An entrepreneur can have a comprehensive business plan, select state-of-the-art machinery, and assemble a skilled team. But the entire operation can be brought to a standstill by a single container of raw materials delayed at a port or stranded by impassable rural roads. For an archipelago nation like Fiji, understanding the nuances of logistics is not a secondary detail; it is fundamental to a project’s success.

This guide offers a foundational overview of Fiji’s supply chain, written for business professionals considering the importation of raw materials for solar module manufacturing. It examines the country’s key port infrastructure, customs procedures, and the unique challenges of inland and inter-island transportation.

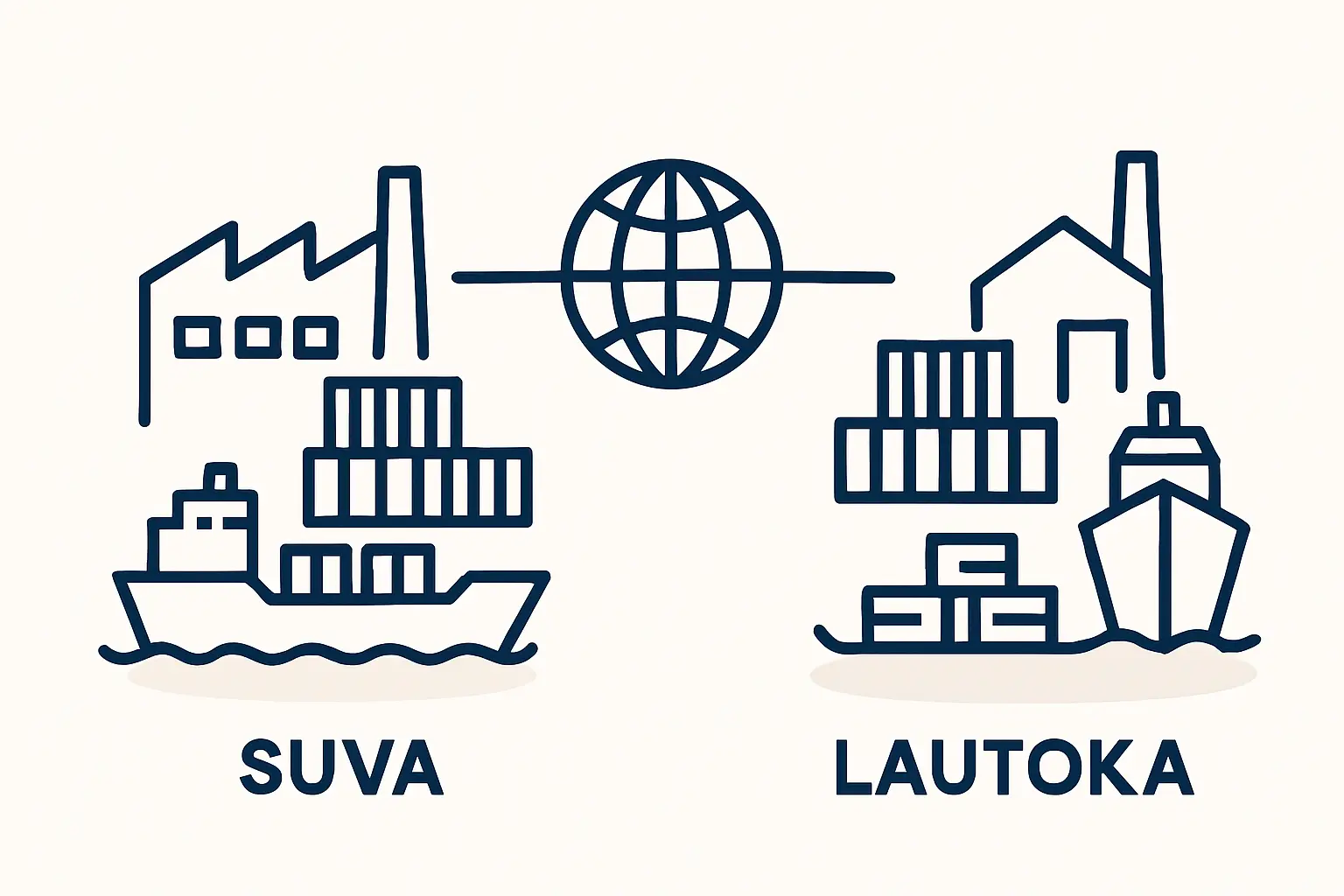

Fiji’s Maritime Gateways: The Ports of Suva and Lautoka

Nearly all raw materials for a solar factory will enter Fiji by sea. The country’s two main ports, both located on the largest island of Viti Levu, are the primary channels for international trade.

The Port of Suva

Located in the capital city, the Port of Suva is Fiji’s largest and busiest maritime facility. Managed by Fiji Ports Corporation Limited (FPCL), it handles approximately 360,000 twenty-foot equivalent units (TEUs) of cargo annually. The port is equipped to handle a diverse range of cargo, including containerized goods, bulk materials, and roll-on/roll-off (RoRo) vessels. For a solar manufacturing venture, Suva is the most likely port of entry for shipments of solar cells, EVA film, backsheets, and aluminum frames.

