The Indian government’s Production Linked Incentive (PLI) scheme, backed by an allocation of over ₹24,000 crore (approximately $3 billion), is one of the most significant opportunities in the global solar manufacturing sector.

This opportunity, however, is as complex as it is significant. A project that appears profitable on paper can fail to secure incentives if its operational structure does not precisely align with the scheme’s stringent requirements for scale, integration, and technology.

This guide outlines a strategic framework for structuring a solar module manufacturing project in Andhra Pradesh, a state well-positioned to support such ambitious ventures. It provides a step-by-step overview for entrepreneurs and investors, focusing on how to align financial and operational planning with the technical benchmarks necessary to capture the full incentives.

Understanding India’s PLI Scheme for Solar Manufacturing

At its core, the PLI scheme is a strategic government initiative that rewards incremental sales of high-efficiency solar PV modules made in India. Its primary objectives are to reduce India’s reliance on imports, build a resilient domestic supply chain, and establish the nation as a global solar manufacturing hub.

The scheme functions by providing a direct financial incentive to manufacturers over five years, calculated based on sales volume, module efficiency, and the extent of local value addition. Success isn’t just about producing modules—it’s about producing the right modules, at the right scale, and with the right level of domestic integration.

Core Requirements for PLI Eligibility: A Strategic Checklist

Participation in the PLI scheme is competitive and requires meeting several non-negotiable criteria from the outset. Your project’s entire structure—from initial investment to factory layout—must be built around these core requirements.

Minimum Manufacturing Capacity

The scheme targets large-scale projects capable of making a substantial impact on national production capacity. Bidders are typically required to commit to setting up a minimum of 1 GW of annual manufacturing capacity. This gigawatt-scale requirement demands significant capital investment and a robust operational plan, setting PLI projects apart from smaller, regional manufacturing setups.

Vertical Integration Level

A central tenet of the scheme is building a complete domestic ecosystem, which is why it heavily favors ‘vertically integrated’ projects. This means a manufacturer must control multiple stages of the production process, not just final module assembly. The minimum required integration is typically from solar wafer to module, with the highest incentives reserved for fully integrated plants that start from polysilicon.

The Value Chain Stages:

- Polysilicon: The raw, ultra-pure silicon base.

- Ingots & Wafers: Polysilicon is melted and formed into ingots, which are then thinly sliced into wafers.

- Solar Cells: Wafers are processed and converted into photovoltaic cells that generate electricity.

- Solar Modules: Cells are interconnected, laminated, and assembled into finished panels.

A project planning only to assemble modules from imported cells will not qualify. The strategic decision of where to enter this value chain is one of the most critical financial and technical choices you will make.

Performance and Efficiency Benchmarks

The PLI scheme is specifically designed to promote advanced technology. To qualify for incentives, the modules produced must meet minimum efficiency ratings, and the incentive amount increases for modules that exceed these benchmarks. Manufacturers must invest in production lines capable of handling next-generation cell technologies like TOPCon (Tunnel Oxide Passivated Contact) or HJT (Heterojunction). Choosing a production line based on older, less efficient technology can render a project ineligible from day one.

Why Andhra Pradesh is a Strategic Location for a PLI Project

While several Indian states offer incentives for industrial development, Andhra Pradesh presents a unique combination of advantages well-aligned with the demands of a large-scale solar manufacturing project.

- Proactive State Government Support: The state is known for its investor-friendly policies, including a single-window clearance system to expedite approvals and a track record of providing customized incentive packages for mega-projects.

- Logistical and Port Advantages: With a long coastline and deep-water ports like Krishnapatnam and Visakhapatnam, Andhra Pradesh offers key logistical advantages for importing raw materials like polysilicon and exporting finished modules to international markets.

- Established Industrial Infrastructure: The state has several well-developed industrial zones with reliable access to power, water, and road connectivity—critical infrastructure for a 24/7 manufacturing operation. Based on experience from J.v.G. turnkey projects, securing a location with pre-built utility access can reduce project timelines by several months.

