An entrepreneur in Greece has identified a promising 8,000 m² industrial plot. With the nation’s ambitious goal to reach 22.7 GW of renewable energy capacity by 2030, the opportunity to establish a local solar module manufacturing facility is clear. But a critical question arises before any investment is made: is this plot truly suitable for a modern 50-100 MW production line?

The answer lies not in the total area alone, but in a careful analysis of building constraints, logistical flow, and the specific needs of solar manufacturing equipment. Many promising ventures face delays or unexpected costs because the physical layout was not optimized from day one. This guide offers a structured approach to evaluating and planning a solar factory layout on typical Greek industrial plots, transforming a real estate decision into a strategic operational advantage.

Understanding the Core Space Requirements of a 50-100 MW Facility

Before assessing any plot of land, it’s essential to understand the fundamental space requirements of a solar module factory. A common mistake is to focus only on the production floor. A successful facility is a balanced ecosystem of production, storage, and logistical areas.

Based on data from numerous turnkey projects, a 50-100 MW facility typically requires:

-

Production Area: Approximately 1,500 to 2,500 m². This space must accommodate the entire production sequence in a logical flow, from cell stringing to final framing and testing.

-

Storage Area: Approximately 1,000 to 2,000 m². This critical and often underestimated component includes climate-controlled storage for sensitive raw materials like solar cells and EVA foil and a separate area for finished modules awaiting shipment.

-

Ancillary Spaces: This includes offices for management and administration, a quality control lab, changing rooms for staff, and technical rooms for utilities.

This means the total required building footprint is between 2,500 and 4,500 m². The key challenge is fitting this footprint onto a standard plot while adhering to local building codes.

Aligning Factory Needs with Greek Real Estate Constraints

Industrial real estate in Greece comes with a specific set of parameters that any layout plan must incorporate. Understanding these rules is the first step in determining a plot’s feasibility.

Typical Plot Characteristics and Building Codes

-

Common Plot Size: Most available industrial plots range from 4,000 m² to 10,000 m².

-

Maximum Plot Coverage: Regulations typically limit the building’s footprint to 60% of the total plot area. This ensures adequate space for access, parking, and green areas.

-

Setback Requirements: Buildings must usually be set back at least 5 meters from all property boundaries.

Applying these rules to our example of an 8,000 m² rectangular plot (e.g., 80m x 100m):

-

Maximum Building Footprint: 8,000 m² x 60% = 4,800 m².

-

Usable Building Area (after setbacks): The 5-meter setback on all sides reduces the buildable area from 80m x 100m to 70m x 90m, resulting in a maximum buildable envelope of 6,300 m².

Here, the 4,800 m² maximum footprint allowed by the coverage ratio is the limiting factor. This calculation confirms that a total building size of 2,500-4,500 m² is comfortably achievable on a standard 8,000 m² plot.

Designing for an Efficient Process Flow

Once the building’s maximum footprint is established, the next step is to design the internal layout. The primary goal is to create a seamless, linear flow of materials to minimize handling time, reduce the risk of damage, and maximize throughput. An efficient layout is a cornerstone of a successful turnkey solar module production line.

