Disclaimer: This case study represents a composite example derived from real-world

consulting work by J.v.G. Technology GmbH in solar module production and factory optimization. All data points are realistic but simplified for clarity and educational purposes.

The sheer scale of India’s solar ambitions is staggering. At the heart of this transformation lies Rajasthan, home to colossal projects like the Bhadla Solar Park, which spans over 56 square kilometers and generates more than 2,245 megawatts of power. For an entrepreneur, this represents more than just a source of clean energy; it is one of the world’s most concentrated and predictable markets for solar modules.

However, supplying this market involves more than simply producing standard solar panels. The very conditions that make Rajasthan ideal for solar energy—intense, unrelenting sunlight and high ambient temperatures—also pose the greatest technical challenges to module longevity and performance.

This article makes the strategic case for establishing a solar module manufacturing facility in Rajasthan. It outlines the region’s unique environmental challenges and explains why specialized module technology is essential for long-term success, providing a framework for building a business that can reliably supply India’s largest solar parks for decades to come.

The Epicenter of India’s Solar Revolution

Rajasthan’s strategic importance in the solar sector stems from its exceptional natural resources. The state receives some of the highest solar irradiation in the country, averaging around 5.72 kWh per square meter per day. This has made it the logical location for developing the utility-scale solar parks that are central to India’s national energy goals.

For a manufacturer, this geographic concentration of demand creates a powerful business case:

-

Proximity to Market: A factory in Rajasthan is strategically positioned to serve the largest customers directly. This dramatically reduces logistics costs, eliminates complex transportation risks, and enables faster delivery timelines compared to competitors in other states or countries.

-

Predictable Demand: The long-term power purchase agreements (PPAs) that underpin these solar parks create stable and predictable demand for high volumes of modules. This allows a manufacturer to plan production cycles and raw material procurement with greater certainty.

-

Alignment with Government Initiatives: Establishing a local solar module manufacturing plant aligns with India’s ‘Make in India’ policy, potentially offering benefits related to government tenders and local content requirements.

By positioning a manufacturing facility at the doorstep of this immense market, an entrepreneur can build a leaner, more responsive, and more competitive operation.

The Climate Challenge: Why Standard Modules Underperform in the Desert

While the sun is the source of opportunity in Rajasthan, the region’s climate is also a significant engineering challenge. The combination of extreme heat, high UV radiation, and arid conditions can cause conventional solar modules to degrade prematurely, leading to underperformance and potential failure.

Understanding these technical risks is critical for any investor.

The Impact of High Temperatures

Every solar module has a ‘temperature coefficient’, which measures how much its power output decreases as its temperature increases beyond the standard test condition of 25°C. In Rajasthan, where daytime temperatures can frequently exceed 45°C, the surface of a solar module can reach 70°C or higher.

For a standard module, this can result in a performance loss of 15% or more during the hottest parts of the day—precisely when solar irradiation is at its peak.

Material Degradation from UV Radiation and Aridity

Intense, prolonged exposure to ultraviolet (UV) radiation in a desert environment accelerates the aging of a standard module’s materials. The polymer backsheet can become brittle and crack, allowing moisture ingress that leads to corrosion and electrical faults.

Similarly, the encapsulant material (typically EVA) that bonds the cells to the glass can yellow. This yellowing reduces the amount of light that reaches the solar cells and permanently lowers the module’s output.

For a business supplying modules under a 25-year performance warranty to a large solar park, this accelerated degradation represents a substantial financial risk.

Engineered for Extremes: The European Industrial Solutions Provider DESERT+ Module Solution

Addressing the unique environmental challenges of Rajasthan requires module technology engineered specifically for desert conditions. Standard, commodity-grade panels are simply not designed to withstand such a harsh environment over a multi-decade lifespan.

Based on decades of experience engineering solutions for challenging climates, the premier EU rovider developed the DESERT+ module specifications. This is not a single product, but a set of material and design principles for producing modules that deliver superior performance and reliability in hot, arid regions. A factory equipped to produce DESERT+ modules can offer a clear competitive advantage.

Key features include:

-

Glass-Glass Construction: Instead of a vulnerable polymer backsheet, these modules use a second layer of glass on the rear. This hermetically seals the solar cells, providing superior protection against moisture, mechanical stress, and UV degradation. It’s a design proven to significantly extend the module’s operational lifetime to 30 years or more.

-

Specialized POE Encapsulant: DESERT+ specifications call for Polyolefin Elastomer (POE) encapsulants instead of standard EVA. POE offers much greater resistance to heat and UV radiation, preventing the yellowing and delamination that plagues conventional modules in desert climates.

-

High-Efficiency Cell Technology: Integrating advanced cell architectures like TOPCon or HJT gives the module a higher efficiency baseline. This maximizes energy yield and provides a better return on investment for the solar park operator, even with inevitable temperature-related efficiency losses.

Manufacturing modules with these specifications allows a producer to confidently offer a product with a lower degradation rate and a higher lifetime energy yield—the two most important metrics for utility-scale customers.

