Iceland presents a compelling paradox for industrial development. Its vast geothermal resources offer some of the most affordable and sustainable electricity on the planet—an ideal foundation for energy-intensive manufacturing.

Yet, its volcanic activity poses a unique operational challenge: abrasive, corrosive ash that can threaten both industrial processes and final products. For an entrepreneur considering solar module manufacturing in such a location, this environmental factor is no mere detail; it is a core engineering problem to overcome.

While it may seem counterintuitive, establishing a solar factory in a volcanic region is entirely feasible. It does, however, demand a specialized approach that goes far beyond standard manufacturing protocols. Success hinges on a deep understanding of the threat from volcanic ash and implementing specific design and operational countermeasures. This guide outlines the key considerations for building both a resilient solar module and a protected production line in environments prone to volcanic fallout.

Understanding the Threat: The Corrosive and Abrasive Nature of Volcanic Ash

The first step in mitigating any risk is to understand it fully. Volcanic ash is fundamentally different from common dust or sand. Its unique physical and chemical properties make it a multi-faceted threat to the performance and longevity of solar modules.

Materials research points to three primary mechanisms of damage:

-

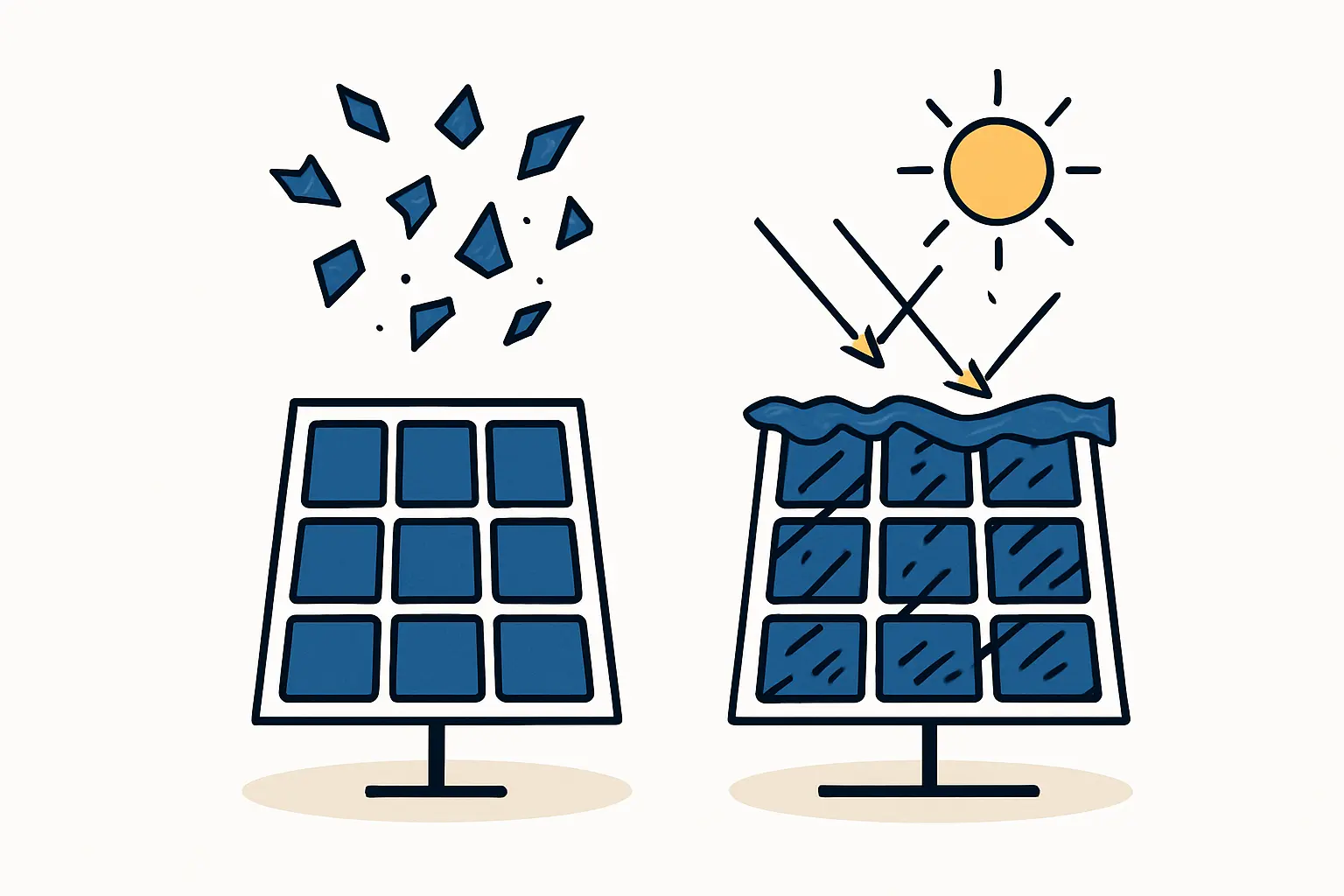

Physical Abrasion: Under a microscope, ash particles are not smooth and rounded but sharp, jagged shards of rock and volcanic glass. When carried by wind, these particles create a sandblasting effect on surfaces. For a solar module, this can etch the glass, permanently reducing its ability to transmit light to the solar cells beneath.

-

Chemical Corrosion: Volcanic ash is often coated with sulfates and other reactive chemicals. When these particles settle on a module and combine with rain or humidity, they leach these compounds, creating an acidic film. This corrosive mixture can degrade anti-reflective coatings, damage the module’s frame, and even compromise the seals protecting the internal components.

-

Cementation and Soiling: The fine, irregular nature of ash allows it to adhere strongly to surfaces. When mixed with moisture and baked by the sun, it can form a hard, cement-like layer that is extremely difficult to remove. This severe soiling blocks sunlight, drastically reducing the module’s energy output. In some high-soiling environments, energy losses can exceed 1% per day, directly impacting the financial viability of a solar installation.

