Imagine an entrepreneur has invested millions in a state-of-the-art solar module manufacturing plant in Eswatini. The machinery is calibrated, staff are trained, and the first major production run is underway. Suddenly, the lights flicker and the entire line grinds to a halt. The cause isn’t an internal failure but a disruption on the national power grid—a setback that could have been anticipated and mitigated.

For any investor considering an industrial project in Eswatini, a thorough analysis of the electrical grid is no mere technical formality; it’s a fundamental part of a sound business strategy. While the nation offers significant opportunities, its power infrastructure presents unique challenges that directly impact production uptime, operational costs, and overall profitability.

This article offers a framework for understanding Eswatini’s grid, quantifying the risks of power instability, and planning the infrastructure needed to ensure continuous factory operation.

Understanding Eswatini’s National Grid Structure

The national electricity supply in Eswatini is managed exclusively by the Eswatini Electricity Company (EEC). Any industrial planner must understand one critical factor: the country’s grid is heavily dependent on external sources.

Historically, Eswatini has imported approximately 80% of its electricity, primarily from Eskom in South Africa and, to a lesser extent, Electricidade de Moçambique (EDM). This reliance creates a direct vulnerability. When South Africa’s Eskom implements load-shedding schedules due to generation shortfalls, the impact is often felt directly in Eswatini, leading to supply interruptions far beyond the EEC’s immediate control.

Local generation capacity, which includes about 60 MW from hydropower plants alongside smaller contributions from biomass and solar, is insufficient to meet the country’s total demand. While the EEC is actively pursuing a strategy for energy self-sufficiency by 2034 through significant investments in renewable energy projects, this import dependency remains a key operational risk for the immediate future.

Quantifying the Risk: What the Data Reveals

To move from a general awareness of risk to a specific business plan, data is essential. The reliability of an electricity grid is measured globally using two key metrics:

-

SAIDI (System Average Interruption Duration Index): Measures the total duration of power interruptions for an average customer over the course of a year.

-

SAIFI (System Average Interruption Frequency Index): Measures how many times an average customer experiences a sustained power interruption over the course of a year.

According to the Eswatini Electricity Company’s 2022/2023 Annual Report, the grid performance was recorded as follows:

- SAIDI: 2,190 minutes

- SAIFI: 34.6 interruptions

For a business professional, this data translates into a stark operational challenge. The average customer location experienced nearly 35 power outages over the year, with a cumulative downtime of more than 36 hours. For a manufacturing facility where continuous processes are critical, these interruptions can lead to significant financial losses from wasted materials, production delays, and potential equipment damage during unplanned shutdowns and startups. This reality underscores why energy resilience must be a core part of the factory’s infrastructure requirements.

