Disclaimer: This case study represents a composite example derived from real-world

consulting work by J.v.G. Technology GmbH in solar module production and factory optimization. All data points are realistic but simplified for clarity and educational purposes.

For many entrepreneurs looking at Africa, the continent’s potential is undeniable, yet significant challenges persist. In Ethiopia, for instance, over 60% of the population still lacks access to a reliable electricity grid—a reality that hampers progress, particularly in the agricultural sector, the backbone of the nation’s economy.

The conventional approach of importing standard solar panels often fails to meet the specific, rugged needs of rural applications. A more strategic solution is to build specialized manufacturing capacity within the country itself, a venture that is more accessible than many assume.

This article outlines a turnkey investment model for a solar module production line in Ethiopia, designed specifically for the agricultural value chain. It explores how a targeted factory, guided by proven engineering principles, can become a powerful engine for both commercial success and national development.

The Untapped Synergy: Solar Power and Ethiopian Agriculture

Ethiopia’s economy is fundamentally agrarian. The sector accounts for nearly 40% of the GDP and employs roughly 75% of the workforce, yet its productivity is severely constrained by a critical dependency on rain-fed farming and a lack of energy for post-harvest activities.

This disparity reveals a clear opportunity:

Energy Deficit: Over 50 million people are without electricity, limiting irrigation, cooling, and processing capabilities.

Irrigation Potential: The country has an estimated 3.7 million hectares of irrigable land, yet less than 5% is currently irrigated, primarily due to the high cost or unavailability of power for water pumps.

Abundant Solar Resource: With an average solar irradiation of 4.5 to 6.5 kWh/m²/day, Ethiopia is one of the most solar-rich countries in the world.

This juxtaposition of agricultural need and solar abundance makes for a compelling business case. Locally produced solar modules can directly address the energy gap where it matters most, helping farmers move from subsistence to commercial productivity.

Beyond Standard Modules: Why a Specialized Factory Makes Sense

Not all solar modules are created equal. A panel designed for a European rooftop grid-tied system has different characteristics from one needed to power a water pump in a remote Ethiopian valley. A specialized factory focuses on producing modules optimized for the local market’s primary needs.

This tailored approach centers on two key agricultural applications:

-

Solar Water Pumping and Irrigation: Standard modules may not be optimized for the specific voltage and current requirements of efficient water pumps. A specialized production line can manufacture modules designed for maximum durability in harsh, dusty environments and configured to power irrigation systems directly, without complex electronics.

-

Agri-Processing and Cold Storage: Post-harvest losses in Ethiopia are significant, often due to a lack of power for milling, drying, and cooling. A reliable supply of locally made solar modules can power small-scale processing units and cold storage facilities for cooperatives, preserving crop value and enabling access to more lucrative markets.

By focusing production on these specific needs, an investor can build a business that solves a tangible, high-value problem rather than competing with global mass producers of generic panels.

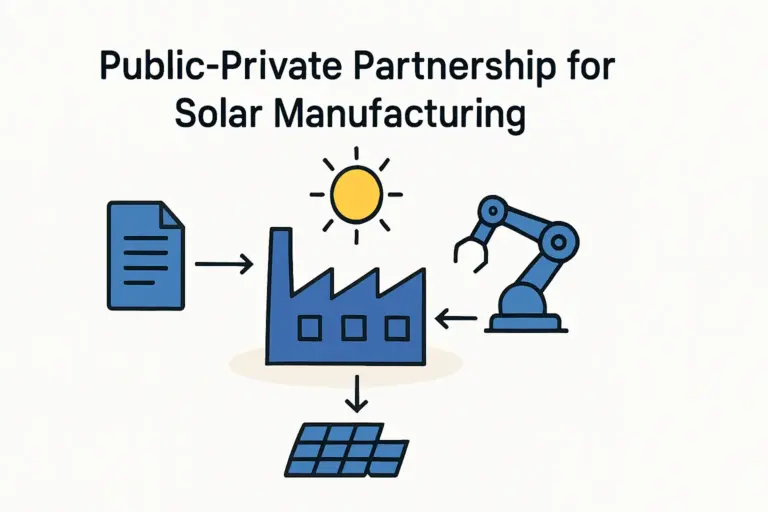

The German Engineering Approach: A Blueprint for Success

Establishing a manufacturing facility in a new market requires a precise, proven methodology. Drawing on decades of experience setting up solar factories globally, German engineering firms like an established European industrial solutions provider have refined a turnkey model that de-risks the investment process. This approach rests on several core principles.

Market-Driven Production

The first step is not to select machines but to deeply understand the end-user’s needs. The demands of the local agricultural market determine the factory’s output—the type, size, and electrical characteristics of the modules. The entire solar panel manufacturing process is then designed backward from that specific goal, ensuring every product has a ready application.

