An entrepreneur can have a comprehensive business plan, secure funding, and even the perfect location for a new solar panel factory. But the project’s success or failure often hinges on one frequently underestimated factor: a steady, reliable flow of raw materials.

For a factory in Estonia, this means mastering the logistics of importing components from global suppliers through its highly efficient Baltic Sea ports. This guide provides a practical overview of supply chain logistics for a solar module factory in Estonia, explaining how to leverage the country’s strategic location and advanced infrastructure to import essential materials like solar cells, glass, and backsheets, transforming a potential bottleneck into a competitive advantage.

Why Estonia? The Strategic Advantage of a Baltic Hub

Estonia’s geographic position offers manufacturers a unique advantage. Situated at the crossroads of the European Union, Russia, and Asian trade routes, it serves as a natural gateway for international commerce. As an EU member, it provides a stable regulatory environment and seamless access to the European single market.

The country’s maritime infrastructure is central to this edge. Key ports, such as the Port of Tallinn (which includes Muuga Harbour, the primary cargo hub) and the Port of Paldiski, are deep-water and remain ice-free year-round. This ensures consistent, uninterrupted operations—a critical factor for any manufacturing business reliant on just-in-time inventory.

Its advanced port infrastructure, combined with modern road and rail networks, makes Estonia a highly effective logistics hub. When considering options for planning your factory’s location, proximity and access to such facilities are paramount.