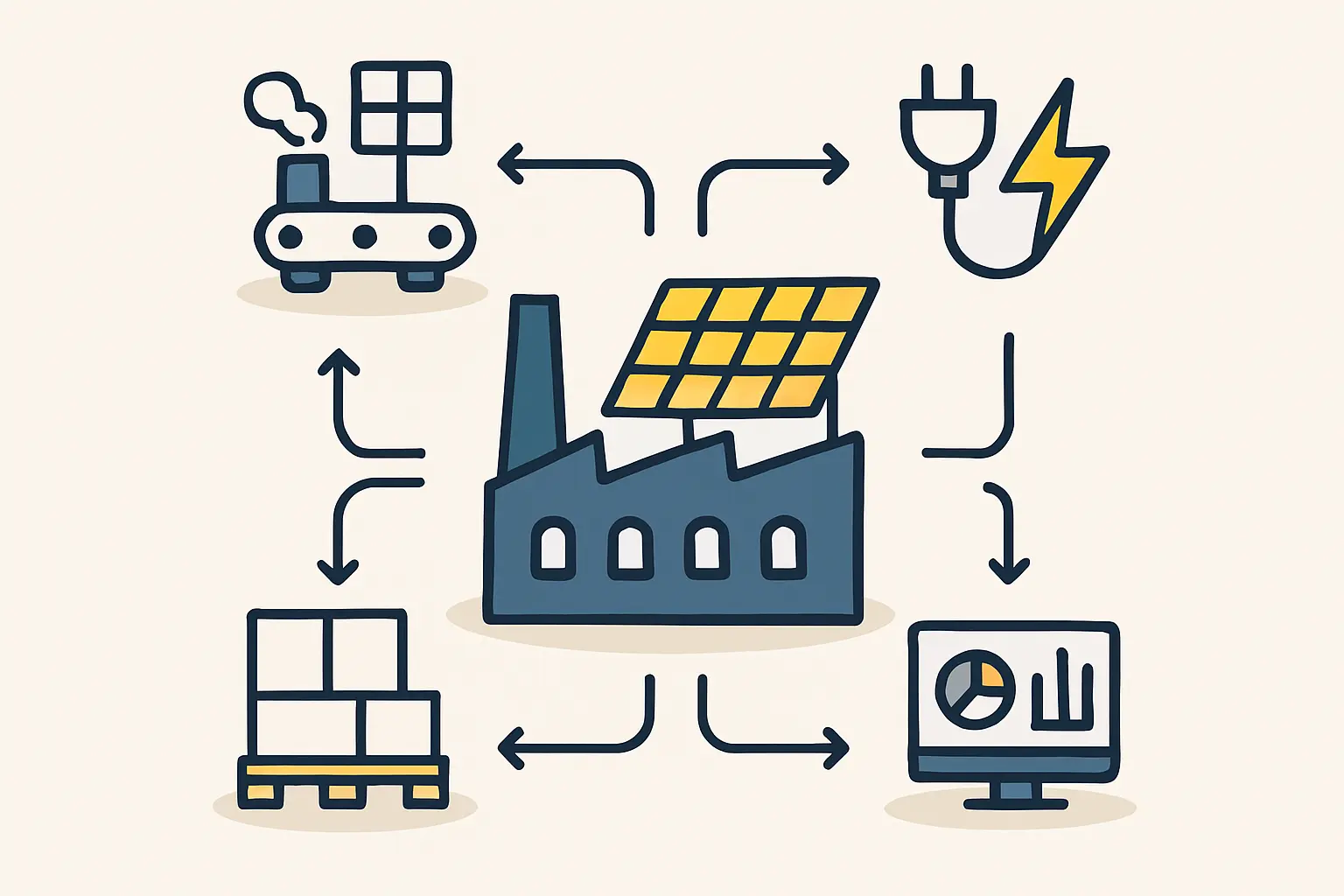

The ‘I-Flow’ vs. ‘U-Flow’ Layout

There are two primary models for a factory layout:

-

I-Flow (Linear): Raw materials enter at one end of the building, flow sequentially through the production line, and finished goods exit at the opposite end. This is often the most efficient model, but it requires a longer, narrower building and truck access at both ends.

-

U-Flow: Raw materials enter and finished goods exit from the same side of the building. The production line forms a ‘U’ shape. This layout is highly practical for typical rectangular industrial buildings, as it consolidates all shipping and receiving activities in one area, simplifying logistics.

For most Greek industrial plots, which are commonly rectangular, the U-flow design is often the most practical and cost-effective solution.

