An investor might see a prime opportunity on a sun-drenched Greek island: affordable land, access to sea-lanes, and an eager local workforce. On paper, the location seems ideal for a new manufacturing facility.

However, a critical factor often overlooked in preliminary assessments is the local energy infrastructure. The stability of the electricity grid and the cost of power can fundamentally alter a project’s financial viability and turn a promising venture into a challenging one.

This analysis explores the crucial differences in grid stability and energy costs between the mainland and an island, using the Greek archipelago as a case study. Understanding these distinctions is essential for planning any capital-intensive project, particularly in regions with fragmented power networks.

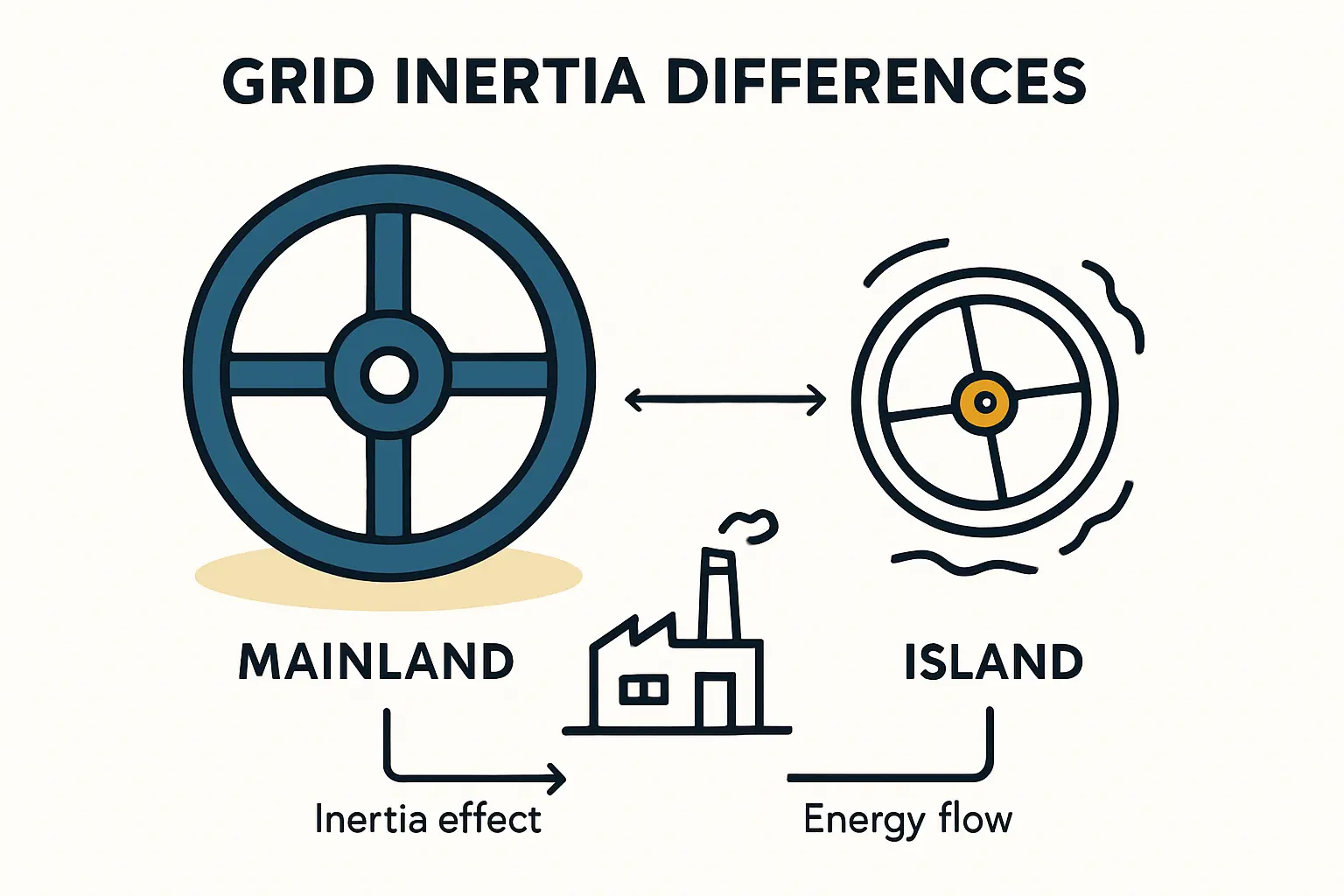

Understanding Grid Architecture: The Mainland Advantage

A factory on the European mainland typically connects to a large, highly integrated electrical grid. This network is a complex web of power stations, transmission lines, and substations spanning multiple countries.

This interconnectedness offers several key advantages:

Redundancy and Reliability

If one power plant goes offline, others within the network can compensate, ensuring a continuous and stable supply of electricity.

Economies of Scale

Power is generated by a diverse mix of large-scale sources (nuclear, gas, hydro, solar, wind), leading to competitive and generally lower electricity prices.

Power Quality

The grid’s sheer size and advanced management systems maintain consistent voltage and frequency, which is critical for sensitive industrial machinery.

The Island Dilemma: Isolated Power Systems

In contrast, many islands, including a significant number in Greece, operate on non-interconnected island (NII) systems. These are small, self-contained grids isolated from the mainland’s power network.

According to a 2020 report by the International Renewable Energy Agency (IRENA), these isolated systems often depend on inefficient, oil-fired power plants. This creates a distinct set of challenges for an industrial operation:

Single Point of Failure

The entire island may rely on a single power station. Any technical fault or fuel supply disruption can lead to widespread blackouts, halting factory production instantly.

Limited Capacity

The grid has a finite capacity, and a new large-scale industrial consumer could strain the network, leading to instability or even a utility’s refusal to connect.

Infrastructure Weakness

