An entrepreneur on a remote Fijian island resort observes a stark contradiction. Pristine nature, clear waters, and abundant sunshine are set against the persistent hum of a diesel generator, the faint smell of exhaust, and the reality of fuel being barged in at great expense. This scene is not unique; it represents a fundamental economic and logistical challenge across Fiji’s 333 islands—and a substantial business opportunity.

For a prospective investor, the real potential lies not in simply importing standard solar panels, but in establishing local manufacturing to meet the specific, unmet needs of Fiji’s key economic sectors. This analysis outlines the business case for a domestic solar module factory focused on the nation’s tourism, marine, and rural electrification markets.

The Unique Energy Landscape of an Island Nation

Fiji’s geography and island-based economy present a distinct set of energy demands. With a population of approximately 900,000 spread across 110 inhabited islands, centralized power distribution is often impractical and expensive. The result is a heavy reliance on imported diesel fuel, which exposes the economy to volatile global energy prices and significant logistical hurdles.

The Fijian government has recognized this vulnerability, setting an ambitious goal of achieving 100% renewable energy by 2030, supported by initiatives like the Fiji Rural Electrification Fund. This national policy creates a favorable environment for ventures that can help accelerate the transition. A local solar module manufacturing facility aligns directly with this objective, positioning an investor to meet a growing, government-backed demand.

Analyzing Key Domestic Markets for Solar Modules

While large-scale solar farms are one aspect of renewable energy, Fiji’s most immediate and commercially viable opportunities are in specialized, off-grid applications. A local manufacturer would be uniquely positioned to design and supply products for these niche markets.

The Tourism Sector: Powering Paradise Sustainably

The tourism industry, which traditionally accounts for 35–40% of Fiji’s GDP, is a primary energy consumer. Remote island resorts depend almost exclusively on diesel generators for their electricity.

The Challenge: Beyond the high cost and supply chain disruptions, diesel detracts from the ‘eco-paradise’ experience that attracts tourists. The noise and pollution from generators are at odds with the marketing message of a pristine natural environment.

