When considering locations for solar energy production, Iceland, with its long, dark winters and northerly latitude, might not be the first country that comes to mind. The common perception is that solar power requires intense, direct sunlight—a resource far more associated with equatorial regions. This view, however, overlooks a significant opportunity: engineering solutions designed specifically for Iceland’s climate, rather than against it.

This article explores the compelling business case for establishing specialized solar module manufacturing in Iceland, examining how advanced technologies can harness the country’s unique atmospheric conditions—including prevalent diffuse sunlight and high reflectivity from snow—to create a viable and strategic energy asset.

Why Standard Solar Modules Underperform in Iceland

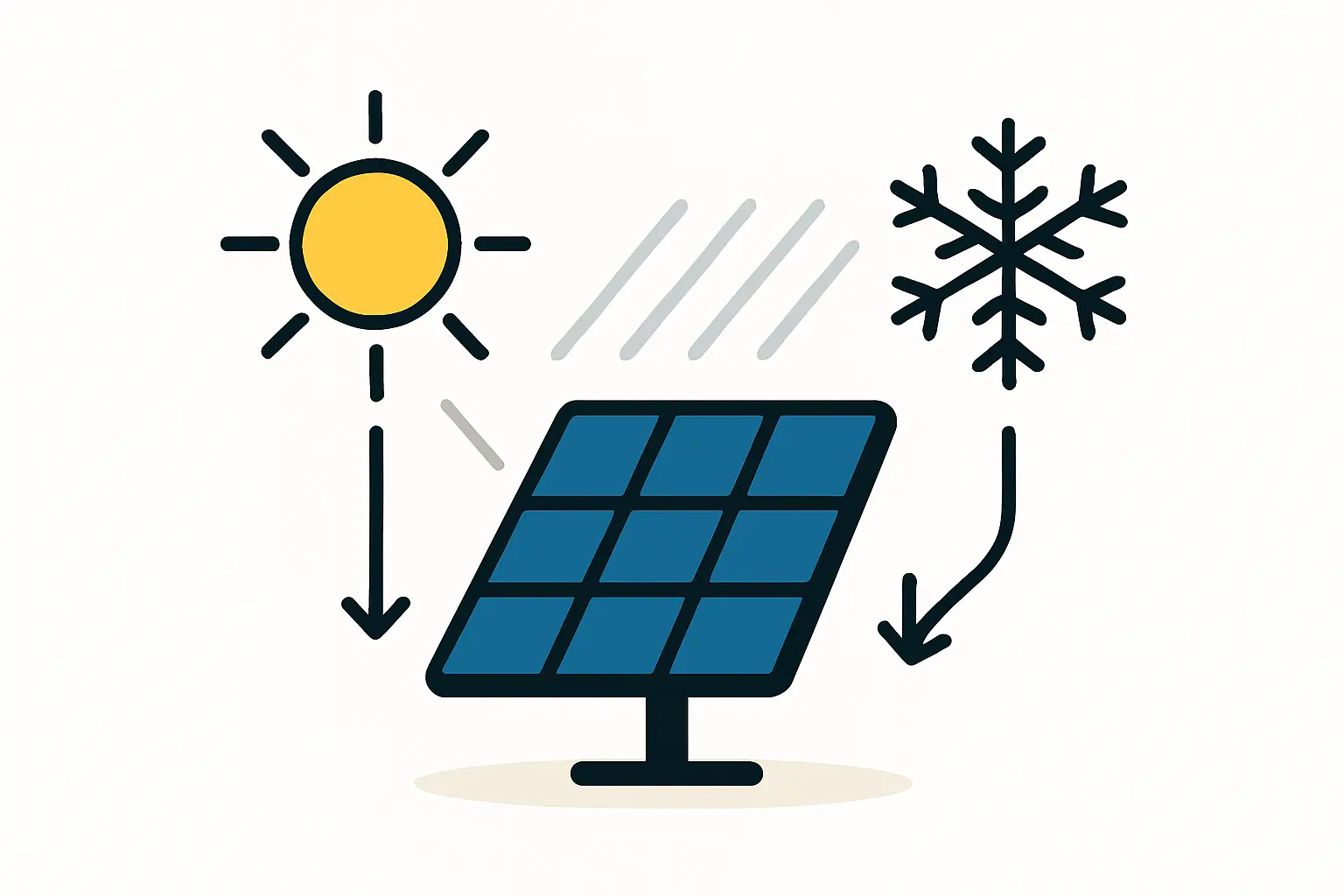

Most solar panels on the global market are optimized for standard test conditions, which assume strong, direct sunlight perpendicular to the module’s surface. These conditions are rarely met in Iceland, where the solar resource is characterized by three key factors:

-

Low Sun Angles: Due to its high latitude, the sun sits lower in the sky for most of the year. This means sunlight must travel through more of the Earth’s atmosphere, which reduces its intensity.

-

High Proportion of Diffuse Light: Overcast skies are common. In these conditions, sunlight is scattered by clouds and atmospheric particles, arriving at the ground from all directions. This diffuse radiation can account for 60–70% of the total solar energy available in Iceland, rendering standard panels designed for direct light inefficient.

-

The Albedo Effect: During winter, snow cover acts like a vast natural mirror, reflecting sunlight from the ground. This reflected light, known as albedo, is a significant source of potential energy that standard monofacial (single-sided) panels are unable to capture.