The local grid may be older and less resilient, making it prone to disruptions from weather or other external factors.

These factors create an operational risk that must be carefully evaluated in any detailed solar panel manufacturing business plan.

The Economic Impact: A Tale of Two Energy Bills

The architectural differences between mainland and island grids directly impact operational costs, primarily through the price of electricity.

Analyzing the True Cost of Power

Energy is one of the largest ongoing operational costs for any industrial facility. On non-interconnected islands, this cost is often substantially higher. The IRENA report highlights that electricity production costs on the Greek islands can be two to seven times higher than on the interconnected mainland system.

This price disparity is driven by several factors:

-

Fuel Costs: Island power plants often run on imported diesel or heavy fuel oil, which is more expensive than the diverse energy sources available on the mainland.

-

Logistical Overheads: The cost of transporting and storing fuel on an island adds to the final price of electricity.

-

Lower Efficiency: Smaller, older power plants are typically less efficient than large, modern mainland facilities, meaning they burn more fuel to produce the same amount of energy.

In Greece, the higher cost of island energy is partially subsidized for residential consumers by mainland users through a Public Service Obligation levy. However, an industrial-scale user cannot assume such subsidies will apply and must plan for the higher underlying cost.

The Hidden Costs of an Unstable Grid

Beyond the price per kilowatt-hour, an unstable grid introduces hidden costs that can cripple a manufacturing operation. Frequent power outages, voltage sags, or frequency fluctuations can lead to:

-

Production Downtime: Every hour the plant is offline represents lost revenue and idle labor costs.

-

Equipment Damage: Sudden power cuts or surges can damage sensitive and expensive manufacturing machinery, leading to costly repairs and long lead times for replacement parts.

-

Material Waste: An interruption in the middle of a delicate production process, such as laminating a solar module, can result in the entire batch being scrapped.

A J.v.G. client once considered a location in a remote coastal area of North Africa. While land was affordable, a detailed analysis revealed the local grid experienced an average of 15 hours of outages per month. The projected cost of these production stoppages made the location unviable without a significant investment in on-site power infrastructure.