Optimized Technology Selection

A specialized factory doesn’t necessarily need the fastest or newest machines on the market. Instead, it requires robust, reliable, and flexible equipment that can efficiently produce the required module specifications. The focus is on selecting a balanced line that minimizes capital expenditure while maximizing output quality and reliability for its intended purpose. This strategic selection is critical when calculating the overall cost to start a solar panel manufacturing plant.

Project-Specific Financial Modeling

Financing for such a project must be as specialized as the factory itself. A turnkey plan includes comprehensive financial models that account for local variables, from supply chain logistics to potential government incentives. These models help secure funding by demonstrating a clear path to profitability based on realistic market assumptions, not generic industry data.

A Case Study in Viability: The Agricultural Value Chain

To understand the impact, consider the journey of a small farming cooperative.

Before local solar production, the cooperative relied on seasonal rains, yielding one primary harvest per year. Diesel pumps were too expensive to run consistently. With the availability of affordable, locally manufactured solar modules designed for irrigation, the cooperative installs solar water pumps.

The results are transformative:

-

Increased Yields: Irrigation allows for two or three harvests per year.

-

Crop Diversification: The cooperative can now grow higher-value fruits and vegetables.

-

Value Addition: The same solar energy infrastructure can power small-scale milling and cooling facilities, reducing spoilage and increasing the market value of their produce.

This creates a virtuous cycle. The factory has a stable customer base, the farmers increase their income, and the nation improves its food security.

Key Components of the Turnkey Investment Plan

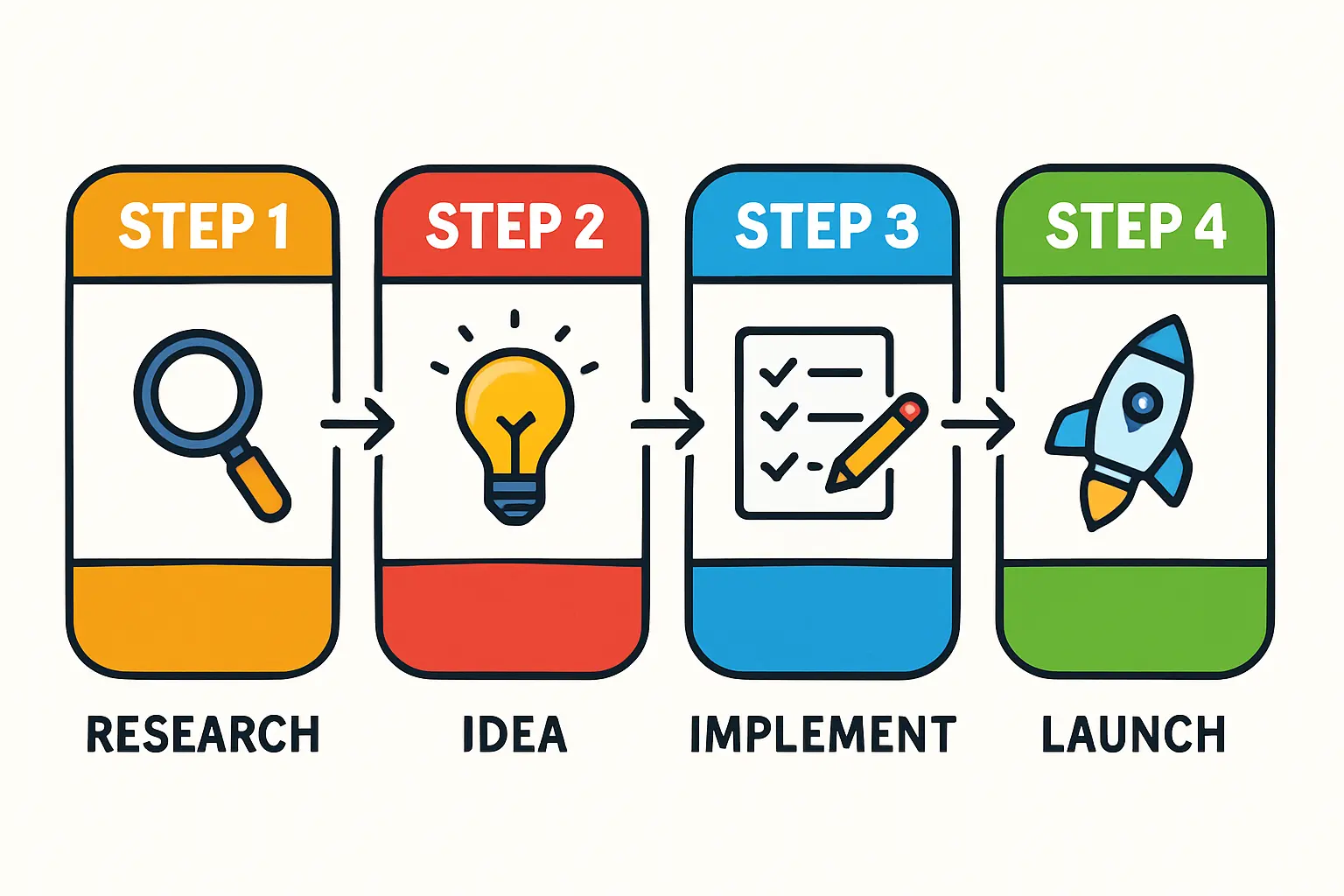

A structured, phased approach is essential for a successful implementation. A turnkey plan managed by an experienced engineering partner typically includes the following stages.