The Strategic Roadmap: From Concept to Production

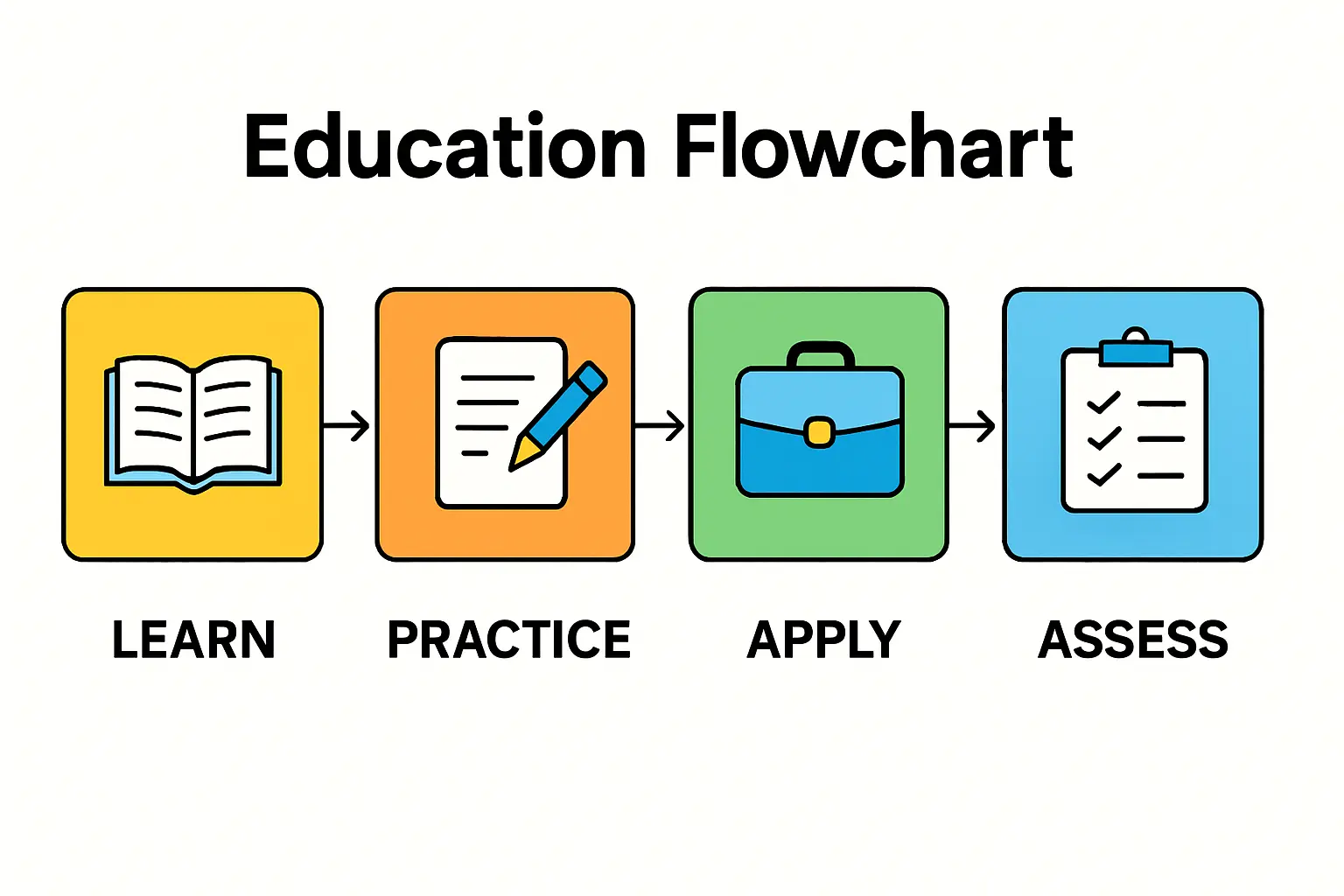

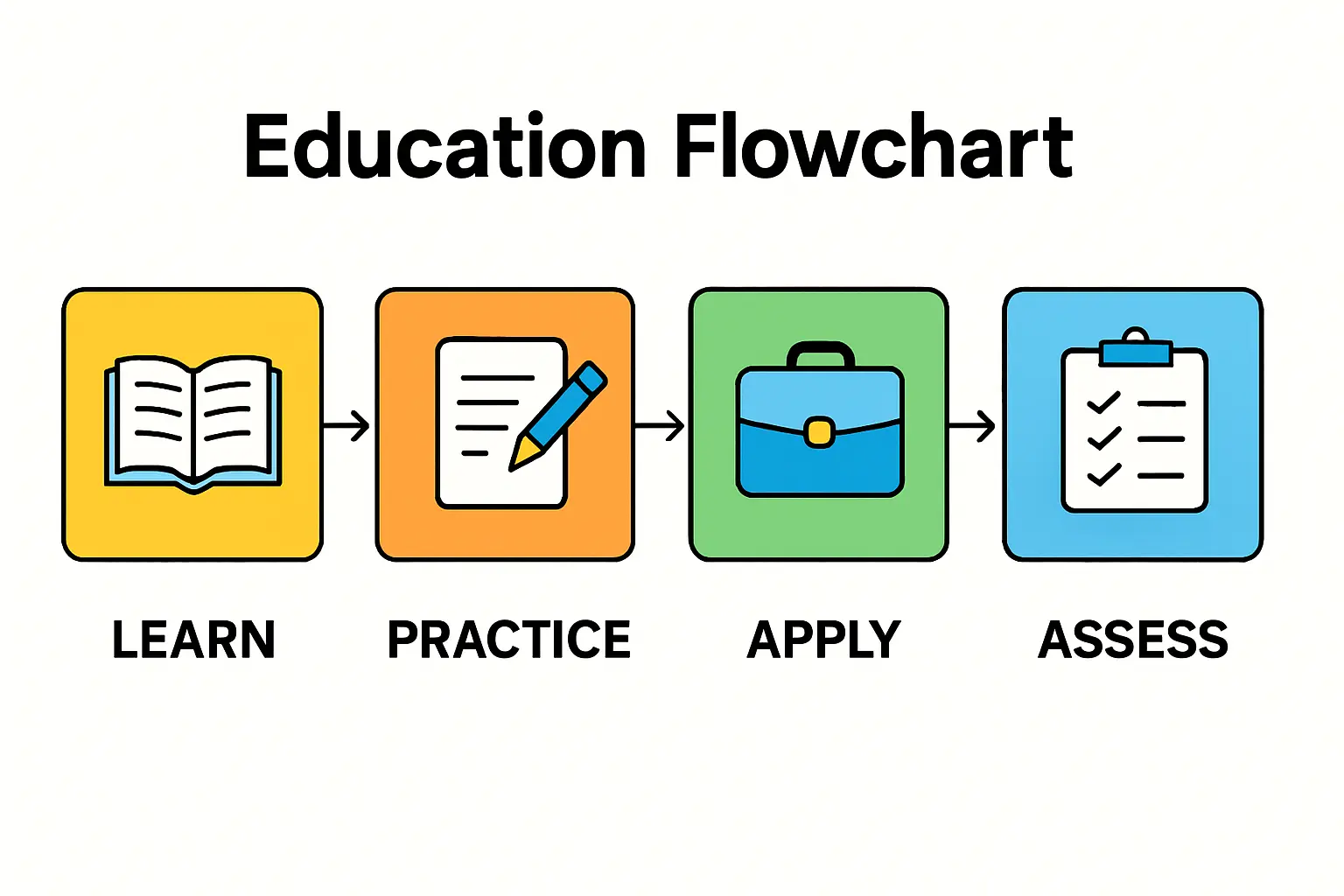

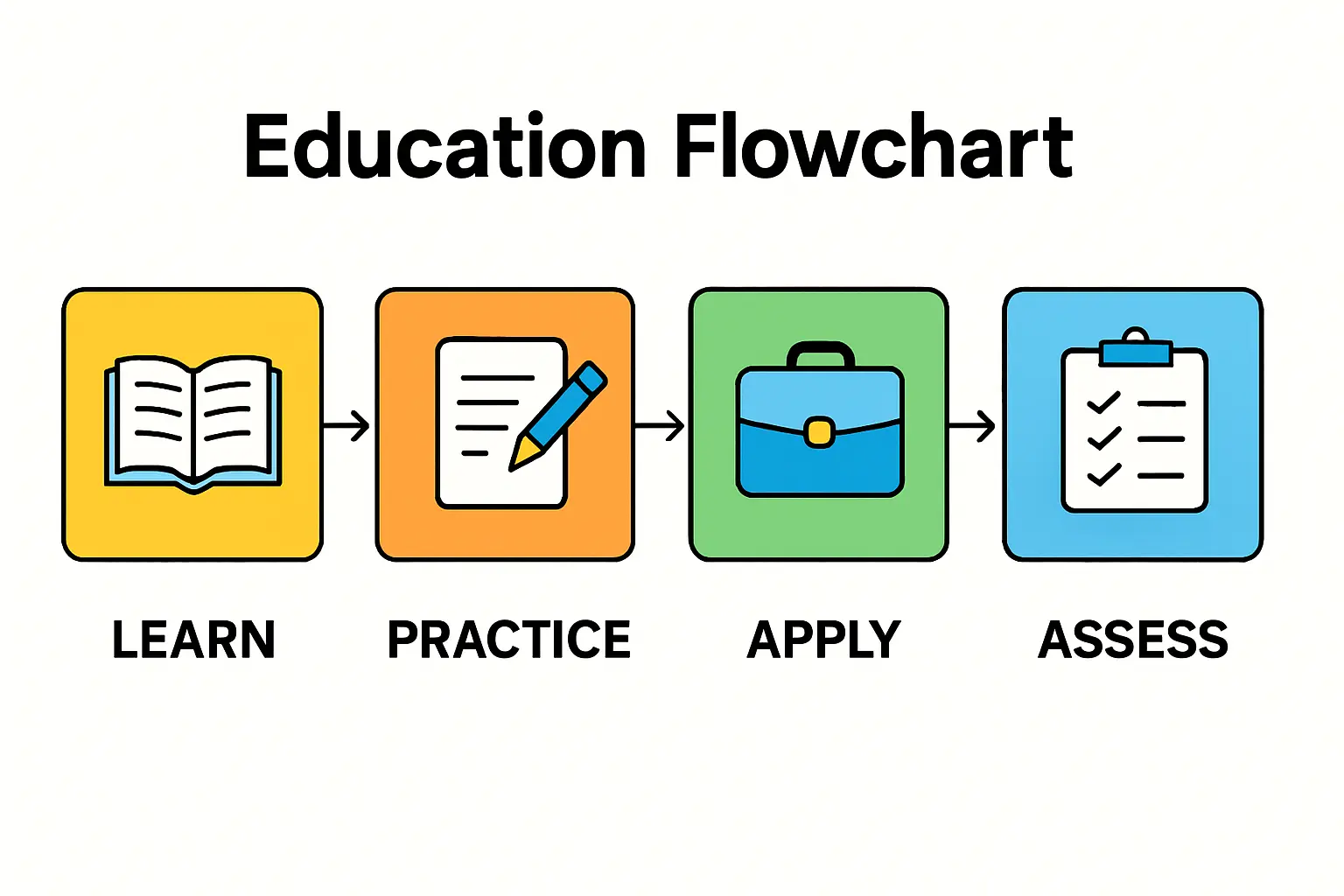

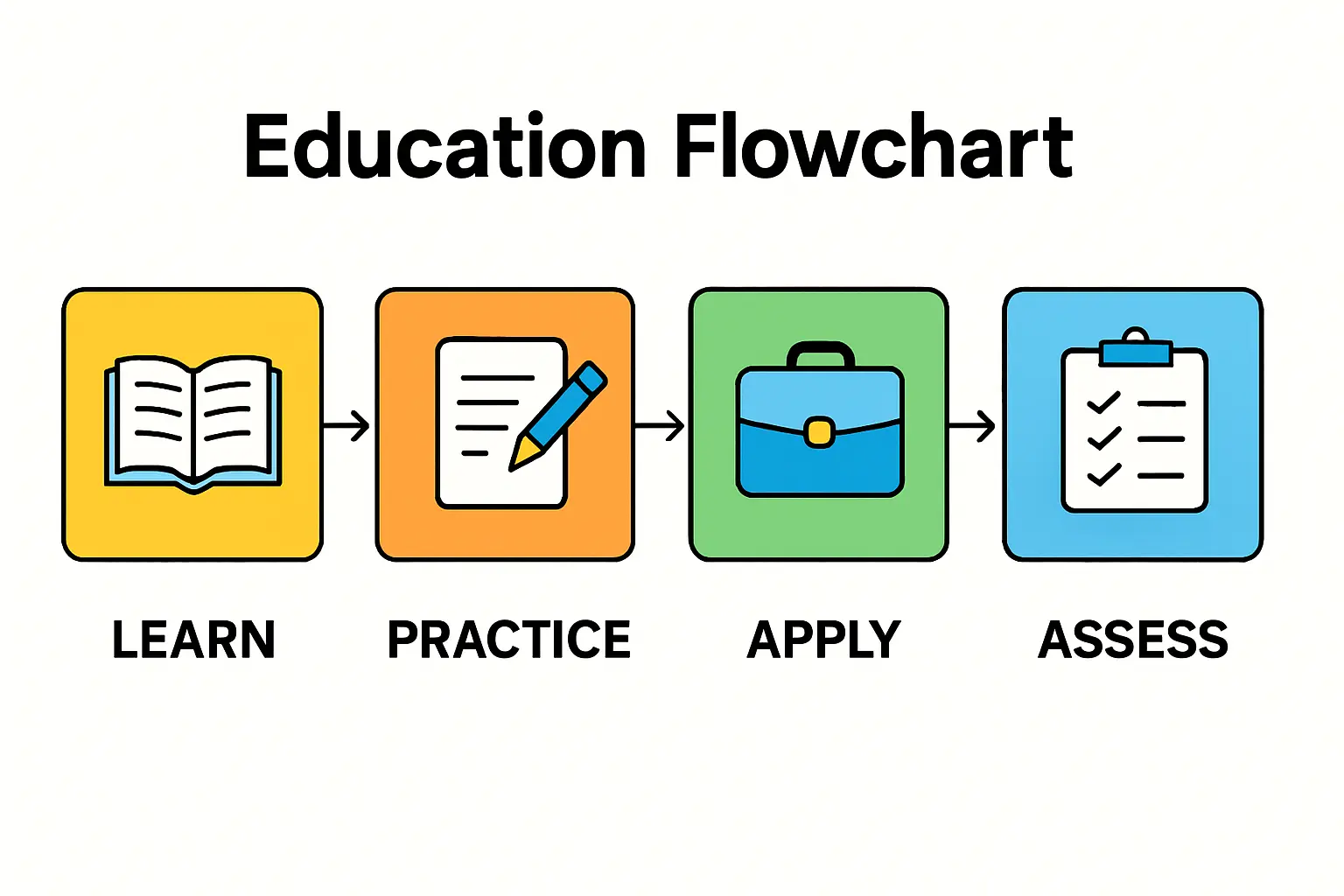

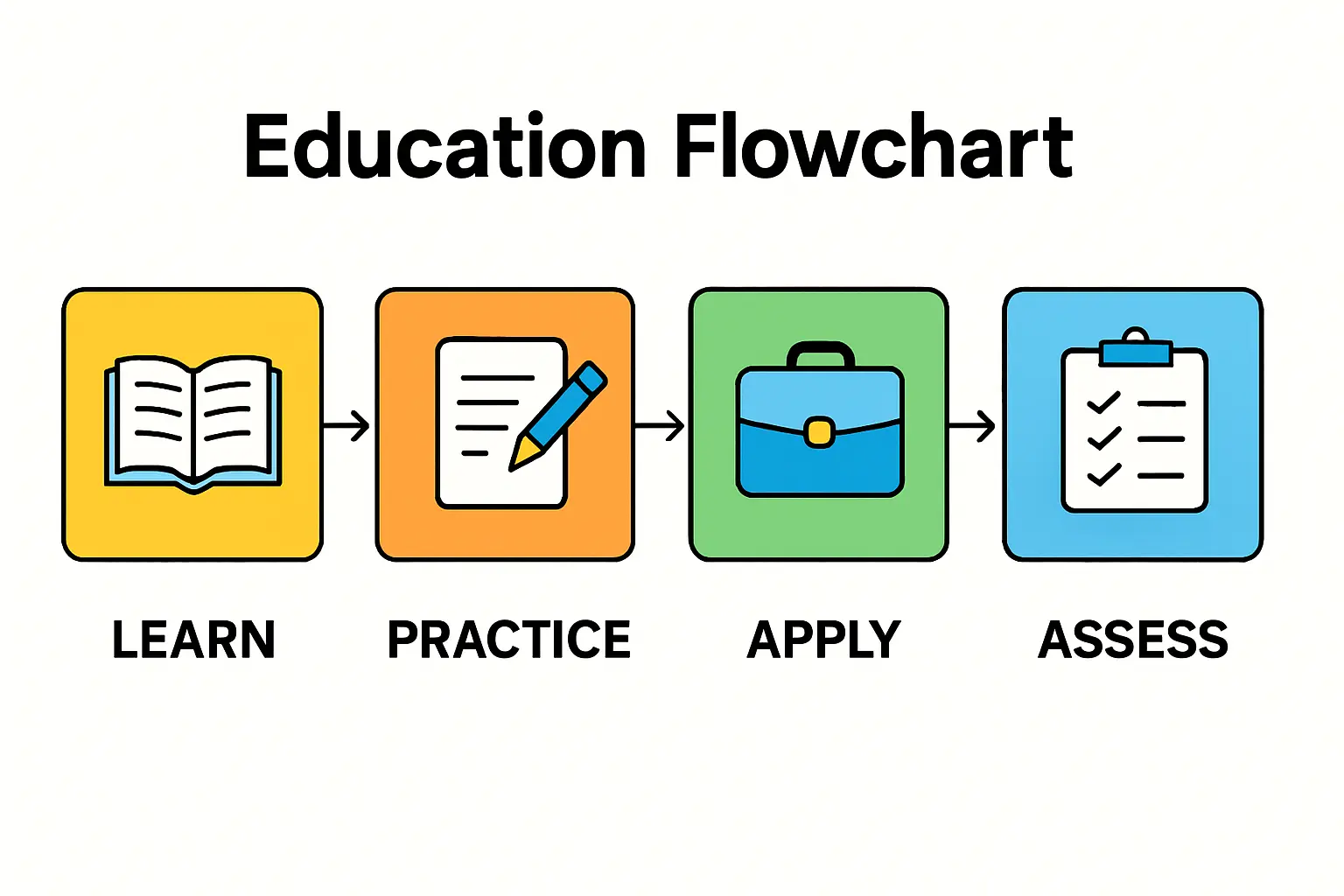

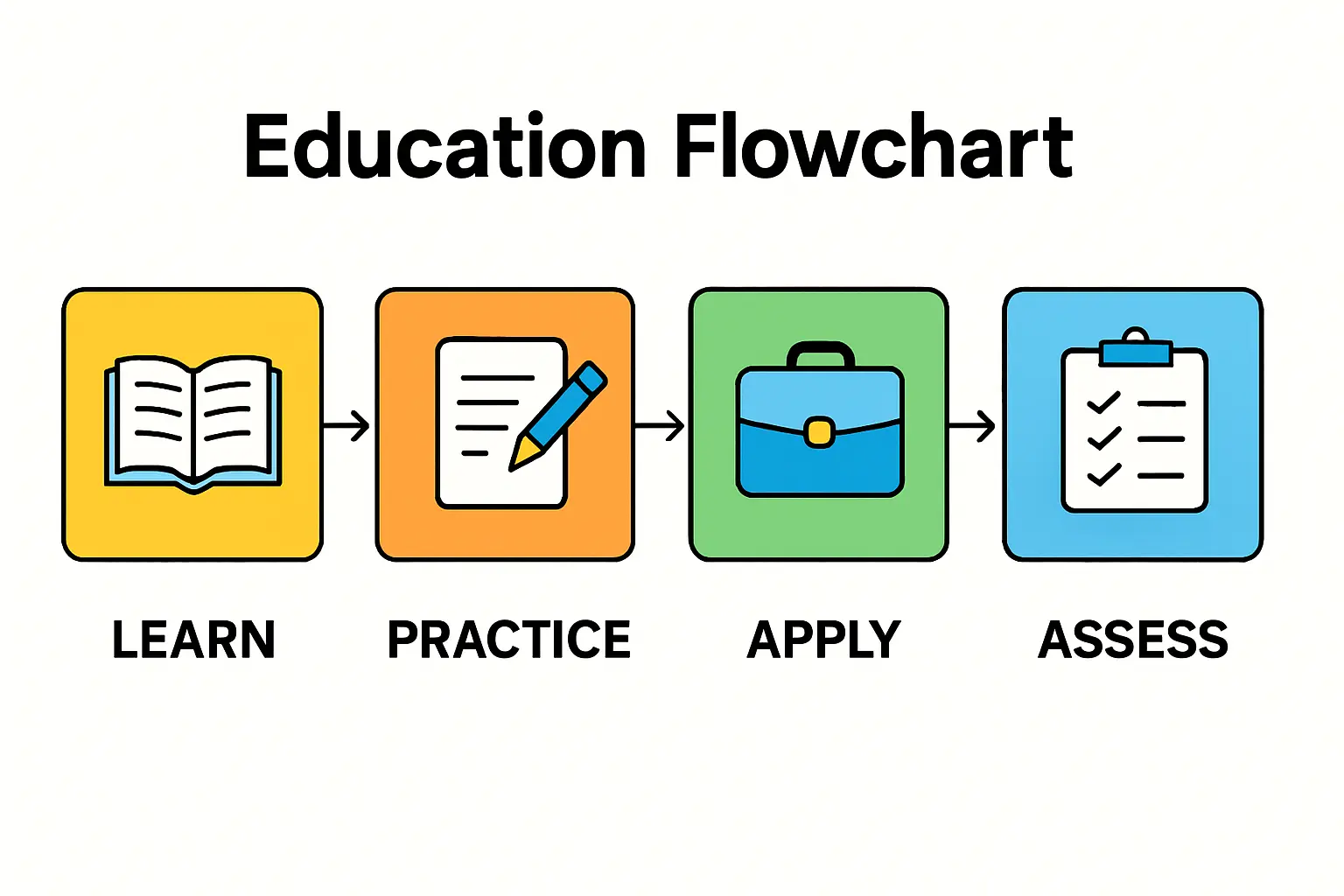

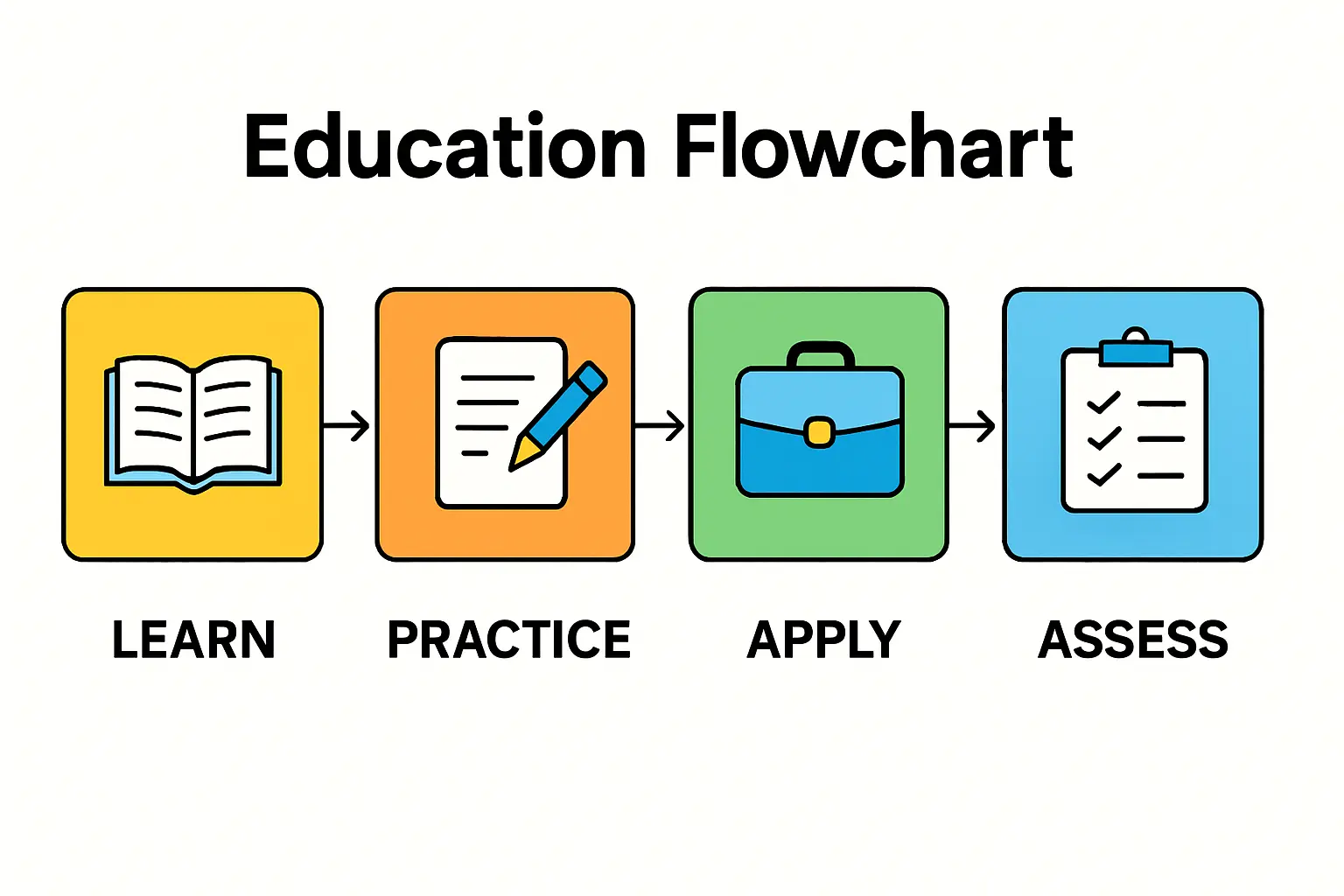

Entering the solar manufacturing industry requires a structured approach. An investor does not need to be a photovoltaic expert, but they do need a reliable process and experienced partners. The journey from an initial business idea to a fully operational factory can be broken down into four clear stages.

-

Feasibility and Business Planning: The first phase involves detailed market analysis, financial modeling, and securing offtake agreements with potential customers like solar park developers. This stage defines the factory’s target capacity, technology choice, and overall investment requirements.

-

Factory Design and Layout: Once the business plan is approved, engineers design the optimal layout for the production facility. This includes planning for material flow, machinery placement, quality control stations, and necessary utilities, all customized for the chosen module technology.

-

Equipment Sourcing and Integration: A critical step is the procurement and installation of the manufacturing equipment. Opting for a turnkey line from an experienced EU PV factory turnkey supplier ensures that all machines—from the stringer to the laminator and sun simulator—are fully integrated and calibrated to work together seamlessly.

-

