An entrepreneur with capital and business acumen might see immense potential in the global demand for solar energy, yet the prospect of navigating a new country’s complex regulatory and logistical landscape can be daunting. It’s a common dilemma for professionals considering a move into solar manufacturing.

However, frameworks exist to mitigate these challenges, and India’s Special Economic Zones (SEZs) are among the most effective. An SEZ is more than just a location; it’s a designated ecosystem designed to function as a foreign territory for trade and tariff purposes. For a solar module manufacturer, setting up a facility within an SEZ can transform a complex undertaking into a streamlined, cost-effective operation. This guide explains the procedural, financial, and logistical advantages of this strategic choice.

Understanding the Indian Special Economic Zone Framework

Established under the SEZ Act of 2005, a Special Economic Zone is a geographically demarcated area within India where business and trade laws differ from the rest of the country. Its primary objective is to create a globally competitive and hassle-free environment for export-oriented production.

Think of an SEZ as a “duty-free enclave” with its own set of rules managed by a dedicated administrative body. For a solar manufacturer, this significantly simplifies the process of importing high-tech machinery and raw materials and then exporting finished solar modules.

The framework rests on three pillars:

- Attracting Foreign Investment: By offering attractive incentives and simplified procedures.

- Boosting Exports: Mandating that units within the SEZ are net foreign exchange earners.

- Generating Economic Activity: Creating employment and developing world-class infrastructure.

These zones are specifically designed to remove the bureaucratic hurdles often associated with setting up a large-scale manufacturing operation in a new market.

Key Financial Incentives for Solar Manufacturers

The most compelling reason to set up a factory in an SEZ is the substantial reduction in capital and operational expenditure. These financial benefits directly impact the viability and profitability of a solar module manufacturing project.

Duty-Free Procurement of Capital Goods and Raw Materials

Setting up a solar production line involves importing a significant amount of specialized machinery. High-value capital goods like cell stringers, laminators, and sun simulators are exempt from customs duties when imported for a unit inside an SEZ.

This exemption provides direct and immediate savings on the initial investment in solar panel manufacturing equipment. The same benefit applies to importing raw materials and consumables required for production, including solar cells, EVA film, backsheets, and aluminum frames. This duty-free environment drastically lowers production costs, making the final product more competitive on the global market.

Goods and Services Tax (GST) Exemptions

The GST framework in India treats any supply of goods or services to a unit or developer in an SEZ as a “zero-rated supply.” This means no GST is levied on the domestic procurement of materials or services for the SEZ unit. This policy ensures that working capital is not tied up in tax payments and subsequent refund claims, improving cash flow—a critical factor for any new manufacturing venture.

Corporate Income Tax Considerations

Historically, SEZ units enjoyed a phased 15-year tax holiday. While this provision for new units has been phased out, SEZs remain financially attractive. Entrepreneurs should be aware of the current corporate tax regime, which may still offer benefits for new manufacturing entities.

Furthermore, the Indian government has proposed a new legislative framework, the Development of Enterprise and Service Hubs (DESH) Bill, which may replace the existing SEZ Act. This proposed legislation aims to integrate these zones further with the domestic economy and may introduce a different set of incentives. This evolving regulatory landscape makes it essential to obtain current guidance during the planning phase of a turnkey factory setup.

Logistical and Operational Advantages

Beyond direct financial savings, SEZs offer a superior operational environment crucial for maintaining a high-efficiency manufacturing plant.

Streamlined Customs and Approvals

One of the most significant operational benefits is the single-window clearance mechanism. Each SEZ is managed by a Development Commissioner, whose office acts as the central point of contact for all approvals, licenses, and clearances. This system cuts through red tape and accelerates the setup process, a stark contrast to dealing with multiple government departments individually. On-site customs officials within the SEZ further expedite the import and export of goods, ensuring supply chain continuity.

World-Class Infrastructure and Utilities

Reliability is paramount in manufacturing. SEZs are developed with high-quality, uninterrupted infrastructure, providing:

- Stable Power Supply: Essential for running sensitive manufacturing equipment 24/7.

