Disclaimer: This case study represents a composite example derived from real-world

consulting work by J.v.G. Technology GmbH in solar module production and factory optimization. All data points are realistic but simplified for clarity and educational purposes.

For an established Indonesian industrial conglomerate, entering a new sector is a matter of strategic precision, not speculative risk. Generations of success are built on calculated expansion, leveraging existing strengths to secure future growth. Today, as Indonesia commits to a transformative energy transition, a significant opportunity is emerging in solar panel manufacturing—one that aligns perfectly with the capabilities of a diversified, family-owned enterprise.

Indonesia has set ambitious targets, aiming for renewable sources to make up 23% of the national energy mix by 2025. This state-driven initiative is more than a policy statement; it is a powerful market signal.

For industrial leaders accustomed to navigating complex supply chains and large-scale production, this signal charts a clear path toward long-term diversification and alignment with national priorities. The question is no longer if the opportunity exists, but how to methodically capitalize on it.

The Unprecedented Opportunity in Indonesia’s Energy Transition

The scale of Indonesia’s renewable energy ambitions creates a protected and growing domestic market. In its 2021-2030 Electricity Supply Business Plan (RUPTL), the state utility Perusahaan Listrik Negara (PLN) outlines plans to add 20.9 GW of renewable capacity. Critically, 4.7 GW of this is designated for solar photovoltaics, creating substantial, predictable demand for locally manufactured solar modules.

This demand is further solidified by a key government regulation: the Local Content Requirement (TKDN). With a mandate for solar power projects to use at least 40% local content, the strategic advantage shifts decisively to in-country manufacturers.

For an industrial group, this regulation transforms a potential investment into a strategic necessity for any company serious about participating in the nation’s energy future. Entering the manufacturing space is no longer just an option; it is the most direct path to serving this burgeoning market.

