh over the system’s lifetime—for commercial solar-plus-storage systems has fallen dramatically, now often ranging between $0.15 and $0.25 per kWh.

This makes it directly competitive with, and often cheaper than, diesel generation. The key advantages include:

- Energy Independence: The factory is insulated from grid failures and volatile fossil fuel prices.

- Predictable Costs: Energy becomes a fixed, predictable operational expense rather than a volatile variable.

- Operational Reliability: A properly designed hybrid system provides power quality and reliability far exceeding that of the public grid, which is essential for protecting sensitive equipment.

- Brand Congruence: Powering a solar panel factory with its own solar energy is a powerful marketing and brand statement, demonstrating a commitment to the technology being produced.

Effective management of such a system requires robust monitoring and control software, allowing facility managers to optimize energy flow and ensure every component is functioning correctly.

Integrating Power Solutions into Factory Planning

The most critical mistake an investor can make is to treat the power supply as an afterthought. The captive power plant strategy must be integrated into the initial factory design and financial modeling. A comprehensive solar panel manufacturing business plan should include a dedicated section on energy strategy, detailing the proposed system size, cost, and projected return on investment.

When sourcing equipment, it is crucial to work with a partner who understands this integrated approach. A provider of a turnkey solar manufacturing line can design the factory layout, machine selection, and power system to work in concert, ensuring a seamless and efficient setup from day one. This holistic planning prevents costly retrofitting and ensures the power infrastructure is perfectly matched to the factory’s load requirements.

Frequently Asked Questions (FAQ)

What exactly is a “captive power plant”?

A captive power plant is an electricity generation facility set up by a company to provide power for its own consumption. It provides independence from the public grid and ensures a reliable power supply tailored to the user’s specific needs.

How large of a solar-plus-storage system is needed for a 50 MW factory?

For a 300–500 kW continuous load, the system might require a solar array of 1–1.5 MWp (megawatt-peak) and a battery storage system of 1–2 MWh (megawatt-hours). The exact sizing depends on local solar irradiation, the number of production shifts, and the desired level of autonomy.

Can the factory sell excess power back to the grid?

This depends entirely on the local regulations and grid infrastructure in Guinea. While technically possible, feed-in tariffs and net metering policies may not be established or reliable. The primary business case should be built on self-consumption and operational savings, not on revenue from selling power.

What is the typical payback period for a hybrid power system?

Compared to the cost of running on diesel alone, the payback period for the additional investment in solar and batteries can be as short as 5 to 8 years. This is driven by savings on fuel and reduced maintenance costs.

Is a diesel generator still necessary in a hybrid system?

For a mission-critical manufacturing facility, yes. While it may run for only a few hours per year, the generator provides the ultimate guarantee of 100% uptime, protecting the multi-million-dollar investment in the production line against extreme or unforeseen circumstances.

The Path Forward

For entrepreneurs looking to establish a solar module factory in Guinea or similar markets, securing a stable and independent power supply is not an option—it is a foundational requirement for success.

The instability of the public grid and the high cost of diesel generation make a captive hybrid power plant, centered on solar and battery storage, the most logical and financially sound strategy. By treating the power system as an integral part of the factory itself, an investor can de-risk the entire operation, ensure consistent production, and build a resilient business ready for long-term growth.

Further exploration of this topic is a crucial step in the planning process, and resources like structured e-courses can provide deeper insights into facility requirements and financial modeling.