Imagine an investor planning a solar module factory in Europe. Their initial focus is naturally on production technology, machine throughput, and capital investment. But when they review the first major public tender documents, a surprising requirement appears: a mandatory low carbon footprint score and a preference for locally sourced products.

Suddenly, the project is no longer just about manufacturing efficiency; it is about market access. This scenario illustrates a critical reality for any new entrant into the European solar market: regional certifications can be as important as the product itself.

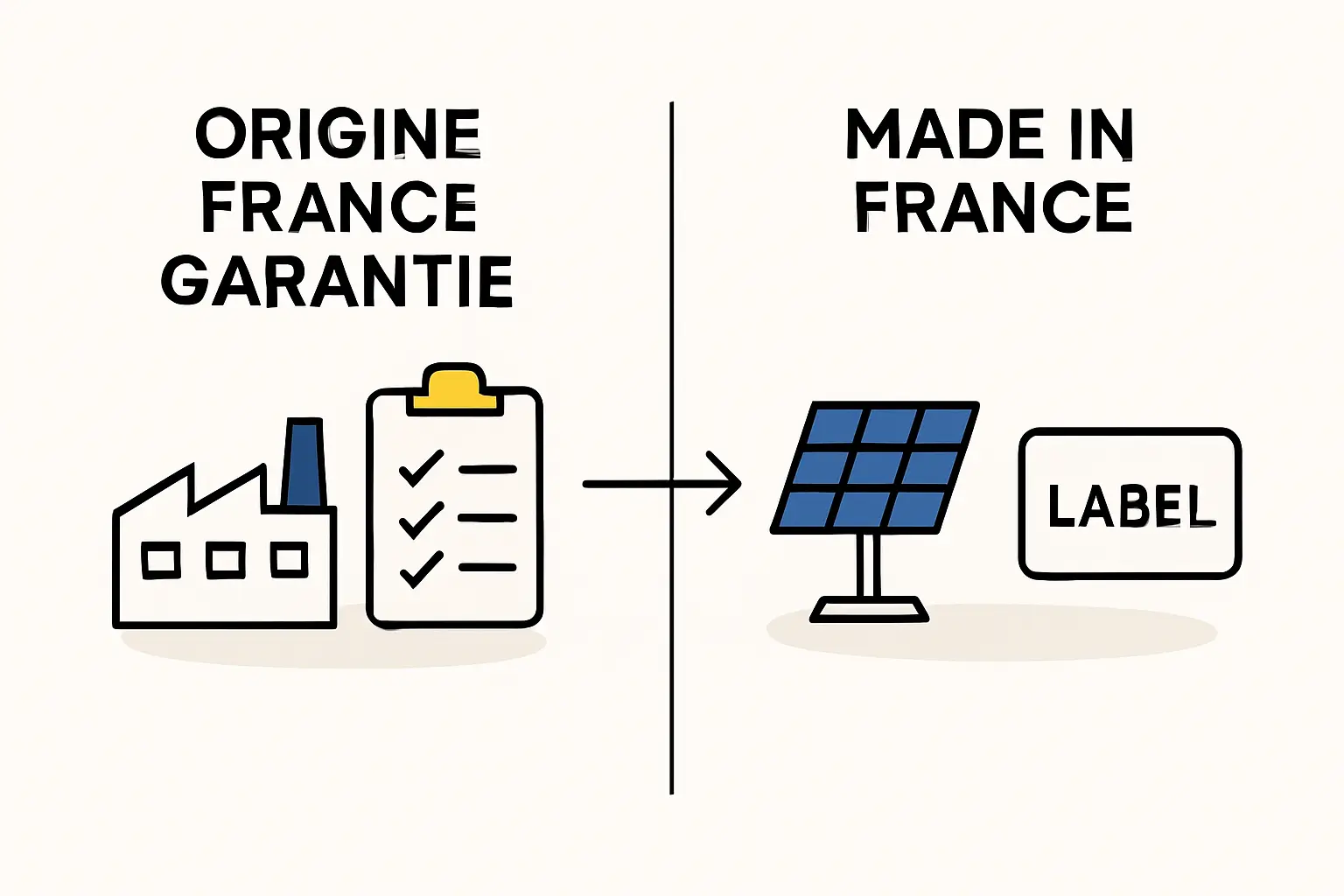

This article outlines the requirements for obtaining the premier French quality label, ‘Origine France Garantie’ (OFG), and explains how the certification serves as a powerful strategic tool for market entry and growth.

