A shipment of high-value manufacturing equipment, representing a significant portion of a project’s capital investment, arrives on schedule at its destination port. Instead of being promptly cleared and transported, however, it sits idle for weeks. Unforeseen documentation issues, opaque fees, and impassable roads create a bottleneck, delaying the entire factory commissioning timeline. This scenario, a common challenge for industrial projects in emerging markets, underscores a critical point: a manufacturing venture’s success often hinges not just on its technology, but on the logistics of getting it to its final destination.

For entrepreneurs planning to establish a solar module factory in Guinea-Bissau, the Port of Bissau is the primary gateway. Understanding its operational realities is essential for effective project planning. This guide provides a practical framework for navigating the customs procedures, port fees, and inland transportation involved in importing solar manufacturing equipment and materials.

Understanding the Port of Bissau: The Gateway to Guinea-Bissau

As the country’s main international deep-water port, all sea freight for a new solar factory will pass through the Port of Bissau. The container terminal, managed by APM Terminals, has an official annual capacity of 15,000 TEU (Twenty-foot Equivalent Units) and serves as the logistical hub for nearly all commercial and industrial goods.

Planners, however, must look beyond official capacity and consider the port’s physical and operational constraints. While the port has a charted draft of 11.5 meters, tidal variations and persistent silting often limit the practical maximum draft to around 7 meters. This can affect the types of ships that can call at the port and may influence shipping schedules. Vessels also typically wait two to four days before berthing—a delay that must be built into any supply chain model.

The Customs Clearance Process: A Step-by-Step Overview

Successfully navigating customs in Guinea-Bissau requires meticulous preparation and local expertise. The process is manageable but can cause significant delays if not handled correctly. A standard clearance timeline ranges from 7 to 14 days, assuming all documentation is in order.

Essential Documentation

A complete and accurate set of documents is crucial for a smooth customs process. Any discrepancies can lead to inspections, fines, and extended delays. The typical required documents include:

- Bill of Lading (B/L): The legal document issued by the carrier detailing the type, quantity, and destination of the goods.

- Commercial Invoice: A document detailing the price and quantities of the goods sold.

- Packing List: An inventory of the shipment’s contents, often required for physical inspection.

- Certificate of Origin: A document certifying the country where the goods were manufactured.

- Pre-Shipment Inspection (PSI) Certificate: In many cases, an inspection of the goods in the country of origin is required before shipping.

The Role of the Local Customs Agent (Despachante)

Attempting to manage customs clearance without a local representative is highly inadvisable. A professional customs agent, or despachante, is essential for navigating the local bureaucracy. This partner handles the submission of documents, coordinates with port and customs officials, and resolves any issues that arise. Their local knowledge and established relationships are invaluable for moving the process forward efficiently.

Financial Considerations: Port Fees and Associated Costs

The total cost of importation extends far beyond freight charges. A detailed budget must account for a range of port and administrative fees, which can sometimes lack transparency. Key costs include:

- Terminal Handling Charges (THC): Fees charged by the terminal operator for handling the container within the port.

- Wharfage: A charge assessed by the port authority for the use of its wharf.

- Pilotage: The fee for a local pilot to guide the vessel into the port.

Obtaining a comprehensive cost estimate from a logistics partner is a critical part of financial planning. These expenses directly impact the project budget and are an important variable to consider when choosing a factory location and assessing its long-term viability.

Inland Transportation: The Final and Most Critical Mile

Once equipment clears the port, the final leg of its journey begins: inland transportation to the factory site. This phase often presents the most significant logistical challenges in Guinea-Bissau. The road network outside the capital is largely undeveloped, with many routes being unpaved and poorly maintained.

The primary risk is the annual rainy season, which typically runs from May to October. During this period, heavy rainfall can render unpaved roads completely impassable for heavy trucks carrying delicate manufacturing equipment. A project’s timeline can be severely impacted if the arrival of critical machinery coincides with the peak of the rainy season.

In a similar solar venture in The Gambia, for example, inadequate road infrastructure delayed machinery commissioning by three weeks. Factoring these potential delays into the project plan is not just prudent; it is essential. This is where comprehensive turnkey project management adds significant value, anticipating and mitigating these local risks through careful scheduling and route planning.

