For international entrepreneurs exploring new manufacturing ventures, the Kingdom of Eswatini presents a compelling case. Its strategic location, stable economy, and government support for industrialization create a market of significant potential. However, the most critical resource for any manufacturing operation is its people. A common question from investors is whether the local labor market can support the high standards required for solar module production.

This analysis provides a practical framework for understanding Eswatini’s labor landscape, moving beyond simple wage data to explore skill availability, training needs, and the strategic steps required to build a proficient and cost-effective local workforce. This process is a cornerstone for any successful launch, a journey detailed in our comprehensive guide on How to Start a Solar Module Factory: The Definitive Guide.

Understanding the Labor Landscape in Eswatini

Eswatini’s demographic profile offers a distinct advantage for new industrial projects. The nation has a very young population, with a median age of approximately 22. This contributes to a high youth unemployment rate (around 47%), but it also means there is a large, available, and motivated pool of potential employees.

Key characteristics of the local labor market include:

-

High Literacy Rate: With a literacy rate of nearly 89%, the general workforce has a strong educational foundation, which accelerates technical training.

-

Existing Vocational Training: Institutions like the Eswatini College of Technology (ECOT) and the Gwamile Vocational and Commercial Training Institute (VOCTIM) provide foundational technical and engineering skills. While not specific to photovoltaics, graduates from these programs often have the aptitude for the specialized training a solar factory requires.

-

English Proficiency: As one of the country’s official languages, English is widely spoken in business and education. This eliminates communication barriers for international management and technical trainers.

This combination of factors creates a favorable environment. The challenge is not a lack of people, but rather channeling this potential into the specific, high-precision skills demanded by the solar industry.

Projecting Labor Costs: A Realistic Framework

One of the primary attractions of establishing a factory in Eswatini is the competitive cost of labor. However, a successful business plan requires a nuanced understanding of wage structures beyond the national minimum wage.

The minimum wage for unskilled labor is approximately E531.60 per month, serving as a baseline. For a solar module factory, which requires precision and adherence to strict quality protocols, a more stratified wage structure is essential for attracting and retaining talent. A typical structure would include:

-

Entry-Level Assembly Operator: These are individuals with no prior experience who undergo initial training. Their compensation would be set above the minimum wage to reflect the semi-skilled nature of the work.

-

Trained Operator / Quality Control Inspector: After completing a full training program and demonstrating proficiency, an operator’s value to the company increases, and their wages should reflect these new skills. Given their importance, quality control staff would fall into this tier or slightly higher.

-

Senior Technician / Line Supervisor: These roles require deeper technical understanding, often involving machine maintenance, troubleshooting, and team leadership. Candidates may come from local vocational schools and will require extensive on-the-job training. Their compensation is significantly higher, reflecting their critical role in maintaining production uptime and quality.

This tiered approach ensures that labor costs remain competitive while also creating a clear career path for local employees, fostering loyalty and reducing staff turnover. Based on J.v.G. Technology’s experience with turnkey projects, a semi-automated 50 MW factory operates efficiently with a team of 25–30 employees per shift, including operators, technicians, and supervisors.

