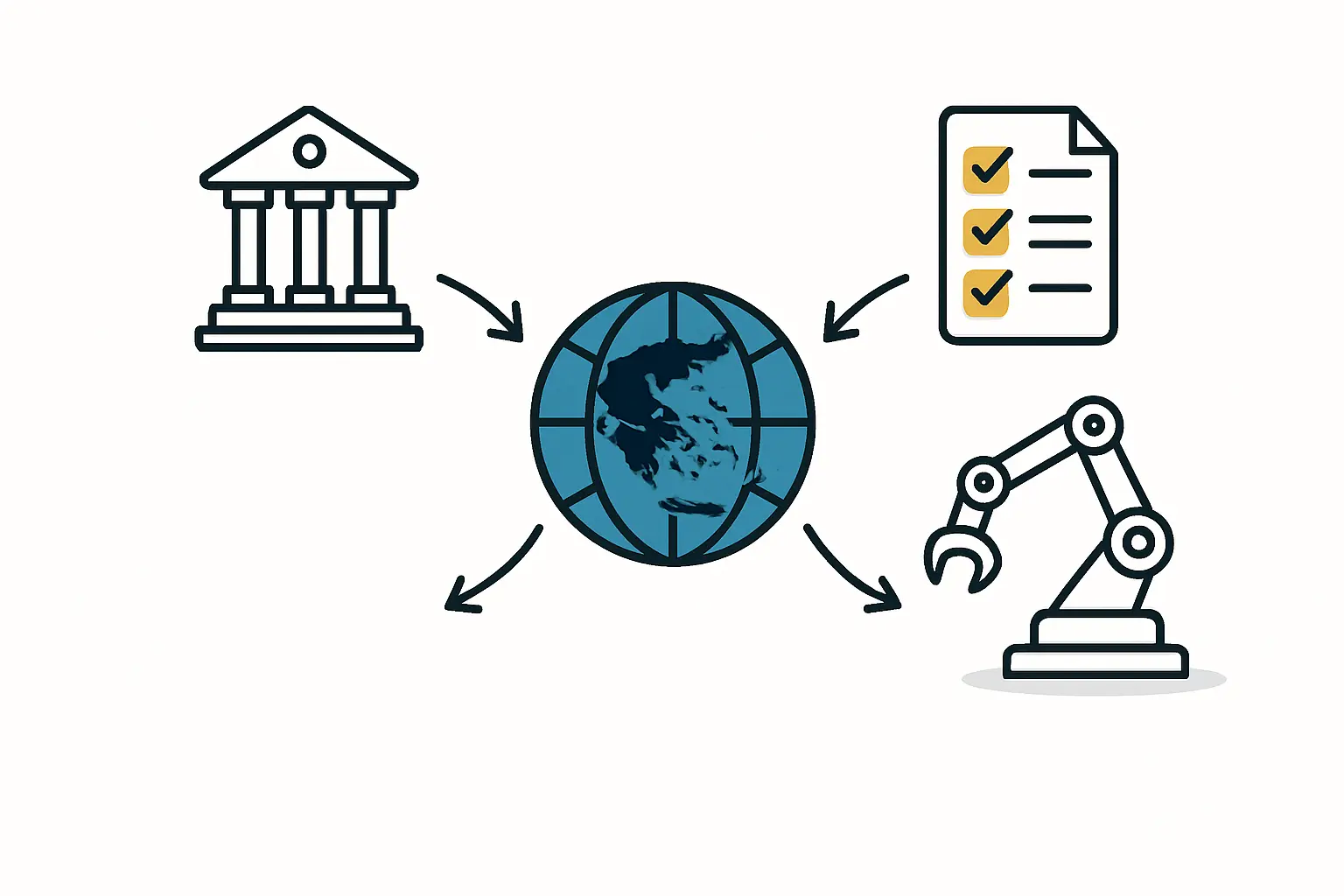

An investor considering a solar module factory in Greece will find immense potential, driven by strong solar irradiation and supportive national and EU policies. Yet, even the most advanced production facility is only as effective as the team operating it. The challenge lies in assembling and training a skilled technical workforce in a market with unique characteristics.

The Greek labor market presents a paradox. While headlines often point to high unemployment, finding personnel with the specific, hands-on experience needed for photovoltaic manufacturing presents a distinct challenge. This article outlines a strategic approach to sourcing, training, and retaining the technical talent needed to build a successful solar production enterprise in Greece.

The Greek Labor Market: A Landscape of Challenge and Opportunity

An effective recruitment strategy begins with understanding the dynamics of the Greek labor market—one defined by both significant challenges and untapped potential.