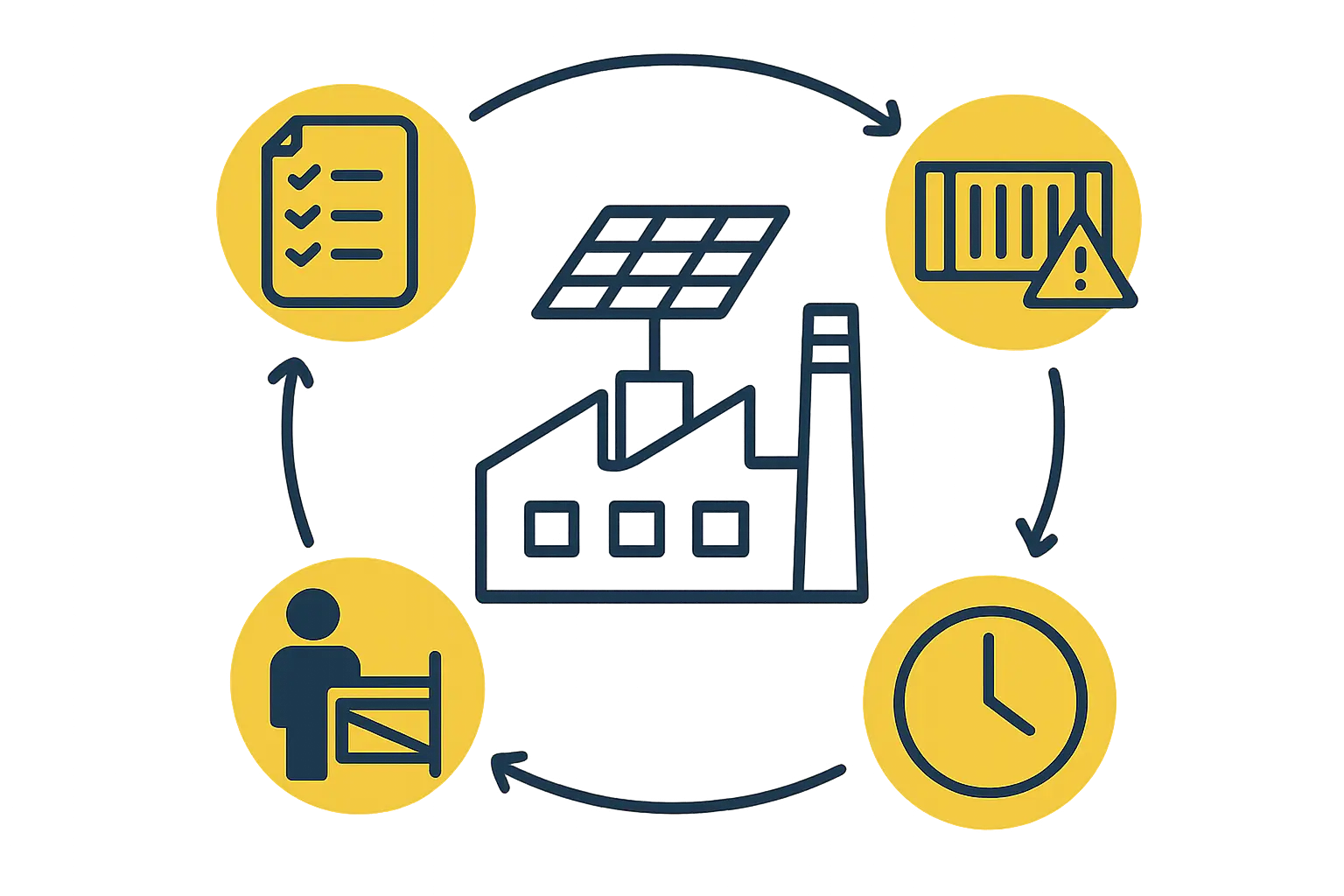

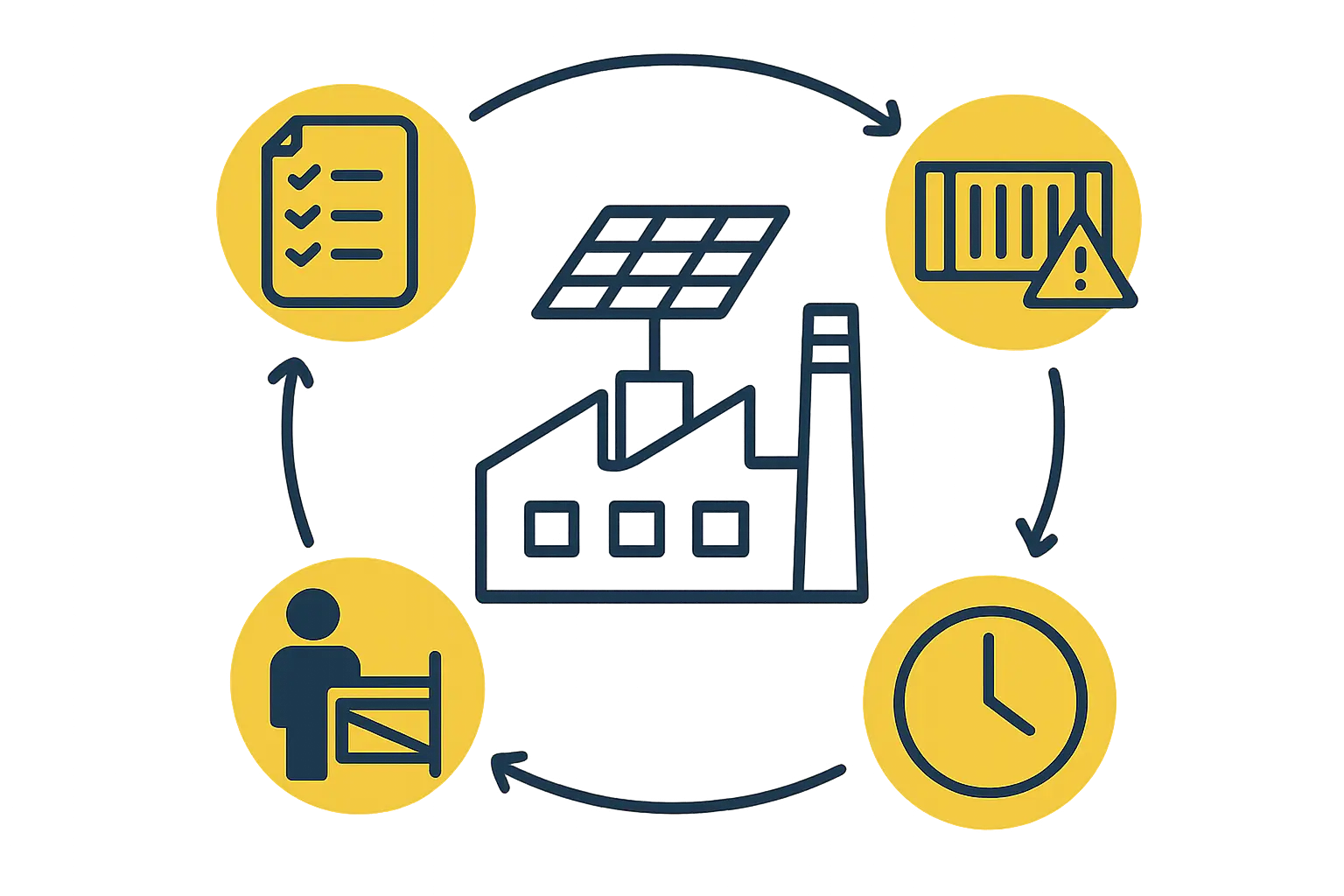

A Strategic Framework for Successful Importation

Mitigating these risks and ensuring a smooth logistical process requires a strategic approach.

Plan for Contingencies

Build a buffer of at least three to four weeks into the project schedule specifically to absorb potential delays in shipping, customs clearance, or inland transport. This prevents logistical issues from derailing the entire project timeline.

Engage a Reputable Local Partner

Identify and vet a reliable local customs and logistics partner well in advance. On the ground, this partner is a critical asset, providing essential expertise and operational support.

Align Shipping Schedules with Local Conditions

Carefully plan shipping schedules to avoid the arrival of sensitive or heavy equipment during the peak of the rainy season (July-September). Whenever possible, schedule these deliveries for the dry season to ensure road access to the factory site.

Frequently Asked Questions (FAQ)

How long should I budget for port clearance in my project timeline?

It is advisable to budget a minimum of two to three weeks for customs clearance alone. Including a buffer for potential inspections or documentation queries is a sound practice.

Can my company handle customs directly without a local agent?

This is not recommended. The complexity of local procedures, language barriers, and the need for established relationships with port authorities make an experienced local agent, or despachante, an essential partner.

What is the single biggest logistical risk for a new factory in Guinea-Bissau?