Strategic Solutions for Non-Mainland Locations

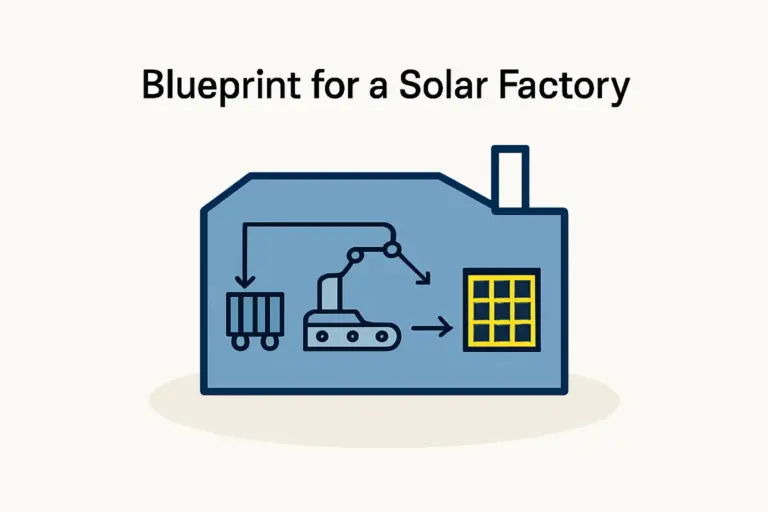

While the challenges of an island location are significant, they are not insurmountable. A factory owner can mitigate these risks through strategic planning and investment in a hybrid power system. This approach transforms the factory from a passive consumer into an active manager of its own energy supply.

A robust factory hybrid system is built on three core components:

-

Grid Connection: The factory remains connected to the local grid, drawing power during periods of low on-site generation (e.g., at night) or high demand.

-

On-Site Solar PV: The location’s primary advantage—abundant sun—can be leveraged by installing a large-scale solar array on the factory roof or adjacent land. For a solar module factory, this offers the unique benefit of using its own products to power operations.

-

Battery Energy Storage System (BESS): This is the critical component for ensuring stability. A BESS stores excess solar energy generated during the day and provides instantaneous backup power the moment the grid fails. It acts as an uninterruptible power supply (UPS) for the entire factory, protecting machinery and ensuring continuous production.

Integrating such systems has direct implications for the facility’s design, demanding careful consideration of the overall solar factory building requirements. Experience from J.v.G. turnkey projects shows that incorporating energy infrastructure planning from the outset is critical for de-risking the investment.

Frequently Asked Questions

Is an island location ever a viable option for a factory?

Yes, but only with a comprehensive energy strategy. If logistics, labor, and land costs are exceptionally favorable, they may offset the required investment in an on-site hybrid power system. The key is to conduct a thorough feasibility study that models the total cost of ownership, including both capital and operational energy expenses.

How much does a factory-scale BESS and solar installation add to the initial investment?

This represents a significant capital expenditure, often running into millions of dollars depending on the factory’s load and desired autonomy. However, this should be evaluated not as a cost but as an investment that delivers a strong return through lower energy bills, near-100% uptime, and protection of capital equipment.

Does this issue only apply to islands?

No. The principles discussed here apply to any location with a weak, unreliable, or non-existent grid. This includes many rural areas, developing regions, and frontier markets where infrastructure has not kept pace with economic growth.

Can a factory operate completely off-grid?

While technically possible for some operations, running a 24/7 manufacturing facility completely off-grid is a major engineering and financial challenge. It requires an oversized generation and storage system to account for seasonal variations and consecutive cloudy days, making a hybrid grid-connected approach far more practical and cost-effective for most industrial applications.

Making an Informed Location Decision

Choosing a factory location is one of the most consequential decisions an entrepreneur will make. While surface-level factors like land cost and port access are important, the underlying energy infrastructure is the foundation for operational reliability and long-term profitability.

The Greek islands provide a powerful example of how a seemingly attractive location can harbor hidden risks. By understanding the dynamics of grid stability and energy costs—and planning for energy self-sufficiency—an investor can make a truly informed decision. A properly planned turnkey solar manufacturing line accounts for these local energy conditions from the outset, ensuring the facility is built on a foundation of resilience and designed for success.