Many entrepreneurs evaluating a solar manufacturing venture begin with standardized financial models. They input global averages for labor, energy, and construction, producing a plan that looks credible on paper.

However, when applied to a unique market like Haiti, such a generic model is not just inaccurate—it can be the blueprint for failure. The Haitian economic landscape, with its specific infrastructural challenges and cost structures, demands a much more granular and localized approach.

This analysis breaks down the critical, Haiti-specific variables that any realistic financial model must incorporate to create a viable business plan for a solar module factory. It moves beyond generic estimates to offer a framework for grounded financial forecasting.

Why a Generic Financial Model Fails in the Haitian Context

A standard financial model often assumes stable infrastructure, predictable supply chains, and a stable currency environment. These assumptions do not hold in Haiti. An effective financial projection must account for:

- Infrastructural Realities: The national electricity grid is often unreliable and expensive, making energy a primary operational expenditure (OPEX) that requires a unique solution.

- Logistical Hurdles: As an island nation with developing port infrastructure, importation costs, customs clearance times, and inland transport are significant variables.

- Currency Fluctuation: The Haitian Gourde (HTG) has a history of volatility against the US Dollar. Since most equipment and raw materials are priced in USD, while local labor and some services are paid in HTG, careful currency management is essential.

- Labor Market Specifics: While labor costs may seem low, the availability of trained technical staff is limited, necessitating investment in comprehensive training programs.

Core Cost Drivers for a Haitian Solar Module Factory

A credible financial model must be built from the ground up using local data, focusing on the key cost centers for a 20-50 MW solar module factory.

Labor Costs: Beyond the Minimum Wage

While Haiti’s statutory minimum wage provides a baseline, a solar factory requires a workforce with varying skill levels. A typical small-scale facility of 20-50 MW might employ 25 to 30 individuals.

-

Unskilled and Semi-Skilled Labor: This group forms the majority of the production line staff. While the official minimum wage is a starting point (approximately 750 HTG per day in the industrial sector), competitive and fair wages are often slightly higher to attract and retain reliable workers. Budgeting around $8-$12 USD per day per worker is a more realistic starting point for financial modeling.

-

Skilled Technicians and Engineers: This is a critical cost consideration, as Haiti has a limited pool of local technicians with experience in industrial automation or electronics. These employees will command a significant premium, and the financial model must also factor in substantial costs for training, potentially including sending key personnel abroad for instruction at the equipment manufacturer’s facility.

-

Administrative and Management Staff: The model must also account for local administrative, logistics, and management personnel, whose salaries will vary based on experience.

Careful planning for human resources, including a dedicated training budget, is a non-negotiable component of the initial investment.