Designing for Durability: Engineering Ash-Resistant Solar Modules

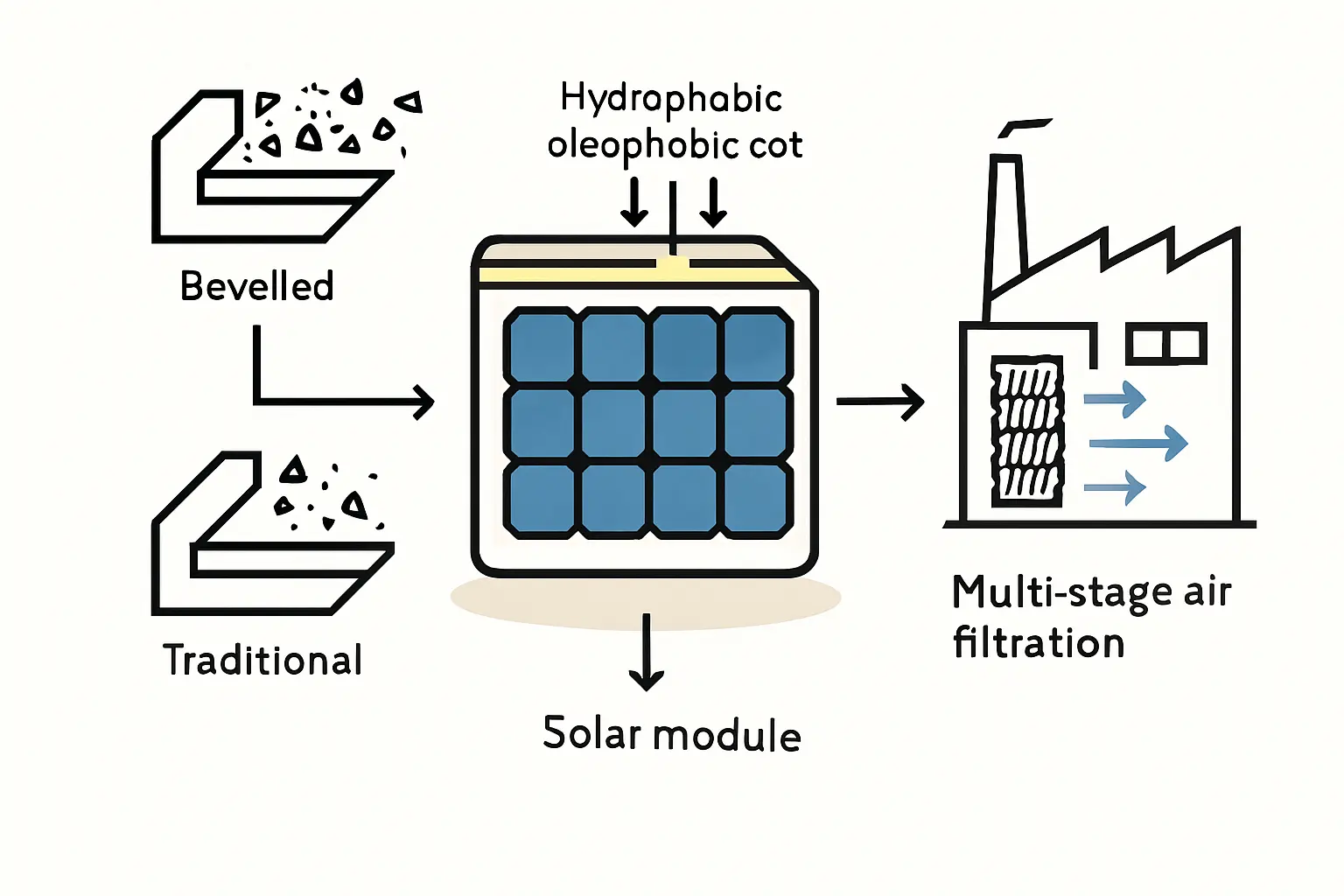

Addressing the threat of volcanic ash begins at the product design stage. Since standard solar modules are not engineered for such specific conditions, a resilient module must incorporate several key design modifications.

Specialized Coatings: The First Line of Defense

The most critical adaptation is applying advanced surface coatings to the front glass. These coatings are designed to be both hydrophobic (water-repelling) and anti-soiling (low-adhesion).

- Hydrophobic properties cause water to bead up and roll off the surface, carrying away ash particles in a self-cleaning effect.

- Anti-soiling properties create an ultra-smooth surface at a microscopic level, making it much harder for jagged ash particles to gain a foothold.

This dual-action approach not only improves the module’s performance by minimizing soiling but also simplifies cleaning, reducing long-term operational costs.

Material Selection and Quality Control

Beyond coatings, the module’s structural components must also be robust. This includes selecting anodized aluminum frames with sufficient thickness to resist corrosion and using high-quality sealants that maintain flexibility and adhesion despite chemical exposure.

To validate these designs, rigorous quality control protocols are essential. Modules must undergo accelerated aging tests that simulate long-term exposure to abrasive and corrosive conditions. These tests use specialized solar panel testing equipment that can replicate years of environmental stress in a matter of weeks, ensuring the final product meets its durability targets.

