An entrepreneur planning a solar panel manufacturing business often looks at broad market trends. The most compelling opportunities, however, often lie in addressing specific, high-cost problems within a nation’s key economic sectors.

In Honduras, a unique combination of high electricity prices and a robust industrial base creates a prime opportunity, particularly in its agricultural and maquiladora industries. For business leaders in these sectors, energy isn’t an abstract concept—it’s a significant operational cost and a critical point of vulnerability. Understanding their specific needs is the first step toward building a targeted and successful local solar module manufacturing enterprise.

The Energy Challenge Facing Honduras’s Economic Engines

Honduras faces some of the highest electricity costs in Central America, a burden driven by its heavy reliance on imported fossil fuels, which exposes the national economy to global price volatility. For any business, but especially for energy-intensive operations, this creates financial uncertainty and a competitive disadvantage.

Grid instability only compounds the problem. Frequent power outages and fluctuations can halt production, damage sensitive equipment, and lead to significant financial losses. These are not minor inconveniences; they are fundamental barriers to growth and profitability for the industries that drive the Honduran economy.

The Maquiladora Sector: A Prime Candidate for Localized Solar Solutions

The maquiladora industry, dominated by textile and apparel manufacturing for major international brands, is a cornerstone of Honduran exports. These facilities run for long hours with vast arrays of machinery, from sewing machines and cutters to lighting and climate control systems. Their energy consumption is immense and, more importantly, must be uninterrupted to meet strict production deadlines.

For a maquiladora operator, an unexpected power outage can idle thousands of workers and delay shipments, potentially incurring contractual penalties. High electricity tariffs also directly impact production costs, squeezing profit margins in a highly competitive global market.

A reliable, cost-predictable energy source is not a luxury—it is a strategic necessity. On-site solar power directly addresses both the cost and reliability challenges.

Powering Agriculture: From Irrigation to Cold Storage

Honduras’s agricultural sector is another vital economic pillar, known for high-value exports like coffee, bananas, palm oil, and melons. Its energy needs are diverse and equally critical: irrigation pumps for crop health, processing facilities for washing and packaging, and non-negotiable cold storage to preserve perishable goods before export.

A power failure here can be catastrophic. An irrigation system going offline during a dry spell can slash crop yields, while a lapse in refrigeration can mean the complete loss of a harvest. For agricultural entrepreneurs, energy reliability is directly linked to product quality and financial survival.

Why Local Manufacturing is the Strategic Answer

While importing solar modules is an option, a local manufacturing line offers distinct advantages tailored to local conditions, transforming a logistical challenge into a strategic asset.

-

Customization and Suitability: Local manufacturers can design and produce modules specifically optimized for the region’s high-temperature, high-humidity climate. This ensures better performance and a longer operational lifespan than generic, mass-produced alternatives.

-

Supply Chain Control: Producing locally eliminates the risks and costs of international shipping, customs delays, and currency fluctuations. It provides a stable, predictable supply chain for installers and project developers serving the industrial and agricultural sectors.

-

Service and Responsiveness: When an industrial facility invests in a large-scale solar installation, reliable post-sales support is crucial. A local manufacturer can offer immediate technical help, warranty services, and replacement parts—a level of responsiveness foreign suppliers cannot match.

-

Economic Alignment: A domestic factory creates skilled jobs and contributes to the national economy, aligning the business with government goals for industrial development and energy independence.