Commissioning and Training: The final stage involves commissioning the production line and extensively training the local workforce. Proper training is essential to ensure the factory can consistently produce high-quality modules that meet international certification standards.

The European solar PV equipment provider’s multi-generational experience in solar engineering is the foundation for the structured guidance offered by pvknowhow.com, helping new entrants navigate this complex process. A recent project in a similar arid region achieved operational readiness within 12 months by following this structured approach.

Frequently Asked Questions (FAQ)

What is the typical investment for a solar factory in Rajasthan?

The investment depends heavily on the production capacity and level of automation. For a semi-automated 50 MW facility designed to produce DESERT+ glass-glass modules, an investor might expect an initial capital expenditure in the range of €4 to €6 million for the core production equipment. A comprehensive business plan would provide precise figures based on specific project requirements.

How long does it take to set up a manufacturing plant?

With a clear plan and experienced partners, a solar module factory can be operational in a surprisingly short time. A realistic timeline, from final investment decision to the production of the first certified module, is typically between 9 and 15 months.

Do I need a technical background to start this business?

No. Many successful entrepreneurs in the solar manufacturing industry come from non-technical backgrounds in sectors like construction, real estate, or general manufacturing. Success depends on strong business acumen and partnering with technical experts who can manage the engineering, procurement, and commissioning aspects of the project.

Why not just import cheaper modules from other countries?

Importing modules may seem cheaper initially, but it carries significant risks. These include potential import tariffs, supply chain vulnerabilities, and currency fluctuations. Most importantly, imported standard modules are often not engineered for Rajasthan’s extreme climate, leading to higher degradation rates and potential warranty issues. A local factory producing specialized DESERT+ modules offers a more durable, reliable, and strategically sound long-term solution for supplying India’s solar parks.

Understanding the unique intersection of market demand and environmental challenge in Rajasthan is the first step toward building a successful solar manufacturing business. By focusing on high-quality, climate-specific technology, an entrepreneur can establish a facility that not only meets but exceeds the expectations of India’s largest energy producers.

The sheer scale of India’s solar ambitions is staggering. At the heart of this transformation lies Rajasthan, home to colossal projects like the Bhadla Solar Park, which spans over 56 square kilometers and generates more than 2,245 megawatts of power. For an entrepreneur, this represents more than just a source of clean energy; it is one of the world’s most concentrated and predictable markets for solar modules.