A Phased Approach to Market Entry: From Concept to Production

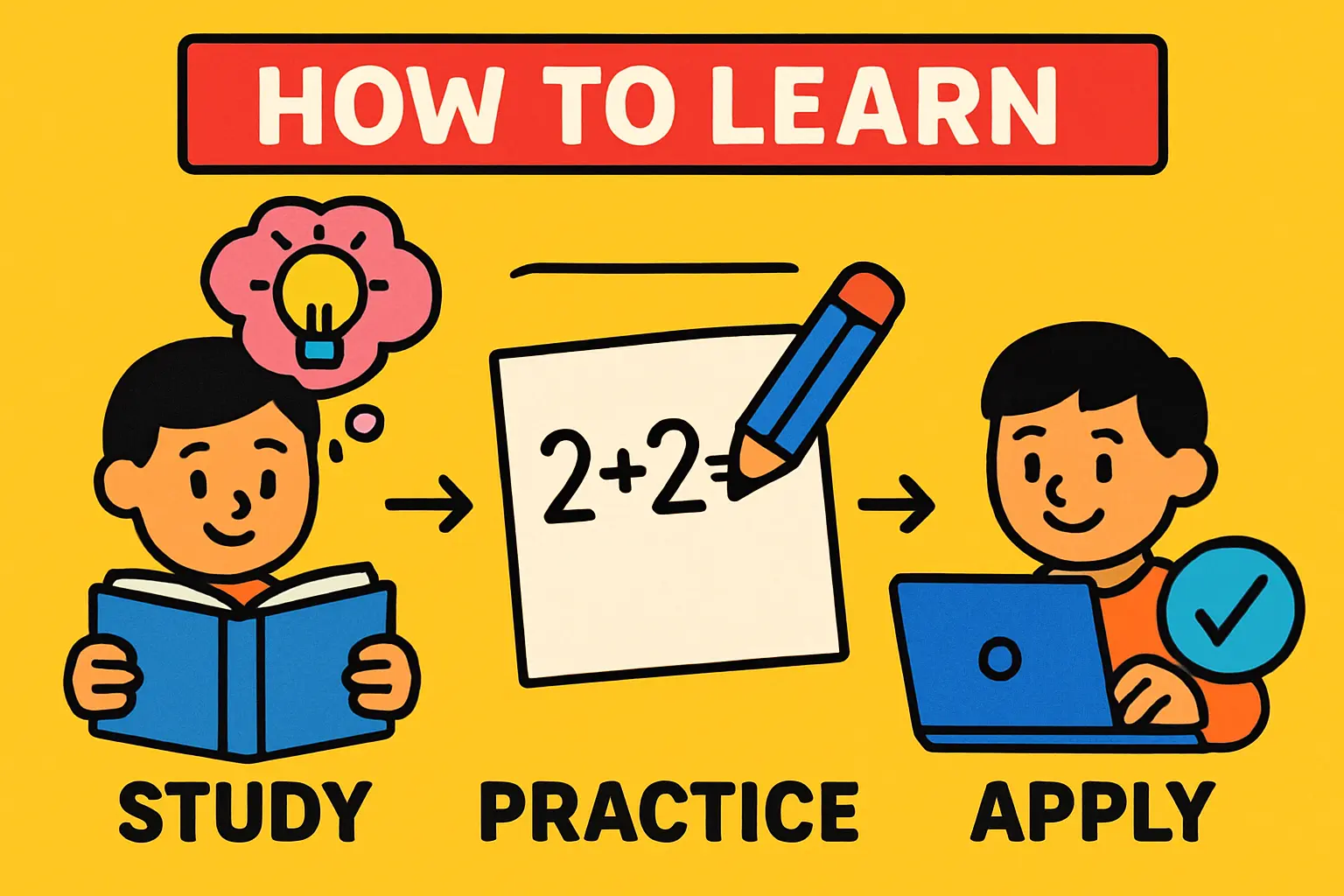

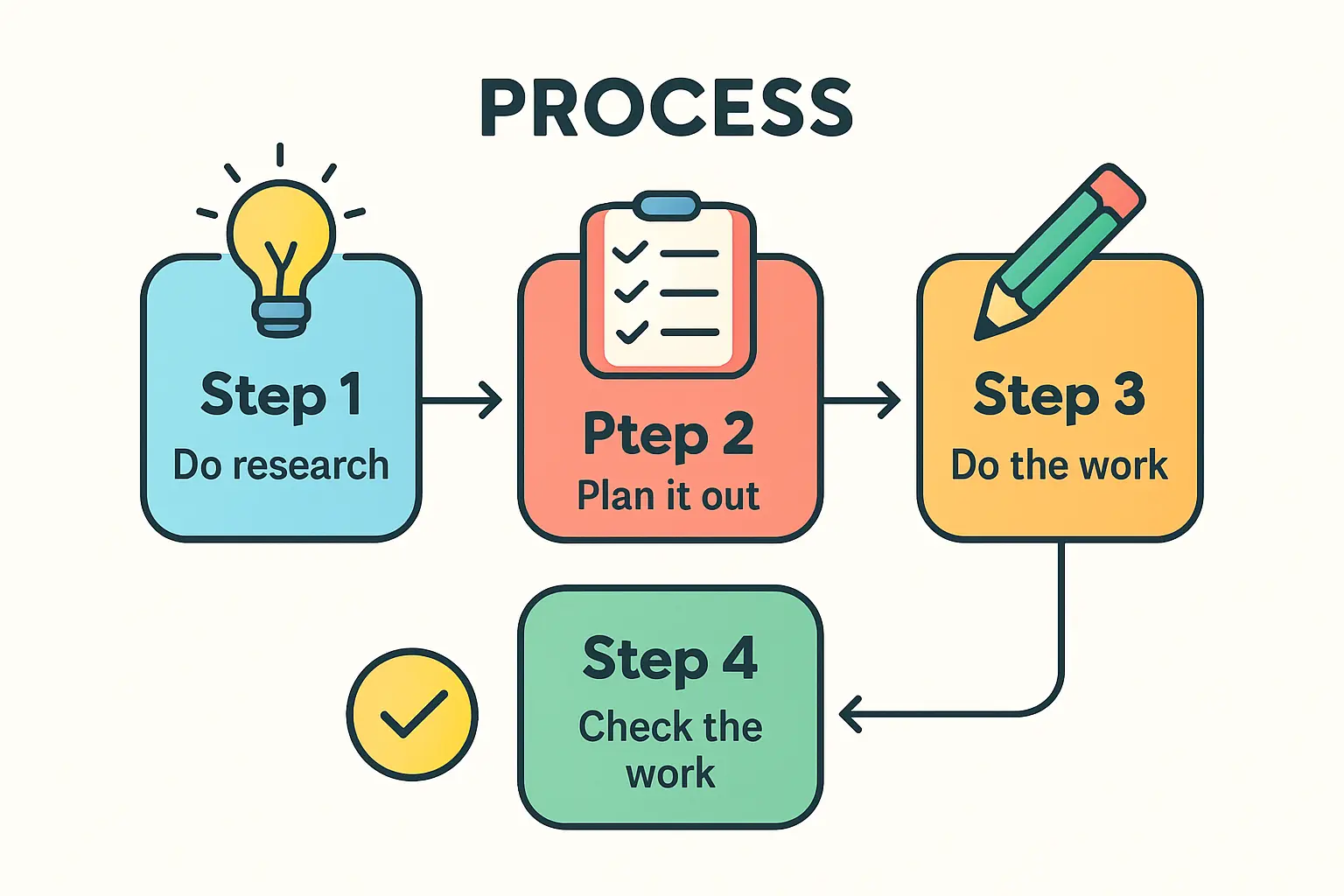

Launching a 200 MW solar manufacturing venture requires a structured, manageable process that minimizes investment risk at every stage. A successful transition from an established industry to advanced manufacturing follows a logical progression that mirrors standard industrial project management.

