Estonia may not be the first country that comes to mind for solar panel manufacturing. Conventional wisdom holds that northern latitudes lack the intense, consistent sunlight needed to warrant a major investment in solar technology. Yet, a closer look at meteorological data and modern photovoltaic advancements reveals a compelling business case—not for mass-producing standard panels, but for creating specialized modules engineered for the unique challenges and opportunities of the Nordic climate.

This article explores the strategic advantages of establishing a solar module factory in Estonia. It outlines the specific technical adaptations needed to maximize energy yield amid low sun angles, heavy snowfall, and diffuse light, charting a clear path for entrepreneurs to serve a growing and high-value regional market.

The Untapped Potential: Why Estonia is a Strategic Base

While Estonia may not experience the same peak sun hours as Southern Europe, its annual solar irradiation is surprisingly robust, ranging from 950 to 1200 kWh/m² per year. This level is comparable to that of Northern Germany, a region with one of the world’s most developed solar markets. That fact alone challenges the idea that the region is unsuitable for solar energy.

Beyond its local solar potential, Estonia offers several key strategic advantages. As a member of the European Union, an Estonian manufacturing base provides frictionless access to the entire bloc, benefiting from the growing emphasis on energy independence and localizing critical supply chains.

A facility would also be perfectly positioned to serve Finland, Sweden, Norway, Latvia, and Lithuania—markets with similar climatic demands and a rising interest in renewable energy.

Finally, Estonia is well-regarded for its straightforward business regulations and digital infrastructure, streamlining the process of setting up and operating a manufacturing facility.

The strategic imperative is not to compete with global mass-producers on price, but to deliver specialized, high-performance products that standard modules simply cannot match.

Designing for Performance: Key Technologies for Nordic Climates

A successful manufacturing strategy hinges on producing modules specifically adapted to Northern Europe’s environmental conditions. Standard solar panels, often designed for ideal, sunny climates, tend to underperform in this region. Several key technical specializations can bridge these performance gaps directly.

Maximizing Yield in Winter: The Power of Bifacial Technology

One of the greatest challenges for solar energy in Nordic regions is the long winter, with its persistent snow cover and low sun angles. Yet this perceived disadvantage can be turned into a significant advantage with bifacial solar modules.

Unlike traditional monofacial panels that only capture light on their front side, bifacial modules have an active rear surface that absorbs reflected light. Snow has a very high albedo, meaning it reflects a large portion of the sunlight that hits it—often over 80%. A bifacial panel installed over a snow-covered landscape captures this powerful reflected light, leading to substantial gains in energy production and boosting winter yield by up to 30% compared to a conventional module.

Engineering for Durability: Withstanding Heavy Snow Loads

The weight of accumulated wet snow can exert immense mechanical stress on a solar panel, risking micro-cracks in the solar cells or even structural failure of the module frame. Standard solar modules are often rated for a maximum pressure of 5400 Pascals (Pa).

For Nordic markets, manufacturing modules with enhanced mechanical strength—using stronger, thicker frames and reinforced glass—is a critical differentiator. By engineering for a higher rating, such as 8100 Pa, a manufacturer can offer a product that guarantees reliability and longevity in alpine or northern regions. This enhanced durability is a crucial selling point for customers who prioritize long-term performance and asset security. The solar panel manufacturing process can be adjusted at the framing and lamination stages to achieve these higher durability standards.

Capturing Every Photon: Excelling in Low-Light Conditions

Nordic climates are also characterized by a high proportion of diffuse light, especially during overcast days and the long dawns and dusks. Modules optimized for these conditions will consistently outperform standard panels. Two technologies are key:

An Anti-Reflective (AR) coating on the front glass minimizes light reflection and maximizes light absorption, particularly when the sun is at a low angle in the sky—a common scenario in northern latitudes.

Modern cell architectures like half-cut and multi-busbar (MBB) designs also significantly improve performance in low-light and partial-shading conditions. Half-cut cells reduce internal electrical resistance, boosting efficiency, while MBB designs create more pathways for electricity to be collected, making the panel more resilient to micro-cracks and shading.

The Business Case: From Concept to Production

Establishing a specialized solar module factory in Estonia is a viable venture for entrepreneurs with a strategic, long-term vision. The focus must be on quality and targeted performance, creating a brand known for reliability in demanding environments.

