An entrepreneur launches a solar module factory in Rajasthan, confident in a standard, high-quality European design. Within two years, field reports reveal the modules are underperforming, with power degradation rates significantly higher than projected. The cause wasn’t a defect in manufacturing quality, but a mismatch between the product and the harsh local environment; the original design hadn’t accounted for extreme heat and fine desert dust.

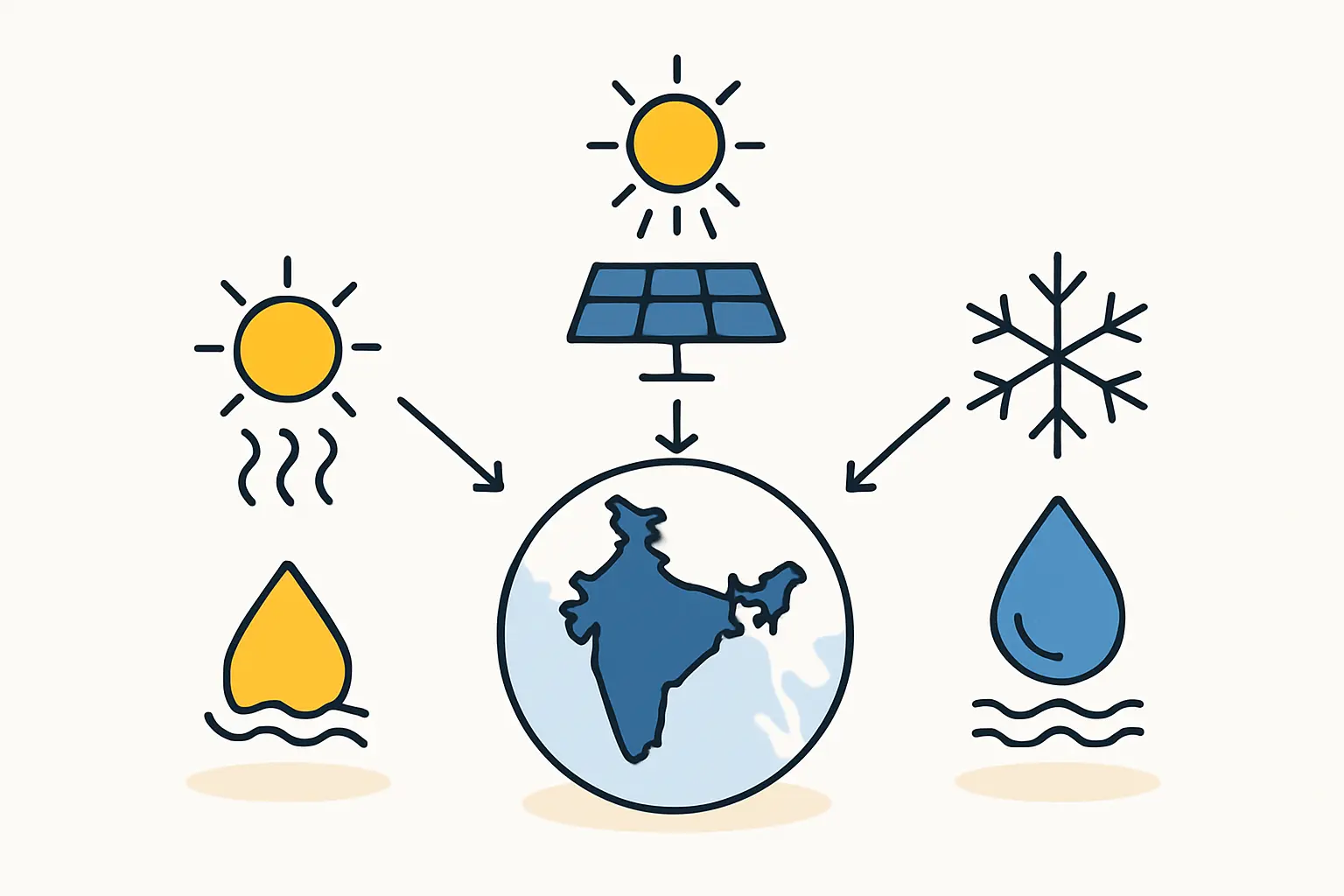

This story highlights a critical reality for investors in India’s solar manufacturing sector: India is not a single, uniform market. It is a subcontinent with multiple climate zones, each posing unique challenges to a solar module’s longevity and performance.

A “one-size-fits-all” approach, while simpler to implement, ultimately leads to reduced energy yields, higher degradation rates, and increased warranty claims.