Producing standard solar panels for this market would mean manufacturing a product fundamentally mismatched to its environment. The strategic advantage lies in producing modules engineered to excel in these specific low-light and high-albedo conditions.

High-Efficiency Technologies for Low-Light Environments

To capitalize on Iceland’s unique solar profile, a manufacturing facility must focus on specific, high-efficiency technologies. Two prominent examples are bifacial and TOPCon cells, which directly address the challenges of low-light and reflected-light conditions.

The Advantage of Bifacial Technology in Snowy Conditions

Bifacial solar modules are designed with transparent materials on both the front and back, allowing them to capture light from both sides. While the front side captures direct and diffuse light from the sky, the rear side absorbs light reflected from the ground.

In a snow-covered Icelandic landscape, this becomes a powerful advantage. The high albedo of snow reflects a significant amount of light upwards, which a bifacial panel can convert into additional electricity. This can result in an energy gain of 5% to 20% annually compared to a monofacial counterpart, with the most significant gains occurring during the bright, snowy months of late winter and early spring. Understanding the value of bifacial technology is therefore critical for anyone considering the solar panel manufacturing process in markets with high ground-level reflectivity.

TOPCon Technology: Superior Performance When Light is Scarce

TOPCon (Tunnel Oxide Passivated Contact) is an advanced cell architecture that significantly improves a module’s efficiency, particularly in non-ideal conditions. For a market like Iceland, TOPCon offers two primary benefits:

-

Excellent Low-Light Performance: The advanced passivation layers in TOPCon cells reduce electrical losses, enabling them to generate more power from low-intensity or diffuse sunlight than conventional cells. This leads to better performance on overcast days and during the long twilight hours of the Icelandic summer.

-

Superior Temperature Coefficient: Solar panels lose efficiency as they heat up. In cold climates, however, they operate closer to their optimal temperature. TOPCon modules have an excellent temperature coefficient, losing less power in the cold than older technologies, allowing them to capitalize fully on Iceland’s cool ambient temperatures.

A local manufacturer equipped to produce TOPCon modules would be creating a product that generates more kilowatt-hours (kWh) per year under real-world Icelandic conditions, delivering superior value to the end user.

The Business Case for Local, Specialized Production

Competing with global mass-producers on standard modules is a difficult proposition. The strategic opportunity for an Icelandic enterprise lies in specialization and addressing local needs in a way that importers cannot.

Moving Beyond Cost-per-Watt to Lifetime Energy Yield

While the conventional metric for solar panel cost is dollars per watt-peak ($/Wp), this figure only reflects a panel’s output under ideal lab conditions. For an investor in Iceland, a more important metric is the Levelized Cost of Energy (LCOE), which measures the cost per kWh of electricity produced over the module’s entire lifespan.

Although the initial investment requirements for a factory with bifacial and TOPCon capabilities may be 15–25% higher, the resulting modules can produce significantly more energy annually. This higher energy yield leads to a lower LCOE and a better return on investment for the end user, creating a strong competitive advantage based on performance rather than price alone.

Strategic Advantages of a Local Manufacturing Plant

Establishing a local manufacturing plant offers benefits that extend beyond the product itself:

-

Energy Security: Local production reduces reliance on imported energy technologies and long, fragile supply chains.

-

Economic Development: A small-to-medium scale factory (e.g., 50–100 MW) creates skilled jobs and fosters a domestic renewable energy industry.

-

Customization: A local facility can design and produce modules for niche Icelandic applications, such as agrivoltaics (integrating solar with agriculture) or vertical installations on building facades.

-

National Branding: Manufacturing high-tech green energy products aligns perfectly with Iceland’s brand as a leader in renewable energy.

Experience from J.v.G. turnkey projects shows that adapting a production line for such specialized modules is a well-understood procedure. The key is planning for this capability from the outset when starting a solar module factory.

Frequently Asked Questions (FAQ)

Is solar power truly viable in a country with such limited winter sunlight?

Yes. While winter production is low, the long summer days with up to 24 hours of daylight help compensate. The business case rests on the total annual energy yield, not just peak performance. By using technologies like TOPCon and bifacial that are optimized for diffuse light and albedo, the annual yield becomes economically attractive.

Can a small factory in Iceland compete with large international manufacturers?

Directly competing on the price of standard, commodity modules would be challenging. The competitive advantage comes from specialization. By manufacturing high-performance modules specifically designed for Nordic conditions, a local factory can offer a superior-value product that large-scale importers do not. The focus shifts from price competition to performance and quality.

How complex is it to add bifacial or TOPCon capabilities to a production line?

Incorporating these technologies requires specific machinery, process controls, and materials. For example, a TOPCon line requires additional deposition and annealing equipment compared to a standard line. While this adds complexity, it is a manageable step within a well-planned, modern factory setup and represents a strategic investment in a higher-value product.

The Path Forward

The opportunity for solar module manufacturing in Iceland is not about replicating a standard model but innovating for a specific environment. By focusing on advanced technologies like bifacial and TOPCon, an entrepreneur can build a business that offers a technologically superior solution for the local market.

Success lies in understanding that for unique climates, the most valuable product is not the cheapest one, but the one engineered best for its conditions. With structured guidance, entrepreneurs can confidently navigate the complexities of this industry and build a resilient, high-value enterprise.