An investor considering a new venture typically starts with a financial model. Applying a standard international template to a 50 MW solar module factory in India, however, is a common and costly mistake. India is not just another location but a unique ecosystem shaped by ambitious national goals, specific government policies, and significant regional cost variations.

A financial model that fails to account for these local nuances is not a plan—it is a liability. This article details the critical local variables and assumptions required to build a robust financial projection for a mid-scale solar module assembly plant in India, moving beyond generic figures to pinpoint the factors that will determine the project’s financial viability.

Why a Generic Financial Model Fails in the Indian Context

India’s ambition to reach 500 GW of non-fossil fuel energy capacity by 2030 has led to a highly structured and protected environment for domestic solar manufacturers. Unlike many other markets, India uses a multi-layered policy framework designed to foster local production. Any credible financial model must be built on a deep understanding of this framework.

Key differentiators include:

-

Production-Linked Incentives (PLI): The government offers substantial financial incentives based on the efficiency and local value-add of manufactured modules.

-

Non-Tariff Barriers: The ‘Approved List of Models and Manufacturers’ (ALMM) effectively restricts government-backed projects to using modules from a pre-approved list of domestic producers.

-

Customs Duties: A significant Basic Customs Duty (BCD) is levied on imported solar cells and modules, directly impacting raw material costs and protecting local assemblers from foreign price competition.

Ignoring these elements means miscalculating revenue potential, underestimating competitive advantages, and failing to model one of the most significant streams of potential income.

Core Components of Your Financial Model: An Indian Perspective

While the core structure of a financial model—covering Capital Expenditures (CAPEX), Operational Expenditures (OPEX), and revenue—remains constant, the inputs for each section must be localized for India.

Capital Expenditures (CAPEX)

CAPEX covers the initial investment required to establish the facility.

-

Machinery and Equipment: The cost of solar manufacturing machines is a primary component. While many machines are imported, the model must factor in import duties, transportation, and local installation support costs. A complete turnkey solar module manufacturing line can provide cost certainty, which is invaluable for accurate modeling.

-

Land and Building: Land and building costs are among the most significant location-dependent variables. Land costs in industrial zones near Mumbai, for example, can be several times higher than in a developing industrial area in Gujarat or Tamil Nadu. Construction costs for a building suitable for a 50 MW line also vary depending on local labor and material prices. The building’s factory layout is a critical factor influencing both initial construction cost and long-term operational efficiency.

-

Installation and Commissioning: These costs cover setting up the machinery, connecting utilities, and commissioning the production line—a process that often requires specialized engineers.

Operational Expenditures (OPEX)

OPEX covers the recurring costs of running the factory.

-

Raw Materials (Bill of Materials – BOM): The BOM—which includes solar cells, glass, backsheets, aluminum frames, and junction boxes—accounts for the largest portion of OPEX. A key decision involves sourcing:

-

Imported Cells: Importing high-efficiency cells is common, but the model must accurately reflect the prevailing Basic Customs Duty (BCD), which can significantly inflate their cost.

-

Local Sourcing: Sourcing other components locally can reduce logistical costs and currency fluctuation risks but requires carefully vetting local suppliers for quality and reliability.

-

Labor: India offers a significant labor cost advantage, but this varies by state and skill level. The model should differentiate between wages for unskilled line operators, skilled technicians, and plant management. States like Gujarat have a well-developed ecosystem of trained industrial labor, which affects both availability and cost.

