When considering a new venture in solar module manufacturing, the choice of location is a critical decision. It extends far beyond the cost of land, influencing supply chain efficiency, operational costs, access to talent, and market reach.

While established manufacturing hubs in Asia or Europe often come to mind first, Estonia presents a compelling and often overlooked alternative, particularly for businesses targeting the European market.

Estonia is well-known for its advanced digital society and streamlined business environment. Its true potential for industrial investors, however, lies in its strategic commitment to green technology, combined with a robust and modernizing infrastructure. This article offers a comparative analysis of key Estonian industrial parks, providing a framework for evaluating the optimal site for a new solar module manufacturing plant.

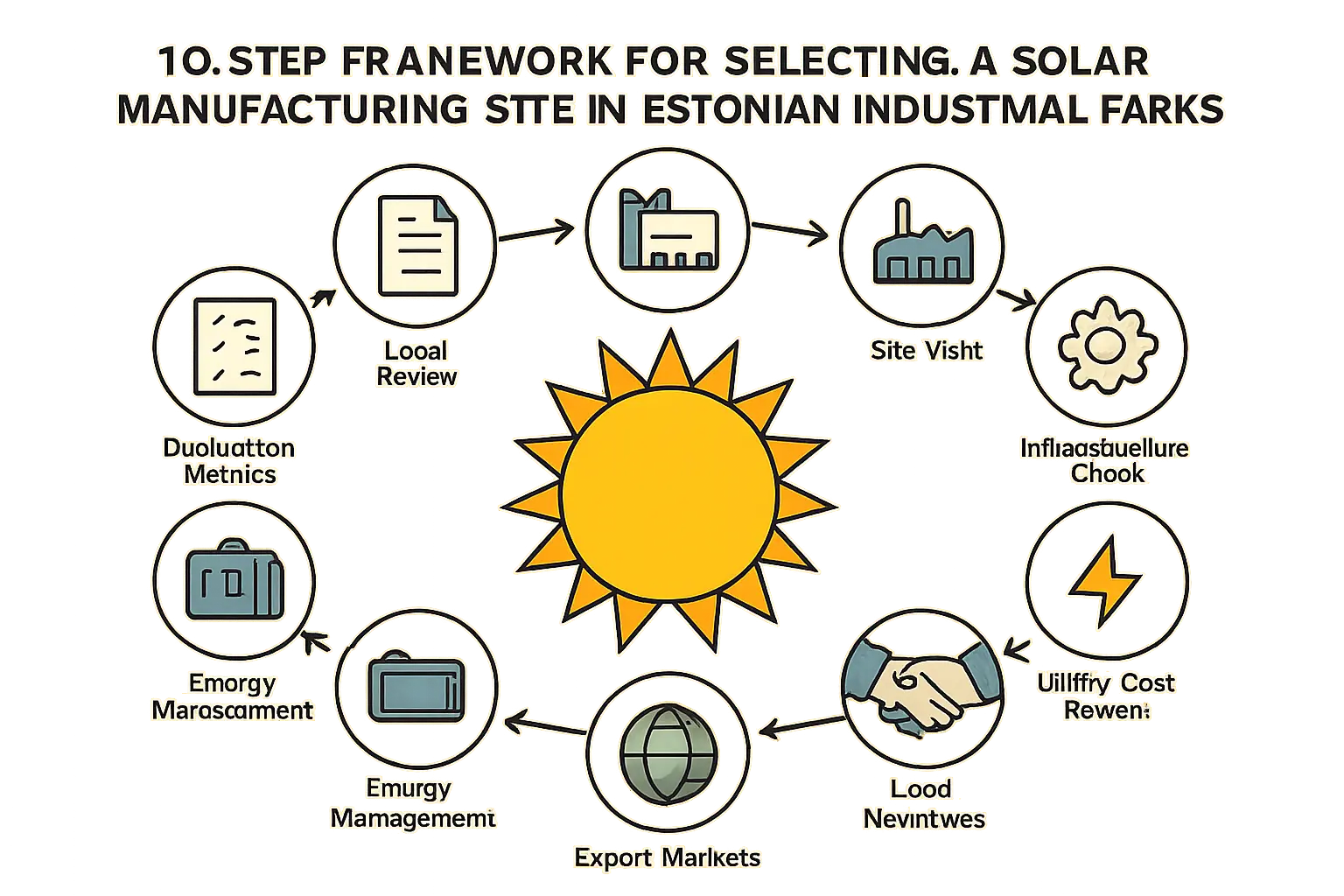

Key Decision Factors for Siting a Solar Module Factory

Before comparing specific locations, it’s essential to understand the primary criteria that determine a manufacturing facility’s success. For a business that involves importing bulky raw materials like glass and aluminum and exporting finished products, these factors are paramount. Based on experience from numerous J.v.G. turnkey projects, a sound location decision rests on four pillars.

1. Logistics and Port Infrastructure

The efficiency of your supply chain is directly tied to your proximity to major transport hubs. A solar module factory requires reliable access to a deep-water port for the cost-effective import of raw materials and export of finished modules. Key considerations include container handling capacity, customs clearance efficiency, and connections to road and rail networks for inland distribution.

2. Utility Costs and Reliability

Solar module manufacturing is an energy-intensive process, and the cost and stability of the electricity supply can significantly impact operating margins. Evaluating local electricity tariffs, grid reliability, and the availability of green energy purchasing agreements is crucial. Reliable access to water for cooling and cleaning processes, as well as industrial waste management facilities, are also key infrastructure requirements.

3. Labor Availability and Skillset

A factory requires a diverse team, from line operators to technicians and quality control engineers. A prospective location should offer access to a pool of skilled or trainable labor. Proximity to technical universities and vocational training centers can be a significant advantage for long-term staffing and innovation. Labor costs, a key part of operational expenditure, also vary between regions.

4. Financial Incentives and Business Environment