Building the Business Case for a Honduran Solar Factory

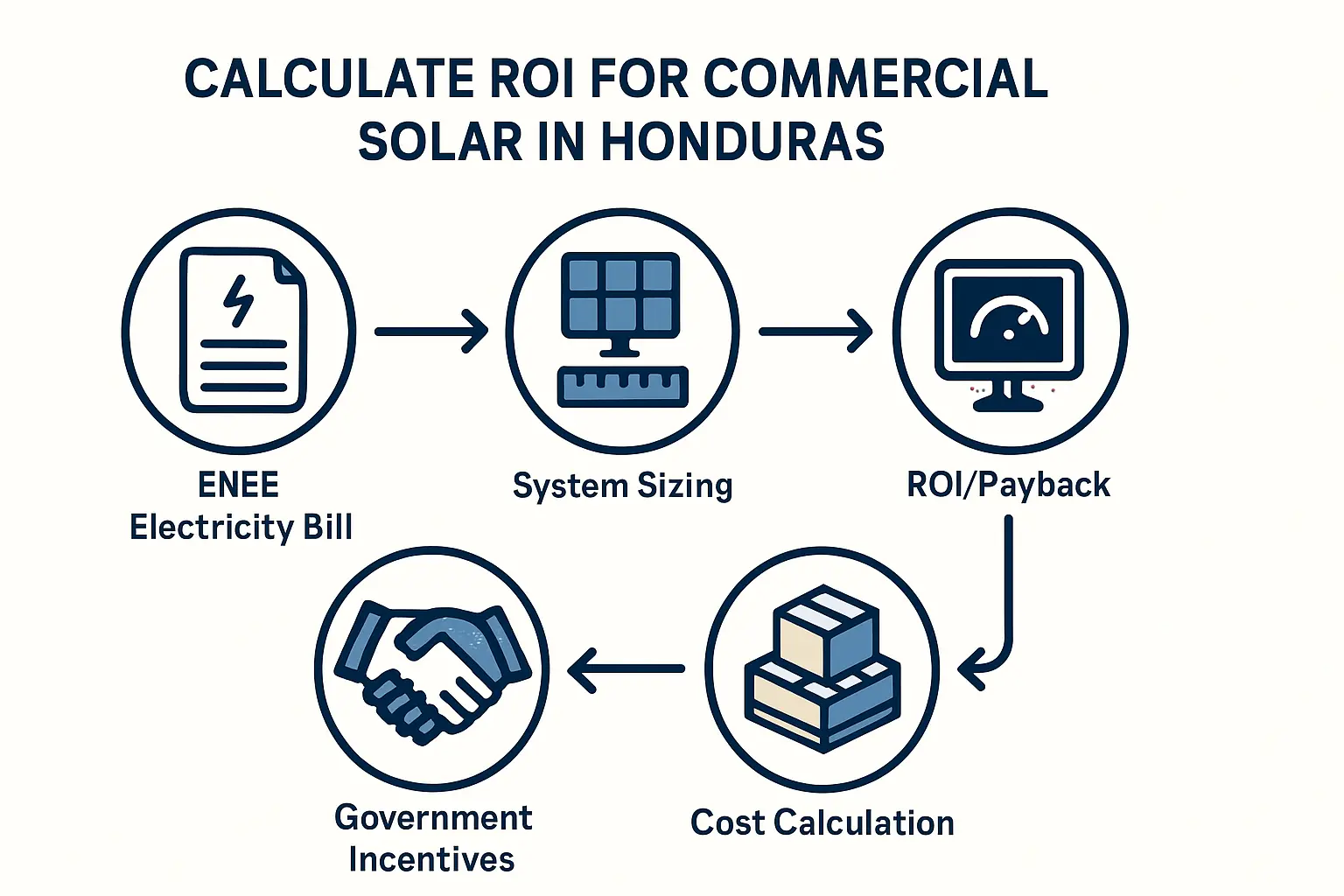

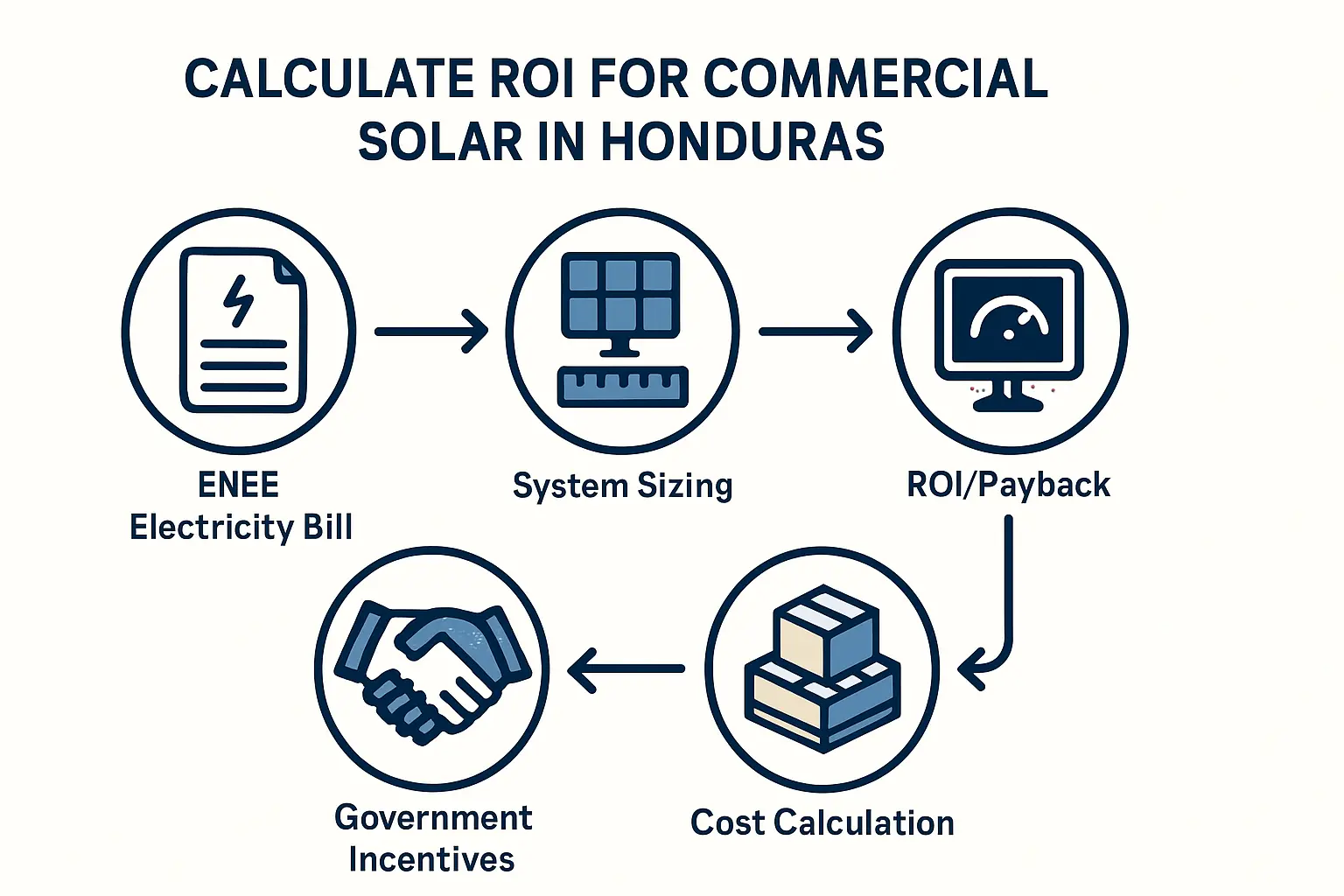

The opportunity in Honduras is not just about selling solar panels; it’s about solving a pressing economic problem. The government has recognized this and offers incentives like tax exemptions for renewable energy projects, strengthening the financial viability of such ventures.

Developing a comprehensive solar panel business plan is the critical next step. This plan should quantify demand from maquiladoras and agricultural cooperatives, model the costs of a local production facility, and project the return on investment based on solving the country’s core energy challenges.

Experience from J.v.G. turnkey projects in similar emerging markets shows that a focused approach targeting specific industrial needs often yields a more robust and faster path to profitability than a general residential strategy.

Frequently Asked Questions (FAQ)

What size factory is needed to serve these sectors?

An initial setup doesn’t need to compete with global mega-factories. A semi-automated line with an annual capacity of 20–50 MW can be highly effective. This size allows for flexibility in production, enabling the factory to produce specific module types required for large industrial rooftops or ground-mounted agricultural projects.

Do I need a background in solar technology to succeed?

No. Successful entrepreneurs in this space typically have strong business and project management skills. The technical aspects of setting up and running the factory can be handled by partnering with experienced engineering firms. The key, as pvknowhow.com materials emphasize, is understanding the business case—not being a photovoltaic expert yourself.

Are there enough skilled workers in Honduras?

Operating a modern, semi-automated solar module factory requires a team of 25–30 employees, and the necessary technical skills are highly trainable. A turnkey factory setup typically includes comprehensive training programs for local operators and technicians to ensure a smooth transition to full production.

How can a local factory compete with low-cost imported panels?

A local factory shouldn’t compete on upfront price per watt alone. Instead, it competes on total value: faster delivery, no import risks, products customized for the local climate, responsive local warranty support, and contributions to the national economy. For a large industrial client, reliability and local service are often more valuable than a marginal saving on imported hardware.

Your Next Step in Exploring This Opportunity

The confluence of high energy costs, grid instability, and a strong industrial base makes Honduras a compelling location for targeted solar module manufacturing. The demand is not speculative; it is rooted in the daily operational challenges faced by the country’s most important businesses.

For entrepreneurs and investors, the path forward involves a detailed analysis of this specific market. Explore the structured resources on pvknowhow.com, designed to guide you through this critical planning and validation phase and help transform a powerful idea into a viable industrial project.