The country has faced economic headwinds, leading to a general unemployment rate of around 10.8% and a youth unemployment rate that has topped 22.5%. These conditions contributed to a significant “brain drain,” with an estimated 500,000 skilled professionals leaving the country since 2010.

Yet this landscape also holds unique opportunities. Greece has a strong foundation in technical education, with highly regarded institutions like the National Technical University of Athens (NTUA) and the Aristotle University of Thessaloniki (AUTH) graduating a steady stream of qualified engineers. Furthermore, government-led initiatives such as “Rebrain Greece” are working to attract skilled expatriates back to the country.

The key for an investor is to bridge the gap between this raw academic talent and the practical demands of a modern solar module production line.

A Strategic Framework for Recruitment

A reactive hiring process is unlikely to yield the best results. Building a robust team of technicians, operators, and engineers requires a proactive, multi-channel strategy.

Collaborating with Technical Universities and Institutions

The most sustainable source of engineering talent lies within Greece’s university system. Establishing partnerships with technical faculties can create a direct pipeline of promising graduates.

-

Internship Programs: Offer structured internships to give students invaluable hands-on experience and allow the company to assess potential full-time hires in a real-world setting.

-

Graduate Recruitment: Actively participate in university career fairs and present guest lectures to build brand awareness and position the company as a desirable employer in a future-focused industry.

-

Research Partnerships: Collaborate on final-year projects or small-scale research to identify top-tier talent with a genuine interest in photovoltaic technology.

Engaging Vocational and Technical Schools

While universities provide engineers for process oversight and management, the daily operation of solar manufacturing equipment requires skilled technicians. Greece’s network of public vocational schools, managed by organizations like DYPA (formerly OAED), can be an excellent source of individuals with foundational skills in electronics, mechanics, and automation who are eager for specialized training.

Attracting Returning and Experienced Professionals

The growing stability and strategic importance of the renewable energy sector make it an attractive industry for experienced professionals, including Greek talent looking to return home. Recruitment efforts can highlight the opportunity to build a long-term career in a high-growth domestic industry, offering a compelling alternative to employment abroad.

Designing an Effective Training Program for PV Manufacturing

Given that direct experience in solar module manufacturing is rare in the Greek market, a robust in-house training program is not just an advantage—it is a necessity. The goal is to transform academically qualified individuals into competent, process-oriented production specialists.

From Academic Knowledge to Practical Application

The primary challenge is bridging the gap between theoretical engineering principles and the day-to-day realities of a production floor. A successful training curriculum must focus heavily on practical, hands-on instruction. Based on experience from J.v.G. turnkey projects, this process typically involves several weeks of intensive, on-site training led by experienced process engineers.