While port operations present challenges, the most significant and variable risk is typically inland transportation. The condition of roads, particularly during the rainy season, can cause severe and unpredictable delays.

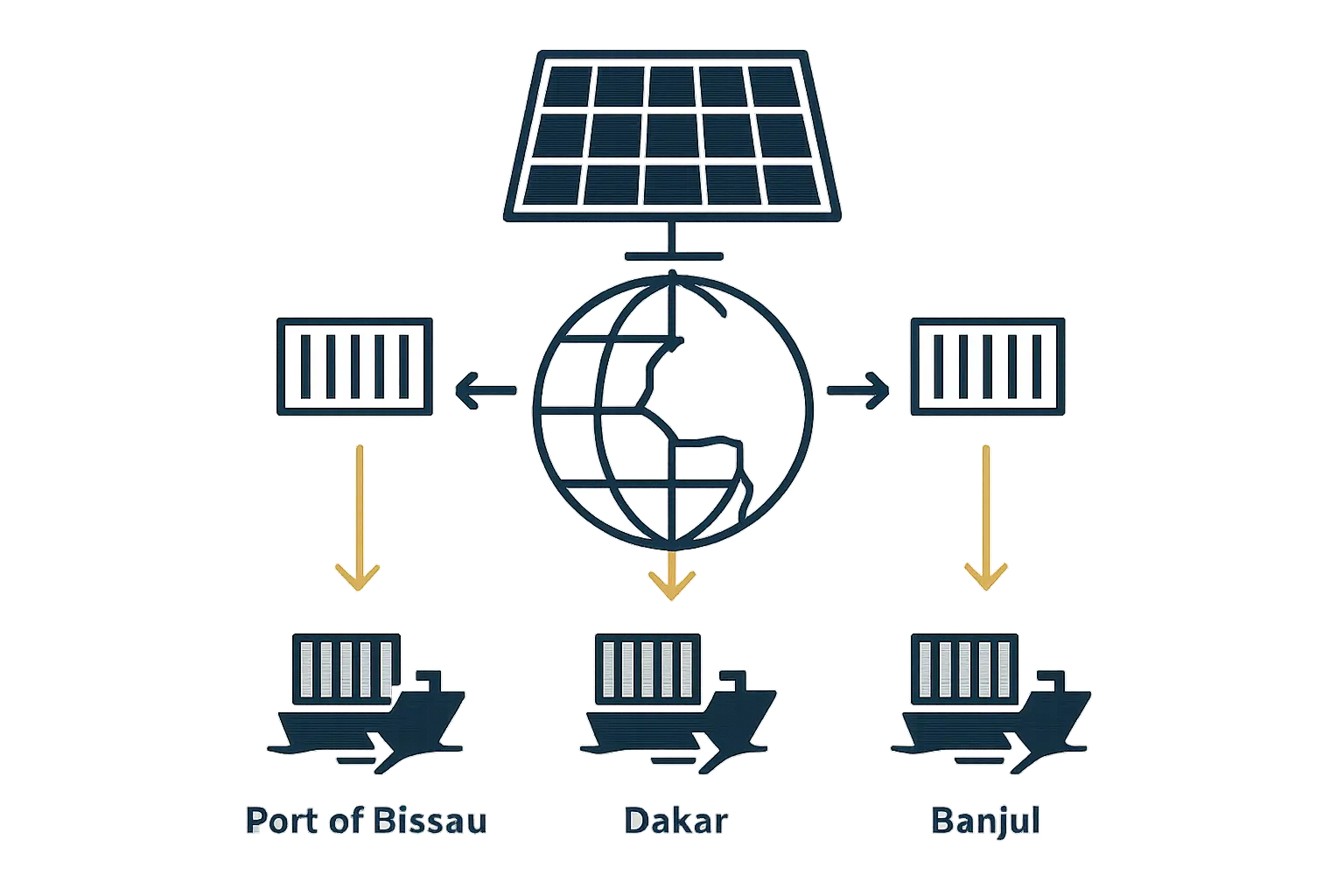

Are there alternatives to the Port of Bissau for importing heavy equipment?

For large-scale industrial imports requiring containerized or break-bulk shipping, the Port of Bissau is effectively the only viable maritime option for accessing the country.

Understanding and planning for these logistical realities is a fundamental part of due diligence for any successful solar manufacturing venture. A business plan that accounts for these supply chain realities is one built on a foundation of operational realism.