An entrepreneur in India secures funding to launch a new solar module assembly plant. With a solid business plan, an identified facility, and the initial team in place, a critical decision looms—one that will define the factory’s cost structure, operational efficiency, and market competitiveness: where to source the core components.

International suppliers, particularly from China and Southeast Asia, offer attractive pricing on solar cells. Domestic Indian manufacturers, however, promise faster lead times, simpler logistics, and alignment with powerful government incentives. This is not merely a question of price, but a complex strategic decision with long-term implications for anyone entering the Indian solar module manufacturing business.

This guide offers a clear, balanced analysis of sourcing key components—solar cells, glass, and backsheets—domestically versus internationally. It is designed to help business professionals navigate the trade-offs between cost, quality, supply chain security, and regulatory compliance in one of the world’s fastest-growing solar markets.

The Core Components of a Solar Module

Before analyzing sourcing strategies, it’s crucial to understand the primary materials that make up a solar panel. For a new manufacturer, three components represent the most significant portion of the bill of materials (BOM):

-

Solar Cells: The heart of the solar module, these components convert sunlight into electricity. The efficiency and quality of the solar cells directly determine the final product’s performance and power rating.

-

Solar Glass: This specialized, tempered glass protects the solar cells from the elements while maximizing light transmission. It must be durable, low-iron, and often features an anti-reflective coating.

-

Backsheet: A multi-layered polymer-based material applied to the rear of the module. It provides mechanical protection and electrical insulation, safeguarding the internal components through decades of outdoor exposure.

Sourcing decisions for these three items will fundamentally shape the final cost and quality of your solar modules.

Analyzing the Sourcing Decision: Key Factors for Consideration

Choosing between domestic and international suppliers involves a careful evaluation of several interconnected business factors. Basing a decision solely on one variable, like cost, can have unforeseen consequences elsewhere in the operation.

Ready to make big Profits?

The solar Industry is Booming

WE HELP NEWCOMERS to the solar industry start their own solar module production line. Customers can make BIG PROFITS by selling modules and finding investors, without wasting money and time on things they don't need!

Cost and Pricing Dynamics

At first glance, international suppliers often appear to be the more cost-effective option. But the initial price quote is only part of the total cost equation.

International Sourcing: Historically, manufacturers in China have offered solar cells at prices 5–15% lower than their Indian counterparts, thanks to massive economies of scale. This advantage is offset by significant import duties; India’s Basic Customs Duty (BCD) on imported cells is a deliberate policy to encourage domestic production. Fluctuating currency exchange rates and high shipping costs also add volatility and expense.

Domestic Sourcing: While the list price for Indian-made components may be higher, the total landed cost can be more competitive. Sourcing domestically eliminates international freight charges, import duties, and currency risk. It also simplifies procurement with shorter payment cycles and more straightforward financing arrangements with local banks.

Based on J.v.G.’s experience in turnkey projects, a comprehensive “landed cost” analysis—including shipping, insurance, duties, and currency conversion—is essential for an accurate comparison. Relying on a supplier’s price list alone can be misleading.

Quality, Technology, and Performance

The performance and bankability of a solar module are directly tied to the quality of its components.

International Sourcing: Leading international suppliers have a long-established reputation for high-efficiency cells and consistent quality control. They often lead in adopting new technologies like TOPCon or HJT, having served the global market for years.

Domestic Sourcing: The Indian solar manufacturing ecosystem is maturing rapidly, spurred by government initiatives like the Production Linked Incentive (PLI) scheme. Many domestic producers now offer products with quality and efficiency ratings competitive with global standards. Consistency, however, can vary between suppliers. A robust incoming quality control process is critical regardless of the source.

A prudent strategy often involves qualifying multiple suppliers, both domestic and international, to create a flexible and competitive procurement environment.

Supply Chain Resilience and Logistics

The COVID-19 pandemic highlighted the vulnerabilities of long, complex global supply chains. For a manufacturer, delays can mean idle production lines and missed delivery targets.

International Sourcing: This path involves lead times of 6–10 weeks, including ocean freight and customs clearance. It exposes a business to the risks of port congestion, shipping container shortages, and geopolitical disruptions. A single delay can halt production for weeks.

Domestic Sourcing: Sourcing from within India drastically shortens lead times to 1–3 weeks. This provides greater agility, allowing for a just-in-time inventory model that reduces warehousing costs and improves cash flow. Direct communication with local suppliers in the same time zone also simplifies problem-solving.

A common challenge observed among new manufacturers is underestimating the working capital required to manage long international supply chains.

Navigating Indian Government Policies: DCR and ALMM

This is arguably the most critical factor for succeeding in the Indian market. Government policy is designed to actively favor domestic manufacturing.

Domestic Content Requirement (DCR): Many government-sponsored solar projects and public tenders mandate the use of modules made with domestically manufactured solar cells. If your business plans to sell to these lucrative segments, sourcing cells from Indian producers is non-negotiable.

Approved List of Models and Manufacturers (ALMM): This government-mandated list of eligible models and manufacturers for use in government projects strongly favors local producers. This makes it very difficult for companies using primarily imported components to get listed and compete.

