An investor secures funding and identifies a promising location for a new solar module factory. The business plan is solid, the technology is selected, and market demand is high. Yet, between that vision and the first module rolling off the production line lies a complex, often underestimated landscape of regulations, permits, and environmental compliance.

The success of major investments in Georgia by companies like Hyundai and Qcells often masks the intricate regulatory groundwork that made them possible. This article provides a structured, timeline-based roadmap for navigating Georgia’s environmental permitting and compliance requirements. While the specifics relate to the U.S. state of Georgia—a rapidly growing hub for clean energy manufacturing—the principles and phases outlined here offer a valuable model for entrepreneurs planning similar industrial projects anywhere.

This guide helps turn a potential bottleneck into a predictable part of the project plan.

Understanding the Regulatory Landscape: Why Georgia is a Case Study

Georgia has actively cultivated an environment for advanced manufacturing, positioning itself as a leader in the American solar industry. This pro-business stance is balanced by a robust regulatory framework overseen by two key bodies:

The Georgia Environmental Protection Division (EPD): The state-level agency responsible for issuing and enforcing most environmental permits related to air, water, and land.

The U.S. Environmental Protection Agency (EPA): The federal agency that sets national environmental standards. The Georgia EPD is typically authorized by the EPA to implement these standards through state-specific programs.

Understanding this dual structure is crucial, especially for international business professionals. While the names of the agencies change from country to country, this fundamental division between national standards and regional enforcement is a common model. The challenges of securing air, water, and waste permits are universal for any industrial facility.

