An investor looking at Guinea-Bissau sees a compelling opportunity: solar irradiation levels average around 1,800 kWh/m² per year, a figure that signals immense potential for renewable energy generation. However, a feasibility study based on sunlight alone is dangerously incomplete. Without a deep understanding of the region’s specific environmental stressors, a project that looks successful on paper can fail prematurely in the field, leading to significant financial losses and reputational damage.

This technical brief outlines the critical environmental challenges in Guinea-Bissau and specifies the solar module technologies required to ensure long-term performance, durability, and a secure return on investment.

Understanding the Unique Environmental Stressors in Guinea-Bissau

The tropical savanna climate of Guinea-Bissau creates a particularly harsh environment for standard photovoltaic (PV) equipment. A successful solar project must be engineered to withstand not just one, but a trio of aggressive environmental conditions.

-

High Ambient Humidity: Relative humidity levels consistently hover between 70% and 90% during the long rainy season (May to November), making moisture ingress a primary concern. This pervasive dampness accelerates material degradation and creates ideal conditions for certain types of electrical failures.

-

Coastal Salinity: A significant portion of the country’s economic activity and potential project sites are located along its Atlantic coastline. Airborne salt mist is highly corrosive and relentlessly attacks metallic components, from module frames to internal cell connections.

-

Harmattan Dust: From December to March, dry and dusty Harmattan winds carry fine Saharan dust across the region. This dust accumulates on module surfaces—a phenomenon known as soiling—which blocks sunlight and reduces energy production. The dust’s abrasive nature also presents a challenge for cleaning and long-term surface integrity.

These three factors work in concert, creating an environment where only robustly manufactured solar modules, specifically designed for these conditions, can survive and perform across their intended 25-year lifespan.

How Climate Corrodes Performance: Key Degradation Risks

Understanding the specific failure mechanisms caused by these conditions is the first step in mitigating them. For a business professional, these are not just technical issues; they are direct risks to project revenue and profitability.

Potential-Induced Degradation (PID): The Silent Performance Killer

Potential-Induced Degradation is a phenomenon that can cause power losses of up to 30% or more within the first few years of operation. It occurs due to voltage differences between the solar cell and the module frame, especially under conditions of high temperature and humidity. The climate in Guinea-Bissau creates a perfect storm for PID, making it one of the most significant non-visible risks to a solar plant’s output.

Corrosion: The Unseen Threat from the Coast

Salt mist contains chlorides that aggressively corrode aluminum frames, mounting structures, and junction box connections. Over time, this corrosion can compromise the structural integrity of the module, lead to faulty electrical connections, and allow moisture to penetrate the module laminate, causing irreversible damage to the solar cells.

Soiling and Abrasion: The Harmattan Effect

The fine dust of the Harmattan winds directly reduces the amount of light reaching the solar cells, causing immediate and significant energy yield losses. If not managed properly, the accumulated dust can mix with morning dew to form a hard, cement-like layer that is difficult to remove. Aggressive or improper cleaning can cause microscopic scratches on the glass surface, permanently reducing its light transmission capabilities.