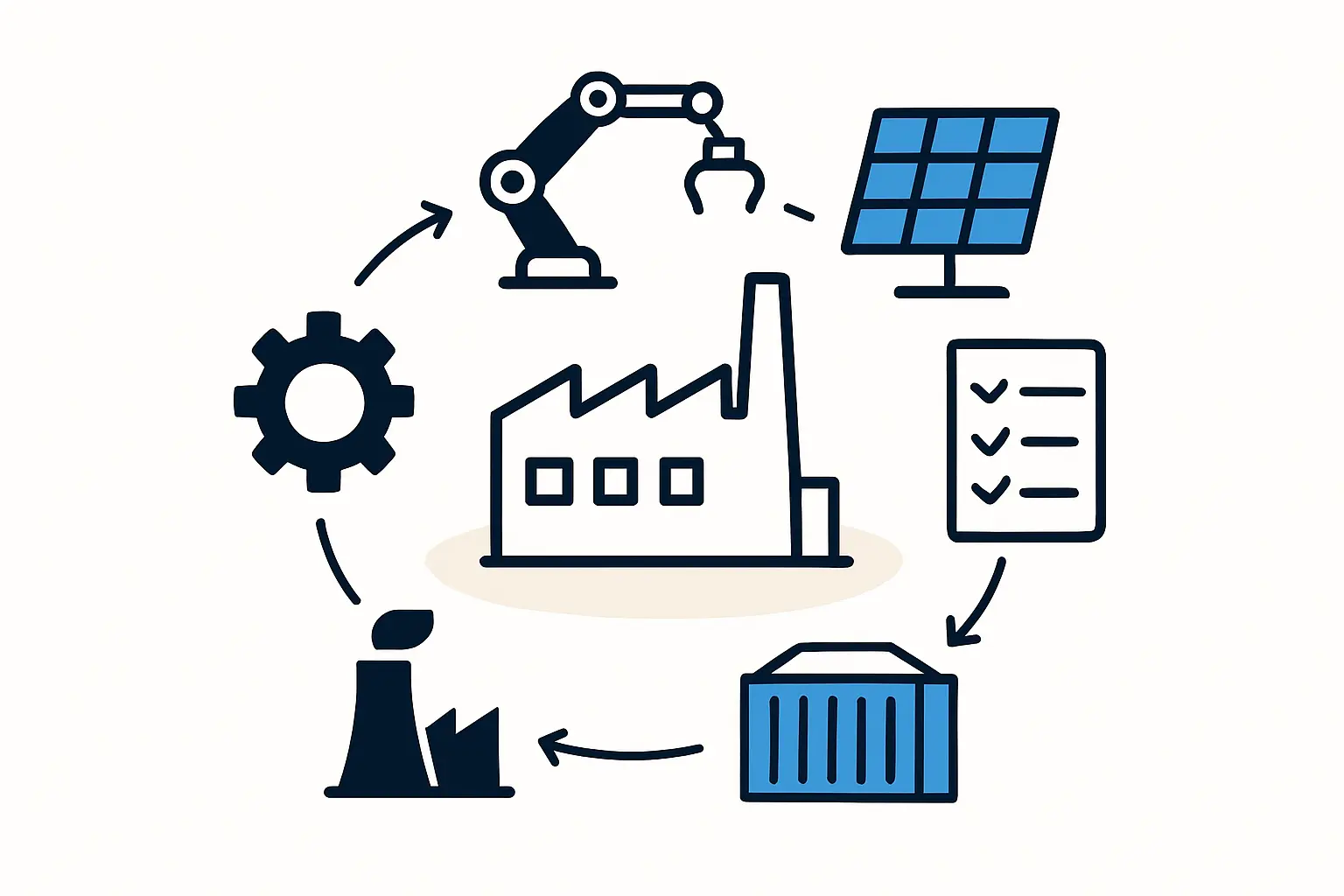

A small- to medium-scale production line, perhaps in the 20 to 50 MW annual capacity range, represents a manageable entry point into the market. Experience from J.v.G. turnkey projects shows that the core solar panel manufacturing machine setup for such a line is similar to a standard one. The key is to configure specific stations—such as the stringer, lay-up, and framing stations—to handle the components required for bifacial, high-load, and half-cut cell modules. This targeted investment in specialization creates a defensible market position.

FAQ: Entering the Solar Manufacturing Market in Estonia

Is Estonia’s solar irradiation really sufficient for a viable market?

Yes. With 950 to 1200 kWh/m² of annual solar irradiation, Estonia’s solar resource is comparable to Northern Germany’s, which supports a mature and thriving solar industry. The key is to use technology optimized for the specific light conditions.

What is the main advantage of local manufacturing over importing standard modules?

The primary advantage is specialization. A local manufacturer can produce modules engineered specifically for the snow, low light, and mechanical stress of Nordic climates. This offers customers a higher-performing, more reliable product. Other benefits include supply chain security, faster delivery times, and the marketing value of a ‘Made in EU’ product.

How much investment is required to start a small-scale factory?

The investment depends heavily on the chosen capacity, level of automation, and technology. A well-structured solar panel manufacturing business plan is essential to accurately forecast costs for equipment, facilities, and working capital for a 20-50 MW setup.

Do these specialized modules require completely different machinery?

Not entirely. The fundamental production process remains the same, but certain machines must be specified or configured to handle bifacial cells, thicker glass, and more robust frames. For example, the stringer needs to be compatible with half-cut cells, and the framing station must be able to handle the reinforced profile.

A Strategic Path Forward

The opportunity for solar module manufacturing in Estonia lies not in competing with global giants on volume, but in excelling through intelligent specialization. By engineering products that address the specific challenges of Nordic and Baltic climates, an Estonian-based enterprise can build a strong, defensible brand recognized for quality and performance.

For entrepreneurs and business leaders exploring this industry, the next step is moving from a general concept to detailed planning. A thorough understanding of the technical requirements, market dynamics, and financial modeling is what transforms a promising idea into an operational reality.