Understanding ‘Country of Origin’ vs. Certified Labels

In international trade, a product’s ‘Country of Origin’ is a customs designation used primarily to determine tariffs and trade regulations. This designation typically refers to where the last substantial transformation of the product occurred.

A certified label like ‘Origine France Garantie’ (OFG), in contrast, goes much further. It is not merely a customs term but a legally protected, independently audited certification that guarantees a specific level of French content and production. For consumers and procurement officials, the OFG label is a trusted signal of quality, transparency, and support for the national economy—carrying far more weight than a generic “Made in France” statement.

Key Requirements for the ‘Origine France Garantie’ (OFG) Label

To qualify for the OFG label, a solar module producer must meet two primary criteria, audited by an independent certifying body such as AFNOR or Bureau Veritas. This rigorous process ensures the label’s integrity and market value.

1. The Site of Essential Production Steps

The place where a product takes on its essential characteristics must be in France. For a photovoltaic module, this means the core assembly processes—transforming individual components into a final, functional product—must take place within a French facility. Key steps include:

- Cell Stringing: The process of soldering solar cells together into series.

- Layup and Lamination: Assembling the layers (glass, EVA, cells, backsheet) and bonding them under heat and pressure.

- Framing and Junction Box Installation: Finishing the module to ensure its structural integrity and electrical connectivity.

Simply performing final inspection or packaging of pre-assembled parts in France is not enough. This requirement directly shapes the design and scope of the solar module production line.

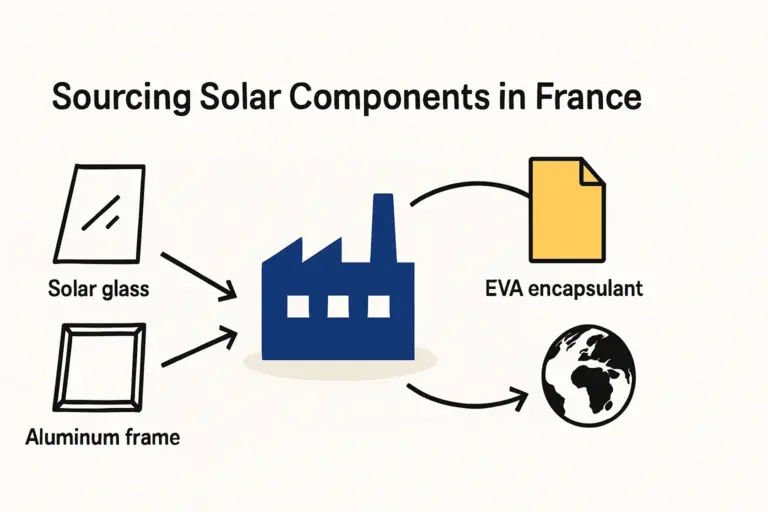

2. A Minimum of 50% French Unit Cost Price

At least 50% of the module’s unit cost price must be of French origin. This crucial business metric requires detailed cost accounting. The value is not limited to materials alone; it is a comprehensive calculation that can include:

- French-sourced materials and components: Glass, frames, or junction boxes from French suppliers.

- Labor costs: Salaries and benefits for production staff in the French factory.

- Factory overhead: Energy, rent, maintenance, and other operational costs incurred in France.

- Amortization of equipment: The depreciation of machinery located within the French facility.

- Research and development (R&D): Costs associated with R&D activities conducted in France.

This structure makes the 50% threshold achievable even when critical components like solar cells are imported, as long as significant value is added through local labor and operations.

The Strategic Business Advantages of OFG Certification

Obtaining the OFG label is not merely a compliance exercise; it is a deliberate business strategy that can unlock significant commercial advantages, particularly within the competitive French and wider European markets.