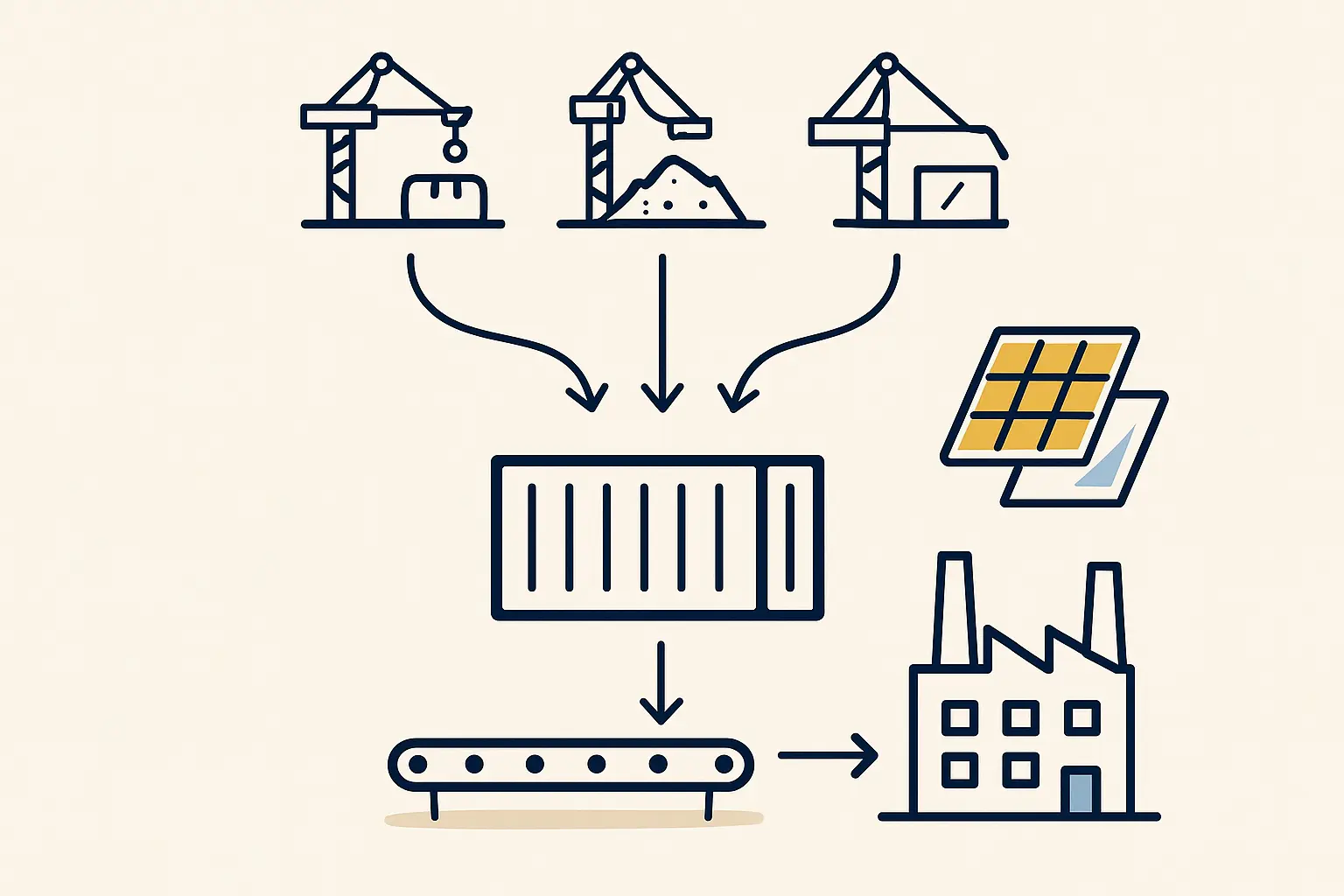

The Solar Component Journey: From Global Suppliers to Your Factory Floor

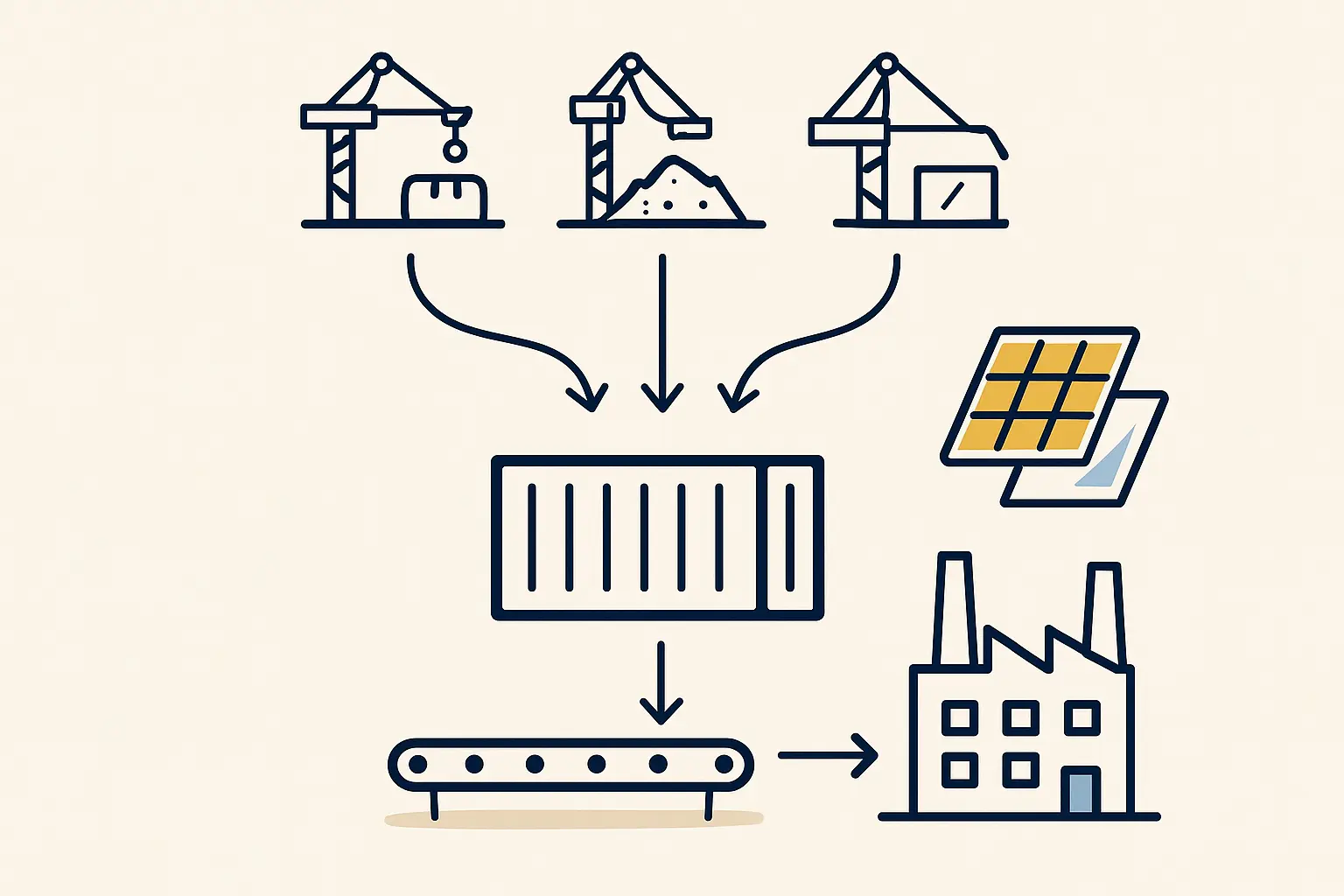

A solar module assembly line requires a diverse range of components sourced globally. A typical supply chain for a European factory includes:

- Solar Cells & Wafers: Primarily sourced from manufacturers in China.

- EVA Film & Backsheets: Often imported from suppliers in Southeast Asia and China.