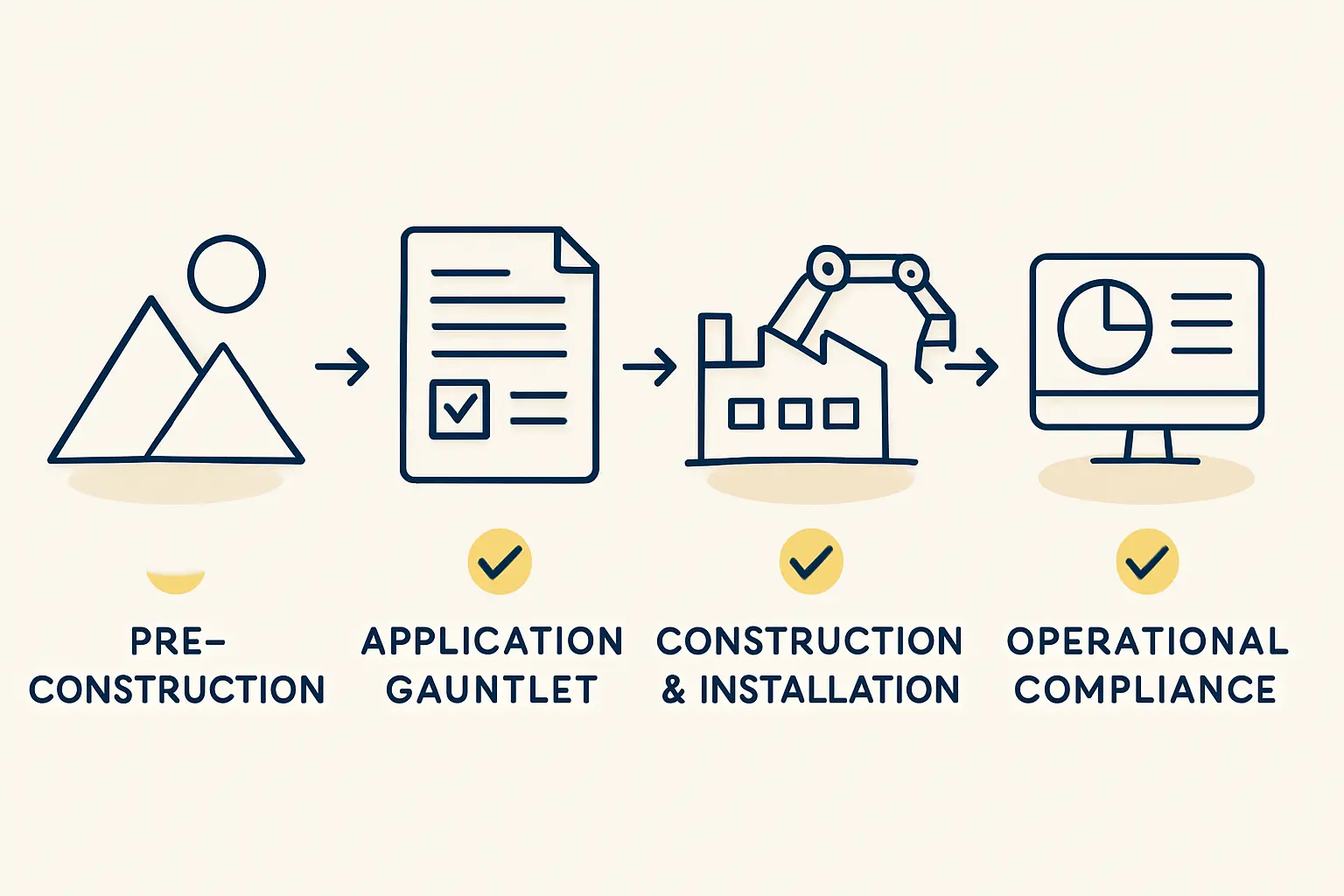

The Permitting Roadmap: A Phased Timeline

A systematic approach to permitting is essential to avoid costly delays. The process can be broken down into three logical phases, typically spanning 12 to 18 months.

Phase 1: Pre-Construction & Site Selection (Months 1-3)

This initial phase is about due diligence, ensuring the chosen site is suitable from a regulatory standpoint before significant capital is committed.

Key Activities:

Environmental Site Assessment (ESA): Before purchasing land, a Phase I ESA is conducted to identify potential historical contamination from previous industrial use. This helps avoid liability for pre-existing environmental issues. Selecting a ‘brownfield’ (a previously developed site) may offer redevelopment incentives but often requires more extensive environmental investigation.

Land Use and Zoning Verification: Confirming that the site is zoned for industrial manufacturing is fundamental. Local municipal or county approval is a prerequisite for any state-level permits.

Critical Habitat & Waterway Screening: This screening surveys the site for protected areas, such as wetlands or habitats for endangered species. Encroachment on these areas can trigger complex and lengthy reviews by bodies like the U.S. Army Corps of Engineers.

A thorough assessment in this phase can prevent a project from being derailed by unforeseen site limitations and is a critical component of evaluating solar panel factory building requirements.

Phase 2: Core Environmental Permitting (Months 4-9)

With a suitable site confirmed, the focus shifts to preparing and submitting the detailed technical applications for primary environmental permits.

Key Permit Categories:

- Air Quality Permit: Solar module manufacturing involves processes that release emissions. Soldering busbars can release lead particulates, and chemical etching and cleaning can release Volatile Organic Compounds (VOCs).

Permit Needed: A Construction Permit is required before building begins, detailing all potential emission sources. This is followed by a Title V Operating Permit once the facility is operational, which consolidates all air quality requirements into a single, enforceable document.

- Water Quality & Discharge Permit: The manufacturing process uses water for rinsing silicon wafers, cleaning glass, and cooling equipment. This wastewater must be treated before being discharged.

Permit Needed: A National Pollutant Discharge Elimination System (NPDES) permit is required to discharge treated wastewater into local rivers or municipal sewer systems, setting strict limits on pollutants. A Stormwater Management Plan is also needed to control runoff from the facility grounds during rain events.

- Waste Management Plan: The facility will generate both non-hazardous waste (e.g., packaging, broken glass) and potentially hazardous waste (e.g., spent solvents, lead-containing solder dross).