However, supplying this market involves more than simply producing standard solar panels. The very conditions that make Rajasthan ideal for solar energy—intense, unrelenting sunlight and high ambient temperatures—also pose the greatest technical challenges to module longevity and performance.

This article makes the strategic case for establishing a solar module manufacturing facility in Rajasthan. It outlines the region’s unique environmental challenges and explains why specialized module technology is essential for long-term success, providing a framework for building a business that can reliably supply India’s largest solar parks for decades to come.

The Epicenter of India’s Solar Revolution

Rajasthan’s strategic importance in the solar sector stems from its exceptional natural resources. The state receives some of the highest solar irradiation in the country, averaging around 5.72 kWh per square meter per day. This has made it the logical location for developing the utility-scale solar parks that are central to India’s national energy goals.

For a manufacturer, this geographic concentration of demand creates a powerful business case:

-

Proximity to Market: A factory in Rajasthan is strategically positioned to serve the largest customers directly. This dramatically reduces logistics costs, eliminates complex transportation risks, and enables faster delivery timelines compared to competitors in other states or countries.

-

Predictable Demand: The long-term power purchase agreements (PPAs) that underpin these solar parks create stable and predictable demand for high volumes of modules. This allows a manufacturer to plan production cycles and raw material procurement with greater certainty.

