Investors exploring opportunities in the Pacific often see Fiji as a strategic hub—a stable economy with favorable investment policies and a gateway to regional markets. While correct, this view is from 30,000 feet.

The success of a venture like a solar module factory is determined on the ground, where practical realities like land acquisition, utility stability, and infrastructure dictate operational efficiency and long-term viability. Overlooking these foundational elements is a common and costly mistake.

This guide offers a structured overview of the critical factors for selecting an industrial site in Fiji. It focuses on the unique aspects of the Fijian context—from its land tenure systems to utility reliability and logistical considerations—to help entrepreneurs make informed decisions from the outset.

Understanding Fiji’s Industrial Landscape for Manufacturing

Fiji’s position as a regional economic leader is well-established. The Asian Development Bank forecasts continued economic growth, and the government actively encourages foreign investment, particularly in sectors like renewable energy. This climate is positive for establishing a solar module production facility.

The primary challenge for any new industrial investor, however, is bridging the gap between this favorable national climate and the on-the-ground requirements of a specific location. A successful site selection process requires a detailed analysis of three core components: land, utilities, and logistics.

Evaluating Industrial Land Options: Cost and Tenure

A factory’s physical location is the most important long-term decision. In Fiji, this means understanding not just the cost of land but also its legal structure—a critical distinction.

Freehold vs. Leasehold: A Strategic Decision

Fijian land is broadly categorized into two types:

-

Freehold Land: Representing less than 10% of Fiji’s total land, freehold properties can be bought and sold outright, offering the most straightforward form of ownership. However, their scarcity, particularly for prime industrial plots, means they command a premium and are in short supply.

-

iTaukei (Native) Land: Comprising nearly 90% of Fiji’s landmass, iTaukei land is communally owned and cannot be sold. It is managed by the iTaukei Land Trust Board (TLTB), which grants long-term leases for commercial, industrial, and agricultural purposes. For industrial investors, securing a lease on iTaukei land is the most common and practical pathway. The process is well-defined and offers strong legal security for the duration of the lease, which can extend up to 99 years.

Comparing Industrial Land Costs

While freehold land is purchased, leasehold land involves annual rental payments. In key industrial zones near Suva, Nadi, and Lautoka, annual lease rates for undeveloped industrial land typically range from FJD $15 to $40 per square meter.

For a typical 20–50 MW solar module factory requiring a 3,000–5,000 square meter building, the annual land lease cost can be estimated from these figures. These numbers represent raw land only; site development, construction, and utility connection costs are separate considerations. A successful solar factory layout must account for these site-specific constraints from the beginning.

Assessing Utility Stability: A Critical Factor for Production

Modern solar module manufacturing is a sophisticated process, one that relies on consistent, high-quality utility services. Experience from J.v.G. turnkey projects shows that underestimating the importance of stable utilities frequently leads to production downtime and quality control issues.