Compliance with DCR and ALMM can open up a substantial portion of the Indian market that is otherwise inaccessible.

A Comparative Breakdown: Domestic vs. International

Solar Cells

Domestic Sourcing: The main advantages are DCR and ALMM compliance, no import duty, short lead times, and greater supply chain security. On the downside, the list price can be higher, and technology might lag behind the top international tier.

International Sourcing: Key benefits include a lower initial cost (before duties) and access to the latest high-efficiency technologies. The disadvantages are significant, including high BCD, long lead times, and logistical risks.

Solar Glass

Domestic Sourcing: Pros include reduced freight costs for this heavy item, support for the local economy, and a reliable supply. The main con is that there are fewer large-scale suppliers than in China.

International Sourcing: The massive production scale leads to highly competitive pricing. However, this is offset by high shipping costs, the risk of breakage during transit, and long delivery times.

Backsheets

Domestic Sourcing: India has a growing number of quality suppliers, offering quick delivery and simplified logistics. The potential drawback is less brand recognition than established global players.

International Sourcing: You gain access to a wide selection of globally recognized brands with proven track records. The cons are potential supply chain disruptions and complex import procedures.

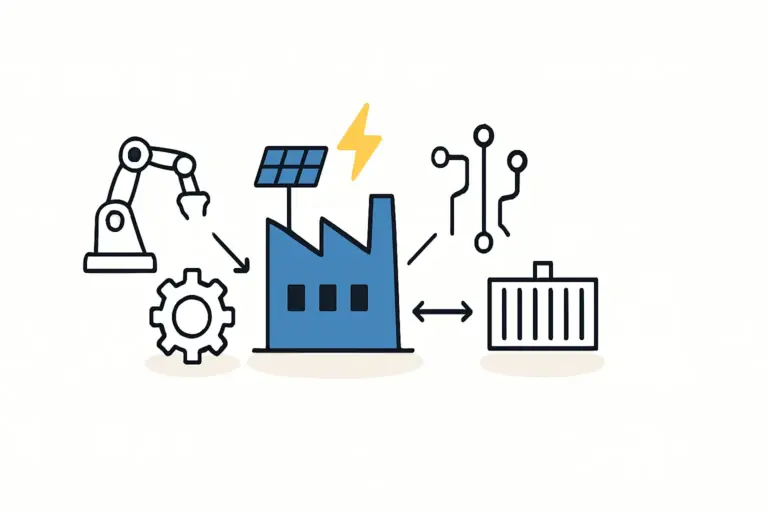

Building a Hybrid Sourcing Strategy

The most resilient approach is often not an “either/or” choice but a hybrid model. A sophisticated manufacturer in India might:

- Source domestically for the bulk of its production to ensure DCR compliance and serve the stable government project market.

- Source internationally for specific high-efficiency cells for a premium product line aimed at the private commercial and industrial (C&I) market.

- Dual-source critical components like backsheets from both a primary domestic supplier and a secondary international one to mitigate risk and maintain price competitiveness.

This balanced approach provides flexibility, optimizes costs across different product lines, and secures access to the widest possible market. Developing this strategy requires deep market knowledge and technical expertise—often facilitated by a partner experienced in setting up turnkey solar manufacturing lines.

Frequently Asked Questions (FAQ)

What is the Domestic Content Requirement (DCR) in simple terms?

DCR is a government policy requiring solar power projects, particularly those funded or tendered by government entities, to use a certain percentage of locally manufactured components, specifically solar cells and modules. The policy is designed to boost India’s domestic manufacturing capabilities.

Are Indian-made solar cells as good as imported ones?

The quality gap has narrowed significantly. Leading Indian manufacturers now produce cells with efficiencies and degradation rates that are globally competitive. That said, it remains crucial for any manufacturer to conduct its own stringent quality checks and supplier audits, regardless of a component’s origin.

How does the PLI scheme affect my sourcing decision?

The Production Linked Incentive (PLI) scheme provides financial incentives to companies that set up manufacturing facilities in India for high-efficiency solar modules, cells, and wafers. The scheme has catalyzed massive investment in domestic capacity, leading to more local suppliers, better technology, and increasingly competitive pricing for domestically sourced components.

What are the main risks of relying solely on imported components?

The primary risks include: 1) exclusion from large government-backed projects due to DCR and ALMM regulations; 2) production halts caused by shipping delays or geopolitical trade disputes; and 3) unpredictable final costs due to fluctuating import duties and currency rates.

Conclusion and Next Steps

Sourcing components for a new solar factory in India is a foundational decision. While international suppliers may offer tempting headline prices, a deeper analysis reveals the powerful logistical, financial, and market-access benefits of developing a strong domestic supply chain.

For entrepreneurs new to the solar industry, navigating these complexities can seem daunting. The optimal strategy balances cost, quality, and risk while aligning with India’s industrial policy. The key is to move beyond simple price comparisons and build a resilient, flexible sourcing plan that positions your business for long-term, sustainable growth in this dynamic market.