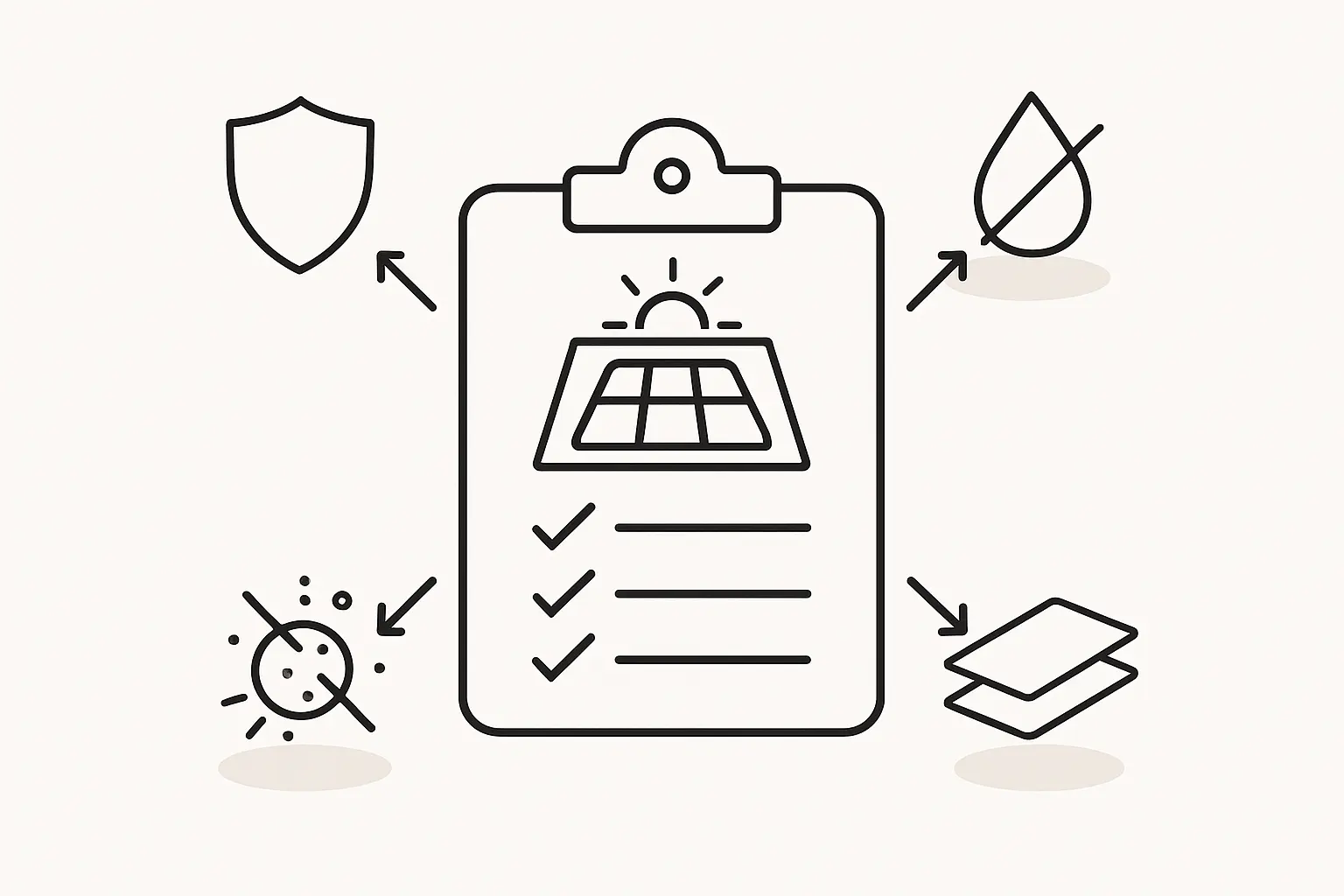

Engineering for Resilience: Specifying the Right Module Technology

To counter these threats, a module specification for Guinea-Bissau must go beyond standard parameters like efficiency and power output. The focus must shift to material science and structural integrity.

The Case for Glass-Glass (GG) Modules

For environments with high humidity and corrosive salt mist, a glass-glass module design offers superior protection. Unlike a standard glass-foil module that uses a polymer backsheet, a GG module encases the solar cells between two layers of glass. This design is hermetically sealed, making it virtually impermeable to moisture and salt mist. This robust construction provides excellent resistance to PID and prevents the backsheet degradation (cracking, delamination) commonly seen in hot and humid climates.

Critical Material Choices: Encapsulants and Backsheets

The materials used for lamination are also critical. Encapsulants like POE (Polyolefin Elastomer) often demonstrate better long-term resistance to moisture and PID than traditional EVA (Ethylene Vinyl Acetate). If a glass-foil design is considered, it is essential to specify a high-quality, multi-layer backsheet with proven resistance to UV radiation, heat, and humidity. While the choice between various cell technologies [Link 1: An in-depth guide to different types of solar panel technologies, such as monocrystalline, polycrystalline, and thin-film.] affects initial efficiency, long-term durability in this climate is ultimately determined by these construction materials.

Fortifying the Structure: Frames and Junction Boxes

Module frames must have a thick, high-quality anodized coating to resist salt mist corrosion. For junction boxes, an IP67 or, preferably, IP68 rating is mandatory. This ensures the enclosure is fully sealed against both dust and moisture, protecting the critical electrical connections inside.