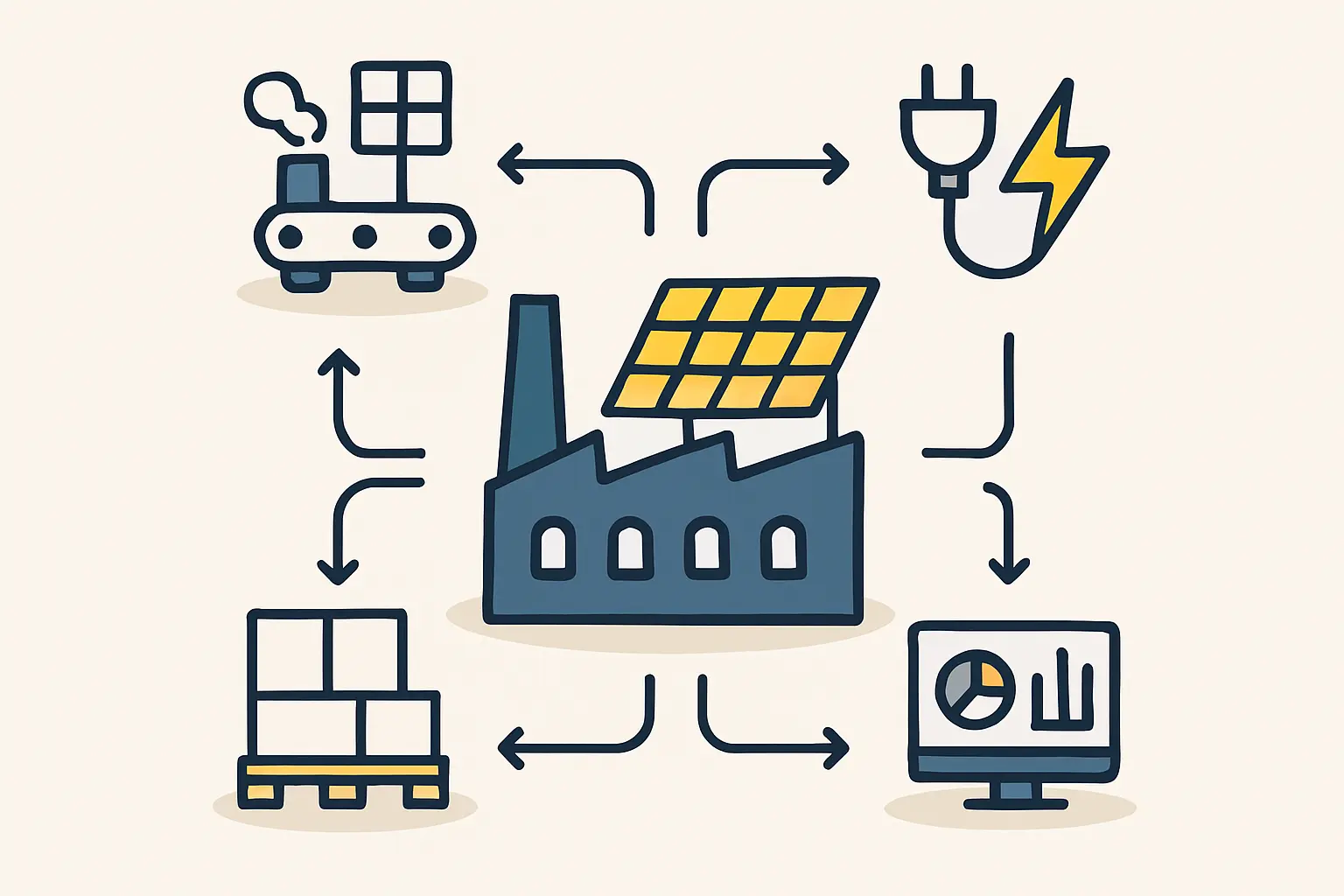

Critical Technical Specifications Beyond Floor Space

A successful factory design considers more than just the two-dimensional layout. Several vertical and structural specifications are non-negotiable for housing industrial machinery.

Ceiling Height

Modern solar manufacturing equipment, especially laminators and automated handling systems, requires significant vertical clearance.

-

Minimum Required Height: A clear ceiling height of 6 meters is the absolute minimum.

-

Ideal Height: An 8-meter clear height is recommended, providing flexibility for future equipment upgrades, maintenance access, and the installation of overhead utility lines like compressed air and electricity.

Floor Loading Capacity

Solar module production machinery is heavy. The concrete slab of the factory floor must be engineered to support these loads without cracking or settling. A minimum floor loading capacity of 2.5 tons per square meter (t/m²) is a standard requirement for areas where equipment like laminators and stringers will be placed.

Logistics and Site Access

The factory’s efficiency depends heavily on how easily materials can be brought in and finished products shipped out. The plan must account for:

-

Truck Access: The yard must have sufficient space for 40-foot containers to maneuver and back up to loading docks.

-

Loading Docks: At least one dedicated dock for raw materials and one for finished goods (or a shared, well-managed area) is essential to prevent bottlenecks.

-

External Storage: Depending on the business model, some space may be needed for external storage of non-sensitive items like aluminum frames or packaging materials.

A detailed plan for the solar module factory investment must account for these site preparation costs, as retrofitting an existing building with inadequate floor strength or ceiling height can be prohibitively expensive.

Frequently Asked Questions (FAQ)

What is the ideal shape for an industrial plot?

A simple rectangular plot offers the most flexibility for designing an efficient factory layout. Irregularly shaped plots can work but often result in wasted space or a less optimal production flow.

Can an existing warehouse be adapted for solar module production?

Yes, but thorough technical due diligence is required. The key factors to check are the ceiling height, floor loading capacity, and the quality of the power supply. Experience from J.v.G. turnkey projects shows that upgrading these three elements in an existing structure can be more costly than a new build.

How much space is required for administrative offices and quality control labs?

For a 50-100 MW facility, 200-400 m² is typically sufficient for offices, a meeting room, a quality control lab, and staff facilities. This area is often designed as a two-story block integrated into the main factory hall to save on footprint.