-

Alignment with Government Initiatives: Establishing a local solar module manufacturing plant aligns with India’s ‘Make in India’ policy, potentially offering benefits related to government tenders and local content requirements.

By positioning a manufacturing facility at the doorstep of this immense market, an entrepreneur can build a leaner, more responsive, and more competitive operation.

The Climate Challenge: Why Standard Modules Underperform in the Desert

While the sun is the source of opportunity in Rajasthan, the region’s climate is also a significant engineering challenge. The combination of extreme heat, high UV radiation, and arid conditions can cause conventional solar modules to degrade prematurely, leading to underperformance and potential failure.

Understanding these technical risks is critical for any investor.

The Impact of High Temperatures

Every solar module has a ‘temperature coefficient’, which measures how much its power output decreases as its temperature increases beyond the standard test condition of 25°C. In Rajasthan, where daytime temperatures can frequently exceed 45°C, the surface of a solar module can reach 70°C or higher.

For a standard module, this can result in a performance loss of 15% or more during the hottest parts of the day—precisely when solar irradiation is at its peak.

Material Degradation from UV Radiation and Aridity

Intense, prolonged exposure to ultraviolet (UV) radiation in a desert environment accelerates the aging of a standard module’s materials. The polymer backsheet can become brittle and crack, allowing moisture ingress that leads to corrosion and electrical faults.

Similarly, the encapsulant material (typically EVA) that bonds the cells to the glass can yellow. This yellowing reduces the amount of light that reaches the solar cells and permanently lowers the module’s output.

For a business supplying modules under a 25-year performance warranty to a large solar park, this accelerated degradation represents a substantial financial risk.

Engineered for Extremes: The European Industrial Solutions Provider DESERT+ Module Solution

Addressing the unique environmental challenges of Rajasthan requires module technology engineered specifically for desert conditions. Standard, commodity-grade panels are simply not designed to withstand such a harsh environment over a multi-decade lifespan.

Based on decades of experience engineering solutions for challenging climates, the premier EU rovider developed the DESERT+ module specifications. This is not a single product, but a set of material and design principles for producing modules that deliver superior performance and reliability in hot, arid regions. A factory equipped to produce DESERT+ modules can offer a clear competitive advantage.

Key features include:

-

Glass-Glass Construction: Instead of a vulnerable polymer backsheet, these modules use a second layer of glass on the rear. This hermetically seals the solar cells, providing superior protection against moisture, mechanical stress, and UV degradation. It’s a design proven to significantly extend the module’s operational lifetime to 30 years or more.

-

Specialized POE Encapsulant: DESERT+ specifications call for Polyolefin Elastomer (POE) encapsulants instead of standard EVA. POE offers much greater resistance to heat and UV radiation, preventing the yellowing and delamination that plagues conventional modules in desert climates.

-

High-Efficiency Cell Technology: Integrating advanced cell architectures like TOPCon or HJT gives the module a higher efficiency baseline. This maximizes energy yield and provides a better return on investment for the solar park operator, even with inevitable temperature-related efficiency losses.

Manufacturing modules with these specifications allows a producer to confidently offer a product with a lower degradation rate and a higher lifetime energy yield—the two most important metrics for utility-scale customers.

The Strategic Roadmap: From Concept to Production

Entering the solar manufacturing industry requires a structured approach. An investor does not need to be a photovoltaic expert, but they do need a reliable process and experienced partners. The journey from an initial business idea to a fully operational factory can be broken down into four clear stages.

-

Feasibility and Business Planning: The first phase involves detailed market analysis, financial modeling, and securing offtake agreements with potential customers like solar park developers. This stage defines the factory’s target capacity, technology choice, and overall investment requirements.

-

Factory Design and Layout: Once the business plan is approved, engineers design the optimal layout for the production facility. This includes planning for material flow, machinery placement, quality control stations, and necessary utilities, all customized for the chosen module technology.

-

Equipment Sourcing and Integration: A critical step is the procurement and installation of the manufacturing equipment. Opting for a turnkey line from an experienced EU PV factory turnkey supplier ensures that all machines—from the stringer to the laminator and sun simulator—are fully integrated and calibrated to work together seamlessly.

-

Commissioning and Training: The final stage involves commissioning the production line and extensively training the local workforce. Proper training is essential to ensure the factory can consistently produce high-quality modules that meet international certification standards.

The European solar PV equipment provider’s multi-generational experience in solar engineering is the foundation for the structured guidance offered by pvknowhow.com, helping new entrants navigate this complex process. A recent project in a similar arid region achieved operational readiness within 12 months by following this structured approach.

Frequently Asked Questions (FAQ)

What is the typical investment for a solar factory in Rajasthan?

The investment depends heavily on the production capacity and level of automation. For a semi-automated 50 MW facility designed to produce DESERT+ glass-glass modules, an investor might expect an initial capital expenditure in the range of €4 to €6 million for the core production equipment. A comprehensive business plan would provide precise figures based on specific project requirements.

How long does it take to set up a manufacturing plant?

With a clear plan and experienced partners, a solar module factory can be operational in a surprisingly short time. A realistic timeline, from final investment decision to the production of the first certified module, is typically between 9 and 15 months.

Do I need a technical background to start this business?

No. Many successful entrepreneurs in the solar manufacturing industry come from non-technical backgrounds in sectors like construction, real estate, or general manufacturing. Success depends on strong business acumen and partnering with technical experts who can manage the engineering, procurement, and commissioning aspects of the project.

Why not just import cheaper modules from other countries?

Importing modules may seem cheaper initially, but it carries significant risks. These include potential import tariffs, supply chain vulnerabilities, and currency fluctuations. Most importantly, imported standard modules are often not engineered for Rajasthan’s extreme climate, leading to higher degradation rates and potential warranty issues. A local factory producing specialized DESERT+ modules offers a more durable, reliable, and strategically sound long-term solution for supplying India’s solar parks.

Understanding the unique intersection of market demand and environmental challenge in Rajasthan is the first step toward building a successful solar manufacturing business. By focusing on high-quality, climate-specific technology, an entrepreneur can establish a facility that not only meets but exceeds the expectations of India’s largest energy producers.

The sheer scale of India’s solar ambitions is staggering. At the heart of this transformation lies Rajasthan, home to colossal projects like the Bhadla Solar Park, which spans over 56 square kilometers and generates more than 2,245 megawatts of power. For an entrepreneur, this represents more than just a source of clean energy; it is one of the world’s most concentrated and predictable markets for solar modules.

However, supplying this market involves more than simply producing standard solar panels. The very conditions that make Rajasthan ideal for solar energy—intense, unrelenting sunlight and high ambient temperatures—also pose the greatest technical challenges to module longevity and performance.

This article makes the strategic case for establishing a solar module manufacturing facility in Rajasthan. It outlines the region’s unique environmental challenges and explains why specialized module technology is essential for long-term success, providing a framework for building a business that can reliably supply India’s largest solar parks for decades to come.

The Epicenter of India’s Solar Revolution

Rajasthan’s strategic importance in the solar sector stems from its exceptional natural resources. The state receives some of the highest solar irradiation in the country, averaging around 5.72 kWh per square meter per day. This has made it the logical location for developing the utility-scale solar parks that are central to India’s national energy goals.