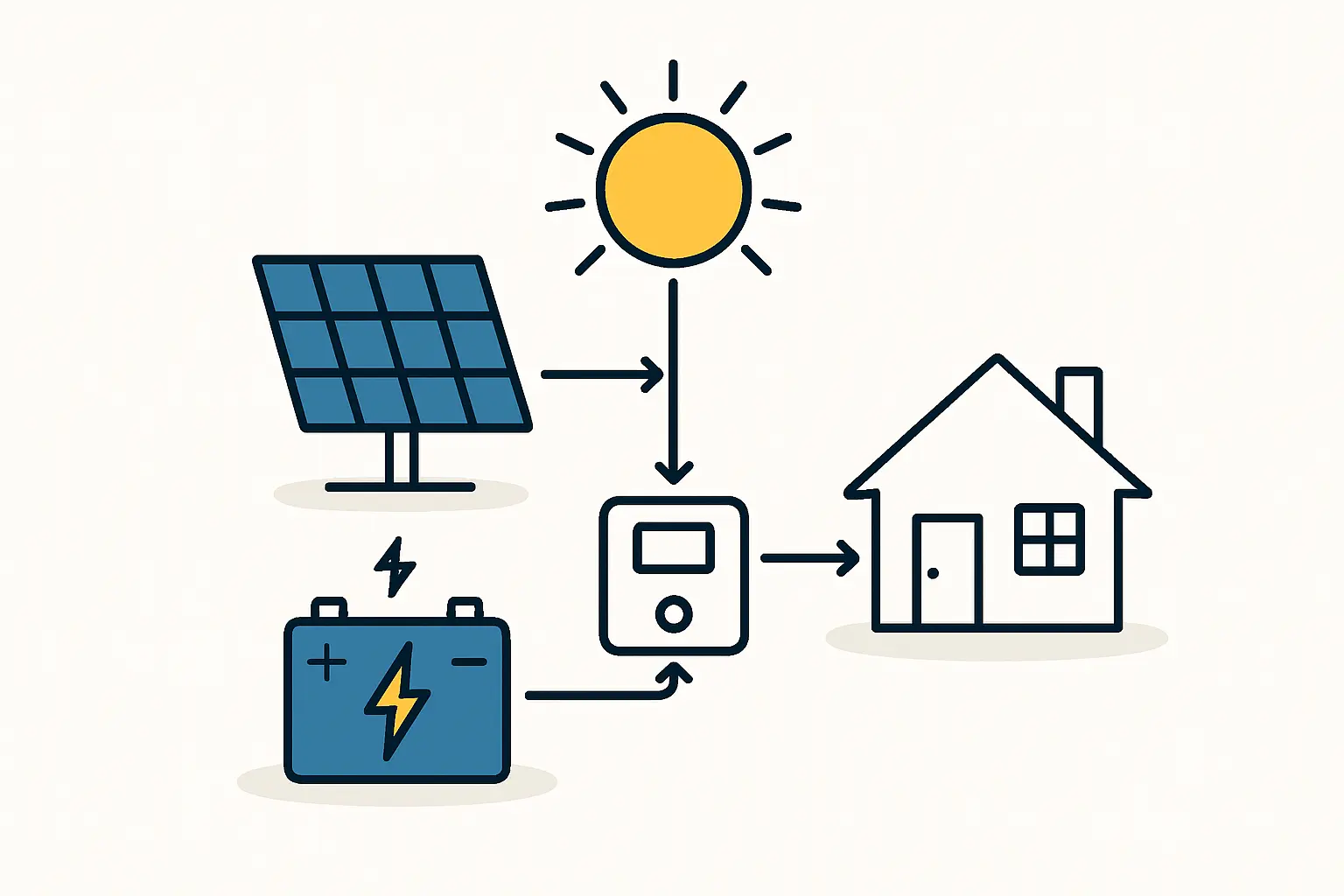

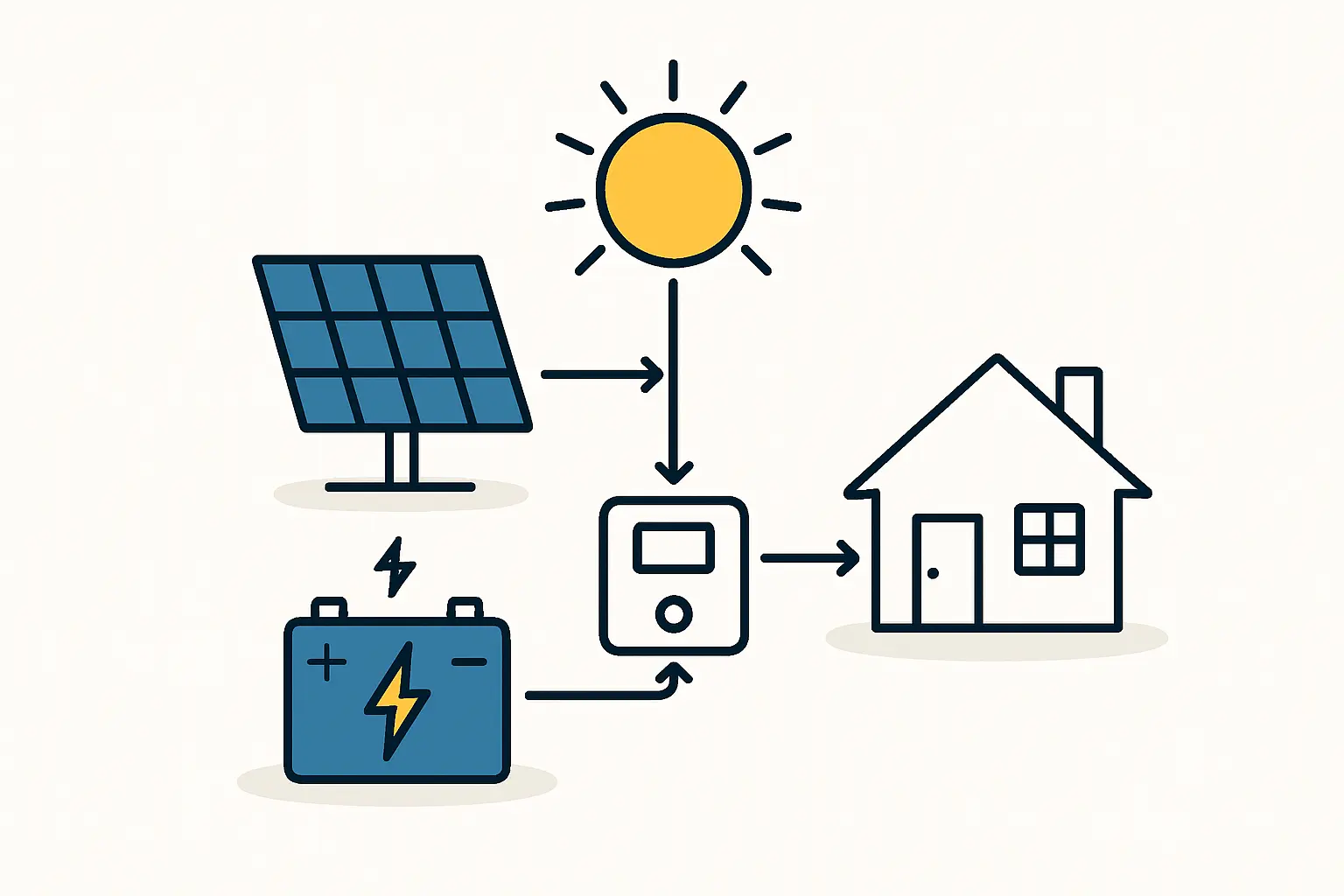

The Solar Solution: Photovoltaic systems offer silent, clean, and reliable power, significantly reducing long-term operational expenses. For resorts, adopting solar is both a sound financial decision and a powerful marketing tool to attract the growing number of environmentally conscious travelers.

Product Requirements: Installations in this sector demand high-efficiency, durable modules capable of withstanding tropical conditions, including high humidity and strong wind loads. A local producer can offer customized solutions and responsive maintenance support that international suppliers cannot.

The Marine Sector: Energy on the Open Water

Fiji’s maritime industry—comprising ferries, fishing vessels, private yachts, and water taxis—is another significant, yet often overlooked, market. These vessels require a constant source of auxiliary power for navigation equipment, lighting, communication systems, and refrigeration.

The Challenge: Powering auxiliary systems by running a vessel’s main engine or a separate diesel generator is highly inefficient and costly.

The Solar Solution: Mounting solar panels on a vessel’s roof or deck provides a continuous, independent power source that reduces fuel consumption and engine wear.

Product Requirements: This application demands highly specialized modules with non-negotiable resistance to salt mist and corrosion. Panels must pass stringent industry tests and often need to be smaller, more robust, or even semi-flexible to fit the limited space on boats. A local factory could specialize in producing such marine-grade panels, a niche where large-scale commodity manufacturers rarely compete.

Rural Electrification: Connecting Remote Communities

Beyond the commercial sectors, access to energy is a critical social and economic need for remote villages. Many of these communities remain off-grid, limiting opportunities for education, healthcare, and local enterprise.

The Challenge: Extending the national grid to remote islands is often economically unfeasible.

The Solar Solution: Small, stand-alone solar home systems or village-level microgrids offer a scalable and affordable path to electrification. These systems can power lights, charge phones, and run small appliances, dramatically improving quality of life.

Product Requirements: This market requires cost-effective, durable, and easy-to-install solar modules. A local manufacturer could produce panels optimized for this purpose and partner with government programs and NGOs to facilitate deployment.

The Strategic Advantage of Local Production in Fiji

A domestic manufacturing plant offers several decisive advantages over relying on imports from large Asian factories:

