As Guyana reaches a pivotal moment in its economic transformation, the opportunity to build a robust renewable energy sector is immense. Entrepreneurs considering entry into solar module manufacturing are well-positioned to meet growing local and regional demand. Yet, a critical strategic decision is often overlooked in the initial planning stages: the choice of module technology itself.

Manufacturing standard solar modules might seem like the most direct path, but Guyana’s unique climate—characterized by high humidity, high ambient temperatures, and intense solar irradiation—presents a significant challenge to conventional module designs.

For long-term success and market leadership, a manufacturer must produce a product engineered to thrive in this demanding environment. This article makes the case that manufacturing high-durability modules, specifically Glass-Glass modules, is a strategic imperative for any new solar venture in the region.

The Environmental Challenge: Why Guyana’s Climate Demands a Superior Module

A solar module is an electronic product designed to perform reliably outdoors for over 25 years. Its durability is constantly put to the test by the environment. In a tropical climate like Guyana’s, three key factors work together to accelerate the degradation of standard solar panels:

-

High Humidity: Persistent moisture is the primary adversary of solar module components. It can slowly penetrate the protective layers of a standard module, leading to corrosion, delamination, and a significant reduction in electrical performance.

-

High Ambient Temperature: While solar panels need sunlight, excessive heat reduces their efficiency and accelerates the aging of materials used in their construction, such as the encapsulants and backsheets.

-

Intense UV Irradiation: The strong equatorial sun emits high levels of ultraviolet (UV) radiation, which breaks down the polymer-based materials in standard modules, causing them to become brittle, yellow, or crack over time.

These factors do not exist in isolation; they create a compounding effect that can cause standard modules to underperform and fail prematurely, damaging a new manufacturer’s reputation and the financial viability of solar projects.

A Structural Comparison: Standard vs. Glass-Glass Modules

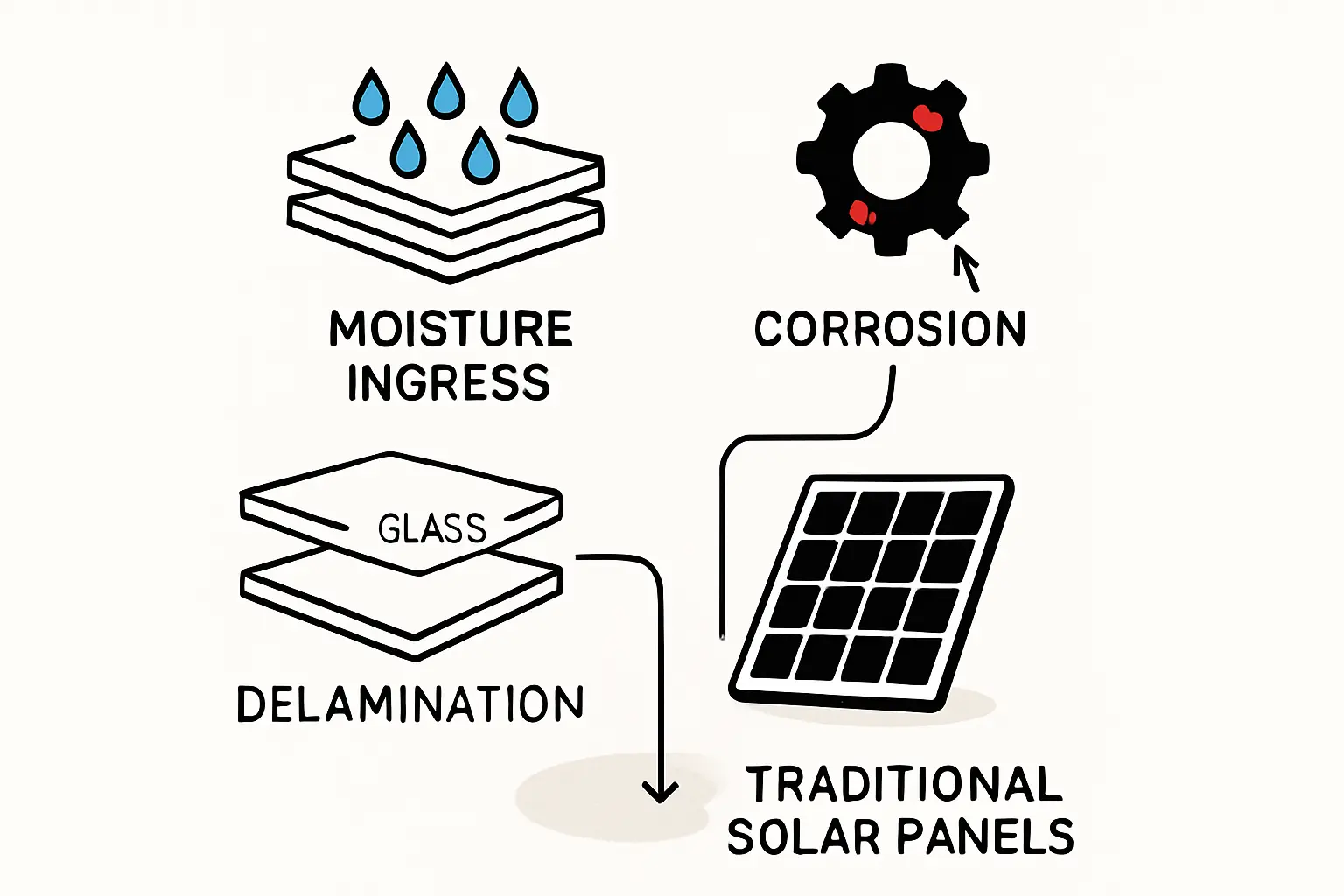

To understand the solution, we must first look at the problem’s source: the structure of a conventional solar module. Most solar panels produced globally are Glass-Foil (or Glass-Backsheet) modules. They consist of a glass front, an encapsulant material that surrounds the solar cells, and a polymer backsheet. While this design is effective in moderate climates, the polymer backsheet is the component most vulnerable to these tropical stresses.