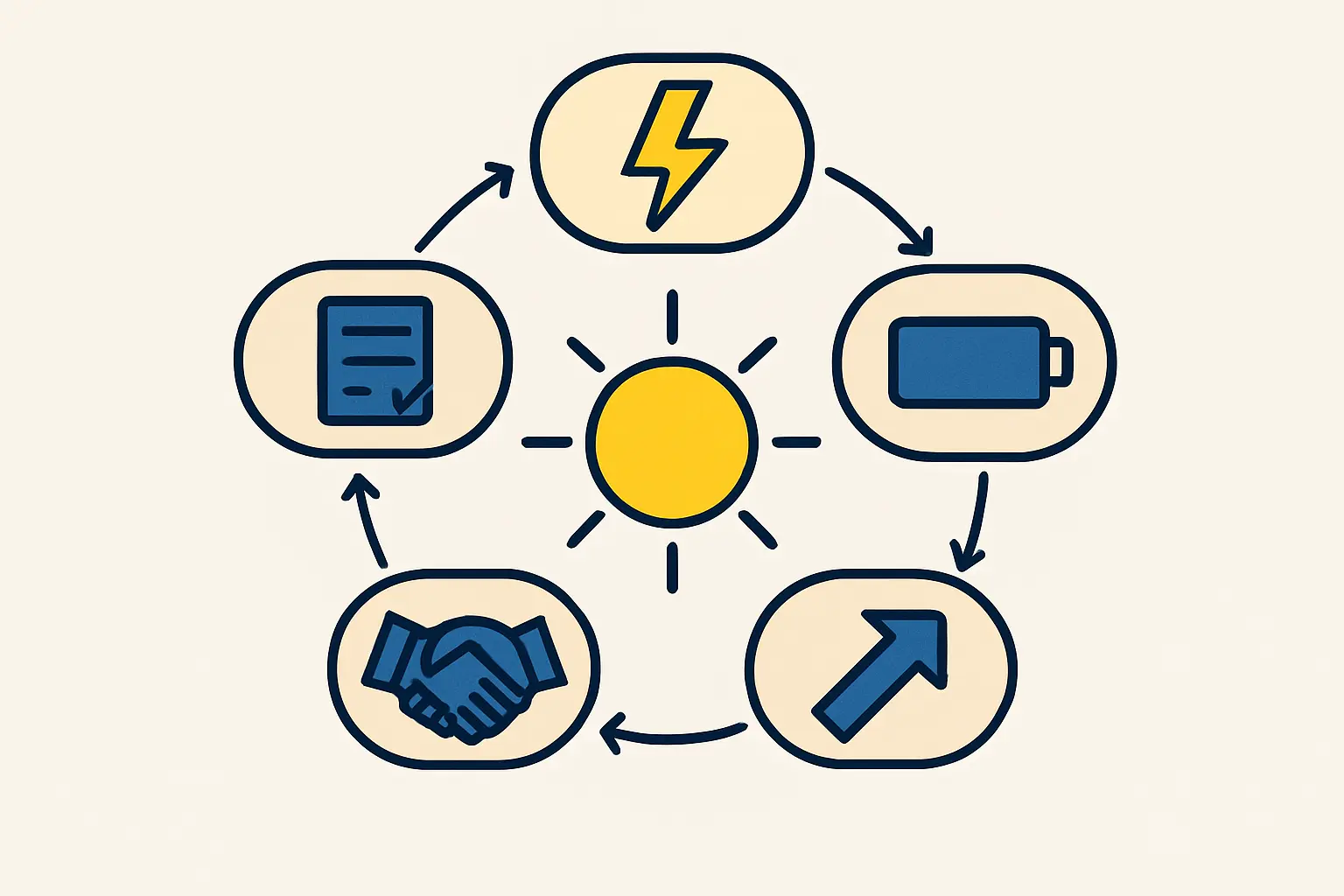

Energy Expenses: The Grid Reliability Factor

Energy is one of the most significant operational risks and costs in Haiti. The state utility, Électricité d’Haïti (EDH), provides power that can be both expensive (upwards of $0.35 USD per kWh) and highly unreliable, with frequent outages.

A factory simply cannot depend on this supply. The financial model must therefore include a robust, independent power solution. This typically involves a hybrid approach:

-

Primary Power Source: A dedicated solar PV system installed on the factory roof or adjacent land. This not only provides stable, low-cost energy but also serves as a powerful demonstration of the product being manufactured.

-

Energy Storage: A Battery Energy Storage System (BESS) is crucial to ensure 24/7 power for critical machinery and to store excess solar energy.

-

Backup Power: A diesel generator remains a necessary backup for prolonged periods of low solar irradiation or for maintenance on the primary power system. The cost of diesel fuel must be factored into the operational budget.

This self-sufficient energy infrastructure is a major capital expenditure (CAPEX) but drastically reduces long-term operational risk and cost. Any financial model that relies on grid electricity is fundamentally flawed. For a deeper look into facility planning, one can review guides on solar factory building requirements.

Logistics and Importation: Navigating Port-au-Prince

Nearly all raw materials for solar module manufacturing—including solar cells, glass, EVA encapsulant, backsheets, and aluminum frames—must be imported. The Port-au-Prince seaport is the primary point of entry.