The Port of Lautoka

Situated on the western side of Viti Levu, the Port of Lautoka is Fiji’s second-largest port, handling around 80,000 TEUs per year. While it facilitates container traffic, its primary function has historically been geared toward exports for the region’s sugar and timber industries. For a factory in Fiji’s Western Division, Lautoka is a viable and important logistical hub, though it handles a lower volume of container traffic compared to Suva.

Understanding the capacity and specialization of each port is a critical first step in planning your import strategy and selecting a final factory building and location.

The Customs Clearance Process: Timelines and Potential Hurdles

Once a shipment arrives, it must clear customs, a process managed by the Fiji Revenue and Customs Service (FRCS). A well-prepared shipment with accurate and complete documentation can typically be cleared within 3 to 7 business days.

However, new importers should be aware of common factors that can lead to significant delays:

-

Documentation Discrepancies: Inaccurate invoices, bills of lading, or certificates of origin are the most frequent cause of delays.

-

Customs Inspections: FRCS may flag shipments for physical inspection, which can add several days or even weeks to the clearance timeline.

-

Valuation Queries: Disagreements over the declared value of goods can halt the process until they are resolved.

These potential delays must be factored into production planning. A two-week hold-up at customs can directly impact manufacturing schedules and delivery commitments unless a sufficient buffer stock of essential raw materials for solar panel manufacturing is maintained.

Beyond the Port: Inter-Island and Inland Transportation

Fiji is an archipelago of over 330 islands. While a factory will likely be located on one of the two largest islands, Viti Levu or Vanua Levu, distributing finished solar modules or sourcing local materials may require navigating a complex transport network.

Inter-Island Shipping

Transport between islands relies on a network of commercial ferries and barges from operators like Patterson Brothers Shipping and Goundar Shipping. While this transport is essential, it’s also subject to several variables:

-

Weather Dependency: During the cyclone season (typically November to April), shipping schedules can be severely disrupted, causing unpredictable delays.

-

Capacity and Frequency: Service to smaller, more remote islands may be less frequent, requiring careful logistical coordination.

Inland Road Network

On the main island of Viti Levu, the Queens Road and Kings Road form a coastal ring that connects the key economic centers of Suva, Nadi, and Lautoka. These primary roads are generally well-maintained. However, transporting goods to inland or rural sites can be challenging, especially during the rainy season when unpaved roads may become impassable.

For a solar enterprise, this means the ‘last mile’ of delivery—whether for raw materials to the factory or finished panels to a project site—can be the most difficult part of the journey.

Key Logistical Considerations for a Solar Factory

A successful solar manufacturing operation in Fiji demands a supply chain strategy built on foresight and resilience.

-

Buffer Stock Management: Given the potential for customs and shipping delays, maintaining sufficient inventory of critical components is not just advisable—it is essential for uninterrupted production.

-

Supplier Reliability: The entire solar panel manufacturing process depends on a steady flow of inputs. Working with freight forwarders and suppliers who have experience in the Oceania region can mitigate documentation errors and transit issues.

-

Strategic Location: The factory’s proximity to a major port can significantly reduce inland transportation costs and complexities. A location near Suva or Lautoka minimizes exposure to road transport risks.

-

Contingency Planning: A robust business plan must account for logistical disruptions, including budgeting for potential demurrage charges at the port and having alternative transport options where feasible. Based on experience from J.v.G. turnkey projects in developing economies, a thorough logistics analysis is a core component of the initial feasibility study.

Frequently Asked Questions

What are the primary ports for importing into Fiji?

The two primary commercial ports are the Port of Suva, the nation’s largest, and the Port of Lautoka. Both are on the main island of Viti Levu and handle containerized and bulk cargo.

How long does customs clearance typically take in Fiji?

For shipments with correct and complete documentation, the standard customs clearance time is 3 to 7 business days. Delays are common if there are documentation errors or if the shipment is selected for a physical inspection.

What is the biggest logistical challenge for operating in Fiji?

The most significant challenge is the variability inherent in an island nation. This includes potential delays from international shipping, customs procedures, and weather-related disruptions that affect inter-island transport, especially during cyclone season.

Are there special considerations for importing solar panel components?

While no restrictions specifically target solar components, they are subject to the same customs duties, taxes, and inspection protocols as other imported industrial goods. Ensuring correct tariff classifications (HS codes) on documentation is critical to avoid valuation disputes and delays.

Conclusion: Integrating Logistics into Your Business Plan

For any entrepreneur looking to establish a solar module factory in Fiji, the supply chain is not merely an operational function—it is a strategic cornerstone. The journey of raw materials from an overseas supplier to your factory floor involves multiple stages, each with its own set of challenges.

By understanding the roles of Fiji’s ports, anticipating customs procedures, and planning for the realities of inter-island and inland transport, you can build a resilient operation capable of navigating the region’s logistical complexities. This foundational work is essential for transforming a promising venture into a sustainable and successful enterprise.