Regulation: The Resource Conservation and Recovery Act (RCRA) governs the handling, storage, and disposal of hazardous materials. The facility must develop a comprehensive waste management plan and register with the EPD as a waste generator.

Based on experience from J.v.G. turnkey projects, data collection for these applications is one of the most time-consuming steps. It demands detailed process flow diagrams, a complete inventory of all chemicals to be used, and precise calculations of potential emissions and discharges.

Phase 3: Public Engagement and Final Approval (Months 10-12)

After the EPD reviews the applications and deems them complete, it prepares a draft permit and begins a crucial public-facing phase.

Key Activities:

Public Notice and Comment Period: For major permits like a Title V air permit, a public notice is legally required, opening a 30- to 60-day window for the public to review the draft permit and submit comments or request a hearing.

Regulatory Response and Final Issuance: The EPD reviews all public comments and may require modifications to the permit. Once all concerns are addressed, the final permit is issued, granting the legal authority to construct and operate.

This phase underscores the importance of community engagement. A well-prepared project that proactively addresses community concerns is less likely to face significant opposition or delays at this final stage.

Common Pitfalls and How to Avoid Them

Navigating the regulatory process presents several common challenges for new market entrants.

Pitfall 1: Underestimating Timelines. Many project plans budget six months for permitting when 12 to 18 months is a more realistic timeframe for a new industrial facility. This miscalculation can severely impact the overall solar panel manufacturing plant cost and time to market.

Pitfall 2: Incomplete Application Data. Submitting applications with missing or inaccurate technical data is the leading cause of delays. The EPD will issue a notice of deficiency, stopping the review clock until the correct information is provided.

Pitfall 3: Neglecting Local Ordinances. State and federal permits are only part of the puzzle. Local building permits, fire code compliance, and utility connection agreements are equally critical and operate on separate timelines.

The Role of an Environmental Consultant

For any entrepreneur entering a new jurisdiction, engaging an experienced, local environmental consulting firm is a strategic investment. These firms are intimately familiar with the Georgia EPD’s processes and personnel. They can anticipate data requirements, manage application submissions, and navigate the nuances of the regulatory system far more efficiently than an in-house team unfamiliar with local laws.

While a platform like pvknowhow.com provides the strategic framework for planning a solar factory, a local environmental specialist is essential for executing the on-the-ground permitting strategy.

Frequently Asked Questions (FAQ)

What is the difference between a state (EPD) and federal (EPA) permit?

The EPA sets national minimum standards for environmental protection. In most cases, it delegates the authority to issue and enforce permits to state agencies like the Georgia EPD, which must meet or exceed federal requirements. A solar factory in Georgia will primarily interact with the EPD.

How much should be budgeted for environmental compliance and permitting?

Costs vary with project complexity, but a preliminary budget for consulting fees, application fees, and required environmental studies can range from $50,000 to over $150,000 USD for a medium-sized manufacturing facility. This does not include the cost of pollution control equipment itself.

Can the permitting process be expedited?

While formal ‘expedited’ tracks are rare, the fastest path to approval is to submit a thoroughly prepared and technically complete application from the outset. This minimizes back-and-forth with the agency and prevents avoidable delays.

What happens if a facility operates without the correct permits?

The consequences are severe, ranging from substantial daily fines to legally mandated shutdowns of operations until compliance is achieved. This poses a significant financial and reputational risk to the business.

Securing environmental permits for a new solar manufacturing plant is not merely an administrative task; it is a critical-path project that demands strategic planning, technical diligence, and local expertise. The process, while rigorous, is designed to be navigable.

By viewing compliance as an integral part of the business plan rather than an obstacle, entrepreneurs can build a resilient, sustainable, and legally sound operation. Understanding this regulatory roadmap is a foundational step. To explore what comes next, learning how to start a solar panel manufacturing business offers a structured path forward.