Electricity Grid Reliability

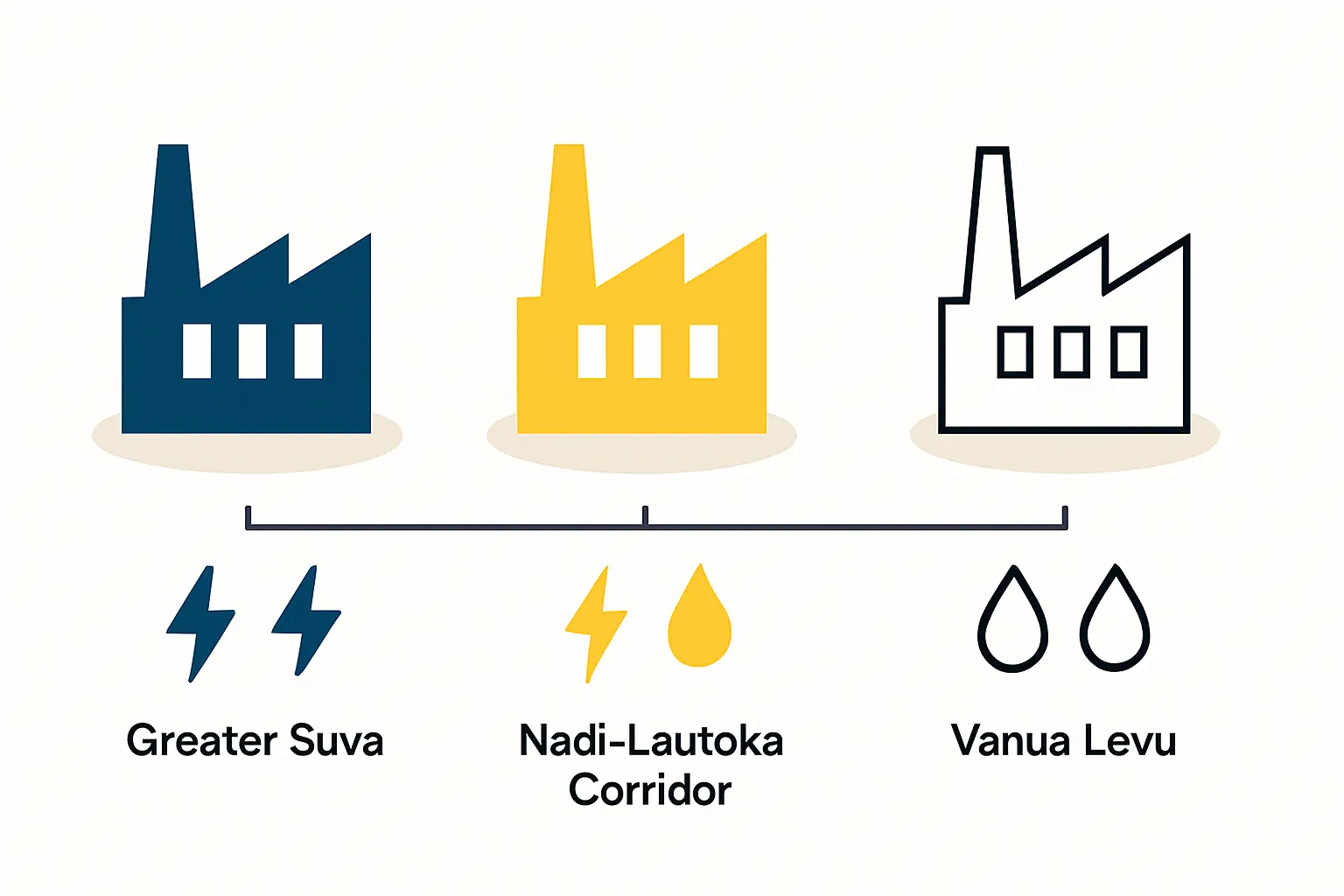

Electrical power in Fiji is managed by Energy Fiji Limited (EFL). The main island of Viti Levu, where the major industrial centers are located, relies on a combination of hydropower and diesel generation. While EFL is actively working to increase its renewable energy capacity, the grid can be susceptible to intermittent outages, particularly during periods of high demand or severe weather.

For a solar manufacturing line, where sensitive equipment like laminators and stringers requires uninterrupted power, this poses a significant operational risk. Investing in a robust backup power system is therefore not an option but a necessity. This typically involves a combination of diesel generators and, increasingly, battery energy storage systems (BESS) to ensure a seamless transition and protect equipment from power fluctuations.

Water Access and Quality

The Water Authority of Fiji (WAF) manages the nation’s water supply. Although generally reliable in urban centers, the supply can face interruptions during extended dry seasons or periods of infrastructure maintenance.

A solar module factory needs a consistent supply of clean water for processes like glass washing and equipment cooling. To mitigate the risk of supply disruptions, standard industry practice is to install on-site water storage tanks. A correctly sized tank can provide a one- to two-day buffer, ensuring production continues uninterrupted during short-term municipal outages. These infrastructure needs are a core component of the initial solar factory investment cost.

Logistics and Infrastructure: Connecting Your Factory to the Market

A factory’s efficiency is directly tied to its logistical connections. When evaluating a site in Fiji, proximity to key infrastructure is paramount. A location should be chosen for its access to:

-

Seaports: The primary ports of Suva and Lautoka are the main entry and exit points for all goods. Easy access to these ports is crucial for importing raw materials like solar cells, glass, and aluminum frames, as well as for exporting finished modules to regional markets.

-

Road Networks: Reliable road access is essential for moving goods to and from the port and for employee commutes. The condition of local roads and potential for congestion should be assessed.

-

Labor Pool: The site should be reasonably accessible for the required workforce, from technicians and operators to administrative staff.

