An entrepreneur invests in a state-of-the-art, German-engineered turnkey solar production line, confident in its proven performance in Europe. The machinery is shipped and installed in a new facility near Jakarta. Production begins, but within weeks, quality control reports a troubling trend: an unacceptable rate of module rejection due to delamination and internal “bubbles.” The machines are functioning perfectly. The problem isn’t the equipment—it’s the air itself.

Indonesia, with its strategic location and growing energy demands, presents a significant opportunity for solar module manufacturing. However, its tropical climate—with average relative humidity levels between 70% and 90%—poses a critical challenge often underestimated by new market entrants.

A production line optimized for a dry, temperate climate will fail to perform to specification without significant adaptation. This article details the technical adjustments required to master solar manufacturing in a high-humidity environment.

The Invisible Challenge: Why Humidity Matters in Solar Module Manufacturing

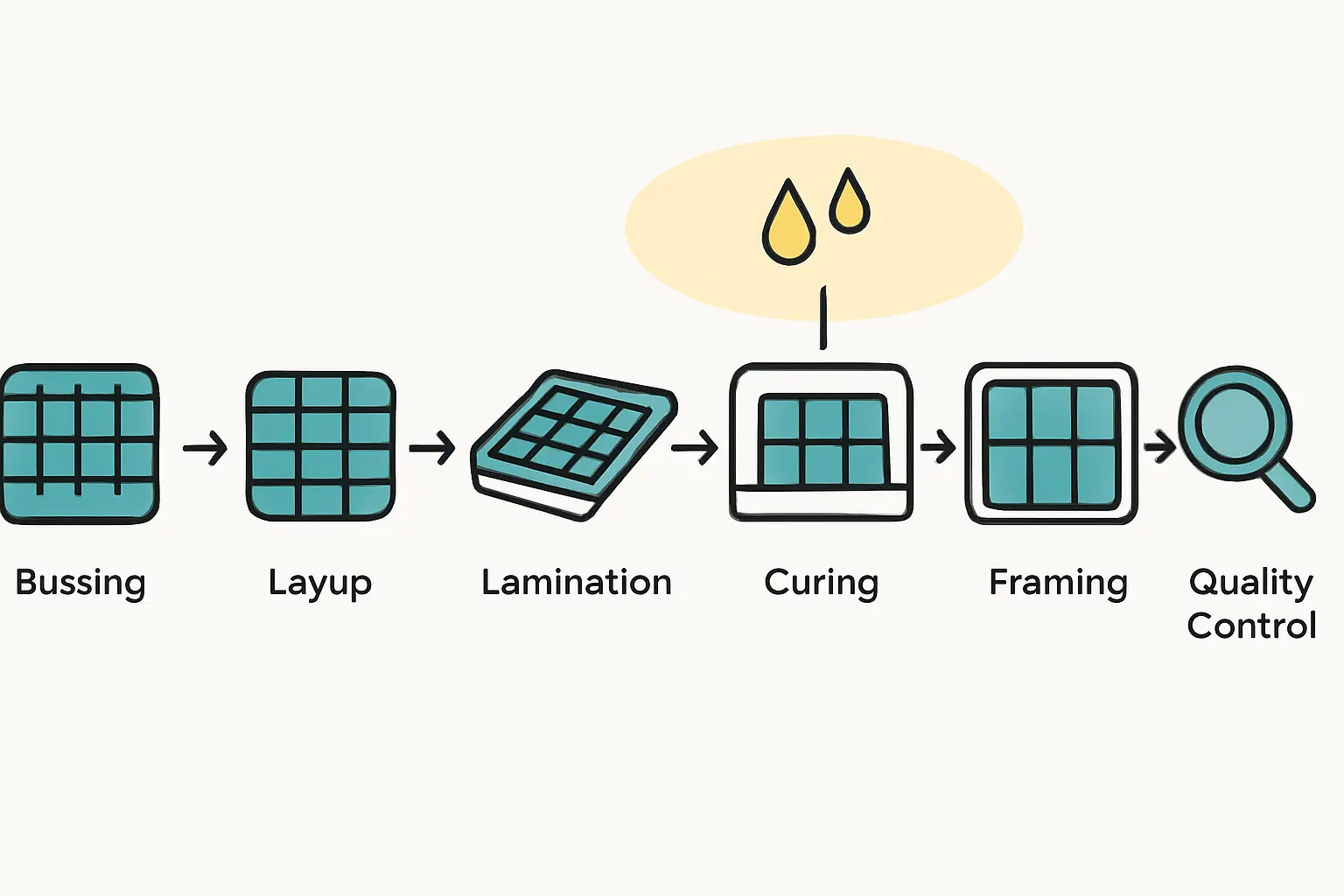

The heart of a solar module’s durability lies in the lamination process, where layers of glass, encapsulant (typically EVA), solar cells, and a backsheet are fused together under heat and pressure. The encapsulant, Ethylene Vinyl Acetate (EVA), is the critical bonding agent that protects the solar cells from the elements for over 25 years.

However, EVA has a property that is particularly problematic in a tropical climate: it’s hygroscopic, meaning it actively absorbs moisture from the surrounding atmosphere. When moisture-laden EVA enters a laminator and is heated to over 140°C, the water turns to steam. This steam creates vapor pressure within the module, leading to several critical defects:

- Bubbles and Voids: Trapped steam forms bubbles that prevent the EVA from properly adhering to the cells and glass.

- Delamination: The module layers fail to bond correctly, allowing moisture and air to penetrate over time and leading to rapid degradation.