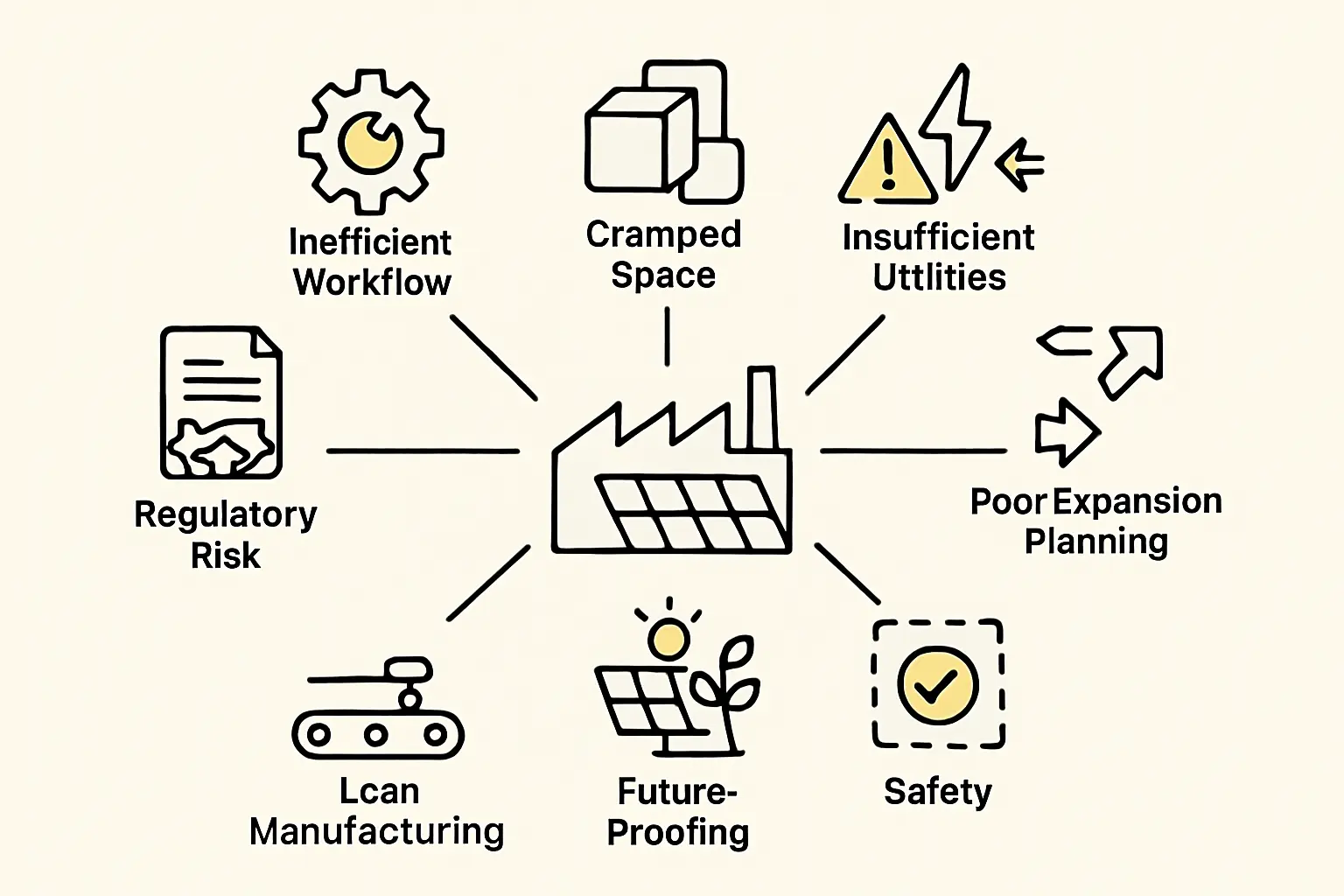

What are the consequences of an inefficient layout?

An inefficient layout can lead to increased material handling, a higher risk of product damage, production bottlenecks, and lower overall output. It creates hidden operational costs that impact profitability over the factory’s lifetime. Proper layout planning is crucial for managing the entire raw material supply chain.

From Plot to Production-Ready Plant

While the prospect of establishing a solar module factory is complex, the physical constraints of typical Greek industrial plots are not an obstacle. A standard 8,000 m² plot offers more than enough space for a highly efficient 50-100 MW facility, provided the planning is meticulous and accounts for local building codes, logistical flow, and the technical requirements of the machinery.

Success begins not when the machines are turned on, but when the first architectural drawings are made. By focusing on a logical process flow and verifying critical specifications like ceiling height and floor loading from the outset, an entrepreneur can lay a solid foundation for a competitive and profitable manufacturing operation in the heart of Europe’s growing solar market.