The financial model must account for:

- Shipping Costs: Freight charges from suppliers in Asia, Europe, or North America.

- Port Fees and Tariffs: Local port authority charges, customs duties, and taxes. While investment incentive programs may offer exemptions, these must be secured in advance.

- Customs Brokerage and Clearance: Fees for local agents to navigate the customs process, which can sometimes involve delays.

- Inland Transportation: The cost of moving containers from the port to the factory location.

Building a buffer into both the timeline and the budget for logistics is a prudent measure. Delays in receiving raw materials can halt production, making supply chain management a critical operational focus.

Land and Construction: Building from the Ground Up

The cost of building a suitable factory is a significant initial investment. While land leasing or acquisition costs vary, industrial construction costs offer a more stable basis for budgeting.

- Building Costs: A reasonable estimate for constructing an industrial-grade steel-frame building in Haiti ranges from $450 to $650 USD per square meter. A 20-50 MW facility typically requires around 2,000–3,000 square meters of production and storage space.

- Site Preparation: This includes grading, foundation work, and utility connections (water, septic), which can add to the total cost.

- Location: Establishing the factory within a designated industrial park, such as the Caracol Industrial Park in the north or others near Port-au-Prince, can offer benefits like better security, more reliable infrastructure, and pre-vetted land titles.

The factory layout must be planned meticulously from the outset—it is a core component of a turnkey solar module production line.