The Importance of Proven Standards: IEC Certifications

Independent verification is non-negotiable. Modules deployed in Guinea-Bissau must have successfully passed rigorous testing standards. The most critical of these are rigorous IEC testing standards [Link 2: A detailed article about the importance of IEC certifications for solar module bankability.]. Specifically, IEC 61701 for Salt Mist Corrosion Testing (at a severity level of 6 or higher) provides assurance that the module can withstand the coastal environment.

The Business Impact of Technical Specification

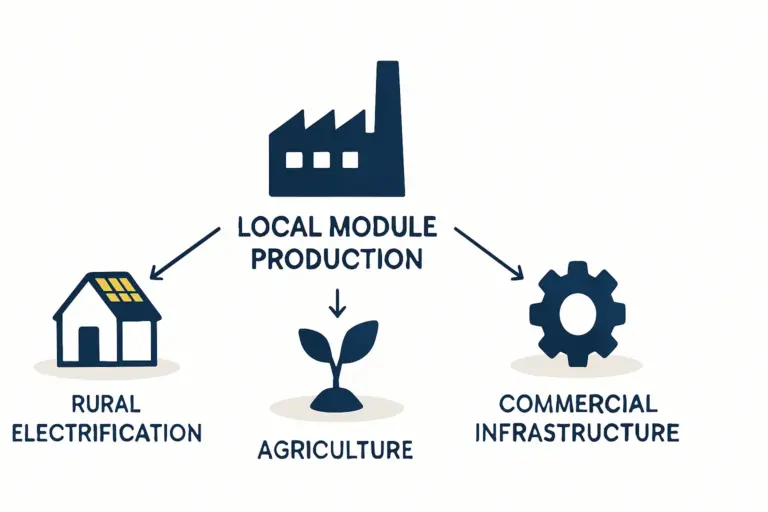

Selecting modules based on these technical specifications has a direct and positive impact on the project’s financial model.

- Higher Lifetime Energy Yield: A durable module that resists PID and degradation will produce more energy over its lifespan.

- Lower Operating & Maintenance (O&M) Costs: Fewer failures and robust construction mean lower costs for replacements, repairs, and cleaning.

- Enhanced Bankability: Projects built with climate-appropriate, certified components are viewed as lower risk by lenders and investors, making financing easier to secure.

This level of technical diligence applies not only to procurement but also to the manufacturing process itself. Building a facility capable of producing such robust modules is a detailed undertaking, integrating specific material choices and quality control measures deep into the manufacturing process [Link 3: A pillar page explaining the solar module manufacturing process from start to finish.]. Experience from J.v.G. turnkey projects shows that this upfront investment in defining the right product for the target market is a key determinant of long-term commercial success.

Frequently Asked Questions (FAQ)

Q1: Are standard solar modules not sufficient for Guinea-Bissau?

Standard modules are typically designed for more temperate climates. They lack the specific material and design features—such as enhanced corrosion protection, high-resistance encapsulants, and moisture-impermeable construction—needed to withstand the combined assault of high humidity, salt, and dust found in Guinea-Bissau. Using them often leads to rapid performance decline and early failure.

Q2: What is the typical performance loss from Harmattan dust?

Soiling losses from Harmattan dust can range from 10% to over 25% if not managed with a proper cleaning schedule. The exact loss depends on the intensity of the season and the duration between cleaning cycles. Anti-soiling coatings can help but do not eliminate the need for regular maintenance.

Q3: Is a glass-glass module significantly more expensive?

Glass-glass modules typically have a higher upfront cost than standard glass-foil modules. However, when evaluating the total cost of ownership over a 25-year project life, their superior durability, lower degradation rates, and reduced risk of failure often result in a lower Levelized Cost of Energy (LCOE), making them a more profitable long-term investment.

Q4: How important is regular cleaning in this environment?

Regular, scheduled cleaning is absolutely critical. It is a core O&M activity required to mitigate soiling losses from Harmattan dust. The cleaning procedure itself must be carefully designed to avoid abrading the module’s front surface.

Conclusion: From Specification to Success

The solar opportunity in Guinea-Bissau is real, but it is reserved for those who approach it with technical diligence. Relying on generic, off-the-shelf solar module specifications is a recipe for underperformance.

A successful and profitable solar venture requires a product engineered specifically for the local environment. By prioritizing durability through technologies like glass-glass construction, corrosion-resistant components, and certified materials, an investor can build a resilient and bankable project. This focus on technical specification is the foundation for any sustainable energy business in the region.