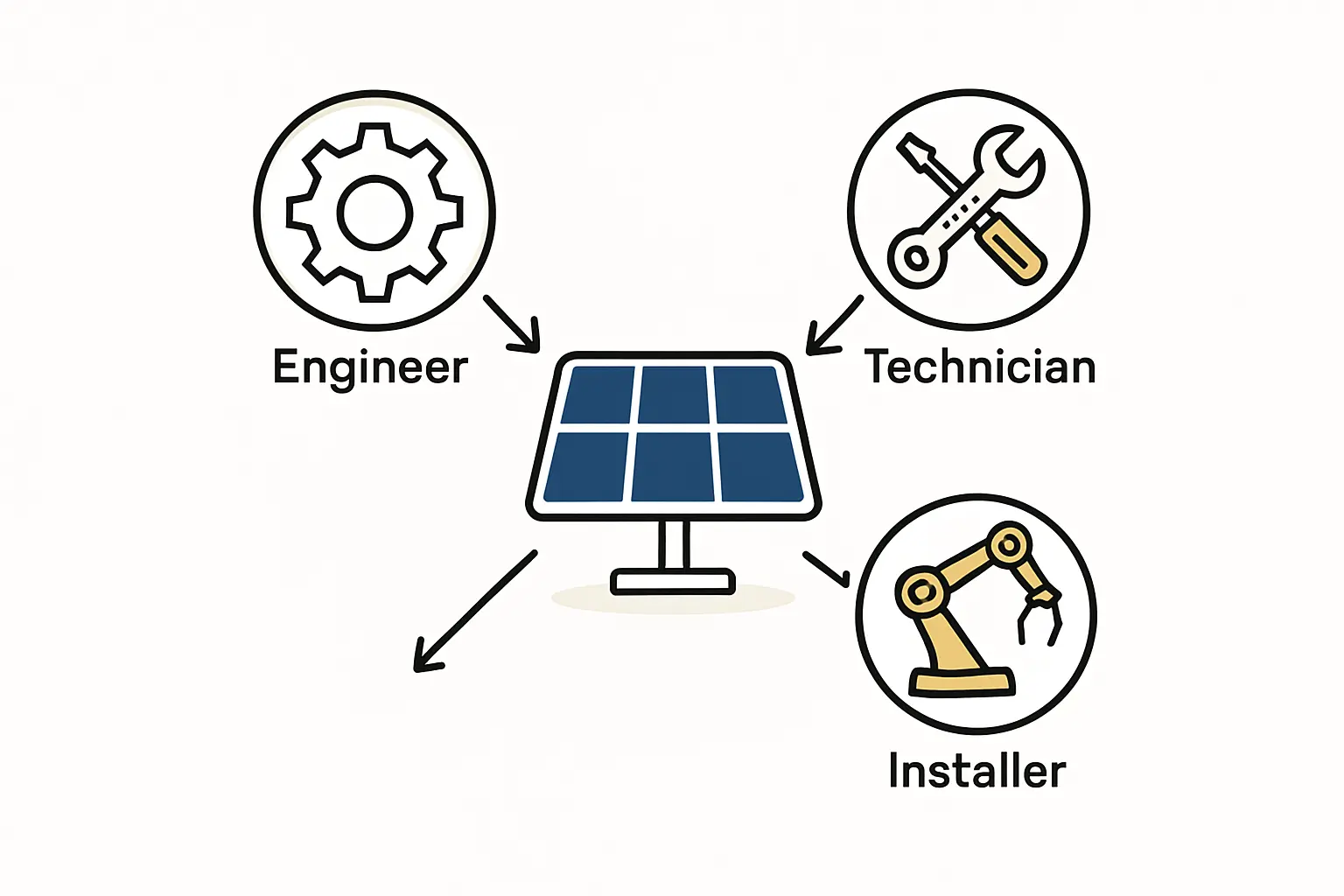

Core Competencies for Your Production Team

A comprehensive training program should cover several critical areas:

-

Machine Operation & Process Control: Detailed instruction on each piece of equipment, from the stringer to the laminator and final tester.

-

Quality Assurance: Training on visual inspection criteria, electroluminescence (EL) and IV testing interpretation, and material handling protocols.

-

Safety Procedures: Rigorous instruction on workplace safety, emergency protocols, and the proper handling of materials.

-

Basic Maintenance: Empowering operators to handle routine maintenance and identify potential issues before they lead to downtime.

Strategies for Retaining Skilled Talent

Recruiting and training a workforce represents a significant investment. Retaining that talent is essential for long-term success, process stability, and continuous improvement.

-

Competitive Compensation: Offering salaries and benefits that are competitive within the Greek industrial sector is fundamental.

-

Clear Career Progression: Employees are more likely to remain with a company where they can see a clear path for advancement, from operator to line leader, shift supervisor, or quality control specialist.

-

Investment in Continuous Learning: Providing ongoing training opportunities demonstrates a commitment to employee development and keeps the team’s skills aligned with evolving technology.

Frequently Asked Questions About Building a Solar Production Team in Greece

What are the most critical technical skills for production staff?

For operators and technicians, a background in electronics, mechanics, or industrial automation is highly beneficial. Key skills include attention to detail, the ability to follow standardized processes, and basic troubleshooting. For engineers, a degree in Electrical, Mechanical, or Materials Engineering provides a strong foundation.

How many employees are needed to run a small-to-medium-sized solar factory?

The exact number depends on the level of automation and planned output. A typical 20–50 MW semi-automated line might require 25 to 40 employees, including operators, technicians, quality control staff, and administrative personnel. A detailed analysis of staffing requirements for a solar factory is a critical part of the initial business plan.

How long does it typically take to train a new machine operator?

For an individual with relevant technical aptitude, basic operational competency can often be achieved within two to four weeks of intensive, hands-on training. Reaching a high level of proficiency and process understanding may take several months of on-the-job experience.

Your Workforce as a Strategic Asset

Entering the solar manufacturing market in Greece offers a compelling strategic opportunity, supported by the country’s favorable location and renewable energy goals. While the local labor market requires a deliberate approach, it offers a deep pool of capable and well-educated talent.

Success is not merely about sourcing labor; it is about strategically investing in human capital. By building partnerships with educational institutions, designing a robust training program, and creating an environment that fosters long-term retention, an investor can build a workforce that becomes a durable competitive advantage. This human element is a vital component of the overall project, influencing everything from production quality to the long-term return on the solar panel manufacturing plant cost. With the right strategy, a skilled local team can be the cornerstone of a thriving Greek solar enterprise.