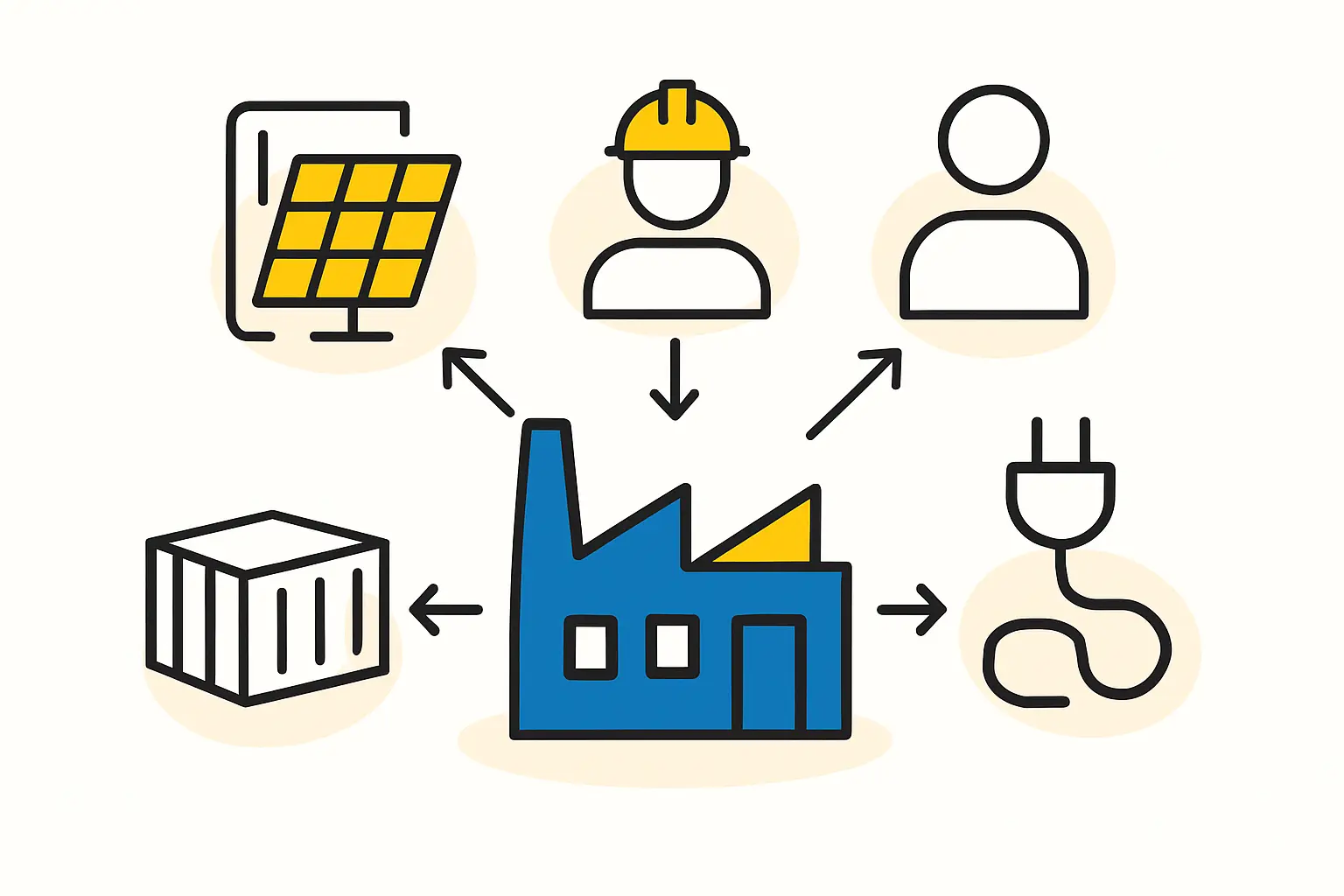

Revenue and Market Considerations

On the revenue side, the Haitian market presents a clear opportunity. The unreliable national grid creates immense demand for decentralized solar solutions for homes, businesses, and critical infrastructure like hospitals and schools.

The financial model should project revenue based on:

- Local Demand: The primary market will be domestic. Pricing must be competitive while reflecting the quality and local availability of the modules.

- Export Potential: Access to CARICOM (Caribbean Community) markets could offer a path for future growth, potentially with preferential trade terms.