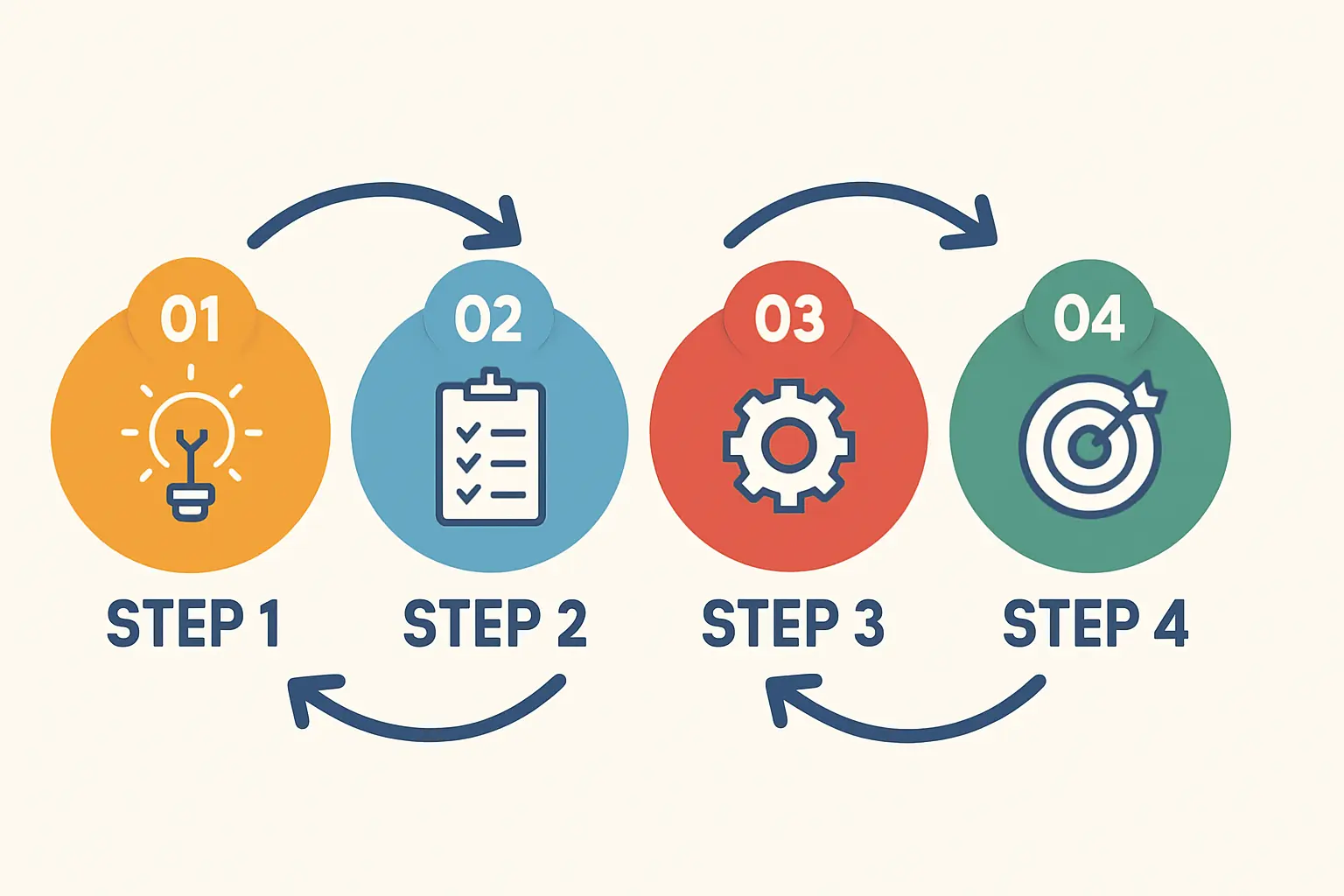

A Step-by-Step Framework for Structuring Your Project

Successfully launching a PLI-compliant factory involves a meticulous, multi-stage process. Rushing any of these steps can create irreversible problems later on.

Step 1: Detailed Feasibility and Financial Modeling

Before any equipment is ordered, a comprehensive business plan is crucial. This plan must go beyond standard revenue projections; it needs to model cash flows based on the five-year PLI disbursement schedule, account for the high capital expenditure of a gigawatt-scale integrated facility, and factor in volatile global raw material prices. During this stage, you determine your optimal level of vertical integration based on your investment capacity.

Step 2: Technology Selection and Production Line Design

This is a critical decision point. Your choice of machinery directly determines your ability to meet the PLI scheme’s efficiency requirements—not just at launch, but for the entire five-year incentive period. A production line must be both robust and adaptable to future technology upgrades. Designing a factory layout that optimizes material flow and minimizes waste is a complex engineering task central to long-term profitability.

Step 3: Navigating the Application and Bidding Process

The PLI scheme is implemented in tranches, each with a limited allocation of funds. This creates a competitive bidding environment where applicants are ranked based on their committed level of integration and efficiency. A well-prepared application, supported by a credible technical and financial plan, is crucial for securing an allocation.

Step 4: Factory Construction and Commissioning

The execution phase requires disciplined project management to meet the timelines committed to in the PLI application. Delays can result in penalties or a shortened incentive period. This phase involves everything from civil works and utility installation to the complex process of installing and calibrating the solar module manufacturing equipment.

Step 5: Audit, Compliance, and Incentive Realization

Receiving PLI benefits is conditional on passing regular audits from government-appointed agencies. These audits verify your production capacity, module efficiency, and domestic value addition claims. Maintaining meticulous production records and quality control documentation is essential for ensuring consistent and timely incentive payments.

Frequently Asked Questions (FAQ)

What is the typical investment for a PLI-compliant factory?

For a 1 GW facility with the minimum required integration (wafer-to-module), investments can range from $150 million to $250 million USD, depending on the technology and equipment selected. Fully integrated polysilicon-to-module plants require substantially higher capital.

Can an existing manufacturer apply for the PLI scheme?

Yes, but the incentive is applicable only to new manufacturing capacity. An existing manufacturer would need to invest in a new, separate production line that meets all the scheme’s criteria for capacity and integration.

How is the incentive calculated and disbursed?

The incentive is calculated per unit of sales (in Watts) and is tiered. The formula considers the module’s efficiency and the extent of local value addition; for example, producing cells and wafers domestically earns a higher incentive. Payments are typically disbursed annually after a successful audit.

What is the biggest risk for new investors in this scheme?

A common challenge observed in J.v.G. Technology GmbH consulting engagements is a mismatch between the business plan and technical execution. Common pitfalls include underestimating the operational complexities of a gigawatt-scale factory or selecting equipment that fails to consistently produce modules at the required efficiency. Such issues can jeopardize the very incentive payments the financial model was built on.

The Path Forward

India’s PLI scheme offers a generational opportunity to build a globally competitive solar manufacturing business. Success, however, is contingent on a strategy built on technical excellence, rigorous financial planning, and flawless execution. The journey from an initial business concept to a fully commissioned, PLI-compliant factory is complex and requires deep domain expertise.

For entrepreneurs and business leaders embarking on this path, the first step is to build a foundational understanding of the entire process. A structured approach, from initial planning to final audit, is the surest way to transform this ambitious national vision into a successful commercial reality. Exploring a comprehensive guide on how to start a solar panel factory can provide the detailed framework needed for this critical first phase.