Phase 1: Feasibility and Market Analysis

The initial phase involves a detailed assessment of the local market, regulatory landscape, supply chain options, and site selection. The goal is to validate the business case with on-the-ground data.

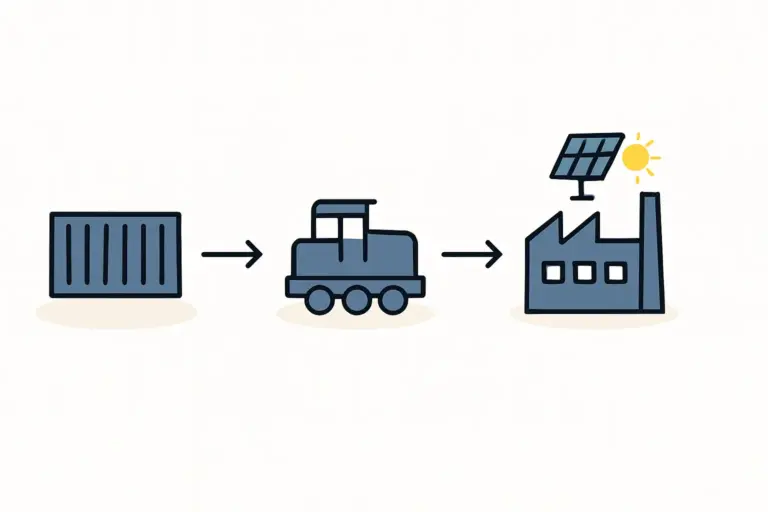

Phase 2: Factory Design and Equipment Sourcing

Based on the feasibility study, engineers design the optimal factory layout and specify the complete solar panel production line. This stage includes sourcing all machinery—from cell stringers to laminators and testers—and ensuring everything is integrated for seamless operation.

Phase 3: Implementation and Training

This phase covers the complete project management of the factory’s construction, machine installation, and commissioning. A critical component is the comprehensive training of the local workforce, transferring the skills needed to operate and maintain the plant independently.

Phase 4: Operations and Market Integration

Once the factory is operational, the turnkey partner supports process optimization, quality control, and achieving necessary product certifications. They also offer guidance on establishing effective distribution channels to reach agricultural end-users.

Frequently Asked Questions (FAQ)

What is the typical investment range for such a factory?

While costs are project-specific, initial investments for a specialized 20–50 MW line are often significantly more accessible than those for large-scale, gigawatt-level factories. A detailed business plan is necessary to determine the exact figure.

How long does it take to become operational?

With a structured turnkey approach, a factory can move from the initial planning stages to full production in approximately 12 to 18 months, depending on local factors.

Do I need a technical background in solar energy?

No. The purpose of a turnkey investment plan is to provide all the necessary engineering, process, and business guidance. The ideal investor brings business acumen and local market knowledge, while the engineering partner provides the technical expertise.

Why produce locally instead of importing cheaper modules?

Local production offers several strategic advantages: it creates local jobs, secures the national supply chain against global disruptions, allows for customization to local needs, avoids import duties and logistical challenges, and helps build a sovereign industrial base.

What kind of government support is available in Ethiopia?

The Ethiopian government has shown a strong commitment to electrification and industrialization through initiatives like the National Electrification Program 2.0. Potential support can include tax incentives, land access, and streamlined licensing, though a detailed consultation with local authorities is always essential.

Conclusion: Building a Sustainable Future, One Module at a Time

Establishing a specialized solar module factory in Ethiopia is more than an industrial project; it is a strategic investment in the nation’s agricultural resilience and economic sovereignty.

By focusing on the real-world needs of farmers and agri-businesses, an investor can build a profitable enterprise that delivers profound social and economic impact. This targeted approach transforms a complex industrial undertaking into a manageable, high-impact business venture.

With the right engineering partner and a clear, market-driven plan, entrepreneurs can play a pivotal role in powering Ethiopia’s agricultural future.

Download the Ethiopia Solar Agriculture Case Study (PDF)

Author: This case study was prepared by the

turnkey solar module production specialists at J.V.G. Technology GmbH

It is based on real data and consulting experience from J.v.G. projects

worldwide, including installations ranging from 20 MW to 500 MW capacity.