Investors often focus on machinery, land, and capital. Yet, one of the most critical decisions determining the long-term success of a new solar module factory is its staffing strategy.

Imagine a key piece of manufacturing equipment malfunctions on a Tuesday afternoon. Is the solution a three-day wait for an expatriate specialist to arrive, or a 15-minute response from a well-trained local lead technician? This choice lies at the heart of operational efficiency and profitability.

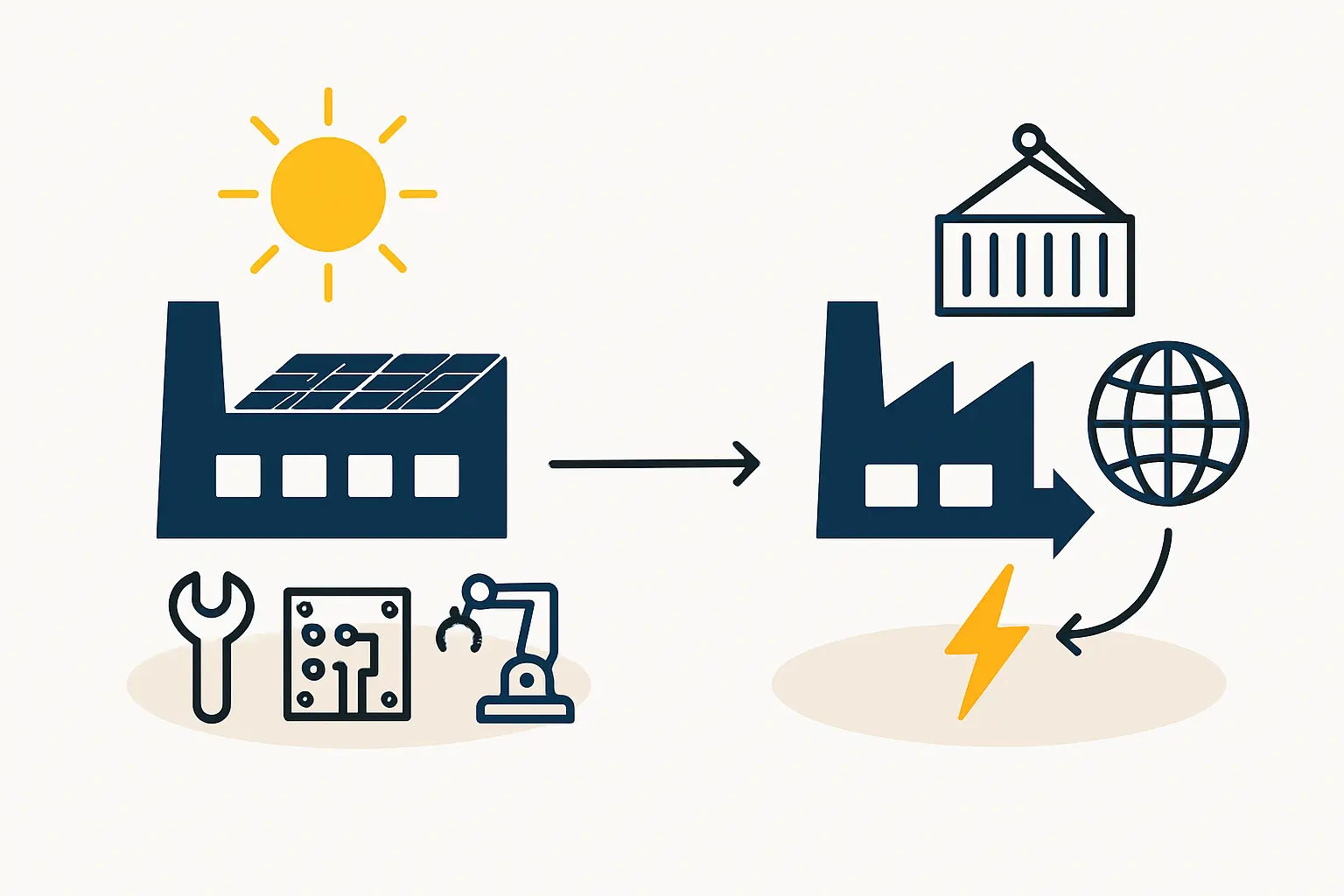

This article weighs two primary staffing models for a new solar factory in Guinea-Bissau: relying on expatriate experts versus investing in developing a local workforce. Understanding the costs, benefits, and strategic implications of each approach is fundamental to building a sustainable and resilient enterprise.

The Strategic Dilemma: Two Primary Staffing Models

When establishing a technically advanced facility like a solar module assembly plant, investors face a clear choice: import expertise or cultivate it locally.

-

The Expatriate Model: This involves hiring experienced engineers and technicians from established solar markets (e.g., Europe, Asia) to manage and operate the factory, prioritizing immediate operational readiness.

-

The Local Workforce Development Model: This strategy focuses on recruiting local talent and investing heavily in comprehensive training programs to build the necessary skills from the ground up, prioritizing long-term sustainability and cost control.

Each path presents distinct advantages and challenges, particularly within the specific economic and social context of Guinea-Bissau.