-

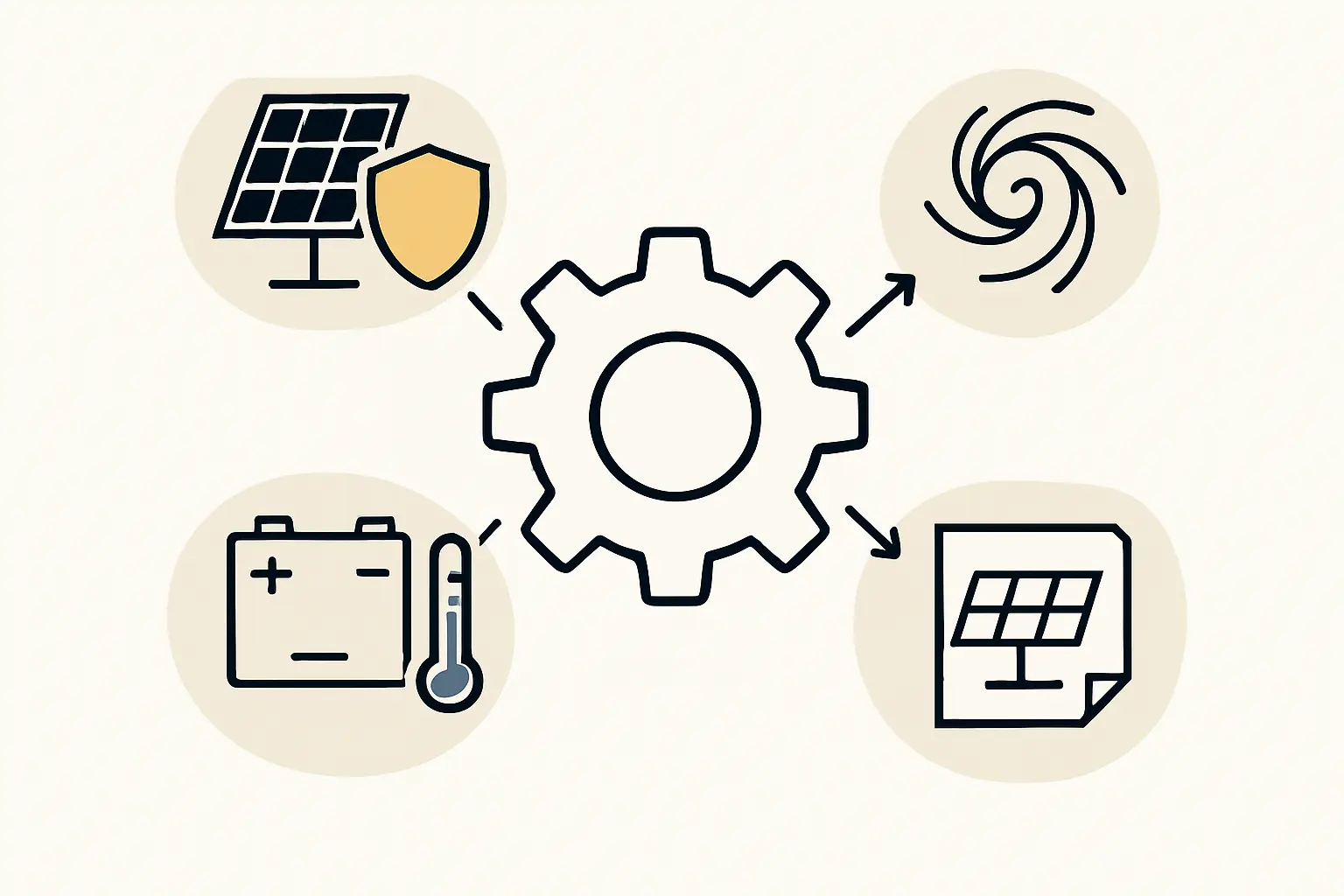

Tailored Products: A local plant can produce modules specifically designed for a tropical marine environment (e.g., with enhanced corrosion resistance and cyclone-rated frames), creating a product perfectly suited to local conditions.

-

Reduced Logistics and Lead Times: Eliminating international shipping reduces costs, complexity, and delivery times, enabling faster project completion for resorts and marine installers.

-

Local Support and Service: A local presence ensures accessible technical support, warranty fulfillment, and replacement parts—a critical factor for building long-term customer trust.

-

Alignment with National Goals: A factory contributes to the ‘Fijian Made’ brand, creates skilled jobs, and directly supports the nation’s renewable energy independence targets.

Key Considerations for a Fijian Solar Manufacturing Plant

Establishing a solar factory requires careful planning. The initial investment requirements for a small-to-medium-scale facility (e.g., 20–50 MW annual capacity) must be carefully evaluated within a comprehensive business plan. A solid plan will detail the target product mix—from robust resort panels to specialized marine modules.

One efficient pathway is to utilize a turnkey production line, which provides all the necessary machinery, process knowledge, and training from a single, experienced partner. This approach significantly de-risks the technical aspects of the venture. Furthermore, securing the right product certifications, such as IEC 61701 for salt-mist resistance, is essential for credibility and market access, particularly in the marine sector.

Frequently Asked Questions (FAQ)

What factory size is viable for a market like Fiji?

Based on experience from J.v.G. turnkey projects in similar markets, an initial capacity of 20–50 MW per year is often a viable starting point. This allows a manufacturer to serve niche local markets effectively without requiring the massive scale needed to compete in the global commodity market.

Are special certifications necessary for panels in a marine environment?

Yes. The most critical is IEC 61701, which tests a module’s resistance to salt mist corrosion. Panels without this certification are likely to degrade quickly in a coastal or marine setting. With local production, a manufacturer can ensure all relevant certifications are secured.

How can a local Fijian factory compete with large-scale imports?

A local factory competes on specialization, not on price per watt for standard modules. By focusing on marine-grade panels, custom sizes, and modules with enhanced cyclone resistance, it serves needs that large importers often ignore. It also competes on faster delivery, local support, and alignment with national interests.

What is the typical timeline to make a solar factory operational?

With a structured approach and a turnkey partner, a small-to-medium-scale solar module line can become fully operational in under a year—from initial planning to producing the first certified panel.