Government support can substantially improve the financial viability of a new manufacturing plant. Support can take the form of direct grants, tax credits, or assistance for training programs. As part of the European Union’s Green Deal, certain regions offer substantial funding to attract green technology investments. The overall ease of doing business, regulatory transparency, and property laws are also vital components of the investment requirements.

A Comparative Overview of Estonia’s Premier Industrial Zones

Estonia offers several distinct industrial regions, each with unique advantages. The optimal choice depends on the specific priorities of the business model—whether it emphasizes the lowest operational cost, the fastest logistics, or access to innovation.

Ida-Viru Industrial Area: Leveraging the Just Transition

Located in northeastern Estonia, the Ida-Viru region is the country’s traditional industrial heartland. It is now undergoing a major economic transformation backed by the EU’s Just Transition Fund (JTF), which aims to support regions moving away from carbon-intensive industries like oil shale.

Advantages:

- Significant Financial Incentives: The JTF provides substantial co-financing for new investments that create jobs in green technology, potentially lowering initial capital expenditure.

- Skilled Industrial Workforce: The region has a long history of industrial production, offering a ready pool of experienced technical and operational personnel.

- Lower Operating Costs: Both labor and land costs are generally lower compared to the capital region around Tallinn.

- Infrastructure: The area has several developed industrial parks, such as those in Narva, Jõhvi, and Kohtla-Järve, with ready-to-use plots and utility connections.

Considerations:

- Logistics: While connected by rail and road, Ida-Viru is further from the main deep-water ports of Tallinn, which could add a minor cost and time component to shipping. The local port of Sillamäe offers an alternative for certain cargo types.

This region is particularly suitable for investors prioritizing low operational costs and leveraging significant grant funding to de-risk the initial investment.

Port of Tallinn (Muuga and Paldiski): The Logistics Powerhouse

For businesses where speed-to-market and supply chain efficiency are top priorities, the industrial zones connected to the Port of Tallinn are the premier choice. This includes Muuga Harbour, the largest cargo port in Estonia, and the rapidly developing Paldiski South Harbour.

Advantages:

- Unmatched Connectivity: Muuga Harbour is a major deep-water port with extensive container, ro-ro, and dry bulk terminals, offering direct sea routes to European hubs like Hamburg, Rotterdam, and Antwerp.

- Free Zone Benefits: Parts of the port operate as a free zone, which can offer tax and customs advantages for import/export-oriented manufacturing, simplifying procedures and improving cash flow.