Navigating Industrial Electricity Tariffs in Eswatini

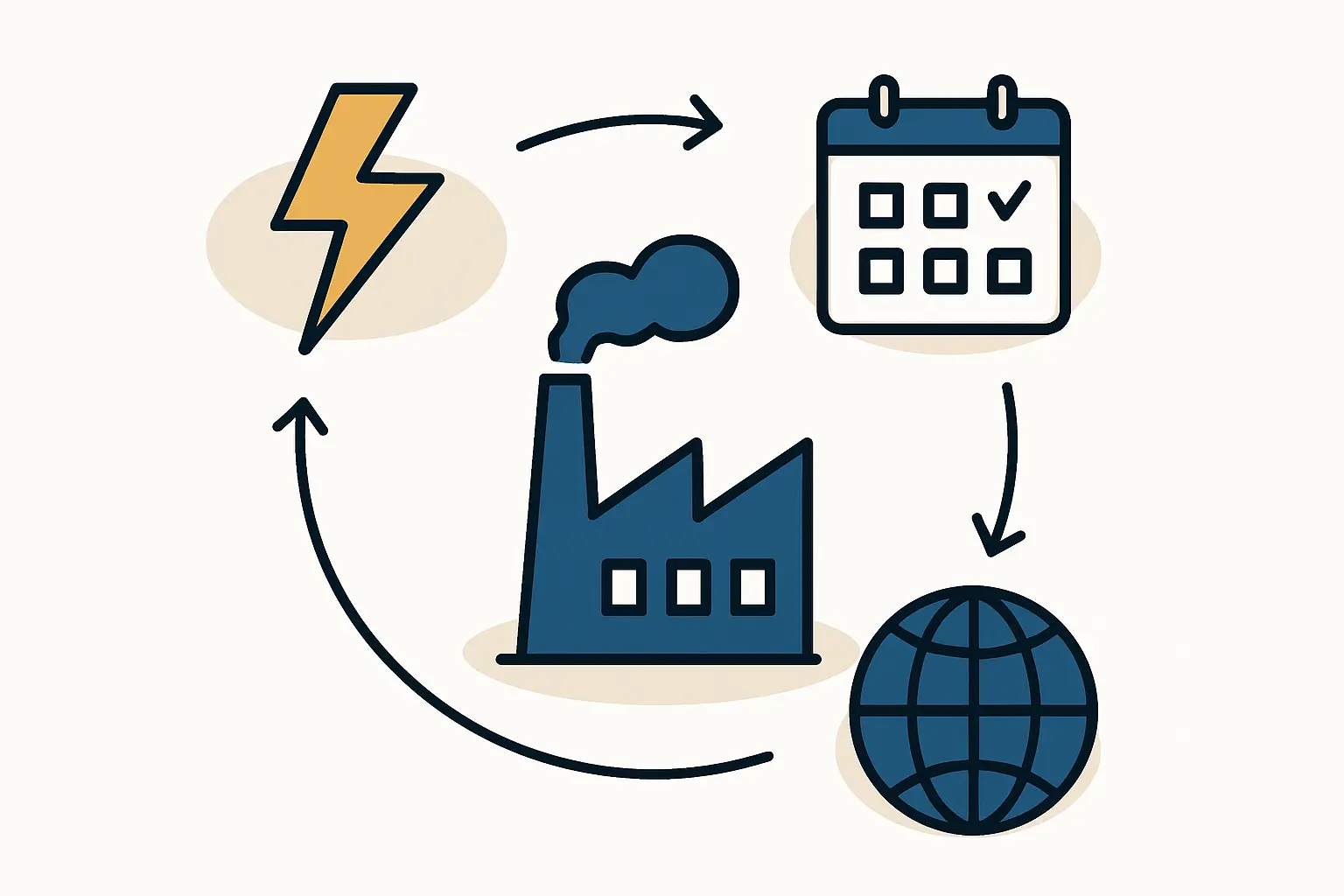

Beyond reliability, electricity costs are a major factor in any factory’s financial projections. The EEC applies a Time-of-Use (TOU) tariff structure for its industrial customers, designed to incentivize consumption during periods of lower overall demand.

The TOU structure is typically divided into three periods:

- Peak: The most expensive rate, usually applied during morning and evening hours when national consumption is highest.

- Standard: A moderate rate that applies for most of the business day.

- Off-Peak: The cheapest rate, typically available overnight and on weekends.

While a factory can strategically schedule energy-intensive processes like lamination to run during off-peak hours to reduce operational costs, the unpredictability of grid outages complicates this strategy. An outage during a critical phase can negate any savings achieved through tariff optimization.

A Framework for Ensuring Production Uptime

Given the quantifiable risks, a proactive approach to power management is essential. A robust backup power system is not an optional extra but a required investment for uninterrupted manufacturing. The planning process involves three key steps.

Step 1: Calculate the Factory’s Critical Load

Not all machinery requires an uninterruptible power supply. The first step is to identify the critical systems that cannot be shut down without causing significant material loss or production delays. In a solar module factory, these typically include:

- Laminators: These machines run on long, temperature-sensitive cycles. An interruption can ruin an entire batch of modules.

- Cell Stringers: Halting these automated machines mid-process can require time-consuming recalibration.

- Climate Control: Maintaining specific temperature and humidity levels in storage and production areas is vital for quality control.

Step 2: Determine Required Backup Duration

The EEC’s SAIDI and SAIFI data provides a baseline for calculating the necessary duration of backup power. With the average outage lasting for approximately one hour (2,190 minutes / 34.6 interruptions ≈ 63 minutes), a system designed to provide at least two to three hours of power for the critical load would cover the majority of incidents.