- Reduced Long-Term Reliability: Even small amounts of trapped moisture can accelerate material degradation and contribute to issues like Potential Induced Degradation (PID), severely shortening the module’s effective lifespan and power output.

These are not merely cosmetic defects; they represent a fundamental failure in the manufacturing process that renders the final product unreliable and unmarketable. Effective quality control in solar manufacturing begins with controlling the production environment itself.

Key Process Stages Vulnerable to High Humidity

Managing ambient moisture isn’t a concern for just one part of the production line; it’s a factory-wide discipline, and several stages are particularly vulnerable.

Raw Material Storage and Handling

The fight against humidity begins before materials even reach the assembly line. Rolls of EVA and backsheet will absorb ambient moisture if stored in an uncontrolled environment. It’s a common mistake to assume the original packaging provides sufficient protection. Based on experience from J.v.G. turnkey projects in Southeast Asia, materials should be stored in a dedicated, climate-controlled room maintained at a relative humidity below 60%. Once a roll of EVA is opened, it should ideally be used within a single shift or moved to a special dry cabinet.

The Lamination and Curing Phase

This is the most critical stage. The lay-up area, where the module “sandwich” is assembled before entering the laminator, must be strictly climate-controlled. If the air in this room is humid, the EVA will absorb moisture in the brief window between being unpackaged and entering the laminator. The subsequent solar module lamination process will then trap this moisture permanently.

Post-Lamination Cooling

After lamination, modules must cool in a controlled manner. Cooling them too quickly in a humid environment can introduce thermal stress and potentially allow moisture to wick into the laminate’s edges before the edge sealant is applied and cured.

Engineering a Climate-Resilient Production Environment

A standard turnkey line must be augmented with a robust climate control strategy. This isn’t a matter of simply installing standard office air conditioning; it requires an industrial-grade solution engineered for manufacturing.

Dedicated Climate Control Zones

The most effective approach is to create a “factory within a factory.” The critical areas—raw material storage and the lamination room—should be enclosed and isolated from the rest of the facility. This zone requires a dedicated Heating, Ventilation, and Air Conditioning (HVAC) and dehumidification system capable of maintaining a stable, low-humidity environment regardless of external weather conditions.

Industrial Dehumidification vs. Standard Air Conditioning

Standard air conditioning systems are designed primarily to cool air. While this process removes some moisture, it is often insufficient to reach the low relative humidity levels required for high-quality solar module production. Industrial dehumidifiers, particularly desiccant-based systems, are designed specifically to remove large amounts of water vapor from the air and provide precise humidity control. Investing in this equipment is non-negotiable for any serious manufacturing operation in a tropical region.

Process Parameter Adjustments

Beyond environmental control, process parameters within the laminator may need fine-tuning. For example, extending the pre-heating and vacuum cycles can help extract any residual moisture from the materials before the main heating and pressure phases begin. This requires experienced process engineers who understand how to adapt machine recipes to local conditions.

The Business Impact of Climate Adaptation

Failing to account for humidity is a significant business risk. The initial investment in a proper HVAC and dehumidification system may seem like an additional expense on top of the cost of setting up a solar factory, but this cost is minimal compared to the financial losses incurred from:

- High Material Waste: Reject rates of 10-20% or more can destroy profitability.

- Failed Certifications: Modules with lamination defects will not pass international certification tests (e.g., IEC 61215), making them ineligible for most large-scale projects.

- Warranty Claims and Reputational Damage: Modules that fail prematurely in the field lead to costly warranty claims and irreparable damage to a brand’s reputation.

Conversely, investing in proper climate adaptation from the outset ensures consistent product quality, high production yields, and the ability to build a bankable brand trusted by customers and project financiers.

Frequently Asked Questions (FAQ)

What is the ideal humidity level for a lamination room?

For best results, the relative humidity in the lamination and material storage areas should be consistently maintained below 60%. Many top-tier manufacturers aim for levels as low as 40-50% to build in a significant margin of safety.

Can existing buildings be retrofitted for climate control?

Yes, it’s possible to retrofit an existing building by constructing isolated, well-sealed rooms for the critical processes. However, it is far more efficient and cost-effective to incorporate these design requirements during the initial planning and construction of the factory.

How does high temperature, in addition to humidity, affect production?

High ambient temperatures can affect the “pot life” or workability of certain materials like sealants and adhesives. More importantly, high temperatures make it more difficult and energy-intensive to control humidity, which is why an integrated and properly sized HVAC system is crucial.

Are there alternative materials less sensitive to moisture?

Research is ongoing into new encapsulants, such as thermoplastic polyolefins (TPO), which are inherently less hygroscopic than EVA. However, EVA remains the industry standard due to its long track record, proven reliability, and cost-effectiveness. For a new manufacturer, mastering the process with standard, high-quality materials is the most prudent path.

Conclusion: A Strategic Approach to Tropical Manufacturing

Setting up a solar module factory in Indonesia is a venture with great promise. However, success depends on recognizing that a production line is more than just a collection of machines; it is an integrated system where the environment is as important as the equipment. A “copy-paste” approach using a European factory layout is destined for failure.

By understanding the specific challenges posed by a tropical climate and investing in the necessary engineering controls for humidity from day one, entrepreneurs can avoid costly mistakes. This strategic planning ensures the production of high-quality, reliable, and bankable solar modules, building a strong foundation for long-term success in this growing market. A structured planning process, supported by expert guidance, is the key to transforming this challenge into a competitive advantage.