- Glass & Aluminum Frames: While available from European suppliers, these are also sourced globally to optimize costs.

The journey for these materials usually begins with sea freight, the most cost-effective method for transporting large volumes. A container shipped from a major port in China travels by sea, navigates through European waters, and arrives at a Baltic port like Tallinn. From there, it must clear customs before being transported inland to the factory.

Understanding and optimizing each step of this journey is essential for maintaining a smooth production schedule and controlling operational costs.

Navigating Costs and Timelines: A Practical Breakdown

Budgeting and scheduling for a solar factory must be grounded in realistic logistics data. The two primary factors are lead times and the total landed cost of goods.

Lead Times

The transit time for sea freight from major Asian ports to Tallinn is typically between 30 and 45 days. This timeframe, however, does not account for potential delays in production, port congestion, or customs clearance. Prudent planning involves establishing a buffer stock of critical components to mitigate the impact of unforeseen supply chain disruptions.

Cost Components

Calculating the final cost of imported materials requires looking beyond the supplier’s invoice. Key financial elements include:

- Freight Rates: The cost of ocean shipping is highly variable and depends on global demand, fuel prices, and container availability. These fluctuations must be factored into the overall project budget.

- Import Duties: A significant advantage of operating within the EU is that most solar components, such as photovoltaic cells, currently have a 0% import duty. This policy substantially reduces the cost of raw materials.

- Value-Added Tax (VAT): Estonia has a standard VAT rate of 22%. This tax is applied to the value of the imported goods. For a registered business, however, this VAT is reclaimable, making it a cash flow consideration rather than a final cost.

- Ancillary Fees: Additional costs include terminal handling charges at the port, customs brokerage fees, and inland transportation.

The Estonian Edge: Digital and Efficient Customs

One of Estonia’s most compelling advantages for importers is its highly digitized and transparent customs process. The country’s e-Tax/e-Customs system allows for electronic submission of declarations and documentation, dramatically streamlining clearance procedures.

This digital-first approach has several clear benefits:

- Speed: Well-prepared shipments can often be cleared in less than a day.

- Transparency: Importers have clear visibility into the status of their shipments.

- Reduced Bureaucracy: The need for physical paperwork is minimized, reducing the risk of errors and delays.

Such efficiency is particularly valuable when coordinating the arrival of materials with the installation schedule for sourcing the right machinery, since logistical delays can have a cascading effect on the entire project timeline.

Common Challenges and Strategic Considerations

Based on experience from J.v.G. Technology GmbH’s turnkey projects, new entrepreneurs should prepare for several common logistical challenges:

- Supplier Reliability: It is essential to vet suppliers not only on price but also on production consistency, quality control, and their ability to meet shipping deadlines.

- Freight Volatility: Engaging an experienced freight forwarder can help manage fluctuating shipping costs and secure reliable vessel space.

- Last-Mile Logistics: The final leg of the journey, from the port to the factory, requires careful planning. Ensuring that local transport partners are reliable and capable of handling your specific materials is crucial.

A proactive approach to these issues—building strong supplier relationships and partnering with knowledgeable logistics providers—is fundamental to a resilient supply chain.

Frequently Asked Questions (FAQ)

What are the main cargo ports in Estonia?

The primary cargo hub is the Port of Tallinn, specifically Muuga Harbour. The Port of Paldiski also handles significant cargo volumes. Both are deep-water and ice-free, allowing for year-round operation.

Are there import tariffs on solar cells in the EU?

Currently, most photovoltaic components, including solar cells, can be imported into the European Union with a 0% customs duty. However, it is always wise to verify the latest regulations and Harmonized System (HS) codes before shipping.

How long does customs clearance typically take in Estonia?

Thanks to the advanced e-Customs system, clearance can be very rapid. If all documentation is correctly submitted in advance, goods can often be cleared the same day they arrive.

Do I need to hire a local customs broker in Estonia?

While not mandatory, it is highly recommended, especially for first-time importers. A licensed customs broker understands local regulations, ensures all paperwork is compliant, and can efficiently resolve any issues that arise, saving valuable time and preventing costly delays.

Can I source any raw materials from within Europe?

Yes. High-quality solar glass and aluminum frames are readily available from European manufacturers. Sourcing these components regionally can significantly reduce lead times and shipping costs, though this must be balanced against the unit price from global suppliers.

Conclusion: Your Next Steps in Planning

Estonia presents a compelling case for a solar module factory, thanks to its strategic position, modern port infrastructure, and exceptionally efficient customs system. By leveraging these advantages, an entrepreneur can build a robust and cost-effective supply chain.

A deep understanding of logistics is not an administrative detail; it is a foundational pillar of a successful manufacturing operation. With careful planning and the right partners, the logistical challenges of importing global components can be managed effectively, paving the way for a competitive and resilient business.