This article covers the technical adaptations in module design and production needed to meet the demands of India’s varied climates. It provides a strategic overview for entrepreneurs and business leaders on how to build a resilient and competitive product line tailored for the Indian market.

Understanding India’s Climatic Stress Factors

Building a durable solar module begins with understanding the environmental forces working against it. In India, these stressors are diverse and often severe, demanding a more robust design than what might be standard in milder European or North American climates.

High Ambient Temperatures

In regions like Rajasthan and Gujarat, summer temperatures can exceed 45°C, pushing a solar module’s operating temperature to 70°C or higher. This sustained heat accelerates the aging of all polymer components within the module, such as the encapsulant and backsheet. It also directly reduces power output due to the negative temperature coefficient of solar cells.

High Humidity and Salt Mist

India’s extensive coastline—home to major industrial hubs like Mumbai, Chennai, and Kolkata—exposes solar installations to high humidity and corrosive salt mist. Moisture ingress is a primary cause of module failure, leading to:

- Delamination: Separation of the module layers.

- Corrosion: Of the cell metallization and interconnecting ribbons.

- Potential Induced Degradation (PID): A significant performance loss caused by voltage leakage paths, which moisture exacerbates.

Intense UV Radiation

While India’s high solar irradiation is an advantage for energy generation, it also means high exposure to ultraviolet (UV) radiation. Over time, UV rays break down the polymer materials in backsheets and encapsulants, causing yellowing, brittleness, and cracking. This compromises the module’s electrical insulation and allows moisture to penetrate.

Dust and Soiling

In the arid and semi-arid zones of Northern and Central India, dust accumulation is a major operational challenge. A layer of dust on the module surface can significantly reduce the light reaching the solar cells, cutting energy production. If not cleaned, localized soiling can also create “hotspots” that permanently damage the cells.

Optimizing the Bill of Materials (BOM) for Local Conditions

The foundation of a climate-resilient solar module is its material composition. The most effective way to counter specific environmental threats is through a strategic selection of components in the Bill of Materials.

Encapsulants: The Critical Choice Between POE and EVA

The encapsulant is the transparent polymer material bonding the solar cells, glass, and backsheet. For decades, Ethylene Vinyl Acetate (EVA) has been the industry standard. However, in hot and humid conditions, EVA is susceptible to hydrolysis, a chemical breakdown that produces acetic acid. This acid can accelerate the corrosion of cell circuits and contribute to PID.

A technically superior alternative for harsh climates is Polyolefin Elastomer (POE). POE offers several key advantages:

- Excellent Moisture Resistance: Its water vapor transmission rate is significantly lower than EVA’s, providing a much better barrier against humidity.

- PID Resistance: POE’s high electrical resistivity and acid-free nature make modules highly resistant to Potential Induced Degradation.

- UV Stability: It demonstrates superior long-term performance under intense UV exposure.

While POE may have a slightly higher material cost, its contribution to a module’s long-term reliability and energy yield makes it a prudent investment for deployments in India’s coastal and high-humidity regions.

Backsheets and Glass: The First Line of Defense

The backsheet is the outermost polymer layer protecting the module from the rear. A standard backsheet can degrade quickly under India’s high UV and heat conditions. High-durability backsheets, often featuring proven materials like Tedlar® (PVF) film, offer better resistance to UV degradation, moisture ingress, and thermal stress.

For the most demanding environments, a leading solution is the Glass-Glass module, which replaces the polymer backsheet with a second pane of heat-strengthened glass. The advantages are clear:

- Impermeable to Moisture: Glass provides a perfect barrier against water vapor.

- Mechanical Stability: The structure is more rigid and less prone to microcracks.

- Chemical Resistance: It is unaffected by salt mist or atmospheric pollutants.

Junction Boxes and Frames

The junction box and frame are crucial for safety and structural integrity. For India, key specifications include:

- High IP Rating Junction Boxes (IP68): This ensures they are fully protected against dust and can withstand submersion in water, a vital feature during monsoon season.

- Corrosion-Resistant Frames: Anodized aluminum frames with proper drainage holes are necessary to prevent water accumulation and corrosion, especially in coastal areas.

Fine-Tuning the Manufacturing Process

Material selection is only half the battle. The manufacturing process itself must be optimized to ensure these materials perform as intended. Integrating these adjustments requires technical expertise and precision.

Lamination Parameters

The lamination process uses heat and pressure to cure the encapsulant and bond the module layers into a single, durable unit. Different materials require different process “recipes.” POE, for instance, typically requires different temperature and time settings than EVA to achieve optimal cross-linking and adhesion. An incorrect lamination cycle can compromise the module’s long-term stability and lead to delamination in the field.