Analyzing the Expatriate Model: Speed at a High Cost

For an investor eager to begin production, the expatriate model often seems like the most direct route. It means bringing in a team with years of experience, minimizing the initial learning curve.

The Immediate Advantages

-

Rapid Deployment: Experienced personnel can get a new production line operational in the shortest possible time. Their familiarity with solar manufacturing equipment reduces setup and calibration delays.

-

Existing Expertise: Their expertise eliminates the need to build foundational knowledge from scratch. Expatriate staff already possess deep technical skills in module assembly, quality control, and maintenance.

-

Reduced Initial Training Burden: The primary focus can shift from education to production, allowing the business to generate revenue sooner.

The Hidden and Long-Term Costs

While appealing for its speed, the expatriate model carries significant and recurring financial burdens. The total cost of an expatriate employee is often two to three times their base salary.

-

High Compensation Packages: Salaries must be competitive on an international scale, putting them substantially above local wage standards.

-

Substantial Overhead Costs: These include international health insurance, relocation allowances, housing, transportation, security, and periodic flights to their home country.

-

Risk of Knowledge Silos: Critical operational knowledge may remain concentrated within a small group of foreign staff. If an expatriate leaves, their expertise leaves with them, creating a significant operational risk.

-

Cultural and Logistical Challenges: Relying on non-local staff can sometimes lead to communication barriers and a disconnect from the local business community and workforce.

Analyzing the Local Workforce Development Model: An Investment in Sustainability

The alternative approach involves a deliberate, strategic investment in training a local labor force. This model acknowledges Guinea-Bissau’s specific context, where youth unemployment stands at approximately 28.4%, indicating a large and available pool of potential workers.

However, with tertiary education enrollment at only 1.4%, this workforce requires structured vocational training.

The Upfront Investment

-

Comprehensive Training Programs: Designing and executing training modules requires a significant initial investment. This often involves bringing in external trainers for a fixed period to ‘train the trainers’ and establish best practices.

-

Longer Ramp-Up Period: A new team naturally takes more time to reach the same level of efficiency as an experienced one. This requires patience and a realistic production timeline in the initial phase.

-

Management Overhead: Local managers and supervisors must also be trained not just in technical skills but also in quality control systems and team leadership.

The Long-Term Benefits

The initial investment in training yields substantial long-term returns that compound over time.

-

Lower Operational Costs: Local salary structures are significantly more economical, drastically reducing long-term payroll expenses. This is a critical factor for maintaining competitive production costs.

-

Knowledge Retention: Skills and expertise are cultivated and retained within the company and the local community. This creates a resilient organization that is not dependent on a few key individuals.

-

Government and Community Goodwill: Investing in local job creation and skills development aligns with national development goals. This can lead to better government relations and a stronger ‘social license to operate.’ Programs like the GIZ’s ‘Energising Development’ (EnDev) in Guinea-Bissau signal a focus on building local capacity in the energy sector.

-

Increased Operational Agility: Having trained staff on-site allows for immediate troubleshooting and maintenance, minimizing costly downtime compared to waiting for external support.

A Comparative Framework for Decision-Making

Visualizing the trade-offs over the project’s lifespan is key to making an informed decision. While the initial investment in a solar panel factory is a primary focus, it’s the ongoing operational expenditures that determine long-term profitability.

| Factor | Expatriate Model | Local Workforce Development Model |

|---|---|---|

| Initial Cost | Lower (no major training program) | Higher (training program design & execution) |

| Operational Cost | Very High (salaries, benefits, housing) | Low (local wages) |

| Speed to Market | Faster | Slower |

| Knowledge Risk | High (knowledge leaves with personnel) | Low (knowledge is embedded locally) |

| Sustainability | Low (dependent on external talent) | High (self-sufficient and resilient) |

| Community Impact | Minimal | High (job creation, skill building) |

Based on experience from numerous J.v.G. turnkey projects, the most successful enterprises in emerging markets are those that commit to local workforce development from the outset.