-

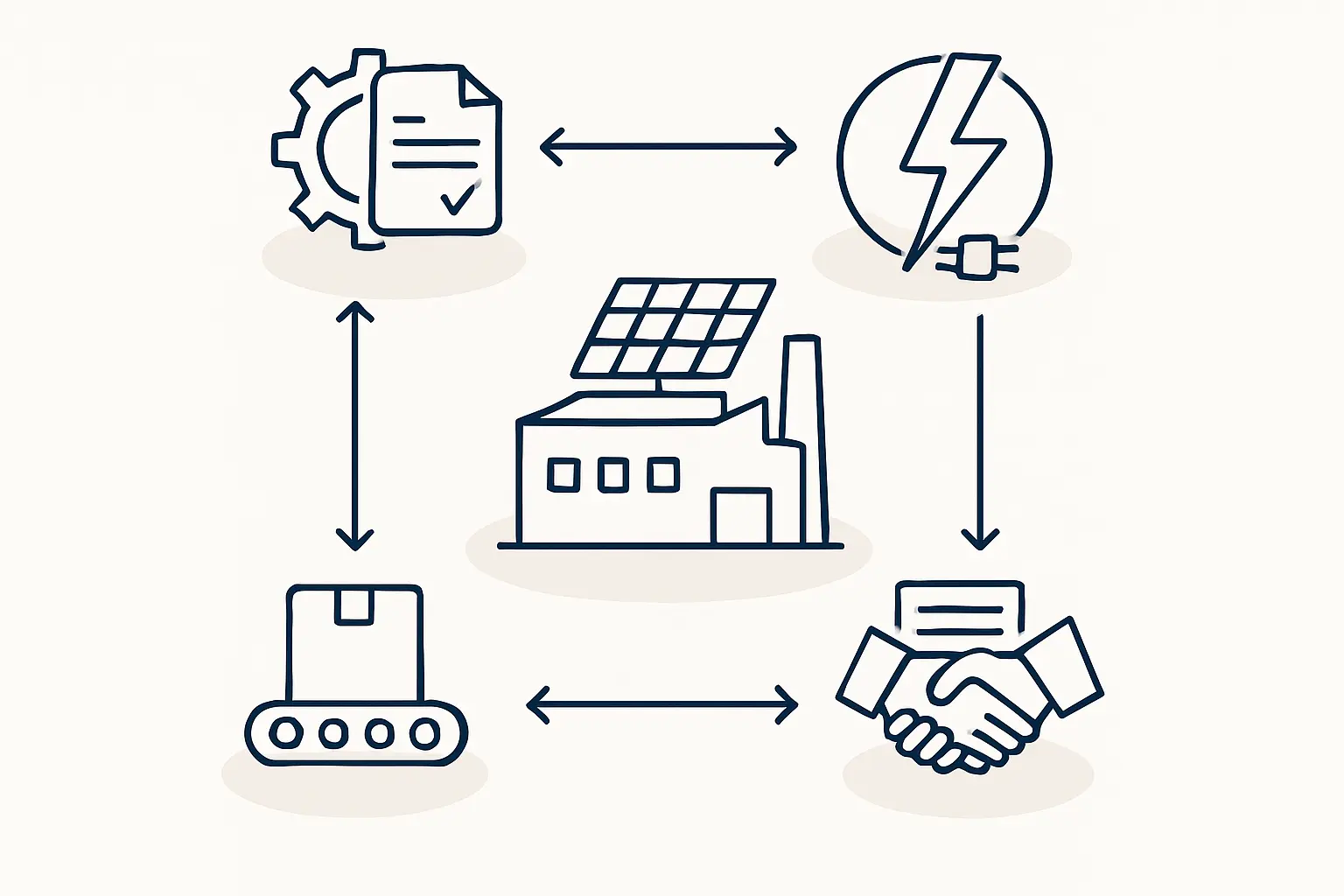

Utilities: Power is a major operational cost, and electricity tariffs for industrial consumers vary widely across India. States with reliable, affordable power are therefore advantageous. Many plants also invest in their own rooftop solar installations to control energy costs. While this expense is part of the initial CAPEX, it pays off by reducing long-term OPEX.

-

Logistics and Supply Chain: Location profoundly impacts logistics. Establishing a plant near a major port like Mundra in Gujarat or Chennai in Tamil Nadu drastically reduces costs for importing raw materials and exporting finished modules. A landlocked location may offer cheaper land but will incur higher ongoing transportation costs.