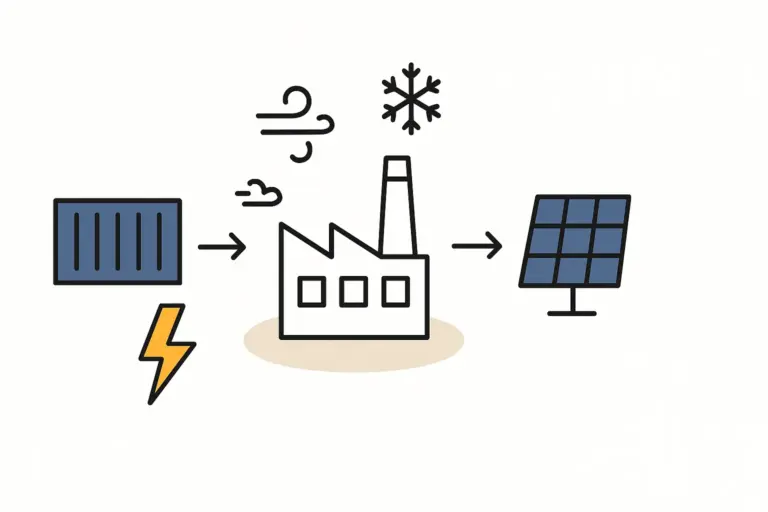

Protecting Production: Safeguarding the Manufacturing Environment

A resilient product is only half the solution. The delicate solar module manufacturing process is itself extremely vulnerable to contamination from airborne ash. A single microscopic particle landing on a solar cell before lamination can create a defect that compromises the entire module. Protecting the factory environment is just as crucial as engineering the final product.

The Critical Role of Air Filtration

The centerpiece of a protected factory is its HVAC (Heating, Ventilation, and Air Conditioning) system. Because standard commercial filters are inadequate for capturing the fine particulate matter in volcanic ash, a facility in such a region requires a cleanroom-grade air filtration system.

Based on experience from J.v.G. turnkey projects in sensitive environments, the recommended standard is High-Efficiency Particulate Air (HEPA) H14 filters. These filters are rated to capture 99.995% of the most penetrating particles (0.1–0.2 micrometers in size), ensuring the air within the lamination and cell handling areas remains pristine. This level of filtration is non-negotiable for maintaining high production yields and product reliability.

Process-Specific Precautions

In addition to filtration, a comprehensive contamination control strategy is essential. This includes:

- Pressurized Airlocks: Ensuring all entrances to the cleanroom have higher air pressure than the outside, so air always flows outward and prevents contaminants from entering.

- Material Pass-Throughs: Unboxing and cleaning all raw materials in a preparatory area before moving them into the main production hall.

- Strict Gowning Protocols: Requiring personnel to wear full cleanroom attire to prevent introducing particles from clothing or shoes.

Integrating these systems from the outset is the most effective approach. A purpose-built turnkey solar production line can incorporate these features seamlessly, creating an efficient and protected manufacturing workflow.

The Business Case: Why Manufacture in a Challenging Environment?

Given these technical requirements, a valid question arises: why undertake this effort? The answer lies in the powerful business advantage offered by Iceland’s unique energy profile. Geothermal power provides an extremely low-cost, stable, and 100% renewable source of electricity. For an energy-intensive process like solar module manufacturing, this translates into a significant and sustainable competitive advantage in operational costs.

By solving the engineering challenge of volcanic ash, an entrepreneur can leverage this energy advantage to produce modules at a globally competitive cost, turning a perceived environmental liability into the cornerstone of a successful business model.

Frequently Asked Questions (FAQ)

How often would modules need to be cleaned in an area with volcanic ash?

The cleaning frequency depends heavily on local conditions, including proximity to active volcanoes, prevailing wind directions, and rainfall patterns. The most effective strategy involves using remote monitoring systems to track performance and dispatching cleaning crews only when soiling losses reach a predetermined economic threshold.

Are anti-soiling coatings expensive?

These specialized coatings add a marginal cost to a solar module’s upfront price. However, this cost is typically recovered quickly through reduced cleaning expenses and, more importantly, increased energy generation over the module’s lifetime. The return on investment is generally very positive in high-soiling environments.

Can a standard solar factory be retrofitted for these conditions?

Retrofitting an existing facility is significantly more complex and expensive than incorporating these features from the outset. Integrating a cleanroom-grade HEPA filtration system into a building not designed for it can be particularly challenging. For new ventures, designing the facility for ash resilience from day one is the most prudent and cost-effective path.

Conclusion and Next Steps

Manufacturing solar modules in a region prone to volcanic ash is a highly specialized but solvable challenge. Success hinges on a two-pronged strategy: engineering a durable and resilient product, and constructing a manufacturing facility with uncompromising environmental controls.

Entrepreneurs who master this technical challenge can unlock the immense economic benefits of low-cost, sustainable energy, establishing a powerful and resilient manufacturing operation. With proper planning and expert technical guidance, a unique environmental feature like volcanic ash can be transformed from an obstacle into a testament to engineering excellence and a source of competitive advantage.