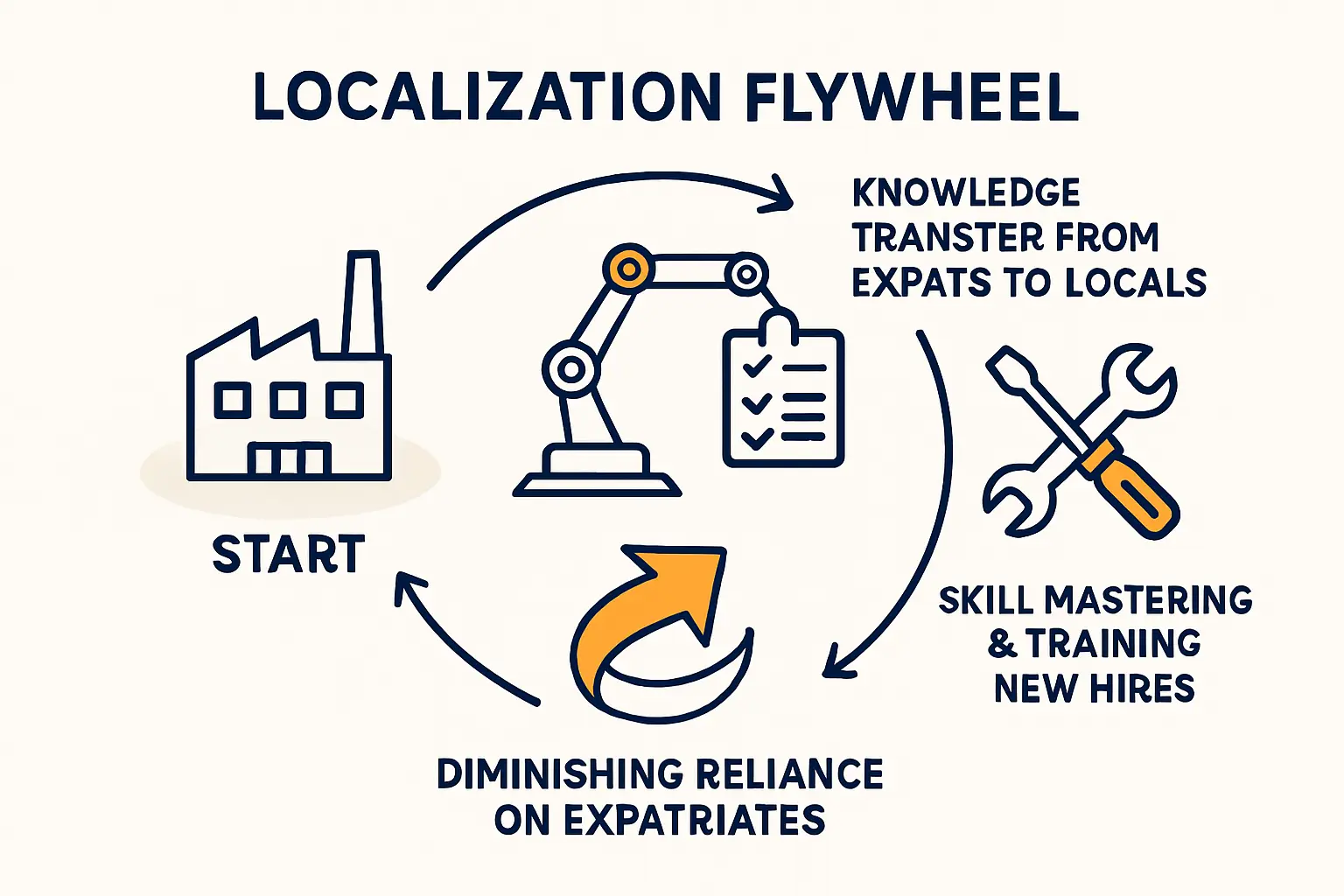

A Hybrid Approach: The Phased Transition Model

A pragmatic and highly effective strategy is the hybrid model, which balances the need for initial expertise with the goal of long-term sustainability.

-

Phase 1: Foundation (Months 1-12): A small, core team of expatriate experts is brought in to oversee plant commissioning and launch production. Their primary mandate, however, is not just to operate machines but to train a hand-picked team of local supervisors and lead technicians.

-

Phase 2: Transition (Months 13-24): The local team takes on increasing responsibility for day-to-day operations. The expatriate team transitions into an advisory and high-level support role, focusing on complex troubleshooting and process optimization.

-

Phase 3: Sustainability (Month 25+): One or two expatriates may remain in senior management or advisory roles, but the factory is run and maintained predominantly by the trained local workforce. The initial training program becomes an ongoing internal process for new hires.

This phased approach is a key component of a robust solar panel manufacturing business plan, as it de-risks the operation while controlling long-term costs.

Frequently Asked Questions (FAQ)

How long does it typically take to train a local solar factory technician?

For a candidate with a basic technical aptitude, a structured program can train a competent machine operator in three to six months. Training a maintenance technician with advanced troubleshooting skills may take 12 to 18 months, combining theoretical instruction with on-the-job training.

What are the typical costs for establishing a local training program?

The initial cost depends on the scale, but it typically includes the salaries for external trainers for 6-12 months, the development of training materials, and wages for trainees during the ramp-up period. While a significant upfront expense, this investment is often recouped within the first two to three years through lower operational labor costs.

Are there government incentives for hiring and training locally in Guinea-Bissau?

Many governments in emerging markets offer incentives for foreign direct investment that includes significant local employment and training components. These can include tax advantages, streamlined permitting, or other forms of support. Investors should engage with national investment promotion agencies to explore available programs.

Conclusion: Building a Foundation for Long-Term Success

The decision between hiring expatriates and developing local talent is not merely an HR choice; it is a foundational strategic decision that will define the cost structure, resilience, and long-term viability of a solar factory in Guinea-Bissau.

While the expatriate model offers a shortcut to initial production, it creates a high-cost structure and operational dependency that can be detrimental in the long run. In contrast, a deliberate investment in training a local workforce, perhaps guided by a hybrid model, builds a more cost-effective, sustainable, and integrated enterprise.

For the serious investor, building local capacity is not an expense—it is the most logical investment in the factory’s future.