- Intermodal Hub: Excellent rail and road network connections ensure seamless movement of goods. Paldiski is also developing as a key hub for offshore wind, creating a green energy ecosystem.

Considerations:

- Higher Costs: Land, lease, and labor costs are higher in the Harju county region around the capital compared to eastern Estonia.

- Competition for Labor: As the country’s economic center, competition for skilled labor is more intense.

For an investor focused on serving the Scandinavian and Western European markets with maximum logistical efficiency, the Port of Tallinn’s industrial parks are a compelling proposition.

Tartu Science Park: The High-Tech and R&D Hub

Tartu is Estonia’s second-largest city and its intellectual center, home to the prestigious University of Tartu. The Tartu Science Park focuses on attracting knowledge-intensive companies.

Advantages:

- Access to Talent and R&D: The park offers unparalleled access to engineering and science graduates. This environment fosters innovation and collaboration on research valuable for future product advancements, such as new cell technologies or module designs.

- High-Tech Ecosystem: The park hosts a cluster of technology companies, creating a dynamic environment for business development and partnerships.

Considerations:

- Inland Location: Being inland, Tartu is not suitable for a large-scale manufacturing plant reliant on bulk sea freight. Logistics costs for transporting materials from a port and shipping finished modules would be significantly higher.

- Focus: The park is better suited for R&D centers, prototyping labs, or small-scale, high-value production rather than mass manufacturing.

A company planning a significant R&D component alongside a smaller, specialized production line might consider Tartu, but for a standard 50-200 MW factory, the logistical challenges are a major drawback.

Synthesizing the Data: A Framework for Your Decision

The choice between these locations is not about which is ‘best’ overall, but which best aligns with your strategic goals.

- For a Cost-Focused Strategy: Ida-Viru offers the most attractive combination of low operational costs and substantial grant funding, ideal for maximizing return on investment on a tight budget.

- For a Logistics-Focused Strategy: The Port of Tallinn (Muuga) is the clear choice for businesses that prioritize efficient, large-scale import and export. The time and cost savings in the supply chain can outweigh higher local operating costs.

- For an Innovation-Focused Strategy: Tartu is the hub for R&D and talent acquisition. A company could establish its primary manufacturing in Ida-Viru or Tallinn while maintaining an R&D satellite office in Tartu.

A thorough analysis requires detailed financial modeling—a core part of any business plan. The suitability of available plots or buildings in each park also depends on factors like specific factory building requirements and the type of machinery for production.

Frequently Asked Questions (FAQ)

What is the EU Just Transition Fund?

The Just Transition Fund (JTF) is a European Union financial instrument designed to support regions facing significant socio-economic challenges in their transition to a climate-neutral economy. In Estonia, the Ida-Viru region is the primary beneficiary, with over €350 million allocated to diversify its economy, create new jobs, and attract investment in green industries like renewable energy manufacturing.

Are there language barriers for managing a factory in Estonia?

While Estonian is the official language, English is widely spoken in the business community, especially among the younger generation. In the Ida-Viru region, Russian is also prevalent for operational management. This makes it entirely feasible for a foreign investor to run a company in English.

How does Estonian electricity cost compare to other EU countries?

Estonia’s electricity prices are generally competitive within the EU. The country is connected to the Nord Pool power market, which provides transparent pricing. The increasing share of renewables in Estonia, including wind and solar, is also expected to help stabilize prices in the long term.

What is the typical timeline for setting up a factory in an Estonian industrial park?

Thanks to Estonia’s efficient digital bureaucracy, the administrative setup can be quite fast. The most time-consuming steps are finding the right plot, securing permits, and construction or renovation. A realistic timeline, from the final decision to the start of production for a turnkey line, is typically 12 to 18 months, assuming all financing is in place.

Next Steps in Your Planning Process

Selecting a location is a foundational step. The next phase involves developing a comprehensive business plan, conducting a detailed feasibility study for your chosen site, and beginning the process of securing financing and necessary solar module certifications.

This process involves many technical and financial variables. Educational resources, such as the structured e-courses available on pvknowhow.com, can provide a clear roadmap for entrepreneurs new to photovoltaic manufacturing, helping transform a strategic vision into an operational reality.