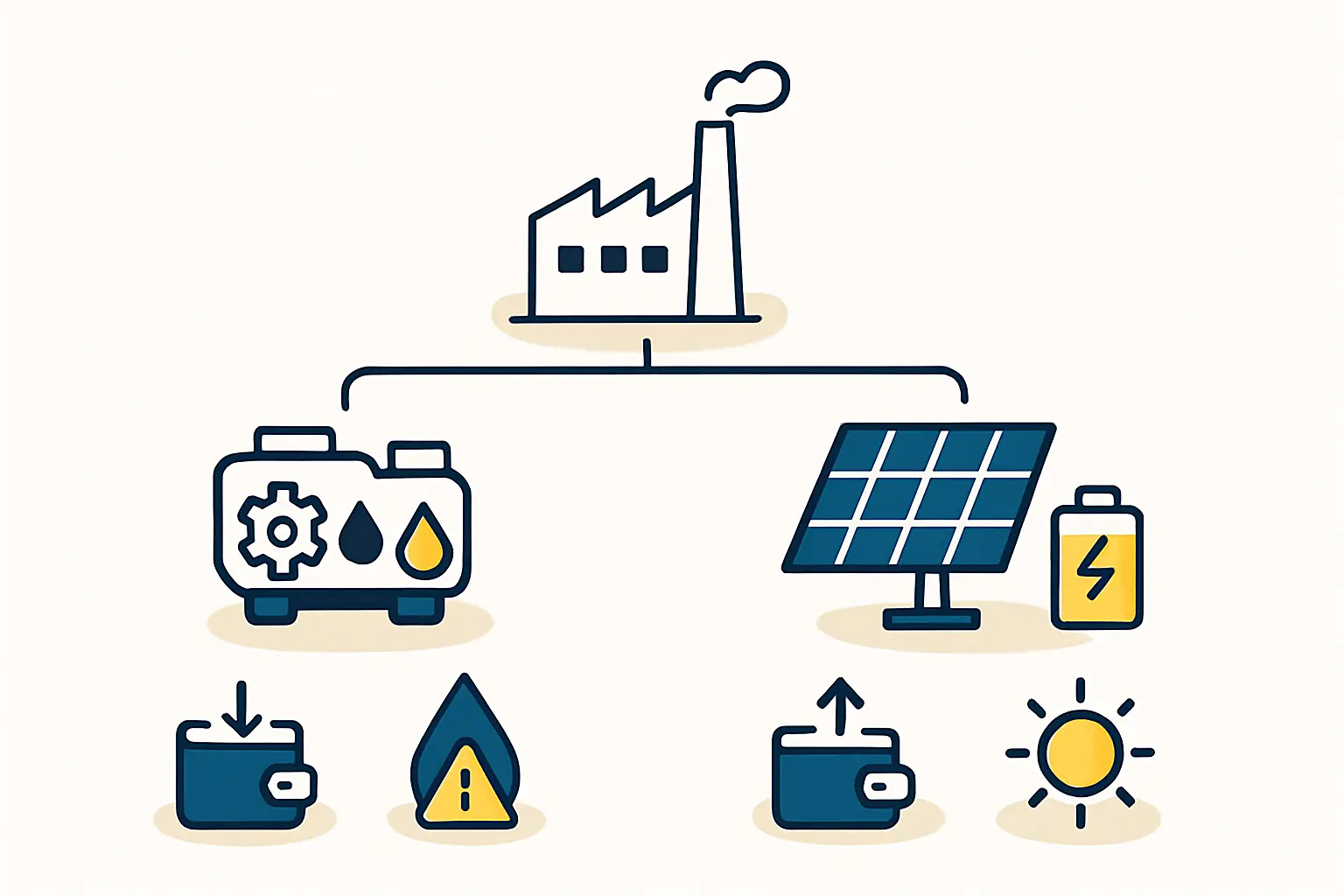

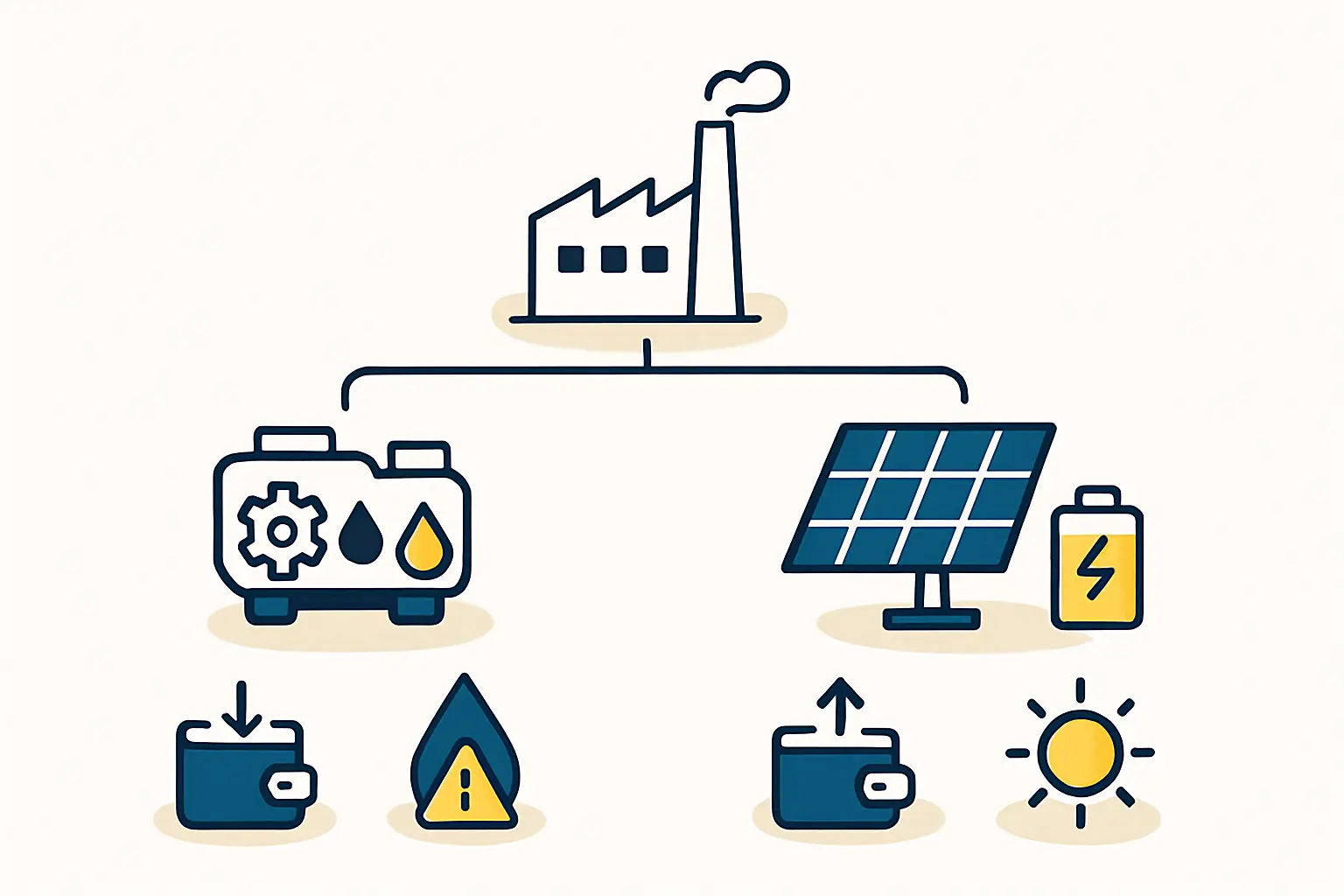

Step 3: Design a Resilient Hybrid Power System

For industrial applications in regions with grid challenges, a hybrid power system offers the most effective solution. This typically integrates multiple sources:

- Grid Power: The primary source of electricity when available.

- On-site Solar PV: A solar module factory can leverage its own product. A rooftop or ground-mounted solar array can significantly reduce reliance on the grid and lower energy costs, particularly during standard tariff periods.

- Battery Energy Storage System (BESS): Batteries store excess solar energy or cheap off-peak grid power. During an outage, they provide instant, seamless power to critical loads. A BESS can also be used for ‘peak shaving’—discharging during expensive peak tariff hours to reduce electricity bills.

- Diesel Generator: As a final layer of security, a diesel generator can provide long-duration power during extended outages, ensuring the factory can operate indefinitely regardless of grid status.

This integrated approach creates multiple layers of redundancy, transforming the factory from a passive energy consumer into a resilient, self-sufficient facility.

Frequently Asked Questions (FAQ)

Why can’t a solar factory just use its own solar panels for power?

While a factory can and should install a large solar PV system, the panels themselves only produce DC electricity when the sun is shining. This energy must be converted to AC power by inverters to power the factory. To provide power at night or during an outage, the system requires a battery storage component and a sophisticated management system to operate independently from the grid.

Is grid instability a problem only in Eswatini?

No, this is a common challenge for industrial investors in many emerging markets across Africa, Southeast Asia, and Latin America. The methodology of analyzing grid data (like SAIDI and SAIFI), calculating critical loads, and designing a hybrid backup system is a universal best practice. Experience from J.v.G. turnkey projects shows this analysis is a standard part of the initial planning phase in nearly every country.

How much does a backup power system for a factory cost?

The investment varies significantly based on the factory’s critical load, the desired hours of autonomy, and the chosen technology mix (e.g., battery capacity, generator size). While the upfront cost is considerable, it should be factored into the total project investment and weighed against the guaranteed prevention of production losses, which can easily exceed the system’s cost within just a few years.

Next Steps in Your Project Planning

Assessing electrical grid reliability is a foundational step in de-risking an investment in solar manufacturing in Eswatini. By moving beyond a general awareness and using official data to engineer a solution, an entrepreneur can build a facility that is resilient, competitive, and capable of consistent production regardless of external grid conditions.

This analysis forms a crucial part of the overall infrastructure plan. The next logical step is to explore the specific building and utility requirements needed to house the production line and its supporting power systems, ensuring your investment is built on a solid foundation.