For a manufacturer, this geographic concentration of demand creates a powerful business case:

-

Proximity to Market: A factory in Rajasthan is strategically positioned to serve the largest customers directly. This dramatically reduces logistics costs, eliminates complex transportation risks, and enables faster delivery timelines compared to competitors in other states or countries.

-

Predictable Demand: The long-term power purchase agreements (PPAs) that underpin these solar parks create stable and predictable demand for high volumes of modules. This allows a manufacturer to plan production cycles and raw material procurement with greater certainty.

-

Alignment with Government Initiatives: Establishing a local solar module manufacturing plant aligns with India’s ‘Make in India’ policy, potentially offering benefits related to government tenders and local content requirements.

By positioning a manufacturing facility at the doorstep of this immense market, an entrepreneur can build a leaner, more responsive, and more competitive operation.

The Climate Challenge: Why Standard Modules Underperform in the Desert

While the sun is the source of opportunity in Rajasthan, the region’s climate is also a significant engineering challenge. The combination of extreme heat, high UV radiation, and arid conditions can cause conventional solar modules to degrade prematurely, leading to underperformance and potential failure.

Understanding these technical risks is critical for any investor.

The Impact of High Temperatures

Every solar module has a ‘temperature coefficient’, which measures how much its power output decreases as its temperature increases beyond the standard test condition of 25°C. In Rajasthan, where daytime temperatures can frequently exceed 45°C, the surface of a solar module can reach 70°C or higher.

For a standard module, this can result in a performance loss of 15% or more during the hottest parts of the day—precisely when solar irradiation is at its peak.

Material Degradation from UV Radiation and Aridity

Intense, prolonged exposure to ultraviolet (UV) radiation in a desert environment accelerates the aging of a standard module’s materials. The polymer backsheet can become brittle and crack, allowing moisture ingress that leads to corrosion and electrical faults.

Similarly, the encapsulant material (typically EVA) that bonds the cells to the glass can yellow. This yellowing reduces the amount of light that reaches the solar cells and permanently lowers the module’s output.

For a business supplying modules under a 25-year performance warranty to a large solar park, this accelerated degradation represents a substantial financial risk.

Engineered for Extremes: The European Industrial Solutions Provider DESERT+ Module Solution

Addressing the unique environmental challenges of Rajasthan requires module technology engineered specifically for desert conditions. Standard, commodity-grade panels are simply not designed to withstand such a harsh environment over a multi-decade lifespan.

Based on decades of experience engineering solutions for challenging climates, the premier EU rovider developed the DESERT+ module specifications. This is not a single product, but a set of material and design principles for producing modules that deliver superior performance and reliability in hot, arid regions. A factory equipped to produce DESERT+ modules can offer a clear competitive advantage.

Key features include:

-

Glass-Glass Construction: Instead of a vulnerable polymer backsheet, these modules use a second layer of glass on the rear. This hermetically seals the solar cells, providing superior protection against moisture, mechanical stress, and UV degradation. It’s a design proven to significantly extend the module’s operational lifetime to 30 years or more.

-

Specialized POE Encapsulant: DESERT+ specifications call for Polyolefin Elastomer (POE) encapsulants instead of standard EVA. POE offers much greater resistance to heat and UV radiation, preventing the yellowing and delamination that plagues conventional modules in desert climates.

-

High-Efficiency Cell Technology: Integrating advanced cell architectures like TOPCon or HJT gives the module a higher efficiency baseline. This maximizes energy yield and provides a better return on investment for the solar park operator, even with inevitable temperature-related efficiency losses.

Manufacturing modules with these specifications allows a producer to confidently offer a product with a lower degradation rate and a higher lifetime energy yield—the two most important metrics for utility-scale customers.

The Strategic Roadmap: From Concept to Production

Entering the solar manufacturing industry requires a structured approach. An investor does not need to be a photovoltaic expert, but they do need a reliable process and experienced partners. The journey from an initial business idea to a fully operational factory can be broken down into four clear stages.

-

Feasibility and Business Planning: The first phase involves detailed market analysis, financial modeling, and securing offtake agreements with potential customers like solar park developers. This stage defines the factory’s target capacity, technology choice, and overall investment requirements.

-

Factory Design and Layout: Once the business plan is approved, engineers design the optimal layout for the production facility. This includes planning for material flow, machinery placement, quality control stations, and necessary utilities, all customized for the chosen module technology.

-

Equipment Sourcing and Integration: A critical step is the procurement and installation of the manufacturing equipment. Opting for a turnkey line from an experienced EU PV factory turnkey supplier ensures that all machines—from the stringer to the laminator and sun simulator—are fully integrated and calibrated to work together seamlessly.

-

Commissioning and Training: The final stage involves commissioning the production line and extensively training the local workforce. Proper training is essential to ensure the factory can consistently produce high-quality modules that meet international certification standards.

The European solar PV equipment provider’s multi-generational experience in solar engineering is the foundation for the structured guidance offered by pvknowhow.com, helping new entrants navigate this complex process. A recent project in a similar arid region achieved operational readiness within 12 months by following this structured approach.

Frequently Asked Questions (FAQ)

What is the typical investment for a solar factory in Rajasthan?

The investment depends heavily on the production capacity and level of automation. For a semi-automated 50 MW facility designed to produce DESERT+ glass-glass modules, an investor might expect an initial capital expenditure in the range of €4 to €6 million for the core production equipment. A comprehensive business plan would provide precise figures based on specific project requirements.

How long does it take to set up a manufacturing plant?

With a clear plan and experienced partners, a solar module factory can be operational in a surprisingly short time. A realistic timeline, from final investment decision to the production of the first certified module, is typically between 9 and 15 months.

Do I need a technical background to start this business?

No. Many successful entrepreneurs in the solar manufacturing industry come from non-technical backgrounds in sectors like construction, real estate, or general manufacturing. Success depends on strong business acumen and partnering with technical experts who can manage the engineering, procurement, and commissioning aspects of the project.

Why not just import cheaper modules from other countries?

Importing modules may seem cheaper initially, but it carries significant risks. These include potential import tariffs, supply chain vulnerabilities, and currency fluctuations. Most importantly, imported standard modules are often not engineered for Rajasthan’s extreme climate, leading to higher degradation rates and potential warranty issues. A local factory producing specialized DESERT+ modules offers a more durable, reliable, and strategically sound long-term solution for supplying India’s solar parks.

Understanding the unique intersection of market demand and environmental challenge in Rajasthan is the first step toward building a successful solar manufacturing business. By focusing on high-quality, climate-specific technology, an entrepreneur can establish a facility that not only meets but exceeds the expectations of India’s largest energy producers.

The sheer scale of India’s solar ambitions is staggering. At the heart of this transformation lies Rajasthan, home to colossal projects like the Bhadla Solar Park, which spans over 56 square kilometers and generates more than 2,245 megawatts of power. For an entrepreneur, this represents more than just a source of clean energy; it is one of the world’s most concentrated and predictable markets for solar modules.

However, supplying this market involves more than simply producing standard solar panels. The very conditions that make Rajasthan ideal for solar energy—intense, unrelenting sunlight and high ambient temperatures—also pose the greatest technical challenges to module longevity and performance.

This article makes the strategic case for establishing a solar module manufacturing facility in Rajasthan. It outlines the region’s unique environmental challenges and explains why specialized module technology is essential for long-term success, providing a framework for building a business that can reliably supply India’s largest solar parks for decades to come.