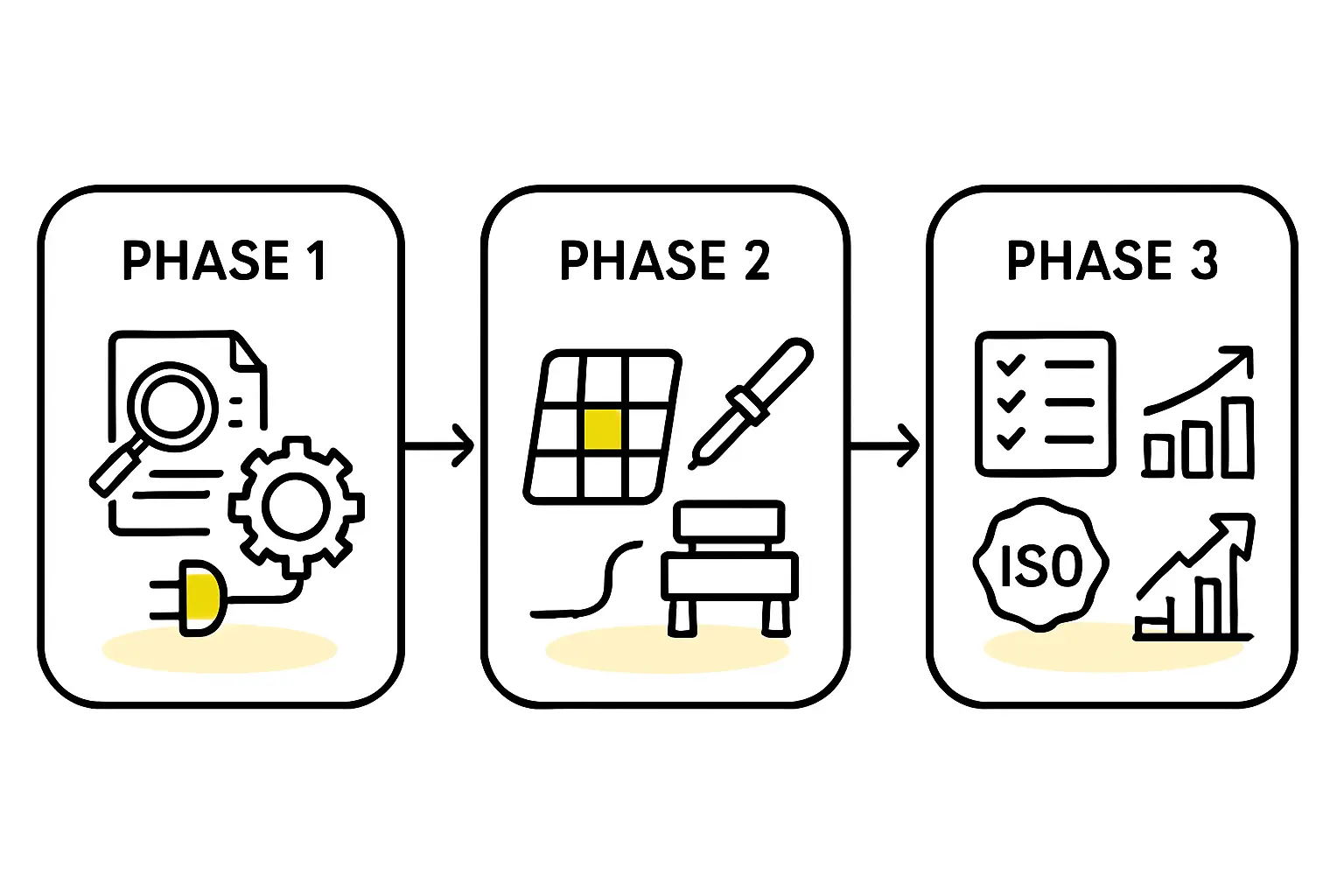

Bridging the Skill Gap: From Potential to Proficiency

The central challenge for any investor is transforming the available labor pool into a highly skilled manufacturing team. While general aptitude is high, direct experience with the Solar Panel Manufacturing Process: A Step-by-Step Overview will be virtually nonexistent. A structured, intensive training program therefore becomes the most critical investment in human capital.

A successful program focuses on two key areas:

-

Procedural Excellence: Training employees on the specific tasks at each stage of the assembly line—from cell stringing and bussing to lamination and framing. This involves hands-on practice until actions are precise and repeatable.

-

Quality Mindset: Instilling a deep understanding of why each step is critical. For example, an operator who understands how a microcrack can lead to module failure is more likely to handle materials with care. This focus on quality is essential for achieving the Essential Certifications for Solar Panel Manufacturing, such as those from the IEC, which are non-negotiable for selling modules on the international market.

Experienced engineers from the equipment supplier or a technical partner typically lead the training. A common approach involves a ‘train the trainer’ model, where a core group of local supervisors and technicians receives intensive instruction and then leads the training for the broader team of operators. This builds local leadership capacity and ensures knowledge is retained within the company.

Building and Managing Your Local Team

Assembling the right team structure is crucial for operational efficiency. A typical small- to medium-sized factory team includes operators for each machine, quality control inspectors at critical points, maintenance technicians, and shift supervisors.

The role of the Quality Control (QC) team cannot be overstated. This team ensures every module meets international standards. They perform visual inspections, run electroluminescence (EL) tests to detect hidden defects, and conduct ‘sun simulator’ tests to verify power output. Their training must be exceptionally rigorous.

Experience from past turnkey projects in similar markets shows that local teams, when given proper training and clear standards, are highly dedicated and precise. Investors, like Mr. Goyal from a project in India, often remark on the rapid learning curve and commitment to quality shown by newly trained staff. This success underscores that process and structure are more important than prior experience.

FAQ: Key Questions on Labor for a Solar Factory in Eswatini

How many employees are needed for a small-scale factory?

For a 20 MW to 50 MW semi-automated production line, a single shift typically requires 25 to 30 people. This includes assembly line operators, quality control staff, maintenance technicians, and a shift supervisor.

What is the typical duration of a training program?

An intensive, hands-on program for a new team generally lasts four to six weeks. This is usually sufficient to bring operators to a level of proficiency where they can produce modules that meet quality standards under supervision. Ongoing training is also recommended.

Are there language barriers to consider?

No. English is an official language in Eswatini and is used throughout the education system and in professional settings. This simplifies the training process and communication with international management and technical partners.

How does automation affect labor requirements?

Higher levels of automation, such as with fully automated stringers, can reduce the number of operators needed on the line. However, it also requires more highly skilled technicians who can maintain and troubleshoot complex machinery. The optimal level of automation depends on the investor’s business model, balancing capital investment against long-term labor costs.

A Strategic Approach to Human Capital in Eswatini

Eswatini offers a compelling opportunity for solar module manufacturing, anchored by its young, literate, and available workforce. The competitive wage structure provides a significant cost advantage, but realizing this potential depends entirely on a strategic and deliberate investment in skills development.

Success is not about finding pre-existing solar experts but about implementing a world-class training system to create them. By establishing robust processes for training, quality control, and team management, an investor can build a highly capable local workforce that produces solar modules meeting the highest international standards. This methodical approach to human capital is the key to transforming Eswatini’s demographic potential into a productive and profitable manufacturing reality.