A solar module is designed to generate clean energy for decades, yet its manufacturing story is often far from clean. The vast majority of solar panels are produced using energy from coal-fired grids. This gives the product a significant carbon footprint before it ever generates its first kilowatt-hour.

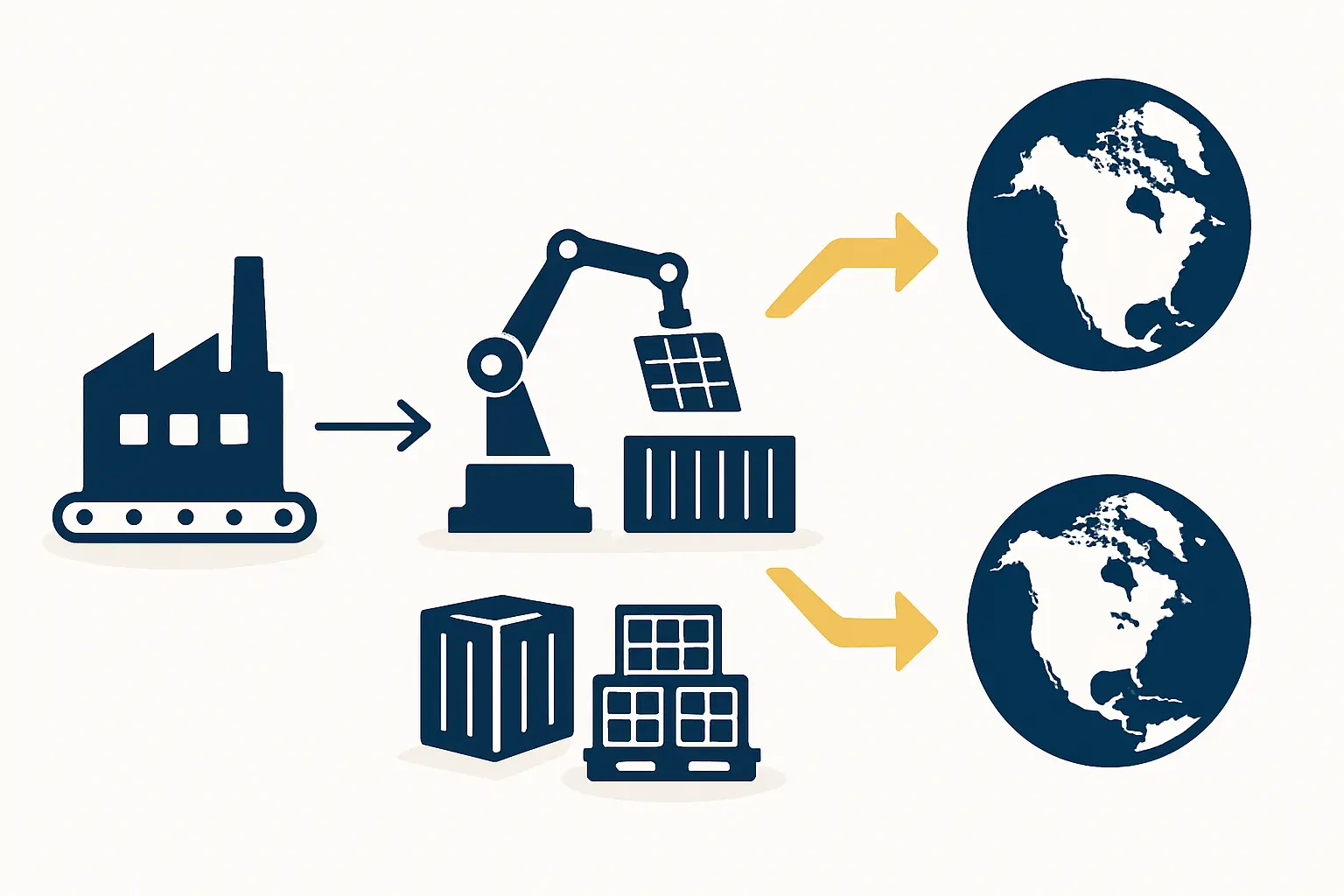

This paradox creates a unique market opening. This article explores the high-potential strategy of establishing a solar module factory in Iceland to export premium, low-carbon solar modules to Europe and North America.

The Hidden Carbon Footprint of Solar Manufacturing

To understand the opportunity, it’s essential to grasp the concept of “embodied carbon.” This refers to the total greenhouse gas emissions generated throughout a product’s manufacturing. For a solar module, the most energy-intensive step is transforming raw polysilicon into wafers and then into solar cells—a process typically performed in Asia.

A standard solar panel manufactured using a fossil fuel-heavy energy grid can take between one and two years of operation to generate enough clean energy to “pay back” the energy used in its production. This is known as the Energy Payback Time (EPBT). While the module certainly yields a positive return over its 25- to 30-year lifespan, this still represents a significant upfront environmental cost.

This hidden footprint is becoming a critical consideration for policymakers and discerning buyers, driving demand for a verifiably “greener” solar module.

Iceland’s Unique Proposition: 100% Renewable Manufacturing

Iceland offers a compelling solution to the embodied carbon problem. The country’s energy mix is unique: nearly 100% of its electricity is generated from renewable geothermal and hydroelectric sources. A solar module factory in Iceland would be powered entirely by clean energy.

This would have a profound impact on the product’s environmental credentials:

-

Drastically Reduced Embodied Carbon: A module ‘Made in Iceland’ could have a carbon footprint up to 70-80% lower than a conventional panel, offering a powerful and quantifiable marketing advantage.