Enhanced Quality Control

A manufacturing line for the Indian market should incorporate a more rigorous quality control regime. This includes:

- Extended Damp-Heat Testing: Subjecting sample modules to 85°C and 85% relative humidity for 2,000 hours, instead of the standard 1,000, provides greater assurance of performance in humid climates.

- Thermal Cycling Tests: Simulating extreme day-night temperature swings, crucial for desert regions.

- PID Testing: Verifying the module’s resistance to Potential Induced Degradation at both the cell and module level.

A Zonal Approach to Module Design in India

Rather than a single “India-proof” module, a more strategic approach is to design product variants tailored to specific climate zones.

Zone 1: Hot and Arid (e.g., Rajasthan, Gujarat)

Challenges: Extreme heat, high UV, dust, and soiling.

Design Focus:

- Cells: Use solar cells with a low temperature coefficient.

- Glass: Apply an anti-soiling coating.

- Backsheet: High UV-resistance (e.g., Tedlar-based) or Glass-Glass construction.

- Junction Box: IP68 rating for dust protection.

Zone 2: Hot and Humid / Coastal (e.g., Kerala, Mumbai, West Bengal)

Challenges: High humidity, salt mist corrosion, and high temperatures.

Design Focus:

- Encapsulant: POE is strongly recommended.

- Construction: Glass-Glass design offers maximum protection.

- Frame: Corrosion-resistant anodized aluminum.

- Junction Box: IP68 rating with high-quality sealants.

Zone 3: Composite (e.g., Delhi, Bangalore, Hyderabad)

Challenges: A mix of seasonal extremes—hot summers, humid monsoons, and air pollution.

Design Focus:

- Encapsulant: POE provides a robust all-around solution.

- Backsheet: High-quality, UV-stable polymer backsheet.

- Frame: Mechanically strong to withstand seasonal wind loads.

From Technical Specification to Commercial Advantage

While adopting a climate-specific manufacturing strategy increases the initial Bill of Materials cost, this investment translates directly into significant long-term commercial advantages.

- Improved Bankability: Projects using modules proven to withstand local conditions are viewed as lower-risk by investors and financial institutions.

- Lower Levelized Cost of Energy (LCOE): Higher energy yield and a longer effective lifespan result in better project economics for the end customer.

- Reduced Warranty and O&M Costs: Durable modules minimize field failures, drastically cutting the costs associated with warranty claims and maintenance.

- Stronger Brand Reputation: A manufacturer known for producing reliable, high-performance modules for the Indian environment can build a powerful brand trusted by developers and installers. Experience from turnkey projects shows that manufacturers who prioritize product localization early on tend to secure a more sustainable and profitable market position.

Frequently Asked Questions

Q1: Is it significantly more expensive to produce climate-specific modules?

The initial BOM cost for premium components like POE encapsulants or Glass-Glass construction can be 5-10% higher. However, this expense is typically offset by the module’s higher energy generation over its 25–30 year lifespan and a significantly lower risk of costly warranty claims.

Q2: Can a single factory produce modules for different climates?

Absolutely. A well-designed, flexible production line can handle different Bills of Materials. For example, the line can switch between running EVA and POE by loading different process recipes into the laminator. The key is planning for this flexibility from the outset in terms of machine capability and supply chain management.

Q3: What are the mandatory certifications required to sell solar modules in India?

All solar modules sold in India must have BIS (Bureau of Indian Standards) certification. Additionally, adherence to international IEC standards (such as IEC 61215 for performance and IEC 61730 for safety) is a baseline requirement for demonstrating quality and reliability to commercial customers.

Q4: Do I need a completely different set of machines to use advanced materials like POE?

Generally, no. The standard machine set for module manufacturing can handle both EVA and POE. The critical difference lies in the process parameters, especially for the laminator. Achieving the correct lamination recipe requires technical expertise and is a crucial service provided by experienced technology partners and consultants.

Conclusion

Success in the Indian solar manufacturing market requires a shift in mindset from producing a generic product to engineering a localized solution. By understanding the distinct environmental stressors across the subcontinent—from the dry heat of the desert to the corrosive humidity of the coast—manufacturers can make informed decisions about materials and processes.

This strategic approach to module design is not merely a technical exercise; it is a fundamental business decision that builds resilience, enhances bankability, and establishes a reputation for quality and reliability. For entrepreneurs and investors looking to enter this dynamic market, aligning product strategy with climatic reality is the first and most critical step toward long-term success.