- Water and Waste Treatment: Readily available utility connections.

- Internal and Connecting Roads: Well-maintained transport links.

- Proximity to Ports and Airports: Facilitating efficient global logistics.

This “plug-and-play” environment allows business owners to focus on their core operations—manufacturing high-quality solar modules—rather than solving basic infrastructure challenges. This is particularly valuable in regions where utility reliability might otherwise be a concern.

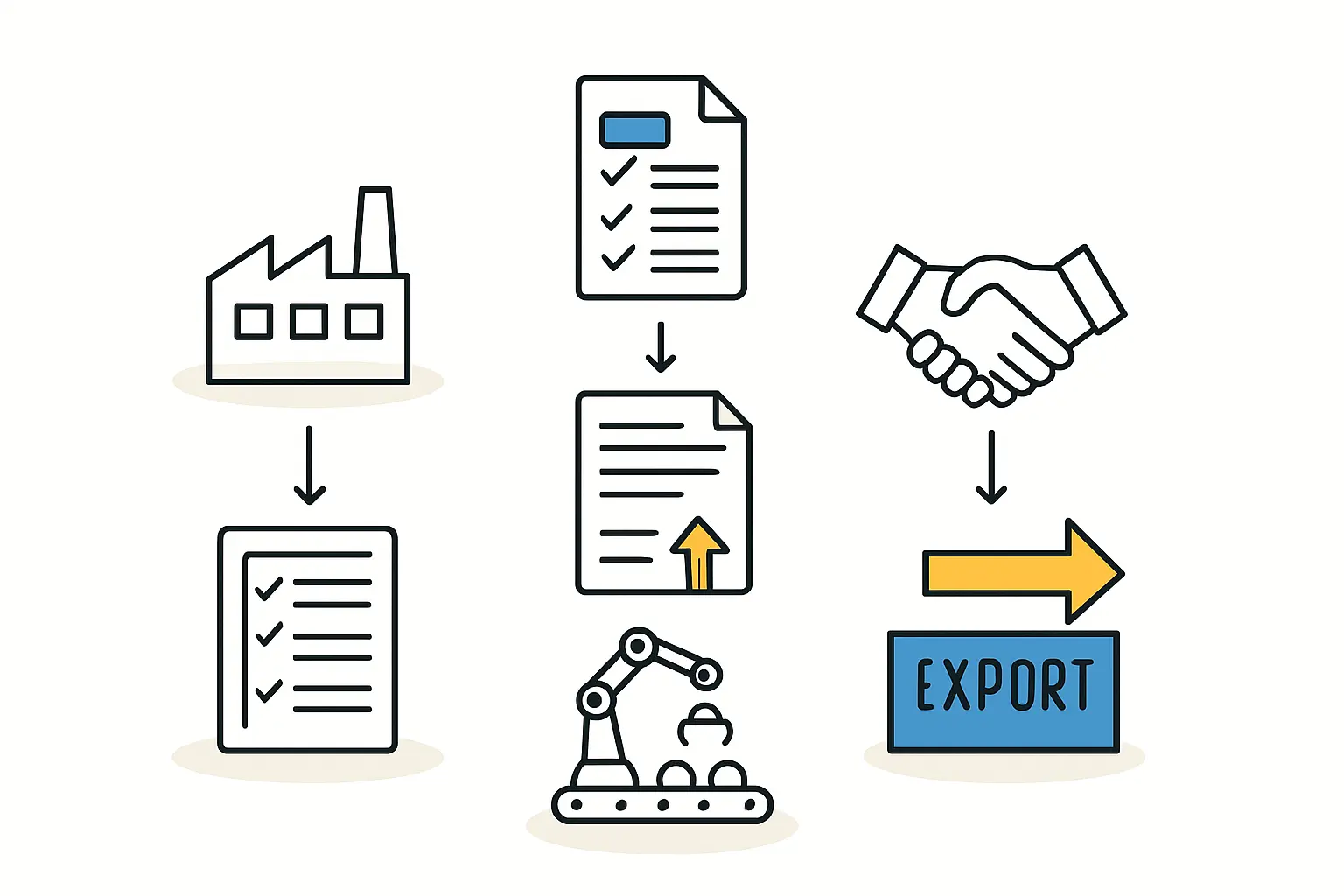

The Process of Setting Up a Unit in an SEZ

While the process is streamlined, establishing an SEZ unit follows a structured path with these key steps:

- Selection of an SEZ: Identify a suitable multi-product or sector-specific SEZ that aligns with your project’s logistical needs (e.g., proximity to a seaport).