-

Shorter Energy Payback Time: The EPBT could be reduced from years to just a few months, making it one of the most sustainable solar products available.

-

A Powerful Brand Story: The narrative of ‘Made in Iceland with 100% Green Energy’ is simple, verifiable, and highly appealing to premium market segments.

This transforms the solar module from a simple commodity judged on price and efficiency alone into a premium product with a strong ethical and environmental value proposition.

Targeting Premium Markets in Europe and North America

A higher-cost production environment like Iceland necessitates a focus on markets where customers are willing to pay a premium for sustainability and quality. Europe and North America are the primary targets.

The European ‘Green Deal’ and Carbon-Conscious Buyers

The European Union is placing increasing emphasis on the carbon footprint of imported goods. Some member states, like France, have already implemented procurement policies (the CFP tender) that favor solar modules with a low, certified carbon footprint. An Icelandic manufacturer would be perfectly positioned to meet and exceed these standards.

Iceland’s membership in the European Economic Area (EEA) also grants it tariff-free access to the EU’s single market, simplifying trade and logistics. As companies across Europe face mounting pressure to report on and reduce their Scope 3 emissions (indirect emissions from their supply chain), procuring low-carbon solar panels becomes a strategic decision. A detailed understanding of the solar module manufacturing process is essential for calculating and verifying these carbon savings.

North America: The Corporate and Residential Premium Segment

In North America, demand is driven less by government tenders and more by corporate ESG (Environmental, Social, and Governance) commitments and discerning residential customers.

-

Corporate ESG: Fortune 500 companies investing in large-scale solar installations for their facilities are highly sensitive to brand perception. Using modules with the lowest possible carbon footprint aligns perfectly with their public sustainability goals.

-

High-End Residential: A growing segment of homeowners is willing to pay more for products that reflect their environmental values. For these customers, a premium of 10-20% for a “cleanly made” solar system is a justifiable expense.

Navigating the Practical Realities: Logistics and Costs

While the marketing proposition is strong, a successful venture depends on sound business logic. Any feasibility study must address the operational challenges, and a clear-eyed assessment is critical, drawing on experience from turnkey projects in diverse locations.

Logistics: Iceland’s location in the North Atlantic is a strategic advantage. It sits directly between the major markets of Europe and North America, with established shipping lanes to ports like Rotterdam, Hamburg, and Halifax. While shipping costs must be factored in, they are manageable and can be optimized through efficient logistics planning.

Operating Costs vs. Premium Pricing: The cost of labor and electricity in Iceland is higher than in traditional manufacturing hubs. However, this is the very foundation of the product’s premium value. A business model must be built around securing a price premium that more than covers these increased costs. Market analysis suggests that a certified low-carbon module could command a significant premium, particularly in the targeted segments. Establishing an efficient factory layout for a 50 MW line can help control costs and maximize throughput.

Building a Business Case: A Feasibility Framework

Launching such a specialized manufacturing operation requires meticulous planning. Entrepreneurs considering this opportunity should follow a structured approach:

-

Detailed Market Analysis: Quantify the addressable market in Europe and North America. Identify specific customer segments (e.g., green building developers, ESG-focused corporations) and validate the potential price premium through market research.

-

Supply Chain and Logistics Planning: Secure reliable sources for raw materials (cells, glass, frames) and establish cost-effective, dependable shipping contracts.

-

Comprehensive Financial Modeling: Develop a detailed business plan that accurately projects capital expenditures, operational costs, and revenue based on a realistic premium pricing strategy. Understanding the investment for a solar module factory is a crucial first step.

-

Certification and Compliance: Plan for obtaining all necessary IEC and UL certifications for market access. Crucially, this includes securing a third-party lifecycle assessment (LCA) to formally certify the low-carbon footprint of the modules.

Frequently Asked Questions (FAQ)

Is Iceland’s limited sunlight a disadvantage for a solar factory?

No. A solar module factory does not require sunlight to operate; it requires a stable and abundant supply of electricity. Iceland’s 24/7 renewable power from geothermal and hydro sources is ideal for energy-intensive manufacturing.

How much of a premium can ‘green’ solar modules command?

This varies by market segment. In government tenders with carbon footprint criteria, it can be the deciding factor for winning a contract. In corporate and high-end residential markets, a premium of 10-25% over standard modules is considered achievable for a product with a strong, verifiable environmental story.

What are the main trade advantages for Iceland?

As part of the European Economic Area (EEA), Iceland enjoys frictionless, tariff-free trade with the entire European Union. It also has established trade agreements with North America, making it a well-positioned hub for transatlantic commerce.

Conclusion: Beyond Manufacturing to Market Leadership

The “Made in Iceland” solar module concept marks a strategic shift from competing on cost to competing on value. This is an opportunity to create a brand that stands for the highest environmental integrity in the renewable energy sector. By leveraging a unique geographical advantage—abundant green energy—an Icelandic manufacturer could meet a growing global demand for truly sustainable products.

This venture is not for everyone. It requires significant capital, a sophisticated market strategy, and precise technical execution. For the right entrepreneur or investment group, however, it offers a path to not only build a profitable business but also to set a new standard for the solar industry worldwide. For entrepreneurs new to the industry, building a foundational understanding for this level of strategic planning is key. Structured resources, such as the pvknowhow.com e-course, can provide a comprehensive starting point.