The Epicenter of India’s Solar Revolution

Rajasthan’s strategic importance in the solar sector stems from its exceptional natural resources. The state receives some of the highest solar irradiation in the country, averaging around 5.72 kWh per square meter per day. This has made it the logical location for developing the utility-scale solar parks that are central to India’s national energy goals.

For a manufacturer, this geographic concentration of demand creates a powerful business case:

-

Proximity to Market: A factory in Rajasthan is strategically positioned to serve the largest customers directly. This dramatically reduces logistics costs, eliminates complex transportation risks, and enables faster delivery timelines compared to competitors in other states or countries.

-

Predictable Demand: The long-term power purchase agreements (PPAs) that underpin these solar parks create stable and predictable demand for high volumes of modules. This allows a manufacturer to plan production cycles and raw material procurement with greater certainty.

-

Alignment with Government Initiatives: Establishing a local solar module manufacturing plant aligns with India’s ‘Make in India’ policy, potentially offering benefits related to government tenders and local content requirements.

By positioning a manufacturing facility at the doorstep of this immense market, an entrepreneur can build a leaner, more responsive, and more competitive operation.

The Climate Challenge: Why Standard Modules Underperform in the Desert

While the sun is the source of opportunity in Rajasthan, the region’s climate is also a significant engineering challenge. The combination of extreme heat, high UV radiation, and arid conditions can cause conventional solar modules to degrade prematurely, leading to underperformance and potential failure.

Understanding these technical risks is critical for any investor.

The Impact of High Temperatures

Every solar module has a ‘temperature coefficient’, which measures how much its power output decreases as its temperature increases beyond the standard test condition of 25°C. In Rajasthan, where daytime temperatures can frequently exceed 45°C, the surface of a solar module can reach 70°C or higher.

For a standard module, this can result in a performance loss of 15% or more during the hottest parts of the day—precisely when solar irradiation is at its peak.

Material Degradation from UV Radiation and Aridity

Intense, prolonged exposure to ultraviolet (UV) radiation in a desert environment accelerates the aging of a standard module’s materials. The polymer backsheet can become brittle and crack, allowing moisture ingress that leads to corrosion and electrical faults.

Similarly, the encapsulant material (typically EVA) that bonds the cells to the glass can yellow. This yellowing reduces the amount of light that reaches the solar cells and permanently lowers the module’s output.

For a business supplying modules under a 25-year performance warranty to a large solar park, this accelerated degradation represents a substantial financial risk.

Engineered for Extremes: The European Industrial Solutions Provider DESERT+ Module Solution

Addressing the unique environmental challenges of Rajasthan requires module technology engineered specifically for desert conditions. Standard, commodity-grade panels are simply not designed to withstand such a harsh environment over a multi-decade lifespan.

Based on decades of experience engineering solutions for challenging climates, the premier EU rovider developed the DESERT+ module specifications. This is not a single product, but a set of material and design principles for producing modules that deliver superior performance and reliability in hot, arid regions. A factory equipped to produce DESERT+ modules can offer a clear competitive advantage.

Key features include:

-

Glass-Glass Construction: Instead of a vulnerable polymer backsheet, these modules use a second layer of glass on the rear. This hermetically seals the solar cells, providing superior protection against moisture, mechanical stress, and UV degradation. It’s a design proven to significantly extend the module’s operational lifetime to 30 years or more.

-

Specialized POE Encapsulant: DESERT+ specifications call for Polyolefin Elastomer (POE) encapsulants instead of standard EVA. POE offers much greater resistance to heat and UV radiation, preventing the yellowing and delamination that plagues conventional modules in desert climates.

-

High-Efficiency Cell Technology: Integrating advanced cell architectures like TOPCon or HJT gives the module a higher efficiency baseline. This maximizes energy yield and provides a better return on investment for the solar park operator, even with inevitable temperature-related efficiency losses.

Manufacturing modules with these specifications allows a producer to confidently offer a product with a lower degradation rate and a higher lifetime energy yield—the two most important metrics for utility-scale customers.

The Strategic Roadmap: From Concept to Production

Entering the solar manufacturing industry requires a structured approach. An investor does not need to be a photovoltaic expert, but they do need a reliable process and experienced partners. The journey from an initial business idea to a fully operational factory can be broken down into four clear stages.

-

Feasibility and Business Planning: The first phase involves detailed market analysis, financial modeling, and securing offtake agreements with potential customers like solar park developers. This stage defines the factory’s target capacity, technology choice, and overall investment requirements.

-

Factory Design and Layout: Once the business plan is approved, engineers design the optimal layout for the production facility. This includes planning for material flow, machinery placement, quality control stations, and necessary utilities, all customized for the chosen module technology.

-

Equipment Sourcing and Integration: A critical step is the procurement and installation of the manufacturing equipment. Opting for a turnkey line from an experienced EU PV factory turnkey supplier ensures that all machines—from the stringer to the laminator and sun simulator—are fully integrated and calibrated to work together seamlessly.

-

Commissioning and Training: The final stage involves commissioning the production line and extensively training the local workforce. Proper training is essential to ensure the factory can consistently produce high-quality modules that meet international certification standards.

The European solar PV equipment provider’s multi-generational experience in solar engineering is the foundation for the structured guidance offered by pvknowhow.com, helping new entrants navigate this complex process. A recent project in a similar arid region achieved operational readiness within 12 months by following this structured approach.

Frequently Asked Questions (FAQ)

What is the typical investment for a solar factory in Rajasthan?

The investment depends heavily on the production capacity and level of automation. For a semi-automated 50 MW facility designed to produce DESERT+ glass-glass modules, an investor might expect an initial capital expenditure in the range of €4 to €6 million for the core production equipment. A comprehensive business plan would provide precise figures based on specific project requirements.

How long does it take to set up a manufacturing plant?

With a clear plan and experienced partners, a solar module factory can be operational in a surprisingly short time. A realistic timeline, from final investment decision to the production of the first certified module, is typically between 9 and 15 months.

Do I need a technical background to start this business?

No. Many successful entrepreneurs in the solar manufacturing industry come from non-technical backgrounds in sectors like construction, real estate, or general manufacturing. Success depends on strong business acumen and partnering with technical experts who can manage the engineering, procurement, and commissioning aspects of the project.

Why not just import cheaper modules from other countries?

Importing modules may seem cheaper initially, but it carries significant risks. These include potential import tariffs, supply chain vulnerabilities, and currency fluctuations. Most importantly, imported standard modules are often not engineered for Rajasthan’s extreme climate, leading to higher degradation rates and potential warranty issues. A local factory producing specialized DESERT+ modules offers a more durable, reliable, and strategically sound long-term solution for supplying India’s solar parks.

Understanding the unique intersection of market demand and environmental challenge in Rajasthan is the first step toward building a successful solar manufacturing business. By focusing on high-quality, climate-specific technology, an entrepreneur can establish a facility that not only meets but exceeds the expectations of India’s largest energy producers.

Download: Rajasthan Advantage Solar Case Study (PDF)

Author: This case study was prepared by the

turnkey solar module production specialists at J.V.G. Technology GmbH

It is based on real data and consulting experience from J.v.G. projects

worldwide, including installations ranging from 20 MW to 500 MW capacity.