This approach ensures core business principles guide the technical implementation. It begins with a deep domestic market analysis, followed by a thorough feasibility study to model the investment. Only then does the process move to technology selection, facility integration, and staff training, culminating in a well-prepared market entry. For those new to the sector, a beginners’ guide to solar panel manufacturing can provide a foundational overview of these stages.

Integrating a Solar Division into Existing Industrial Operations

An established conglomerate holds a key advantage: the ability to leverage existing assets, which significantly streamlines the launch of a new manufacturing division.

Leveraging Infrastructure and Financial Modeling

Existing landholdings, warehouses ready for conversion, and established logistical networks can dramatically reduce initial capital expenditure and project timelines.

The core challenge lies in accurate financial planning. A detailed assessment of the investment requirements is fundamental to developing a bankable business plan. This involves modeling costs for machinery, facility upgrades, raw material supply chains, and operational expenses against projected revenues based on the domestic demand outlined by PLN.

Staff Retraining and Skill Development

A loyal, existing workforce is one of a family business’s greatest assets. Instead of recruiting from scratch, a strategic retraining program can prepare dedicated employees for new roles in the solar factory.

This process typically involves a combination of theoretical instruction and hands-on training provided by the technology partner. Experience gained from European PV manufacturers’ turnkey projects shows that machine operators, quality control technicians, and maintenance staff can be trained effectively within a structured, multi-month program, ensuring they are operationally ready from day one.

Selecting Technology Suited for the Indonesian Climate: The DESERT+ Advantage

Technology selection is perhaps the most critical decision in this process. Standard photovoltaic modules may perform adequately in moderate European climates, but the tropical conditions of Indonesia—characterized by high heat, humidity, and intense UV radiation—demand a more robust solution. Premature degradation can compromise a project’s financial viability and a manufacturer’s reputation.

The DESERT+ technology portfolio is specifically engineered for such challenging environments. These modules are designed for enhanced durability and sustained performance at high ambient temperatures, ensuring a reliable energy yield across a 25- to 30-year lifespan. This focus on long-term reliability is crucial for securing financing for utility-scale projects and building a brand trusted for quality and endurance.

The Critical Role of Expertise and Partnership

For any business entering a new, technologically advanced field, the right partnership is key to mitigating risk and accelerating the learning curve. The complexity of setting up a solar production line—from sourcing equipment to calibrating processes—can be overwhelming without experienced guidance.

This is where the value of a partner with multi-generational expertise becomes clear. Transitioning into a new industry is as much a business challenge as a technical one. Guidance from experts who understand both the engineering intricacies and the strategic realities of diversifying a family-owned business is invaluable.

Engaging a partner to deliver a turnkey production line is a common and effective strategy. This approach consolidates responsibility for equipment procurement, installation, commissioning, and staff training with a single, experienced entity. This allows the conglomerate’s management to focus on high-level strategic concerns, such as market positioning, offtake agreements, and supply chain development.

Frequently Asked Questions (FAQ)

What is the typical timeline for launching a 200 MW factory?

With a clear plan and an experienced implementation partner, a 200 MW solar manufacturing facility can be operational in 12 to 18 months from the final investment decision. This includes machinery procurement, factory setup, commissioning, and the initial phase of staff training.

Do we need to hire specialized solar engineers from day one?

While a senior technical manager with industry experience is advisable, the core operational team can be built from your existing workforce. A comprehensive training program provided by the turnkey partner is designed to equip machine operators, quality control inspectors, and maintenance teams with the necessary skills.

How does local manufacturing help navigate grid integration challenges?

By manufacturing modules locally, an enterprise gains control over the product’s technical specifications. This ensures the panels supplied to domestic projects meet the precise requirements of the national grid code—a significant challenge when dealing with inconsistent or poorly documented imported products.

Is it possible to start with a smaller capacity and scale up?

Yes, a phased approach is a prudent strategy. Many businesses begin with a smaller line—a 50 MW capacity, for example—to master the production process and establish a market presence. Once the operation is stable and profitable, the facility can be expanded with additional lines to reach a capacity of 200 MW or more. This modular approach allows for growth aligned with market demand and internal cash flow.

Download the 200 MW Solar Manufacturing Case Study (PDF)

Author: This case study was prepared by the

turnkey solar module production specialists at J.V.G. Technology GmbH

It is based on real data and consulting experience from J.v.G. projects

worldwide, including installations ranging from 20 MW to 500 MW capacity.