A Glass-Glass module, by contrast, replaces the polymer backsheet with a second layer of heat-strengthened glass.

This seemingly simple modification creates a fundamentally more durable and resilient product. The rear glass acts as an impermeable barrier to moisture and provides superior mechanical stability and UV protection.

Key Degradation Risks and How Glass-Glass Technology Mitigates Them

Experience from J.v.G. turnkey projects in challenging climates shows that focusing on a technology that directly counters local environmental risks is crucial for building a bankable and reputable brand.

Potential Induced Degradation (PID)

PID is a form of power loss caused by stray currents that can occur between the solar cell and the module’s frame, especially in high-voltage systems. This effect is severely accelerated by high humidity and high temperatures. With glass on both sides, a Glass-Glass module offers superior electrical insulation, significantly reducing the risk of PID and preserving power output over the module’s lifetime.

Moisture Ingress and Delamination

In a Glass-Foil module, moisture can eventually work its way through the polymer backsheet or around the edges. This moisture can corrode the electrical connections within the module and cause the layers to separate—a process known as delamination. A Glass-Glass module creates a nearly hermetic seal that effectively locks out moisture for the life of the product. This is a critical advantage in coastal or high-humidity regions.

Microcracks and Mechanical Stability

Solar cells are inherently fragile. Temperature fluctuations, physical stress from transportation, or even heavy winds can cause tiny, invisible microcracks to form in the cells, which reduces power output. The rigid, symmetrical structure of a Glass-Glass module provides exceptional mechanical stability, protecting the cells from these stresses far more effectively than a flexible polymer backsheet.

The Business Case for Manufacturing High-Durability Modules

Choosing to produce Glass-Glass modules is not merely a technical decision; it is a powerful business strategy. For entrepreneurs entering the market, this approach offers several distinct advantages:

-

Brand Reputation: By manufacturing a product demonstrably superior for the local climate, a new company can quickly establish itself as a provider of high-quality, reliable solutions. This builds trust with project developers, financiers, and end-users.

-

Bankability and Project Finance: Large-scale solar projects require financing, and banks conduct extensive due diligence on the equipment used. Modules with a lower risk of degradation and a longer performance lifespan, like Glass-Glass, are considered more ‘bankable,’ making it easier for your customers to secure project funding.

-

Longer Warranties and Higher Value: Glass-Glass modules often come with 30-year performance warranties, compared to the 25-year industry standard for Glass-Foil. This provides a clear value proposition and allows a manufacturer to compete on quality, not just price.

-

Lower Levelized Cost of Energy (LCOE): For a solar power plant owner, the LCOE—the total cost of energy produced over the system’s lifetime—is the most important metric. Because Glass-Glass modules degrade slower and produce more energy over time, they contribute to a lower LCOE, making them the superior long-term investment.

Production Line Considerations

Setting up a turnkey production line for Glass-Glass modules involves specific equipment considerations, particularly in the lamination and framing stages. While the initial investment may differ slightly from a standard Glass-Foil line, the strategic benefits and potential for higher profit margins can provide a compelling return. The underlying processes and many of the solar module components remain similar, making the setup process both structured and manageable.

Frequently Asked Questions (FAQ)

Are Glass-Glass modules much more expensive to produce?

The cost of the second sheet of glass is higher than a polymer backsheet, leading to a slightly higher material cost. However, streamlined manufacturing processes and economies of scale have narrowed this gap significantly. The premium market positioning and longer product lifespan often justify the difference.

Is special equipment required for a Glass-Glass line?

Yes, certain machines, like the laminator, must be specified to handle the dual-glass structure. An experienced technology partner can design a production line optimized for Glass-Glass manufacturing from the outset.

Can a single factory produce both Glass-Foil and Glass-Glass modules?

It is possible but requires a flexible production line design. For a new entrant in a market like Guyana, specializing in the more durable technology can provide a clearer market identity and operational focus.

How does this technology selection apply to other tropical regions?

The principles discussed are highly relevant for any region with a hot and humid climate, including the Caribbean, Southeast Asia, Central America, and parts of Africa and South America. Manufacturing a product tailored to environmental realities is a universally sound business strategy.

A Strategic Foundation for Long-Term Success

Entering the solar manufacturing industry is a significant undertaking. To ensure long-term success, entrepreneurs must look beyond simply producing a solar panel and instead focus on manufacturing the right one for their target market. In Guyana and similar climates, the evidence strongly supports the strategic production of Glass-Glass modules. This approach builds a foundation of quality, reliability, and trust—the essential pillars for a leading manufacturing enterprise in the new energy economy.