1. Enhanced Access to Public Tenders

The French government, through its energy regulation commission (CRE), regularly issues large-scale tenders for solar energy projects. A key evaluation criterion in these tenders is the project’s carbon footprint, measured by the Évaluation Carbone Simplifiée (ECS).

Modules produced locally in France with a transparent, shorter supply chain inherently achieve a more favorable ECS score than modules transported from overseas. The OFG label offers credible, third-party proof of these local production claims, giving a manufacturer a distinct competitive edge when bidding for these lucrative, state-backed contracts. Based on J.v.G. Technology’s experience with European projects, access to these tenders can be a primary driver of a factory’s long-term profitability.

2. Price Premium and Consumer Trust

In the residential and commercial rooftop solar markets, brand perception and trust are paramount. French consumers have demonstrated a strong preference and willingness to pay a premium for locally manufactured goods. The OFG label acts as a powerful marketing tool, allowing a producer to:

- Justify a higher price point: The label communicates superior quality, reliability, and local economic contribution.

- Build installer loyalty: Solar installers can leverage the OFG brand to differentiate their offerings and appeal to discerning end-customers.

- Strengthen brand credibility: It provides an immediate, verifiable mark of quality that new market entrants often struggle to build.

3. A Foothold in the Wider European Market

While the OFG label is specific to France, the principles behind it—supply chain resilience, low-carbon manufacturing, and verifiable local production—are gaining traction across the European Union. Policies like the EU’s Net-Zero Industry Act aim to bolster domestic clean-tech manufacturing.

Establishing an OFG-certified factory in France positions a company not just as a national supplier but as a strategic European manufacturer, one that is well-aligned with the continent’s long-term industrial policy. It signals a commitment to quality and sustainability that resonates with commercial buyers and policymakers throughout the EU.

Navigating the Certification Process: A Practical Overview

Entrepreneurs planning a solar factory should consider OFG certification from the very earliest stages.

- Strategic Factory and Supply Chain Design: The choice of suppliers and the bill of materials must be structured to meet the 50% value-added rule. Turnkey line setups can be configured from the outset to optimize for these requirements.

- Robust Documentation: Meticulous records of supply chain origins, cost accounting for every component, and detailed production process flows are essential for the audit.

- Application and Audit: The company formally applies to an accredited certification body. The process then involves a documentation review and an on-site audit of the production facility to verify all claims.

- Maintaining Compliance: Certification is typically granted for one year and requires an annual renewal audit to ensure standards are consistently met.

Understanding the investment requirements for a solar factory is the first step, but integrating certification goals into the business plan is essential for long-term market relevance.

Frequently Asked Questions (FAQ)

Is OFG certification mandatory to sell solar modules in France?

No, it is not mandatory. However, it provides a significant competitive advantage, particularly for accessing public tenders and the premium residential market segment where consumers value local production.

How long does the certification process typically take?

Once the factory is operational and documentation is prepared, the certification process—from application to final decision—usually takes two to four months.

Can a foreign-owned company operating in France obtain the OFG label?

Yes. The label is awarded based on the location of production and where value is created, not on the nationality of the company’s owners.

Do all components need to be from France to meet the 50% value rule?

No. The 50% threshold is calculated on the total unit cost price. This allows for a mix of imported components (like solar cells) and French value addition (labor, local components, factory overheads, R&D). This flexibility is key to making the certification achievable.

What is the difference between OFG and a simple “Made in France” claim?

The ‘Origine France Garantie’ is a legally protected, independently audited certification with strict, transparent, and publicly available criteria. A generic “Made in France” claim is largely unregulated, may be based on looser customs definitions, and lacks the credibility and market power of the OFG label.

Conclusion: Beyond a Label, A Market Entry Strategy

For professionals entering the solar manufacturing industry, the ‘Origine France Garantie’ label is far more than a marketing asset. It is a strategic key that unlocks the most stable and profitable segments of the French solar market.

By integrating OFG requirements into their initial factory design and business plan, entrepreneurs can build a manufacturing operation that is not only technologically sound but also perfectly aligned with the commercial realities and policy direction of their target market. Understanding these regional dynamics is as critical to success as mastering the production technology itself.

To build this foundational knowledge, explore the comprehensive e-course from pvknowhow.com for a structured path from concept to a fully operational facility.