- Submission of Proposal: Prepare and submit a formal application to the Development Commissioner of the chosen SEZ. This application must include a detailed project report outlining the business plan, investment, export projections, and employment figures.

- Letter of Approval (LoA): Upon scrutiny and approval by the Unit Approval Committee, a Letter of Approval is issued. This LoA is the foundational document for setting up the unit.

- Lease and Registration: Execute a lease deed for the land or premises within the SEZ. Then, obtain necessary registrations, including the Importer-Exporter Code (IEC) and GST registration.

- Commencement of Operations: Once all approvals are in place and the facility is constructed, the unit can begin its commercial operations.

A well-prepared business plan for a solar factory is the cornerstone of a successful application, as it gives the committee confidence that the project is viable and will meet its obligations.

Important Considerations and Compliance

Operating within an SEZ comes with specific compliance requirements that are essential to understand from the outset.

Net Foreign Exchange (NFE) Earnings

The core mandate of an SEZ unit is to be a net foreign exchange earner. This means that over a five-year block, the unit’s export earnings must exceed its foreign exchange outgo for imported machinery, materials, and services. For a solar module factory planning to export its entire output, meeting this NFE obligation is a primary objective that requires careful management and reporting. Based on experience from J.v.G. turnkey projects, accurately forecasting NFE compliance is a critical part of the initial business planning.

Domestic Tariff Area (DTA) Sales

While SEZs are export-focused, it is possible to sell finished goods into the Indian domestic market, referred to as the Domestic Tariff Area (DTA). However, such sales are treated as an import into India. This means the DTA buyer must pay all applicable customs duties, effectively making the SEZ unit an international supplier.

Frequently Asked Questions (FAQ)

Is 100% Foreign Direct Investment (FDI) allowed for a solar factory in an SEZ?

Yes, for the manufacturing sector, 100% FDI is permitted through the automatic route, meaning no prior government approval is required for the investment itself.

What is the typical timeline for getting approvals to set up a unit?

Thanks to the single-window clearance system, the timeline for receiving a Letter of Approval can be as short as a few weeks, provided the application and project report are comprehensive and accurate.

Can I sell solar panels manufactured in an SEZ to the Indian domestic market?

Yes, but this is considered an export from the SEZ and an import into the Indian domestic market. The transaction would attract full customs duties as applicable at the time of sale.

How might the proposed DESH Bill affect my plans?

The DESH Bill aims to reorient the SEZ framework, potentially with a greater focus on boosting domestic manufacturing and job creation. It may change the incentive structure. Investors should seek current, expert advice to understand how legislative changes could impact a new project.

Do I need a local partner to set up in an SEZ?

A local partner is not legally mandatory. However, having on-the-ground expertise to navigate administrative procedures, site selection, and local regulations is highly beneficial and can significantly de-risk project execution.

Your Strategic Gateway to Global Solar Markets

For an international entrepreneur looking to enter the solar manufacturing industry, an Indian SEZ offers a powerful and structured path forward. It creates a business-friendly micro-environment that mitigates many of the challenges typically associated with foreign investment, from high import duties to bureaucratic delays. By leveraging this framework, a business can significantly reduce its initial investment, streamline its supply chain, and establish a competitive, export-oriented manufacturing hub.

Understanding these regulatory and financial structures is the first step. The next involves detailed technical planning and financial modeling to build a robust business case. Resources like the structured e-course available on pvknowhow.com can provide manufacturers with a comprehensive roadmap for every stage, from initial concept to a fully operational solar factory.