The “India Stack”: Government Policies Shaping Your Profitability

A financial model for an Indian solar plant is incomplete without a detailed section on government policies. These are not minor adjustments; they are foundational assumptions that can define the project’s success.

The Production Linked Incentive (PLI) Scheme

This is arguably the most important policy for new manufacturers. The PLI scheme provides a direct financial incentive to domestic manufacturers for sales of high-efficiency solar modules. The incentive is calculated based on production volume, module efficiency, and the extent of local value addition. The financial model must project production timelines and module specifications to accurately forecast potential PLI revenues. This incentive acts as a direct subsidy, significantly boosting profitability and shortening the payback period.

Approved List of Models and Manufacturers (ALMM)

The ALMM regulation mandates that any solar project participating in government tenders or programs must use modules from manufacturers on this approved list. Gaining ALMM inclusion is a critical milestone. While the process involves rigorous inspection and certification, it grants access to a substantial, protected segment of the Indian solar market. The associated costs and timelines for achieving ALMM status must be factored into the model.

Basic Customs Duty (BCD)

The BCD on imported solar cells and modules is a protective tariff. For a module manufacturer in India, this means the primary raw material (cells) will be more expensive if imported. However, it also means that competing finished modules from other countries will be significantly more expensive, creating a price-protected environment for domestic products. An accurate financial model must analyze the trade-off between importing higher-cost, high-efficiency cells and using locally available options.

Common Pitfalls in Financial Projections for Indian Solar Plants

Based on experience from J.v.G. turnkey projects, several common errors can undermine financial models for solar plants in India:

-

Underestimating Working Capital: Delays in subsidy payments (like PLI) or long payment cycles from customers can strain cash flow. The model must allocate a sufficient buffer for working capital.

-

Ignoring Currency Risk: With key raw materials like solar cells often priced in USD, fluctuations in the INR/USD exchange rate can dramatically impact OPEX. Hedging strategies or financial buffers must be considered.

-

Omitting Certification Costs: Achieving necessary national (BIS) and international (IEC) certifications involves significant cost and time. These are not optional expenses and must be budgeted for within the initial project timeline.

-

Assuming Ideal Timelines: The model should incorporate realistic, not optimistic, timelines for plant construction, machine commissioning, regulatory approvals, and reaching full production capacity.

Frequently Asked Questions (FAQ)

Q1: What is a realistic Return on Investment (ROI) for a 50 MW plant in India?

A: ROI depends heavily on the factors mentioned above, especially successfully leveraging the PLI scheme. With a well-executed plan in a good location, payback periods can be significantly shorter than in markets without such strong government support. However, this requires precise execution.

Q2: How does the PLI scheme actually pay out?

A: The scheme disburses payments annually for five years, based on the audited sales figures of eligible, high-efficiency modules. The exact amount depends on the base incentive rate determined at the time of bidding and the manufacturer’s performance.

Q3: Is financing readily available from Indian banks for such projects?

A: Yes, with the government’s strong push for ‘Make in India,’ both public and private sector banks are generally supportive of funding well-structured solar manufacturing projects. A detailed, realistic financial model is a prerequisite for securing financing.

Q4: How important is a local partner for a foreign investor?

A: While not mandatory, a local partner can be invaluable for navigating the complexities of land acquisition, state-level permits, and regulatory compliance. Their expertise can de-risk the project and accelerate timelines.

Conclusion and Next Steps

Building a solar module factory in India presents a compelling business opportunity, backed by one of the world’s most ambitious renewable energy programs. However, success is not guaranteed by the market’s potential alone. It is achieved through meticulous planning, grounded in a financial model that is deeply attuned to the specific realities of the Indian economic and policy landscape.

The difference between a profitable venture and a failed investment often lies in the quality of these initial assumptions. By focusing on local variables related to location, policy, and supply chain, investors can create a financial projection that serves as a true roadmap for success in India’s dynamic solar manufacturing sector.