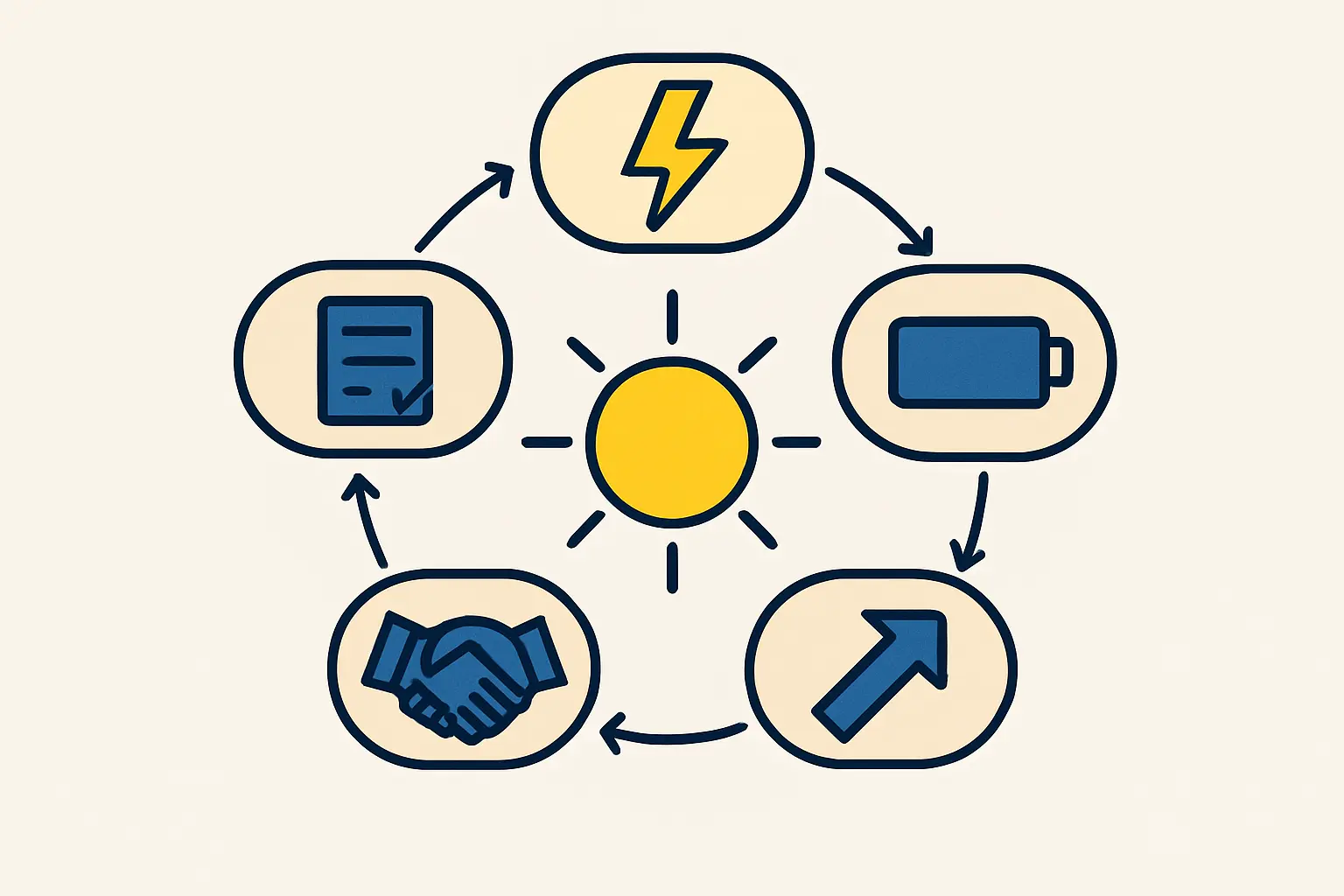

- Distribution Channels: Establishing strong partnerships with local installers, distributors, and NGOs is key to reaching end-users.

Integrating Local Realities into a Credible Financial Projection

To create a robust financial model, an entrepreneur must replace generic data with verified local costs. This involves engaging with local consultants, construction firms, and logistics providers to gather accurate quotations.

Experience from J.v.G. Technology GmbH turnkey projects in emerging markets suggests that a contingency fund of at least 15-20% of the total initial investment is strongly recommended. This fund provides a critical buffer to manage unforeseen costs related to logistics, customs, or construction delays. Selecting the right solar manufacturing equipment is also fundamental, as equipment choices directly influence both CAPEX and long-term OPEX.

Frequently Asked Questions (FAQ)

What is a realistic initial investment for a small factory in Haiti?

For a 20-50 MW semi-automated production line, a typical investment range is between $3 million and $5 million USD. This includes equipment, building construction, initial raw material stock, and the independent power system.

Are there government incentives for manufacturing in Haiti?

Yes, Haiti’s Investment Code offers potential incentives for new industrial enterprises, which can include tax holidays for several years and exemptions from customs duties on equipment and raw materials. Securing these benefits requires a formal application and approval process.

How does currency risk affect the business plan?

Since revenues may be partly in HTG while major costs are in USD, currency depreciation can impact profitability. Strategies to mitigate this include pricing products in USD or a USD-pegged equivalent and keeping operational cash reserves in USD wherever possible.

How long does it typically take to set up a factory in Haiti?

With proper planning and an experienced partner, a solar factory can become operational in 12 to 18 months from the start of the project. This timeline includes company registration, site selection, construction, equipment installation, and staff training.

Next Steps in Your Planning Journey

Developing a financial model for a solar factory in Haiti is a complex but manageable task. It requires a departure from standard templates and a deep commitment to on-the-ground research. By systematically analyzing local costs for labor, energy, logistics, and construction, an entrepreneur can build a projection that is not only convincing to investors but also serves as a reliable guide for operations.

This detailed planning phase is the foundation of a successful venture. For those seeking a structured approach, the pvknowhow.com platform provides comprehensive resources, including e-courses and sample business plans, to guide entrepreneurs through each stage of this process.