Frequently Asked Questions (FAQ) for Site Selection in Fiji

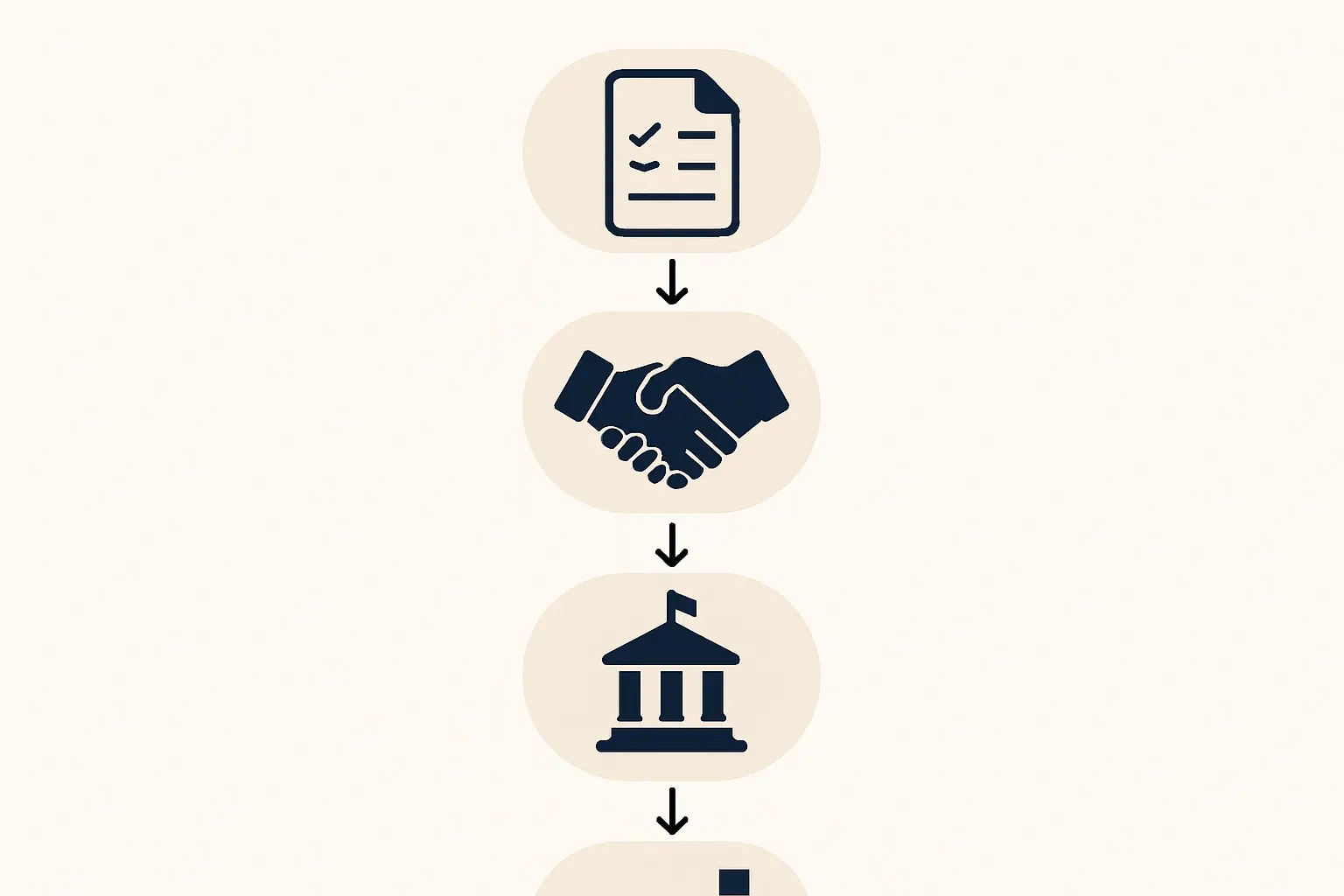

How long does it take to secure a lease on iTaukei land?

The process for securing a lease through the TLTB is structured and transparent but requires patience. Investors should plan on a timeline of 6 to 12 months, which covers application, due diligence, and final approval. Starting this process early is critical.

What are the typical dimensions for a small-scale solar factory building?

A manufacturing line with an annual capacity of 20–50 MW generally requires a building with a floor area of 3,000 to 5,000 square meters. A key requirement is a minimum internal ceiling height of 6 meters to accommodate machinery and material handling equipment.

Are there specific industrial zones recommended for new investors?

For new entrants, focusing on established industrial zones near Suva, Nadi, and Lautoka is the most prudent approach. These areas offer the best combination of existing infrastructure, utility access, logistical connections, and a skilled labor pool.

What level of backup power is typically required?

The capacity of a backup power system depends on the specific electricity demands of the production machinery. As a baseline, J.v.G.’s feasibility studies recommend a system capable of powering all critical equipment for at least 4-8 hours. This ensures that a full production cycle can be completed during a grid outage, preventing material waste.

Choosing the right site is the foundational step in building a successful manufacturing operation in Fiji. It requires a detailed analysis that goes beyond simple cost comparisons to include the nuances of land tenure, the reality of utility infrastructure, and the practicalities of logistics. By addressing these factors diligently during the planning phase, investors can build a solid foundation for long-term success.

For a deeper understanding of the entire process, consider our guide on how to start a solar factory.